Custom Wall Ornaments: CNC Plasma Cut

Custom wall ornaments made out of steel have a endless design options and can be made using stainless steel and mild steel depending on what you are looking to have made.

https://www.youtube.com/watch?v=jaKn8PzDg1E/

What I generally tell CNCROi.com customers is that if you want your metal to be colorful, such as painted, go with mild steel, if you want it to look like steel, then stainless steel is your clear winner.

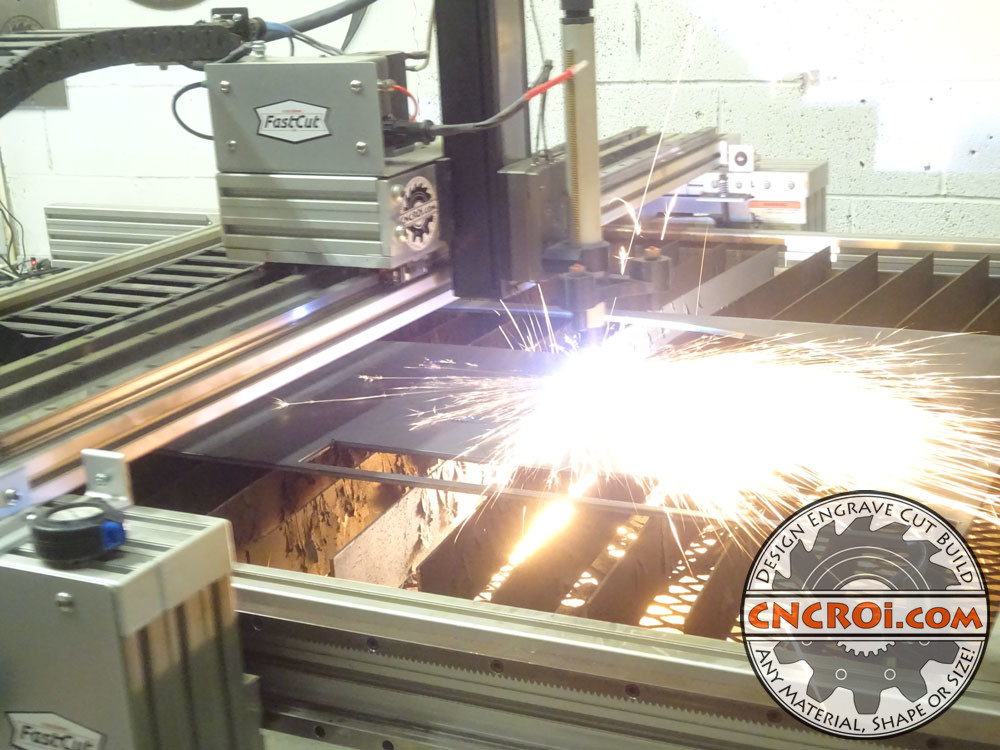

Plasma cutting metal is a very efficient process, it melts through it like butter and the quality of the finish and precision is just as good as any other machine we can use to cut this material at CNCROi.com as long as the tolerances make sense.

Things have been so crazy at CNCROi.com on jobs across the board as we ramped-up to Christmas that I haven’t had time to post videos and blog posts but now that that massive rush in production runs is complete, I can go back and start posting what we did at the shop during this time that isn’t covered by NDAs.

Custom wall ornaments can be made out of any material at CNCROi.com, don’t want steel? We can make them out of wood, plastics or even stone… there really are no limits as to what we can cut.

Of course, plasma cutting isn’t the only way to cut metal, we can also make custom wall ornaments using the waterjet too, each machine has it’s advantages and disadvantages, for this job specifically, the plasma was the clear winner, hence going that route.

https://www.youtube.com/watch?v=AftM2ajVkQw/

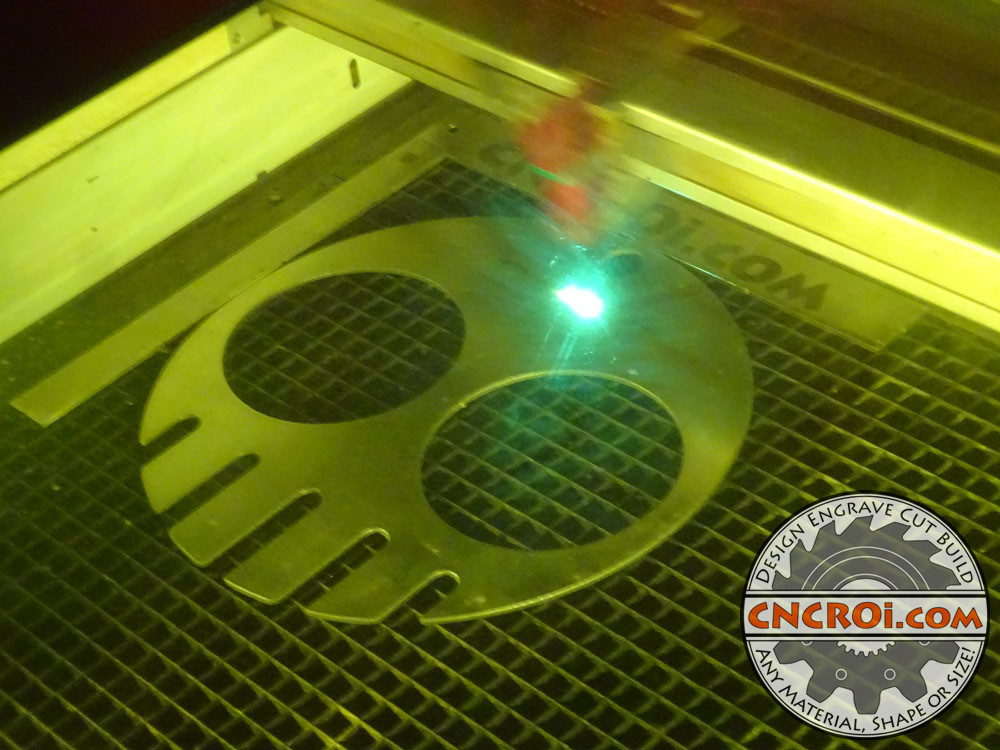

Why was the plasma the winner for these specific custom wall ornaments? It was faster, required less clean-up after production and with one product being mild steel, no flash rusting issues to contend with.

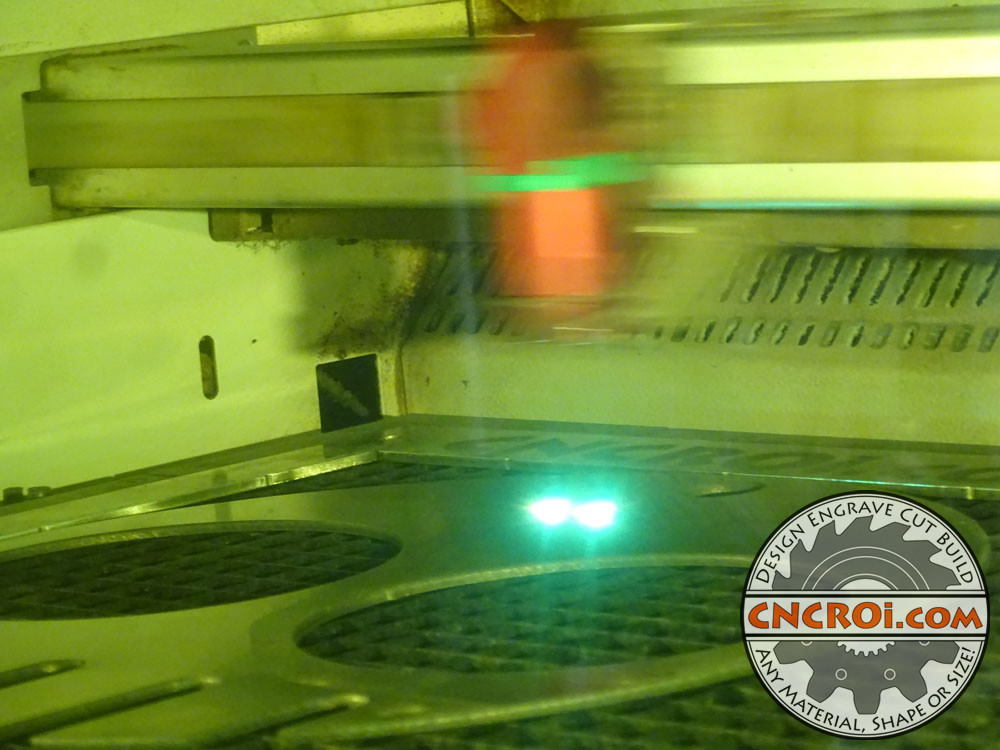

It’s always a sight to behold to be able to control so much electrical power while standing only a few feet away making sure all production was happening to spec and at the quality standards I’ve established at CNCROi.com for all our work.

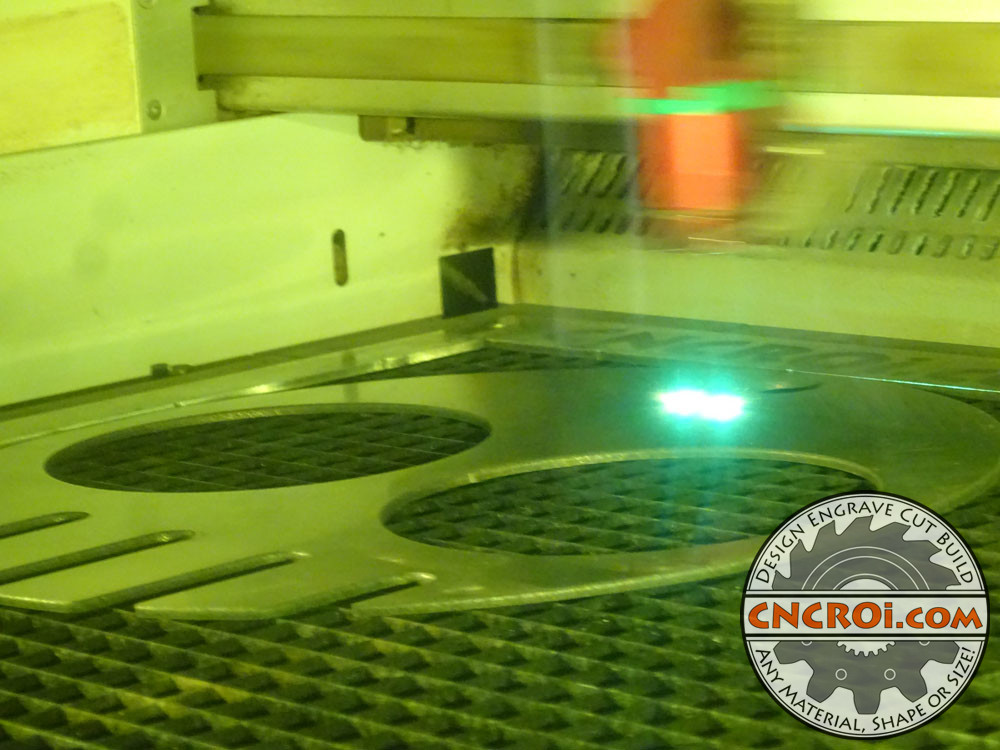

The custom wall ornaments were cut in order, meaning the inside parts first followed by the outside, this assured things didn’t move during production and were cut with the upmost quality and precision possible.

Of course, if you wanted custom wall ornaments made out of a mix and match of materials, CNCROi.com can also use our CNC router to produce the matching wooden items.

https://www.youtube.com/watch?v=vqiPA6lVGN0/

I just love the synergy we have at CNCROi.com, being able to custom fabricate things efficiently across multiple machines regardless of materials involved.

The sparks you see during the production of the quarter inch mild steel quickly dissipate, so they aren’t a safety hazard as long as you don’t have a wood pile right next to the machine, this is why our CNC routers (we have two of them at CNCROi.com) are in the “front” of the shop while the plasma is in the back to make sure flammable dust from one machine doesn’t get onto the other.

You can see in these photos how powerful the plasma arc is, just look at that fire shooting down through the table – it’s just awesome to watch this being made.

Tons of very neat things can be plasma cut.

https://www.youtube.com/watch?v=W1eJ0VT8wWM/

CNCROi.com‘s plasma cutter is so overbuilt for this specific job, we were cutting 1/4″ Mild Steel and with our system, we can cut up to two inches with this machine alone!

When it comes to custom fabrication, these custom wall ornaments are easy 2D shapes but we can also go full 3D as well to give items height, width and length rather than just just two dimensions.

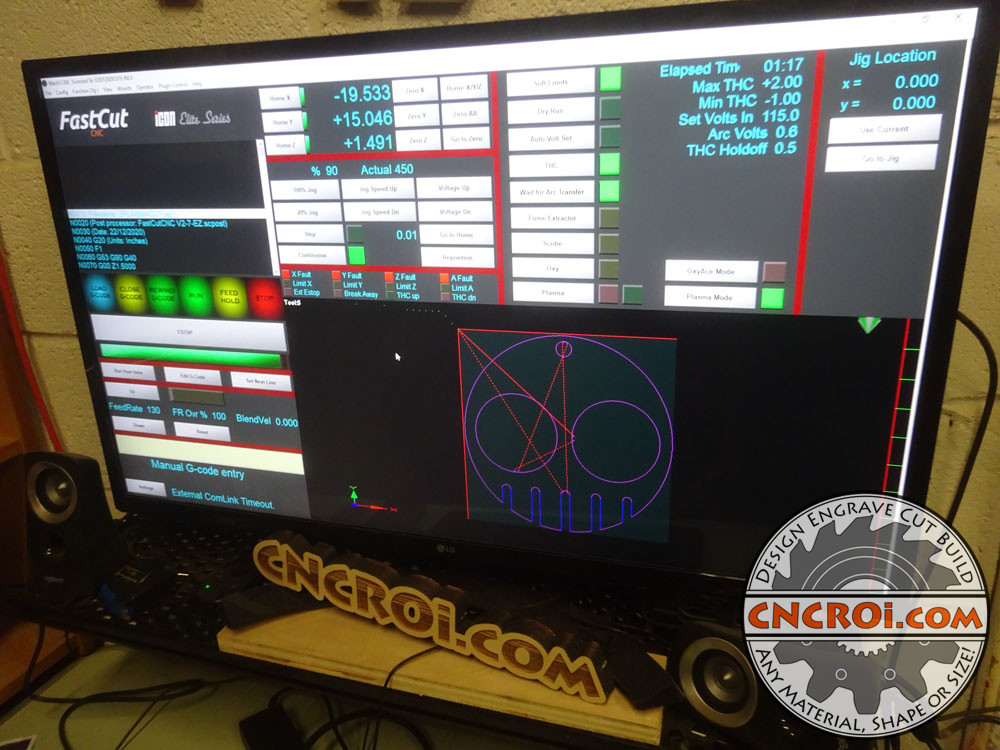

Each machine has their own user interface, in this case, CNCROi.com‘s plasma controls look complicated but really they are rather simple, adjust amperage and speeds and literally cut away once you have the proper home coordinates inputted into the machine.

Although there is a difference between fiber etching and fiber annealing, etching wins far more often.

https://www.youtube.com/watch?v=EdEIRd9_c4w/

Unlike the CNC router, laser or waterjet (sometimes), having lead-in and lead-out holes are necessary as the initial blast of power coming out of our plasma cutter can be a significantly larger diameter compared to the actual cutting diameter.

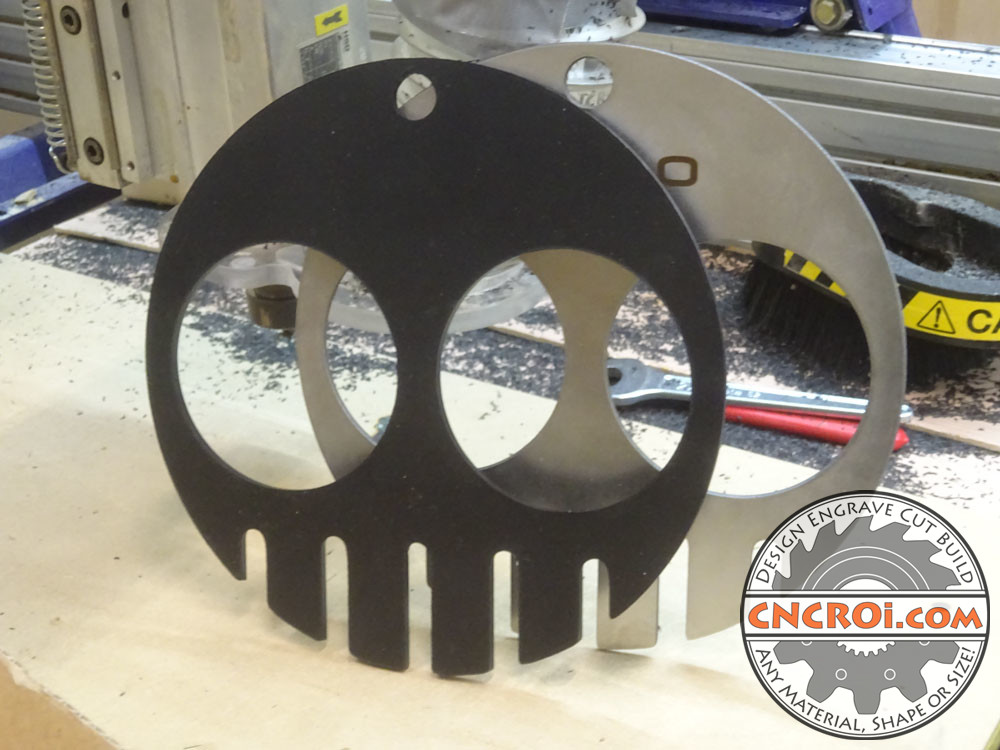

The results look spectacular, there is almost no dross on the front or back, that comes from lots of experience cutting stainless and mild steel in the shop, and endless tweeking after each production run to improve settings.

For the stainless steel custom wall ornament, the next step was fiber etching it, again, the synergy of multiple CNC platforms is awesome once the investments are made in both the hardware and software end of things.

Literally any vector image can be fiber laser etched using our CNC laser at CNCROi.com.

https://www.youtube.com/watch?v=mOsxRyCauCU/

Fiber etching is a permanent process, the results will not fade, crack or peel over time.

Fiber laser etching the stainless steel plasma cut custom wall ornament is also a contactless process, meaning the machine itself never touches the final work piece, very similar to the plasma in that respect.

2020 has been a CRAZY year, we’ve processed more stainless steel this year than all the previous years combined, fiber etching has also been off the charts in volume with no slowdown in sight!

I love fiber etching, its such a seamless and zen process, so relaxing!

https://www.youtube.com/watch?v=a5JdXkAFz1M/

You can now see the completed fiber etched 304 stainless steel custom wall ornament, it’s about 3 mm thick or 1/8″ or 12 ga.

The mild steel custom wall ornament has a different fate though, as it can rust, we must create a barrier, and paint is a wonderful one for that, enamel paint does wonders!

Here are the finished two custom metal wall ornaments, each has their esthetic, but both were awesome fun to produce!

Need custom wall ornaments? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=WUapVP2lVoI/