Custom Window Coverings

Custom window coverings are items I’ve been wanting to add to the shop front windows for a while but never got around to it until I had some scrap plywood left over from a recent job we did, machinery and material met with passion at CNCROi.com!

As with many other items CNCROi.com fabricates, there is absolute flexibility in design, material, fonts and imagery so just because I made a tree and abstract circle custom window coverings, doesn’t mean you have to have a tree and circles made by us for your use.

Plywood is a wonderful material when it comes to making custom window coverings, it’s relatively strong for its weight and paints very well, in addition, it’s easy on machinery though it does have some drawbacks as well.

Luckily, I had a few full sheets of half inch (12 mm) thick plywood in the shop so I finally got around to making a quick demonstration about what CNCROi.com can do when it comes to custom architectural accents and design possibilities when it comes to making custom window coverings.

When it comes to plywood, I’ve used this material extensively for a wide variety of applications to helping with custom tabletop displays…

to furniture…

to lighting solutions…

and even signage to name just a few ideas.

Yes, my “Jon sized wooden big wheels” was also made using plywood.

So I’m very familiar with this and many other materials and thus, if you wanted custom window coverings out of acrylic, Corian or MDF, that’s no problem either.

I wanted to make two custom window coverings, one raw right off the machine and the other with a bit more finishing to show just what’s possible, this is absolutely not the best grade of plywood either, higher more expensive grades would produce a better finish but also weight more.

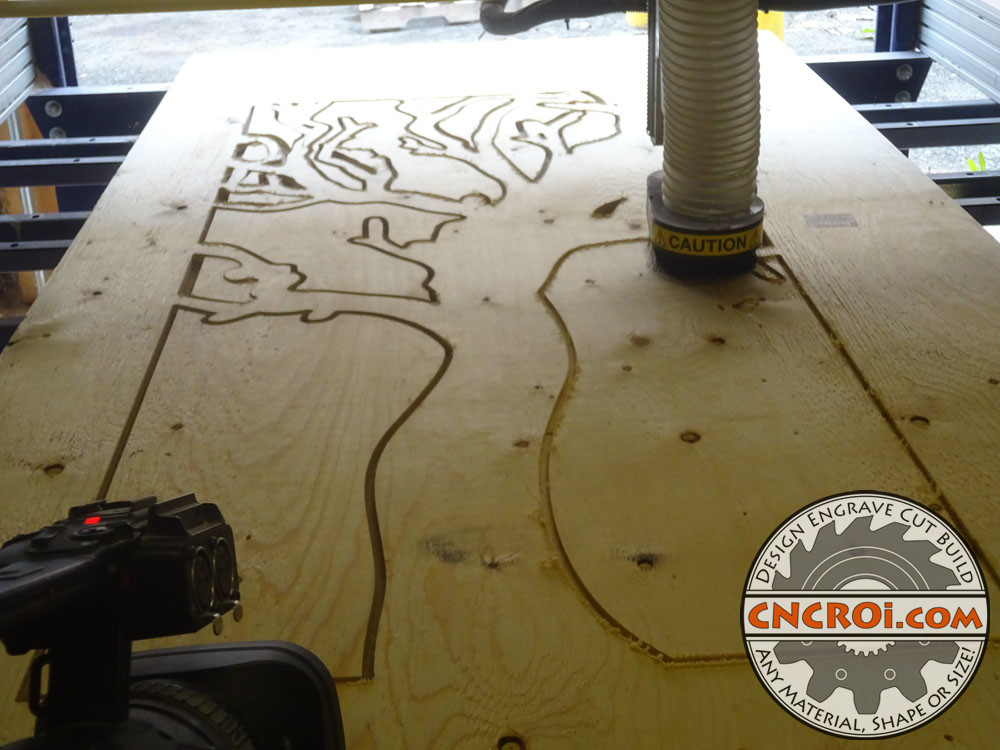

I decided the raw custom window cover would be that of a tree silhouette, as this is plywood and that’s made mostly out of wood while the other would be a very abstract design made to resemble something made out of aluminium or even steel using regular spray paint.

What I really like about plywood over MDF is that it’s light weight but more resiliant but the cost to this is more a lower finish quality unless CNCROi.com made this with furniture or marine grade plywood (which we can).

To give you an idea of the size of these two custom window coverings they are roughly 3 ft wide by 6 ft high but if you wanted something smaller or bigger, made-up of one solid piece or multiple, CNCROi.com can offer you that flexibility.

Like custom stencils that CNCROi.com also makes, you want to make sure all the inside parts are held together within a frame of material for strength and to get the best results when they are placed into a window frame.

Of course, if you wanted to use these custom window coverings as stencils to spray directly onto the window, that’s no problem either but we’d probably make them out of a material more apt to that application.

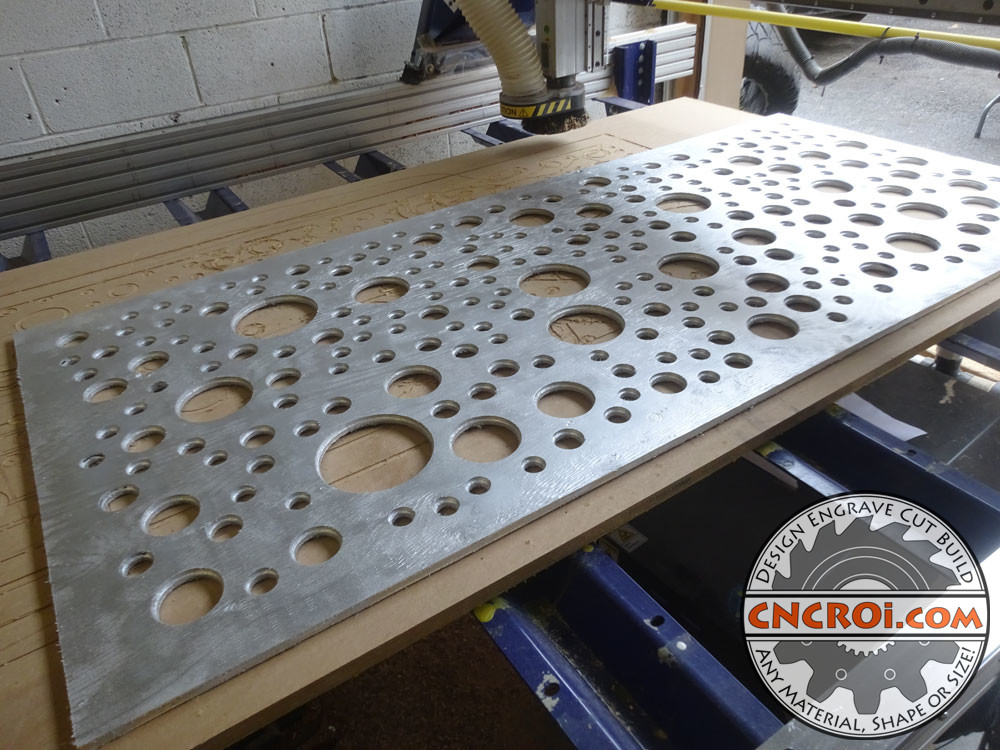

After the tree stencil was fabricated, it’s time to make another window cover using random sized and placed circles cut through which I’d then finish-up with a slight bevel for added lighting effects.

I really enjoy the diversity that we can offer our customers when it comes to producing projects that they once thought were only possible in their mind.

My ShopBot PRSAlpha is a wonderful CNC router, we use it for a host of other totally unrelated applications including live edge flattening.

And making polycarbonate parts for our customers.

So if you wanted your custom window coverings made using any of these materials, no problem either.

The dust you see building-up on the table surface is caused because I closed the vacuum system while doing this custom window cover because it was sucking-up the circles and that’s not a good thing as empellers don’t like chewing on plywood.

I also had the vacuum system at CNCROi.com running and putting holes through a piece of plywood also started to affect adhesion of the plywood to the CNC router surface.

The abstract circle design for this custom window cover is now finished the CNC routering aspect of the job, next up was cleaning it up and routering it all out again using a hand held version of my CNC router table.

Technically I could have gone through the design again with my CNC router but I wanted to get a little exercise, a palm held router got me what I was after.

After adding an inner bevel to all the circles, the next step was to sand the surface to make the overall esthetics look a little more presentable, this is plywood and as such, there are splinters all over it, sanding will reduce them as well.

It’s surprising how well plywood actually sands, you can start off with a pretty rough looking low quality sheet of plywood and end-up with something that’s very much presentable.

The sanded surface also provided a wonderful surface for the paint to adhere to so I can make this custom window cover look like metal, without the costs and weights associated with it.

From a distance, this plywood does very much look and act like metal, it’s amazingly light weight and I can always change the color later too if I choose to make it match something else in the CNCROi.com shop.

Once finished, the installation process was pretty easy, just squeeze it into the window frames and done!

If you want custom window coverings, contact CNCROi.com right now!