Custom Wood Birthday Card: 1/8” or 3 mm thick MDF laser engraved and cut

This is a good case study as to design changes required to get a project to fit within a specific budget for a volume and detail requirements.

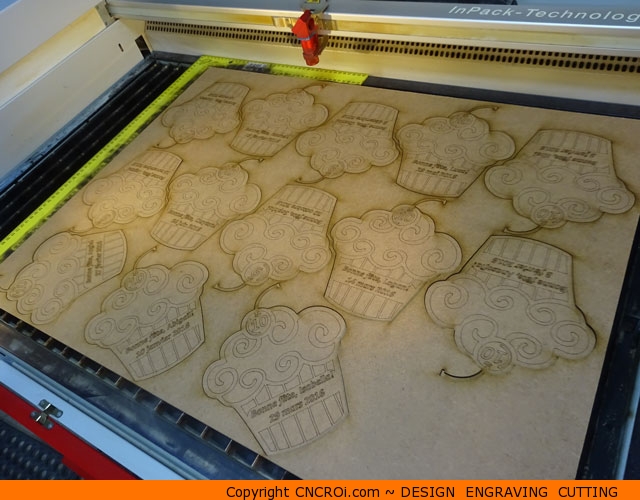

The above is the finished production version of this laser cut cupcake prototype we made below. The changes are very slight, it was made smaller and you’ll notice the engraving and age is outlined and not full.

Although we could have made this birthday card out of just about any material, MDF wood was used to keep things in budget and on time. Using a laser means we don’t need to use any paint to achieve a contrast.

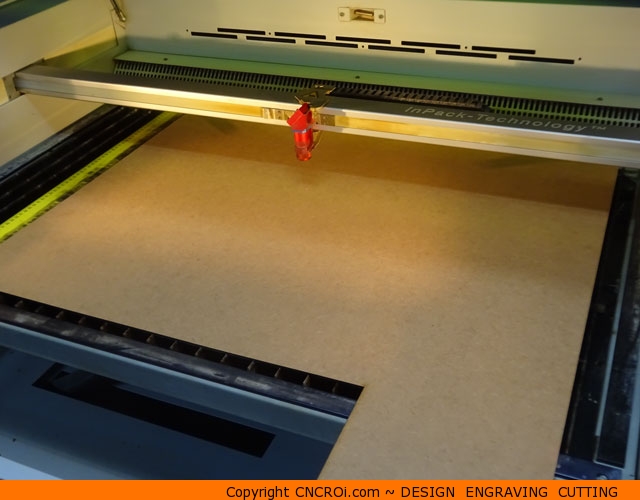

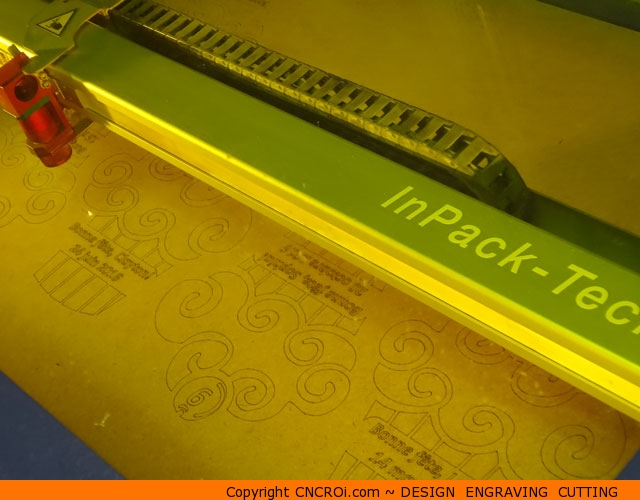

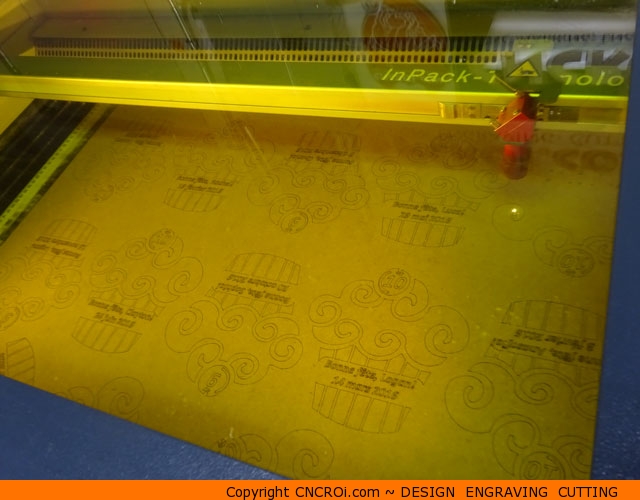

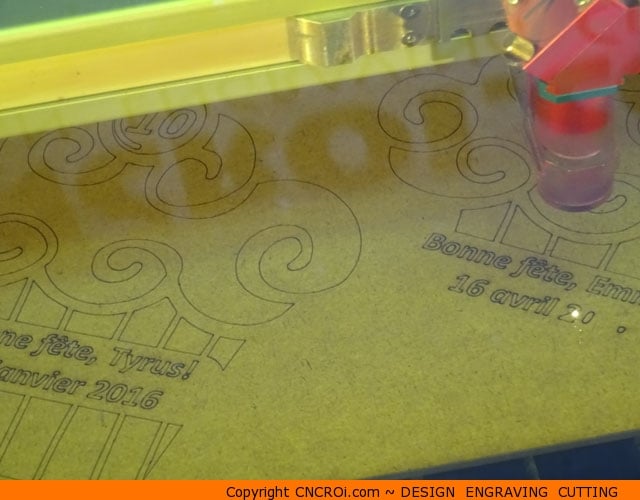

Having a large format Austrian industrial laser means we can feed larger sheets into the machine without having to cut them to size. That’s especially nice for this project as you’ll see.

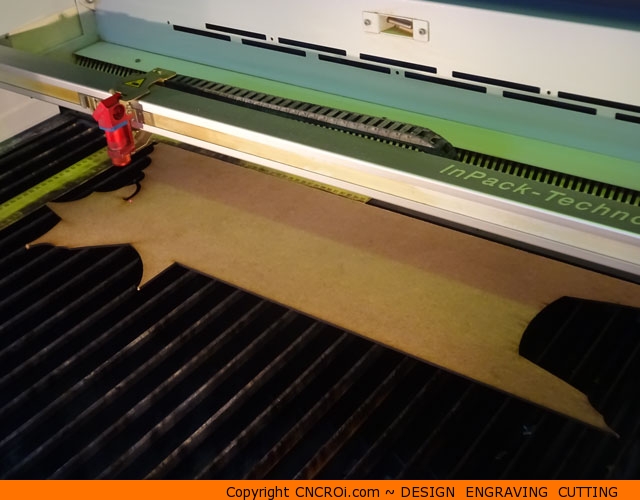

In this case, the sheet was left over from another MDF project we did, it’s an odd shape but for this, a perfect fit and we used the entire scrap sheet for this project.

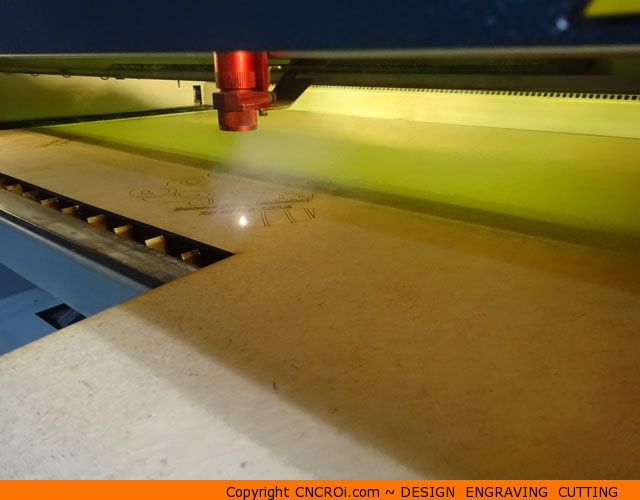

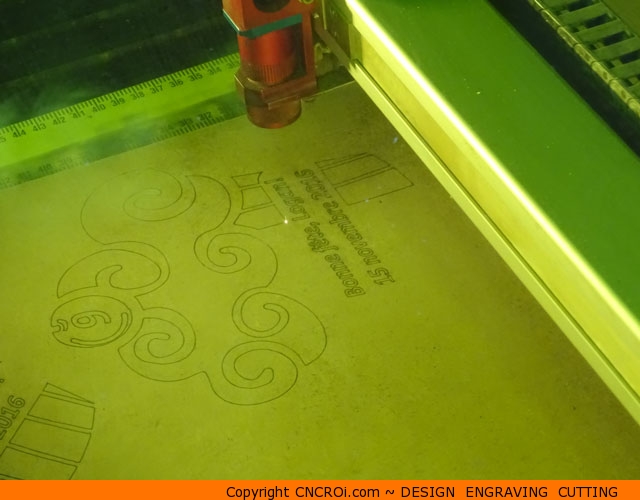

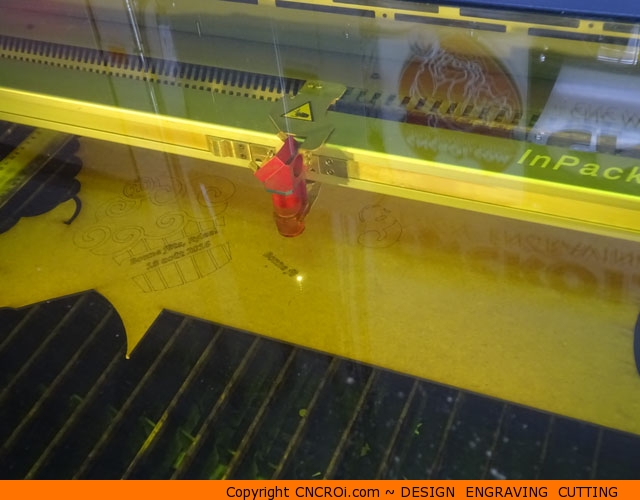

The design of this MDF cup cake was optimized specifically to be entirely engraved using a low powered cut line, the goal was to darken the lines, not cut through.

Using cut lines instead of engraving lines saved a significant amount of laser time. This works great for this design but doesn’t always work for other design types where lines are particularly thick or need lots of infill.

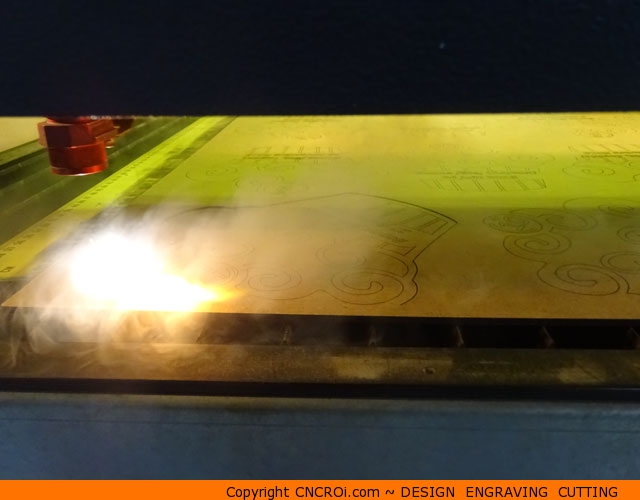

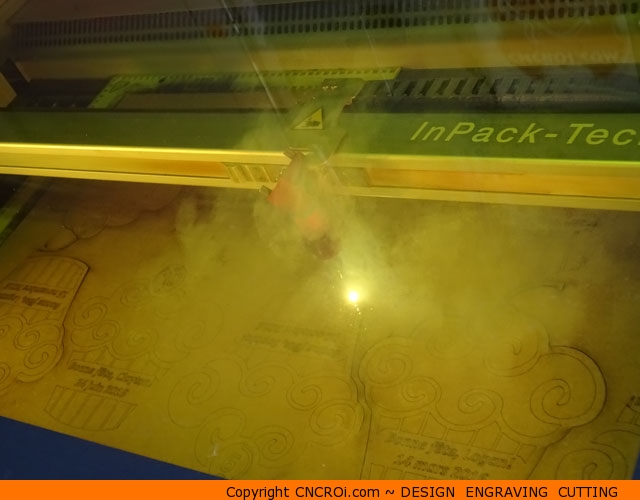

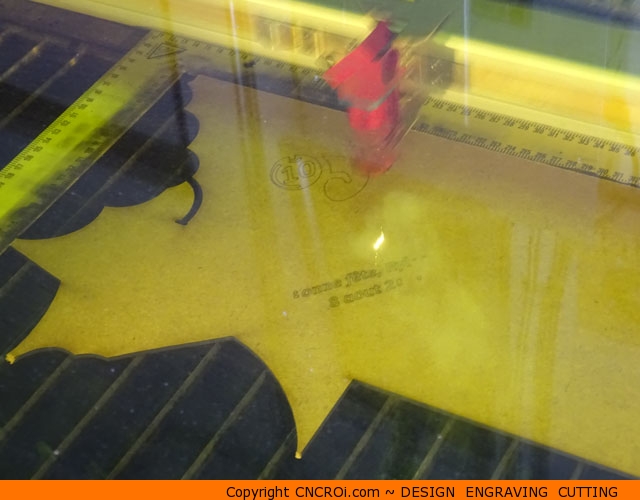

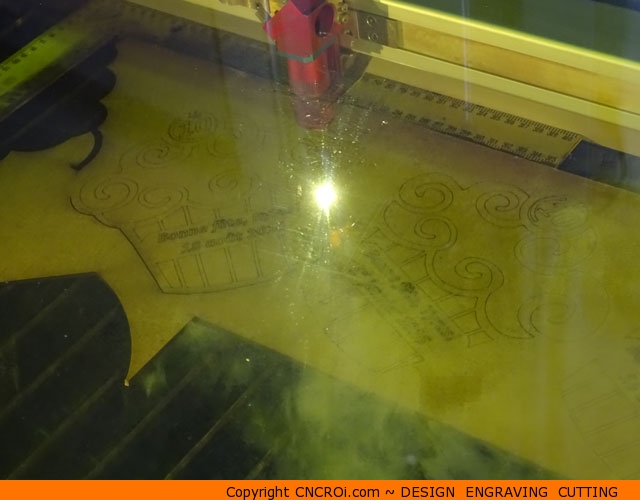

MDF is an especially smoky material, due to the heavy glue content within this wood. The advantage we have is that, we have a very strong vacuum system along with compressed air going down on the sheet.

Although there is some spot ignition, the laser with our other bells and whistles quickly extinguish them as soon as they form. It makes for some very interesting fireworks.

It’s interesting how much you learn about a material by vaporizing it. All the material benefits and flaws are revealed when they are heated, cut and engraved.

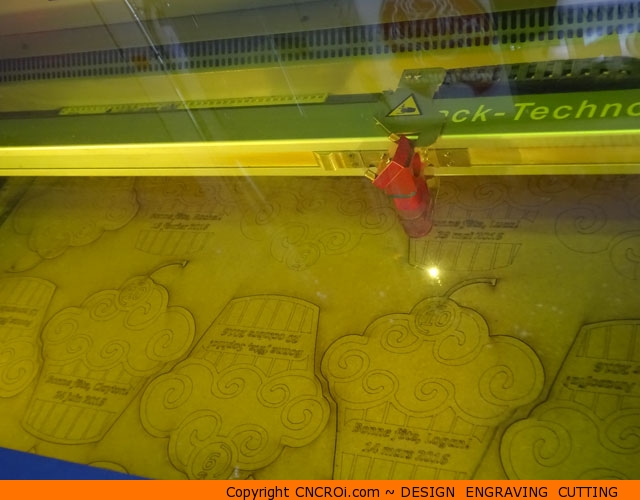

After all the CNC laser engraving passes are finished using weak cut lines, we then shift focus into actual cutting by increasing the power of our Austrian CO2 laser.

Now that everything is finished both being engraved and cut, it’s time to liberate this custom birthday cup cakes from their MDF bonds.

They all look great, they are each personalized and they are ready to be given out at the student’s birthday. The top number represented the age while the bottom had the student’s name.

Here’s what this first production run looks like, everything is nice and clearly legible. The precision is unparalleled and the optimization to fit within a specific budget using material at hand worked perfect.

Now for the final round of custom wood MDF birthday cup cakes, this was the part that was hanging out from the industrial laser in the first photo on this blog post. The first production run cleared the space for the second.

These cup cake are identical to the first round, just with a different year and name than the others. The dimensions are the same as is the material qualities and surface finish.

Making such perfect and precise cut lines, good enough to replace what would traditionally be engraved, is something that’s only possible thanks to our top of the line laser.

It’s just as precise cutting using a CO2 laser source as is our fiber, so whether it’s annealing stainless steel in specific lines that are a fraction of the width of a human hair.

Our industrial Austrian CNC laser is meant for 24/7 operation, so doing production runs, big or small, across a range of projects is no problem at all. This means every aspect of our machine, from the steel frame to the high quality tube that costs more than most people’s CNC lasers, our machine is built for speed and endurance.

Making cup cakes out of MDF is a very cost-effective way to create cards, it provides very good contrast, it’s relatively cheap and is very consistent which means the results are repeatable result wise and it cuts fast.

The amount of detail that’s achievable is only limited by your budget, it plays a direct role on the pricing we come up with using our industrial job quoting software.

Looking for custom solutions across a wide range of applications? We can work from your design files or develop our own for your specific project at hand. Generally the best file formats are EPS with a PDF along with dimensions.

Contact CNCROi.com right now, we are passionate about helping you out with your custom requirements!