Custom Steps: 3/4″ MDF

CNCROi.com does an increasing amount of “architectural” type work thanks to our massive Thermwood CNC router, and some of those elements I can share online such as these custom steps made using 3/4″ MDF.

It’s incredible what I can do with my new router at CNCROi.com, having access to 19 different tools is a game changer, my old machine had but 4,

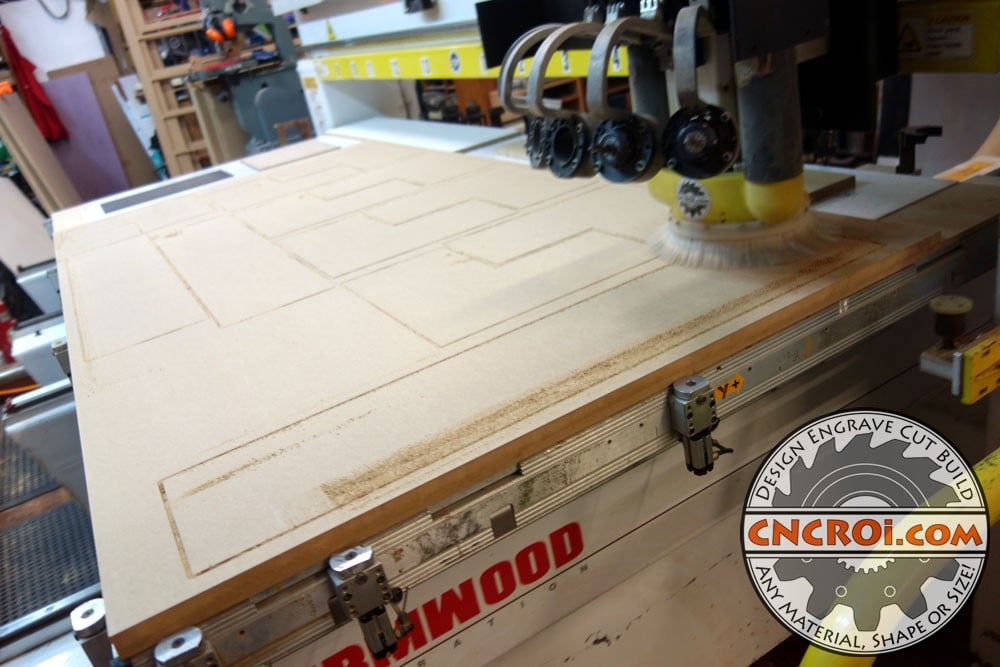

For this specific job, I only needed to use one bit for the entire thing, but what made this job easier with my new machine was the orientation in the shop, it makes things so much easier to load things the way you see it now rather than having the table move in the other direction.

These custom steps are made for training purposes, so they are to be used once and then essentially thrown-out, which is why they are made out of glorified cardboard instead of hardwood or even plywood at CNCROi.com.

The other major improvement over my old Thermwood CNC router is the hold-down, it seems to be a lot better with this machine, as instead of having two sheets of MDF, I only have one over a channelled aluminium table, it does make a difference with a lot more suction power.

When it comes to MDF, it’s a wonderful material for a huge variety of jigs, the one above is similar, though smaller, than the one in today’s blog post, made using our old Thermwood CNC router but it was equally as accurate as the one we have now.

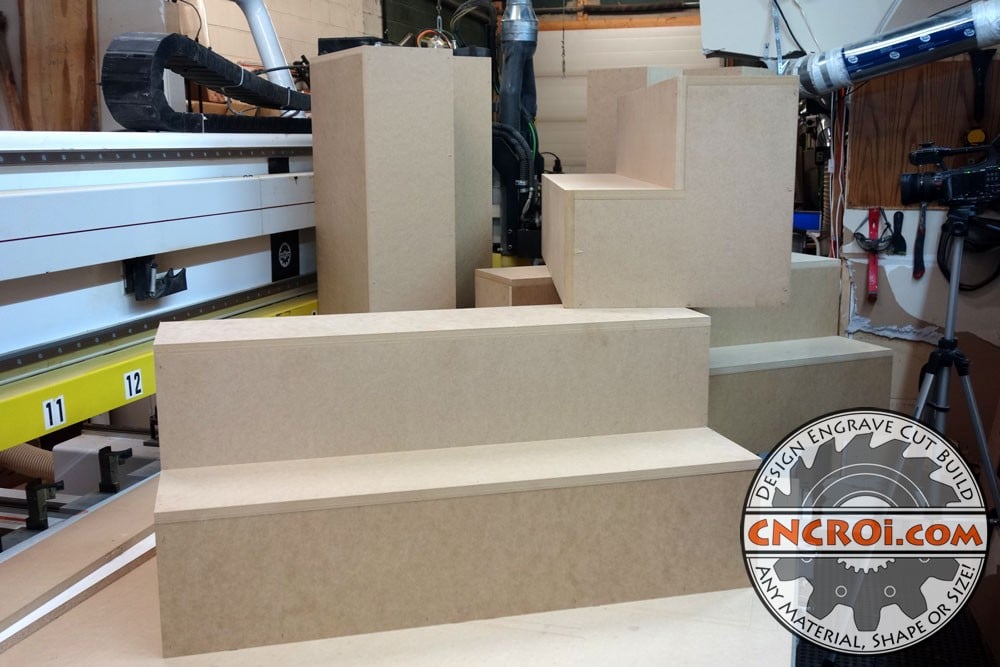

These custom steps were sent to me as a photograph, which I then had to design and confirm dimensions with the customer before going ahead and cutting them out on their behalf… as each step was basically made-up of a full sheet of 3/4″ MDF, these were HEAVY!

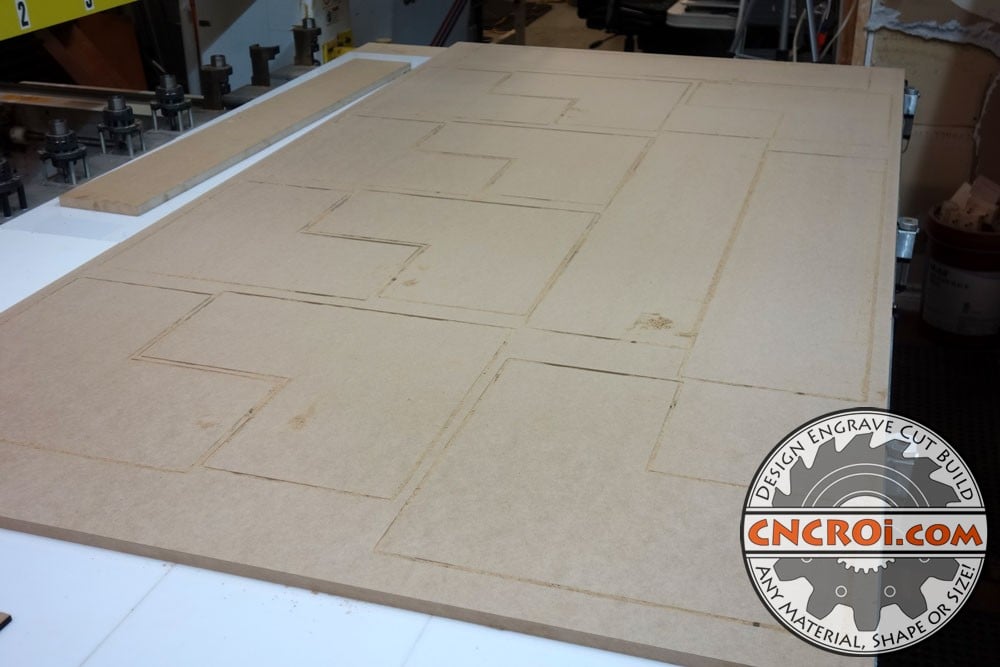

The reason you don’t see me cutting the steps entirely on a full sheet is because of nesting, I was able to save material by splitting and optimizing things at CNCROi.com, saving myself half a sheet of material that would otherwise had gone to waste.

One thing I really dislike is the amount of dust that MDF makes, it’s fine and full of bad things, regardless, it cuts very well and paints even better… I have a few other projects using MDF in the shop which I’ll be painting shortly.

Most of the MDF we process in the shop is actually used for templates, in this case, a guitar jig made using our CNC laser on 1/4″ MDF, the one used for the steps was 3/4″ to give you an idea of thickness varieties we process though at CNCROi.com.

If you are wondering what material makes for the best custom steps, it really depends where along the process of fabrication you are, if you have a design that hasn’t been tested, using MDF is a great way to prototype things before moving onto more expensive material.

But if your design is ready for prime time, I’d suggest 3/4″ plywood as it is a lot more study and paints relatively well after a good coating of primer – the same design can be used for both materials as long as the thicknesses are accounted for in the design.

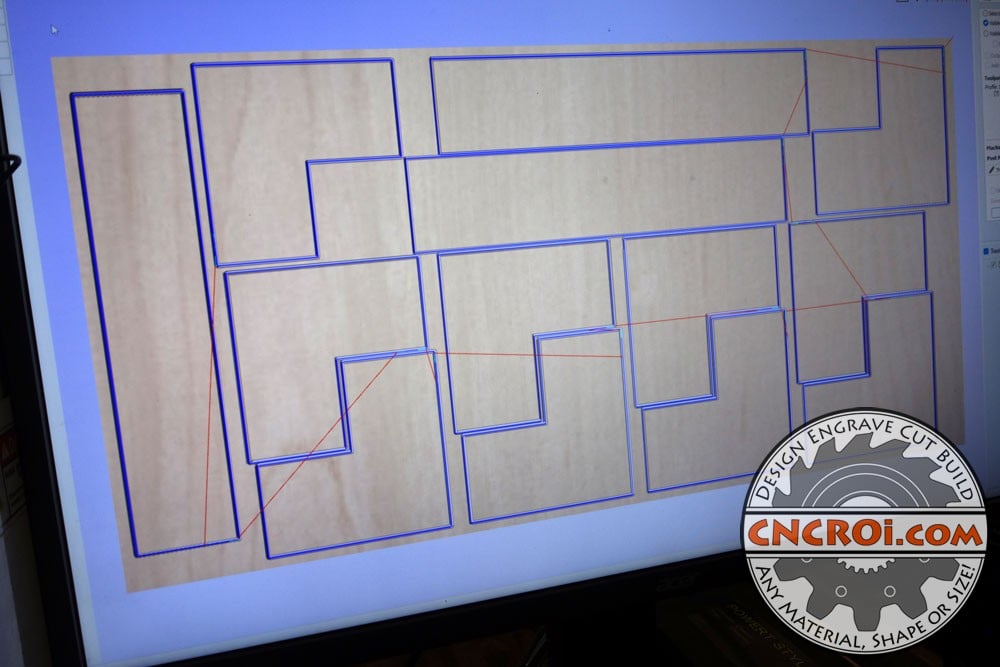

In the above design, you can see how close all the nesting is for these custom steps, the red lines indicate where the router is moving but there is no cutting and the blue lines where it is cutting, you don’t see the table movements but as the gantry is static, movement can only be done along one axis with the router and the other using the dual tables at CNCROi.com.

MDF also glues together into solid blocks very well, it’s certainly something to consider, especially if it’s only going to be used once or as a reference or mold for a more permanent solution.

The nice thing about a dual-table set-up on a CNC router is that if I only want to use one, I can do so, and focus all the vacuum on that table, essentially, doubling the sucking power.

Another advantage of a dual-table set-up is that I can also have them act as one solid table, so I have the entire 5 ft x 10 ft available, though most of the materials that CNCROi.com processes is 4 ft x 8 ft.

Even using a quarter inch bit for cutting this MDF, there is still a tremendous amount of dust created, I have tons of filters and a powerful vacuum to take care of it but regardless, it still gets everywhere at CNCROi.com.

There really are no limits to what CNCROi.com can produce for you using our CNC routers, we’ve since retired our little CNC router to aluminium processing and keep our big one to do pretty much everything and anything else.

The above full sized sheet of MDF is all cut-up, dust was picked-up during production, but a whole bunch more is on full display once I lift the waste from the table as you can see in the image below.

After that dust is cleaned-up using a hand-held vacuum system, the MDF is ready to go with little clean-up required as it’s essentially just dust and resin, there is no wood grain or other things to deal with as if this was a solid or plywood type cut.

Once I have all the pieces cut for the custom steps at CNCROi.com, it’s time to sort them out by what they do and then use my nail gun to stick it all together, it’s a better tool than screws as I can put more nails to hold everyhing together witout worrying about screws ripping through even with pilot holes.

Assembly of these custom steps is very straight-forward, I’ve done a lot more complex assemblies in the past when I designed kids toys and the like, everything also just fits one-way.

Although MDF machines well, it paints even better, but you have to be careful with it as it really dislikes getting wet or working in humid conditions.

As I’ve got limited space at CNCROi.com due to all the equipment and machinery I have, I find the 5 ft x 10 ft table does wonders as a setup platform, the table is flat, parallel and rigid with zero give… perfect for assembling things.

You can see the finished custom step, I made a few of these and they are all identical, built through final presentation at CNCROi.com… got to love the repeatability that CNC equipment offers my clients.

When it comes to making architectural elements, for housing or training, keep CNCROi.com in mind – I enjoy a challenge!

Need custom steps or anything else, contact CNCROi.com right now!