Custom… when commodities won’t do!

I had a good chat with a friend the other day who also runs a custom CNC shop, he actually has a similar machines to mine and one piece of equipment that’s better than my ShopBot Desktop CNC router, a full-sheet Shopbot!

Like my previous article about CNCROi.com booming, he was experiencing the same, he had a backlog and he got that way because he threw himself into custom several years ahead of me. Where many shops think they can grow by importing product, sticking a badge on it then shipping it out, he, like me, realized early on that the money was in providing a total solution, a custom solution, to customers.

When you are selling a commodity, you are squeezed as the value proposition isn’t there as you are essentially selling the same thing everybody else is, if you go custom, well, your competition is yourself.

There are a lot of “holes” in my business that I’d like to fill in the coming year, once we move to a larger shop, a full sheet ShopBot is a must, the “small” desktop model we have now is great for what it does but it does have limits. Our laser is awesome but even that has limits… the less of these limits I have, the more creative freedoms I can have with my customer.

Being self-taught, I don’t quite know what is or isn’t possible, I just figure out a way to make it so. Thankfully, many of our customers have AWESOME capabilities that I can call on anytime from custom aluminum anodization to high precision machining. As mentioned previously, CNCROi.com is part of supply chains, however we organize them, that’s the product that leaves the shop but most importantly, the supply chains can be started by anybody. My customers can become suppliers at the drop of a hat and vice versa. This gives incredible creative potential.

One of the main reasons I always ask for a shop tour when visiting new customers is because it gives me ideas that I can maybe apply to a customer project down the line.

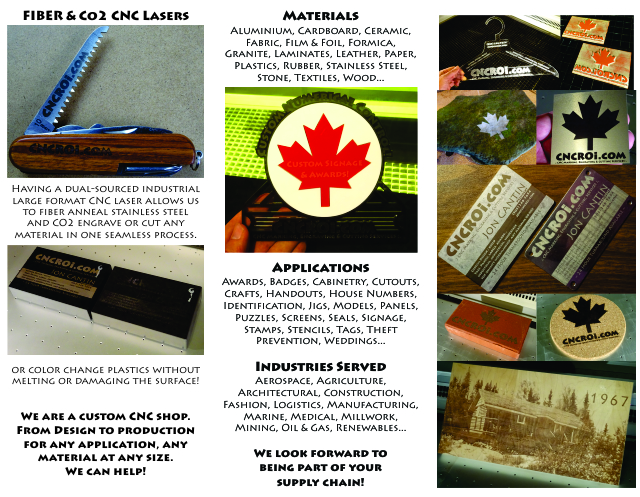

As for the direction of CNCROi.com, we are firmly living in the future. Whatever capabilities we have in our shop, we have contacts in industry to greatly augment them to suit our clients requirements. From making custom UV printed dibond signage custom cut to spec at pretty much any size to aluminum jigs for us and customers, there really isn’t much we can’t make or have the contacts to create the possibility of making.

One technology I’m looking into myself is plasma cutting, it would allow us a lot more flexibility we don’t currently have regarding metal tags. We currently either custom stamp them or laser cut them but for some applications, they are overkill. If you have a custom tag that is in low volume, making a custom die for stamping doesn’t make much sense and although KW range lasers (I’d like one of those too!) do an incredible job, they can only produce 2D outlines. The solution, in addition or compliment to these would be a CNC mill, yes, those cost a lot of money, so did our laser, so will our full-sheet Shopbot and a bunch of other stuff we have in the plans. Custom CNC isn’t for the light of heart or wallet!

I’d really like to get into custom CNC machining to augment dramatically our capabilities with metal. We already have metal bending and forming abilities, the next step up is machining. Do I have an education in high-precision machining? Nope, makes no difference, I know what I’d want to make with it and I’ll figure it out… and then become proficient enough to do the same for others.

Technically, our CNC router is a milling machine but I’d use that just to make flat aluminum and dibond metal tags as we do now with it. The milling station I’m considering for the shop later is a PCNC 1100 personal CNC which is a whole other ball game with a tool changer, full enclosure and a bunch of other features far beyond what our ShopBot can do. This would also allow us to make solid aluminum molds for our hot press clients, right now, we are limited to rubber up to 90 durometer. The quality is fantastic on our molds, but offering aluminum would open up a whole other market for us.

If you are looking for a custom CNC shop to make just about anything, you’ve found us.