Custom Welding Table: Laser Cut Downdraft Table Evolutionary Leap!

Building a custom welding table was my very first attempt at designing using only metal and then welding it all together to create something CNCROi.com now needs in the shop, I’m very proud of the results and look forward to using this for years to come for our customers around the world!

If you are wondering where the downdraft table that provides the base of this welding table came about, check-out this video.

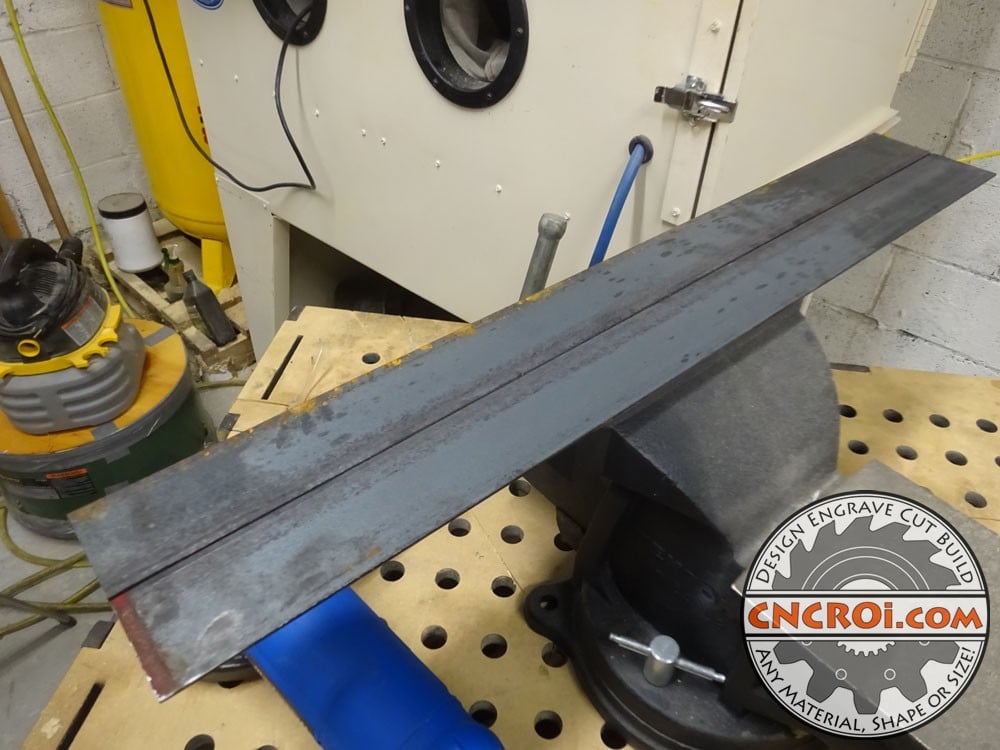

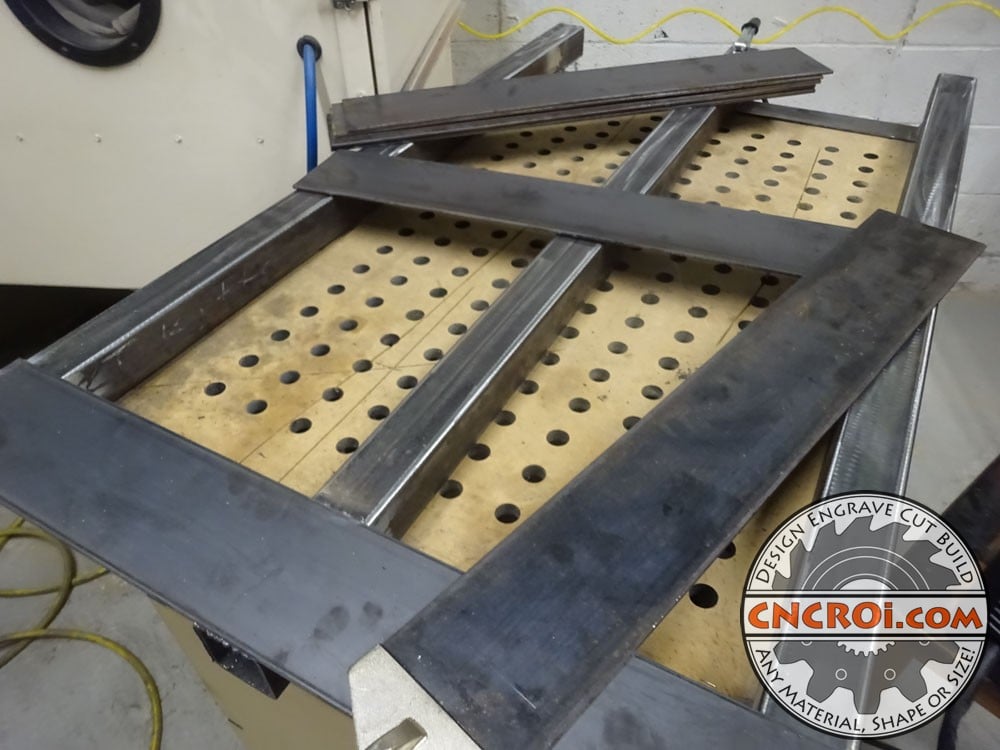

Before anything is done, like any other material, a dry fit is required, just to see how everything comes together before actually beginning the process of creating the custom welding table.

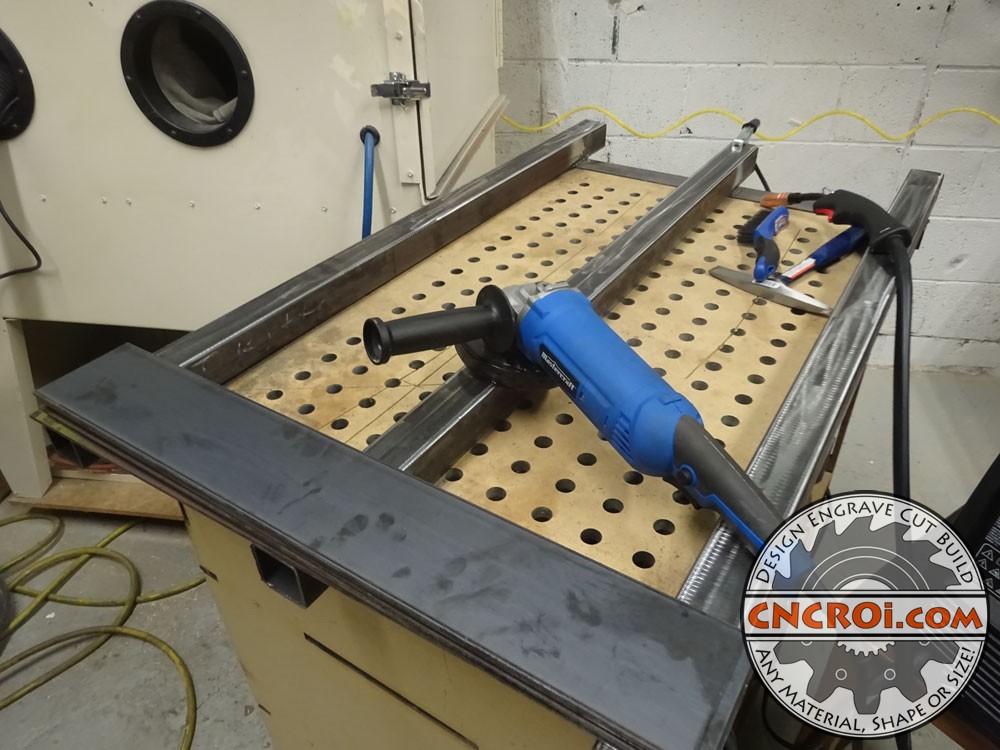

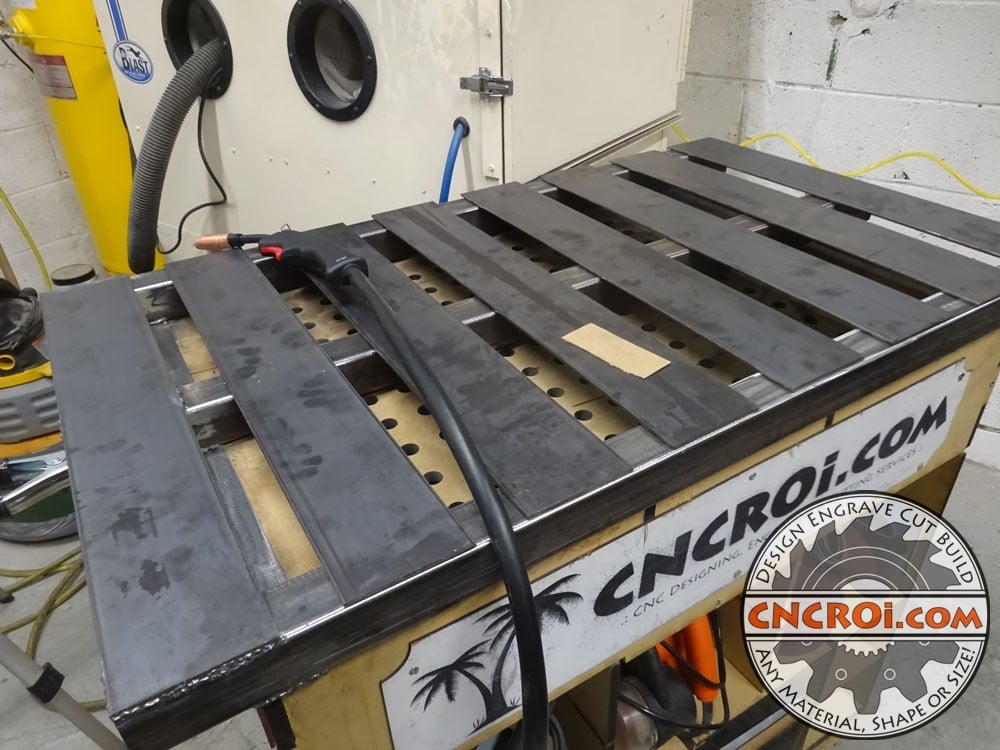

Of course a custom downdraft table is used for sanding and as such, there are some wood chips all sizes underneath but that’s quickly resolved using a vacuum cleaner.

Last thing I want in the CNCROi.com shop is a fire under my welding table, as the custom downdraft table itself was made using MDF, it’s incredibly hard to catch on fire even if the metal above it (which was sometimes steaming from welding) gets hot.

I often joke with my friends around the fire pit that if you want to put the fire out, just throw some MDF on it, as such, welding over MDF is perfectly safe and don’t forget that it is a downdraft table.

My cousin owns a welding company that I’ve featured a few times on this blog and projects, the above was a CNC waterjet and enamel sign I made for him and below, stainless steel bottle openers for his business.

Up to this point, I’ve always been outside looking in, this is my first time welding and I learned a lot about the entire process and can thoroughly enjoy a good weld now!

As such, sparks and heat never have a chance to build-up in the table and the added bonus is that any fumes generated during grinding or welding get sucked right up as well, keeping the whole shop clean!

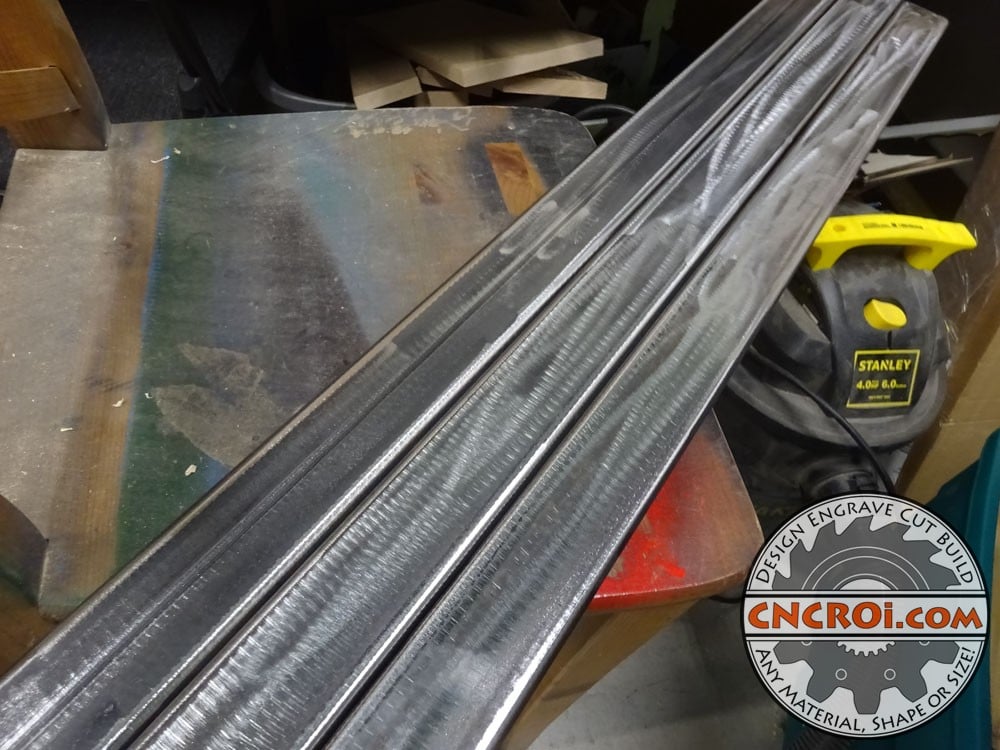

Before welding anything, the mill scaling must be removed from the metal, for this, I use the CNCROi.com angle grinder and a huge vice that I’ve used endless times to hold and sand bigger projects in the shop.

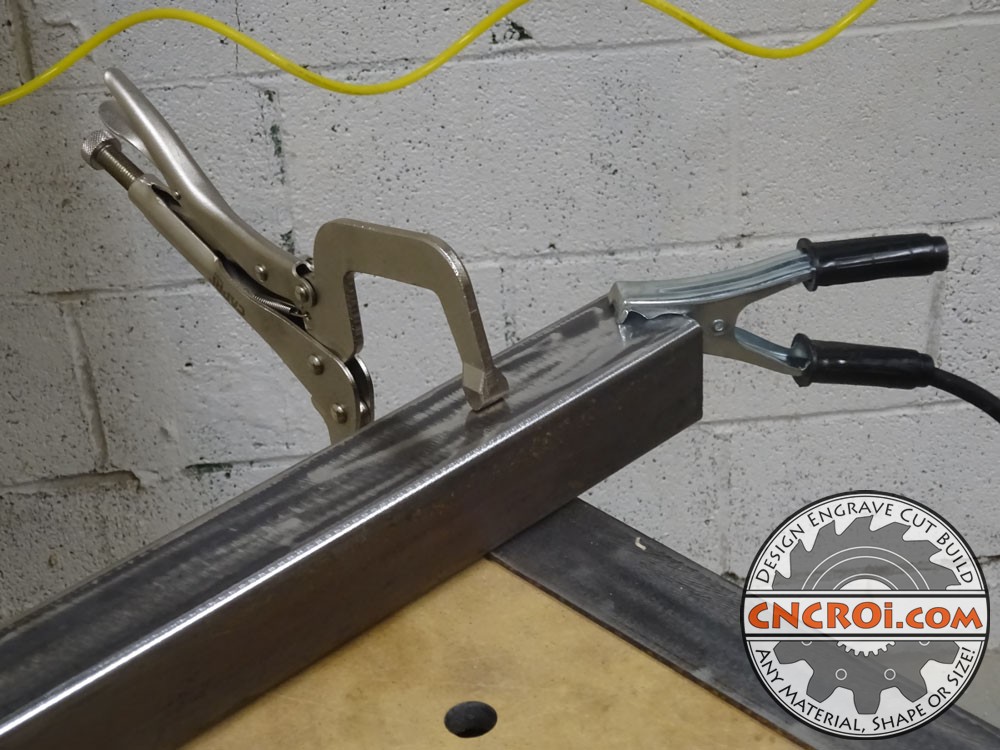

Building a custom welding table is pretty straight forward for me, I already had the base, so it was just a matter of putting two angle irons on each outer edge and then welding everything to fit above it.

This way, when I just want to use the downdraft table for sanding purposes, the welding attachment could be easily removed and if I want to weld, just sticking it on top is a piece of cake.

CNCROi.com has extensive experience with metal, this just happens the first time that I actually make something using welding to put it all together.

The welding table itself is about 70 pounds, this MDF table has lots of interlocking parts and as such, I could easily stand on it without it breaking, as I’m more than 30 kg, it’s safe to weld on this far heavier items.

My first ever weld has way too much fluxcore on it but that’s fine, after each weld, as part of my self-training (I never took any courses on welding, just bought the MIG and go), I cleaned the weld and evaluated my work.

This process of evaluation after each weld is a fast way to learn, I know what a proper weld looks like, my goal was to get my welds up to that point and the custom welding table was the perfect instrument in order to create something useful at the same time.

After the perimeter of the custom welding table was welded together, it was time to make the internal middle support permanently part of the table as well, this isn’t really needed due to the small size of this welding table but I wanted to make sure everything was straight and level.

Over-building is always better than under-building in my book, the little bit of extra effort and money put into adding that middle part is a fraction of what it would be should I decide that I needed to put one in after.

The custom welding table being made at CNCROi.com now has its very first slat of 4″ x 25.5″ flat iron that’s a quarter-inch thick, the square tubes are 2″ square with a 1/8″ wall, wicked overkill in my book but I prefer to build things well the first time.

As I progressed through the welding of this custom welding table, my personal opinion is that my welds were getting better and better, welding straight from zero knowledge for a few hours evaluating each weld is a quick way to get the hang of things.

That’s how I taught myself CAD, 3D animation, CNC router and laser work and doing the same with CNC waterjet and so forth, jump in the deep end and figure-out how to swim ASAP!

I also enjoy testing the work that I do, when I tell a customer we make the best and most durable welding tags on the market, I mean it, and can show proof that we’ve tried to destroy them.

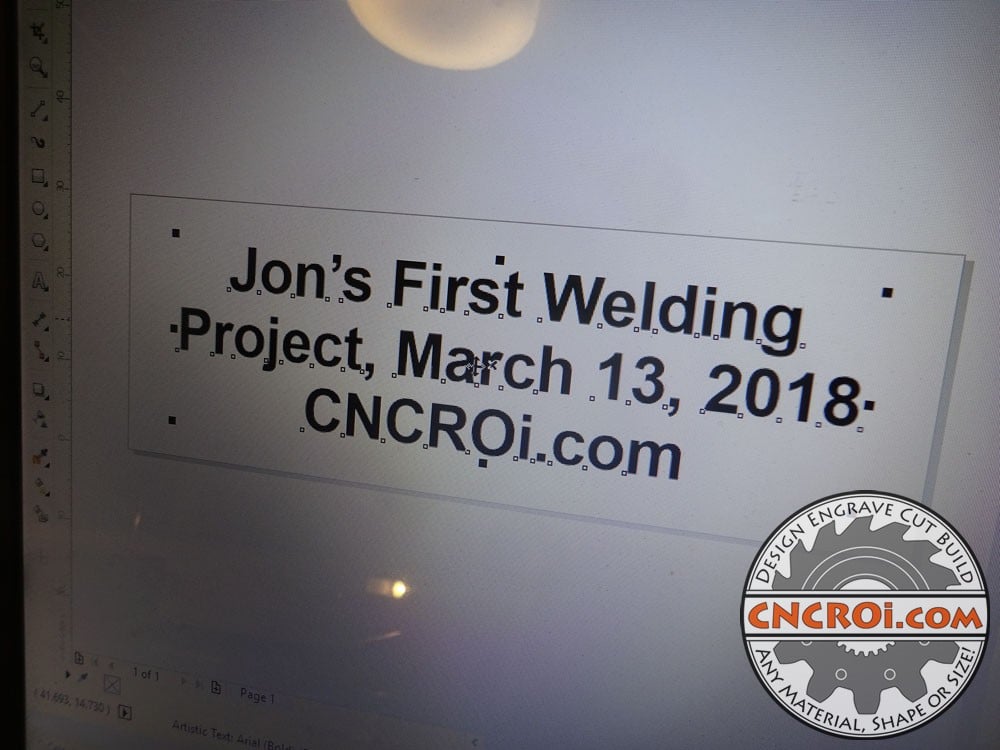

Now that the overall initial structure of this custom welding table was finished, I decided to take a break (welding is surprisingly taxing!) and make a custom welding tag that I would weld onto this table after it’s finished.

I have lots of customers who are welders, and after building this custom welding table, I can more thoroughly appreciate the artistry and experience that goes into the amazing welds they produce over the awful ones I’m currently making.

As I tell them all the time, their worst welds are my best, but like all skills, it’s just a matter of practicing and giving myself custom welding projects to increase the quality and esthetics of my welds, for now, it looks like I’ll become good friends with my angle grinder.

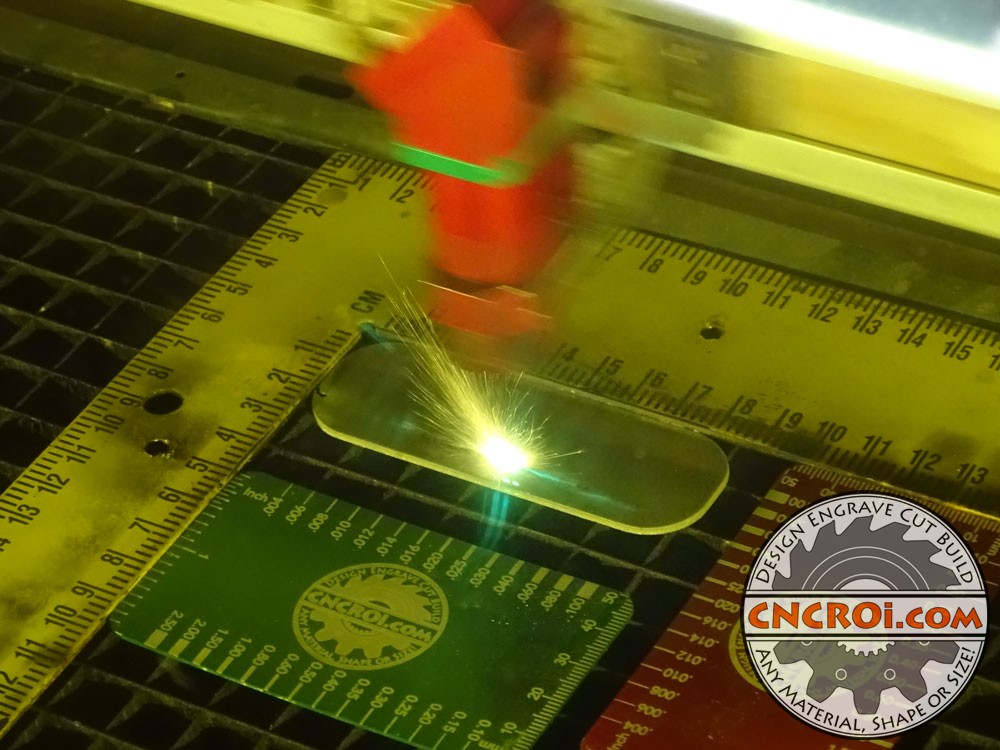

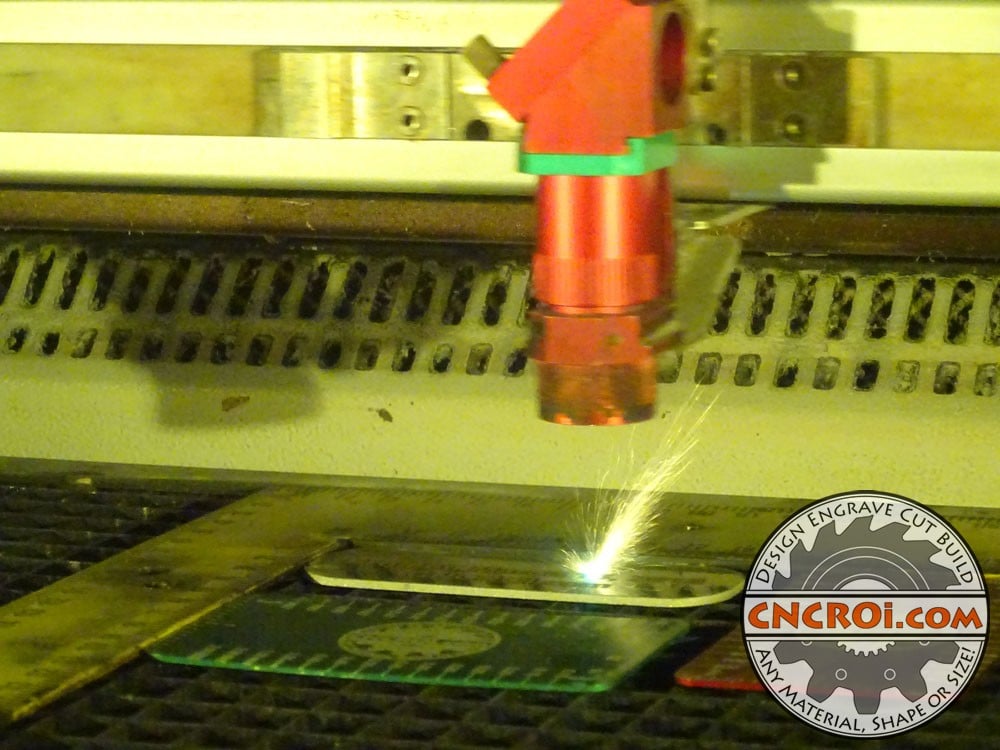

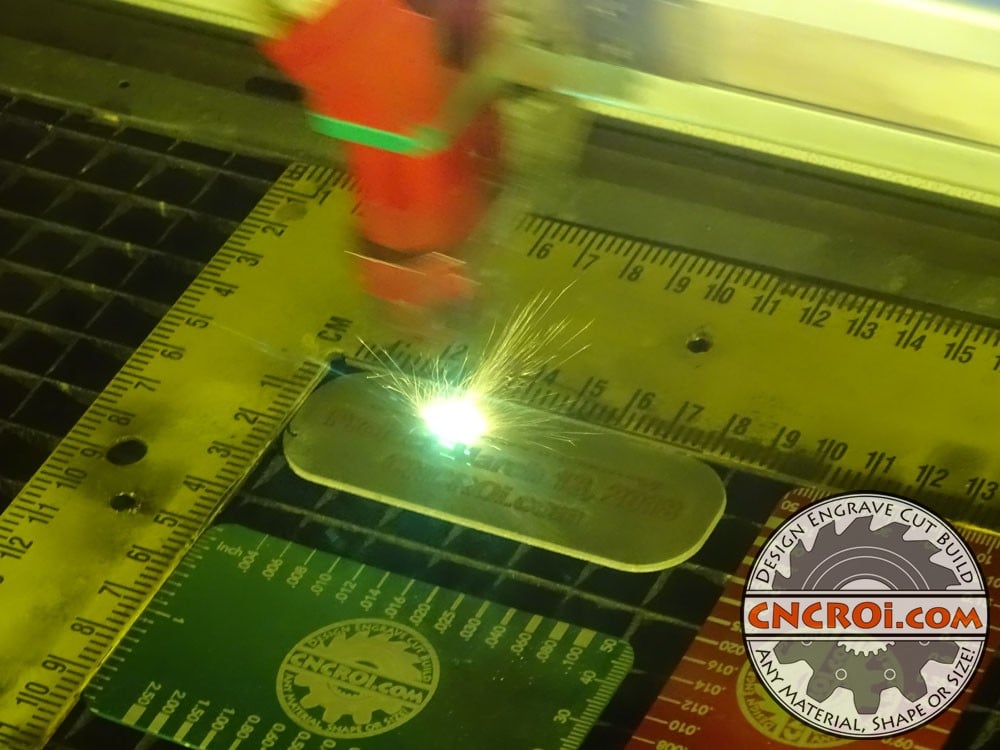

Having a wide-format industrial Trotec Austrian laser in the shop is wonderful, I was able to produce a custom welding tag while the table cooled down and get things ready for the next round of welding.

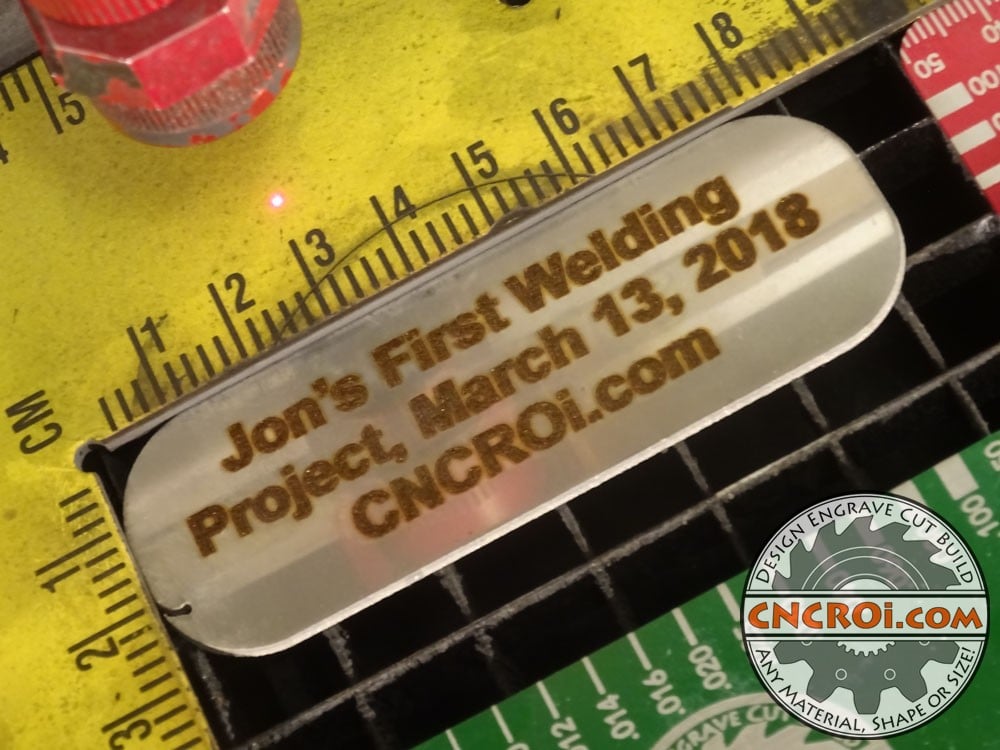

CNCROi.com uses our fiber laser source in order to etch and then anneal into the tag, as there are no budgets for my own work, I etched this multiple times and then annealed it, its a very expensive option that we only do for a few select clients but being the owner of CNCROi.com has it’s benefits.

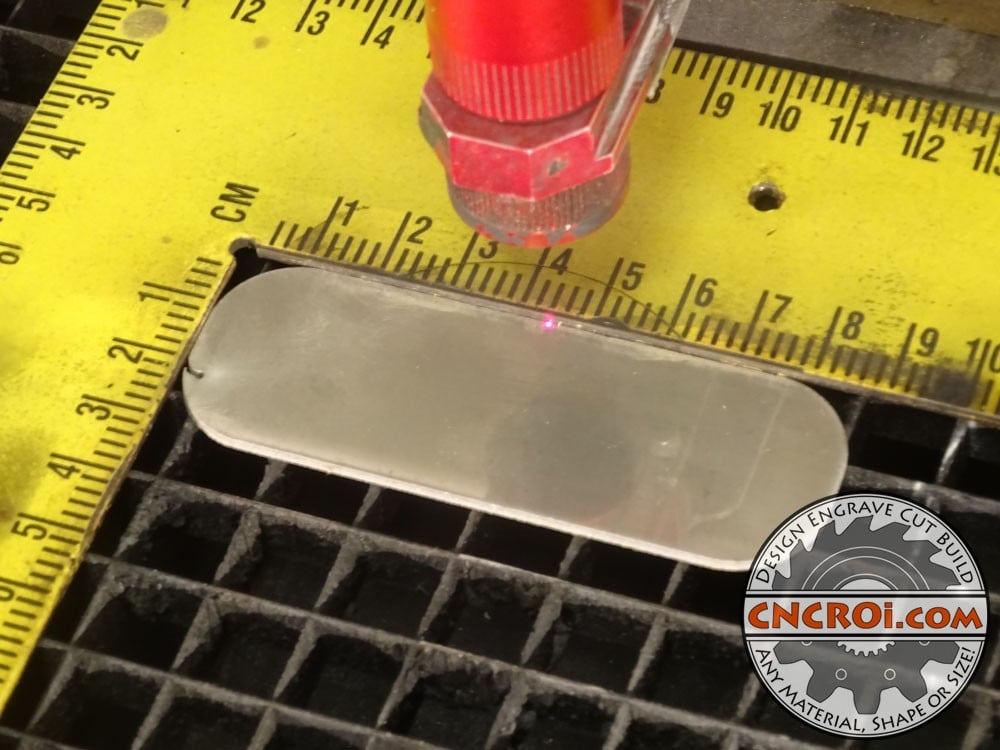

The tag I used for branding my first welding project is actually a piece of scrap from a waterjet job, their issue if you notice, is they have a slight cut into them along the bottom left edge, it’s totally fine for this application though, welding along the edge removed this cut right away.

That is one nifty and expensive custom welding tag, it’s 1/8″ or 3 mm thick and will outlast the last human on Earth!

CNCROi.com uses the best processes, best materials and best laser on the market to produce amazing welding tags and this one is no different, I’m as proud about the metal tag I made with our Trotec fiber laser as I am about the welding table that took eons longer to fabricate in the shop!

Of course, if you wanted valve tags made out of brass, CNCROi.com can produce those too!

It was now time after the CNC laser break to focus my attention back on the custom welding table, it’s ready to be branded but only after it’s finished!

For spacing, I used a small piece of cardboard, I’m not a big fan of measuring things, always easier to do it by eye when it isn’t critical to be within 1/32″ of any one other things.

CNCROi.com also made the custom pieces of branding metal using 316 stainless steel to better allow us to film and photograph the work we do here in the shop.

After finishing the custom welding table, it was time to weld my custom 304SS welding tag onto the table, as it’s fiber etched and annealed, even if the tag got super hot, there is nothing to vaporize or melt off, the work we do is there permanently short of using an angle grinder to remove it.

The fluxcore makes stuff look dirty but that’s why I have a metal brush, after welding thick flat iron, going to a small tag was a little tricky, I didn’t account for it melting faster than the surrounding metal.

Regardless, the custom welding table was looking great and you can see how close the welds got to the custom fiber work I did and how nothing on the tag was removed, even after brushing it with an iron brush and super heating it.

The custom welding table in the CNCROi.com is almost done, it’s now the very long process of removing the mill scaling on the flat bar.

After literally a few hours, I got tired but got most of it off, I’ve resorted to the point where before my next welding project and between future ones, I’m going to spend a few more minutes removing more mill scale and rust that builds-up on the table.

Eventually, this custom welding table will look all nice and shiny, if you want some custom work done regardless of material, size or shape, contact me at CNCROi.com!