Custom Wedding Coasters: Pine with Branded Polycarbonate Inlay

What’s the difference between custom wedding coasters and custom corporate coasters? NONE! They both make for amazing gifts, built to spec by CNCROi.com!

In this case, we needed something that was durable, strong yet very light weight and it had to ship within 48 hours of go-ahead, you can see the date on the custom wedding coasters relative to this blog post as to why, the mail man is now bringing these as I write this!

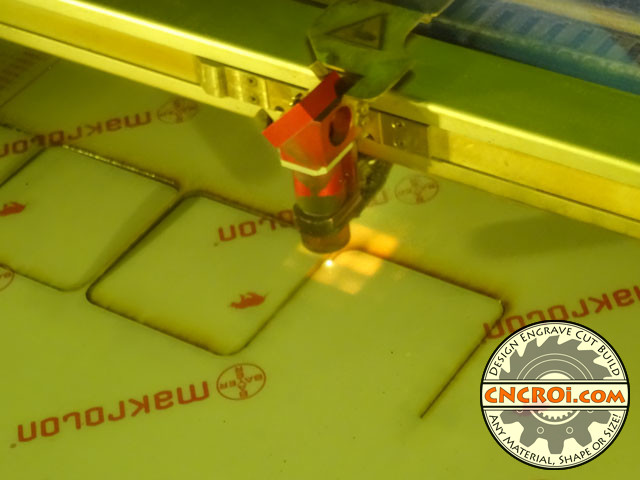

Thus, polycarbonate that was CO2 laser cut and then permanently color changed using our fiber laser worked perfect as it’s a fraction of the weight of using stainless steel or anodized aluminium and could be easily produced by CNCROi.com within this tight deadline.

As for the Pine, it machines a lot faster than Oak or other hard woods when it comes to CNC routering it and sands also exceptionally well and fast too.

The added bonus of the polycarbonate is that it’s transparent, which means you can see the machining mark when the pocket holes were made in the pine for these custom wedding coasters, it’s called adding extra detail without associated costs, that helps really showcase the custom nature of these Pine and polycarbonate coasters.

CNCROi.com uses polycarbonate, 0.06″ thick in this case, for a lot of our custom machine tags, it’s incredibly durable, literally bullet proof and produces amazing contrast that won’t fade, crack or peel as there are no “inks” involved with the blackness you see on these custom wedding coasters.

That being said, polycarbonate is nasty stuff production wise, you can see the on the mask the yellowing, that’s why I left the masking on during the cutting as it’s incredibly difficult to remove this if it gets onto the optically clear polycarbonate that makes-up the inlay on these custom wedding coasters.

After a quick MDF jig is made, as two processes (and tubes) are needed for this color changing, it’s putting the polycarbonate custom wedding coasters inlays into it with one side of the mask removed for the fiber laser color changing to happen.

The process of color changing the surface uses the same power and speed settings (high and very slow) as we use for our stainless steel metal plaques, it just shows you how tough this polycarbonate inlay really is, that it can take that much heat and pressure and not even blink.

The color changing is jet black, just awesome for these custom wedding coasters made by CNCROi.com but unlike stainless steel, you can’t wash these with detergents as it will dissolve them, it is plastic that may be bullet proof but that doesn’t make it chemical proof.

If you are curious, here’s the same process used for 316 stainless steel, again, same power and speed settings, just a different material.

CNCROi.com keeps quite a bit of polycarbonate in stock as we run through it for various applications that require something strong, durable and can take a beating, these custom wedding coasters will have a beer mug or glass of wine put onto them at most, overkill but wonderful at the same time.

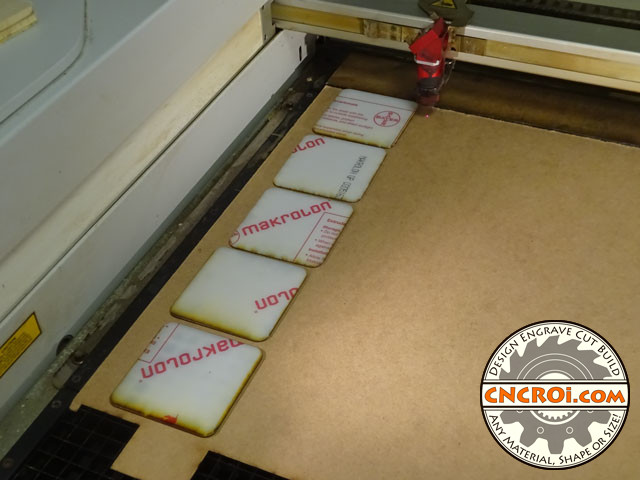

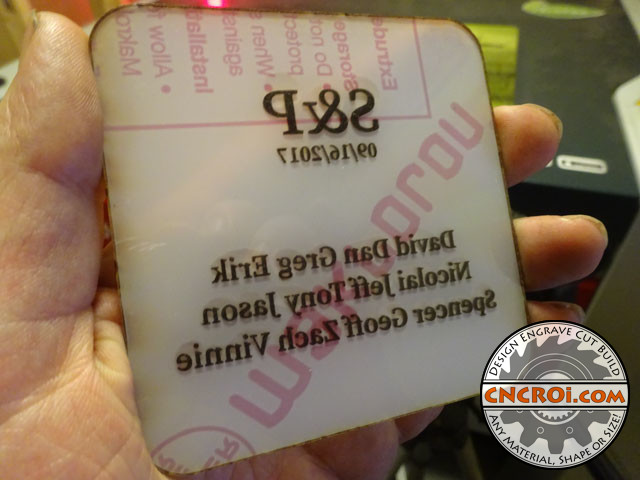

Removing the back mask, you can see on the optically clear polycarbonate how amazing the contrast is after production where our CO2 laser source but out the custom wedding coasters inlays and the fiber color changed it permanently.

There were quite a few of these custom wedding coasters inlays required, hence the jig saves a lot of time and best of all, keeps everything from moving during production as we got some serious air flying around in our machine to make this a safe operation at the utmost resolution.

Now that all the custom polycarbonate are cut out and color changed, it’s time to move to the Pine and cut out the rest of these coasters, you can see the prototype in the picture below that we used to make sure what CNCROi.com “thought” was possible actually is!

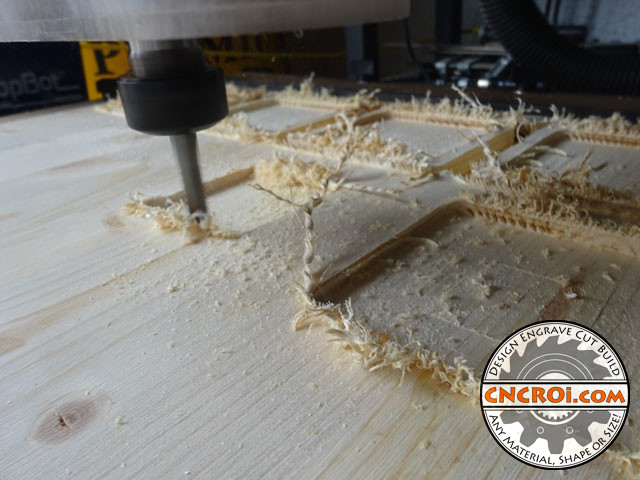

CNCROi.com has a full wood and metal shop in addition to our laser, so we booted up our ShopBot CNC router and stuck some Pine into it to begin the custom wedding coasters wooden aspect of this project.

The stringy Pine is no problem, it will be sanded right off after all the Pine is cut to spec by CNCROi.com.

We used an industrial bit to cut through this Pine, it’s no match and produces very consistent and clear results across a huge range of woods and in this case, across over 70 custom wedding coasters.

There was a lot of dust made during the process of creating these custom wedding coasters because I removed the guards to take better photos and video, generally, a large portion of the surface is covered which makes for boring videos, like this.

CNCROi.com has full custom design facilities in addition to production, so just about anything you want, we can make and yes, if you wanted your custom wedding coasters to be in the shape of a 3D Mangonel, budget allowing, that’s no problem!

Lots of Pine was used in the production of these custom wedding coasters, they all came out great and the inlays are all identical to spec, using our CNC laser to cut them out and CNC router to make inlays makes for a perfect match.

Each of these custom wedding coasters are the same yet unique in their own way, the Pine grain pattern is what makes them special as it’s a natural flow to the highly machine and precise nature of the custom polycarbonate inlay and shape of the total coaster.

CNCROi.com didn’t sand the inside of these inlays other than removing some splinters as they add a lot of extra detail as mentioned before to the overall piece.

Now that all these custom wedding coasters are finished their CNC routering, it’s time to cut them down to size, and for that job, we’ll use our industrial bandsaw which will transform these into something more manageable for our sander.

I really love our bandsaw, it really does wonders for a huge variety of projects we do here at CNCROi.com, the precision is absolutely amazing whether it’s cutting simple things like coasters from their Pine enclosures to industrial Corian house number signs that require a few additional “hand” details.

There are tabs on these custom wedding coasters during CNC routering, that’s because we have a bandsaw that will quickly cut the 1/16″ or 2 mm skin on the backside, it just makes sanding easier but it’s still very fragile, hence using a jigsaw would break all these apart in a random fashion.

You can see the back skin clearly on these photos, each of these custom wedding coasters needs to be roughly cut to size leaving just a little room for the sander to remove the skin around them.

Big or small, CNCROi.com‘s bandsaw gets everything cleaned-up!

We started off with clean sheets of solid 3/4″ or 18 mm pine and here’s all that’s left beside our bandsaw after the CNC routering and bandsaw but don’t worry, still lots of saw dust yet to be produced to finish these amazingly unique custom wedding coasters.

A diamond in the rough!

Here’s an idea of what the finished custom wedding coasters look like before the sanding.

This isn’t an industrial sander but it has been amazing for us, and I’ve never really needed anything bigger as we have other sanding tools to do what this little machine can’t.

Before picture of what all these custom wedding coasters look like before sanding…

… and after picture, it’s the same coaster, notice the knot in the top right.

The sanding process was performed on each of these custom wedding coasters.

The end result looks amazing, but CNCROi.com isn’t done yet, there are still some splinters and other small things that need to be cleaned-up using a simple manual knife.

After all these custom wedding coasters are cleaned-up, it’s time to marry the polycarbonate to the Pine, it’s a simple process and we let gravity keep them together along with a little friction.

The end result is spectacular, you see the grain of the Pine though the polycarbonate along with the CNC routering pattern produced during the creation of the inlay on these custom wedding coasters.

Lots of custom wedding coasters were made during this quick turnaround production.

The color changed acrylic really shines, it’s almost like there is nothing there, that’s how optically clear polycarbonate is and the only give-away that it was used is the reflection of the light.

These will last a very good long time, there is just a little give in the inlay portion of the polycarbonate to account for wet drinks expanding the Pine.

These amazing custom wedding coasters are now ready to ship!

See, the reflection is the only give-away that there is an inlay and that these are not “ink” printed which would smudge.

Need custom custom wedding coasters or corporate or coasters for whatever application? Contact CNCROi.com right now!