Custom Wood Trays: Poplar

Custom wood trays using live edge Poplar are a potent mix of utility and beauty, CNCROi.com can make them with any mix of design and species specs you may have.

Having a large assortment of live edge wood in our shop means instant access to lumber for custom wood trays of any shape, size or design profile.

As with most live edge, to get the very best result, we have to make sure that the live edge slab is completely flat and parallel, it makes things easier for the CNC router and our CNCROi.com customers love it when they use our custom trays of their design that don’t twist or bend on their flat tables.

Just to give you an idea of the flexibility of CNCROi.com‘s approach towards custom wood trays, here’s a cigar tray we made in the shape of two American states, Alabama and Texas.

You aren’t limited to states, you want them square, circles or any random shape like an animal, cloud or what have you, we can make it using a variety of different wood species, using both dimensional lumber and live edge.

When it comes to custom wood trays, CNCROi.com isn’t just limited to making big production runs much less them all being the same, whether you have one or a thousand units, all the same or totally different, we can make them as one production cycle so you gain from volume discounts.

Our CNC machines are top of the line, they take their jobs very seriously, never taking coffee breaks or complaining about the weather, we throw work at them and they are happy doing it regardless of the design or specs required by our customers.

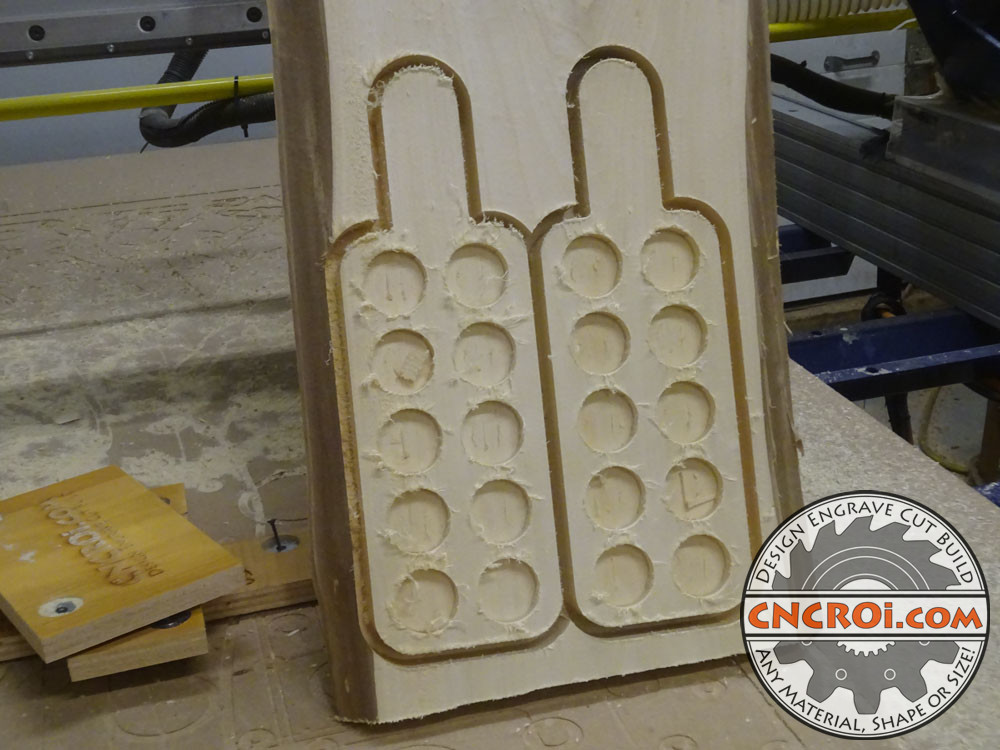

You can see from the mess of chips in the above photo what a custom tray looks like after it’s finished being machined, in this case, the Poplar wooden tray is looking amazing, just a bit of sanding and it’s ready for prime time.

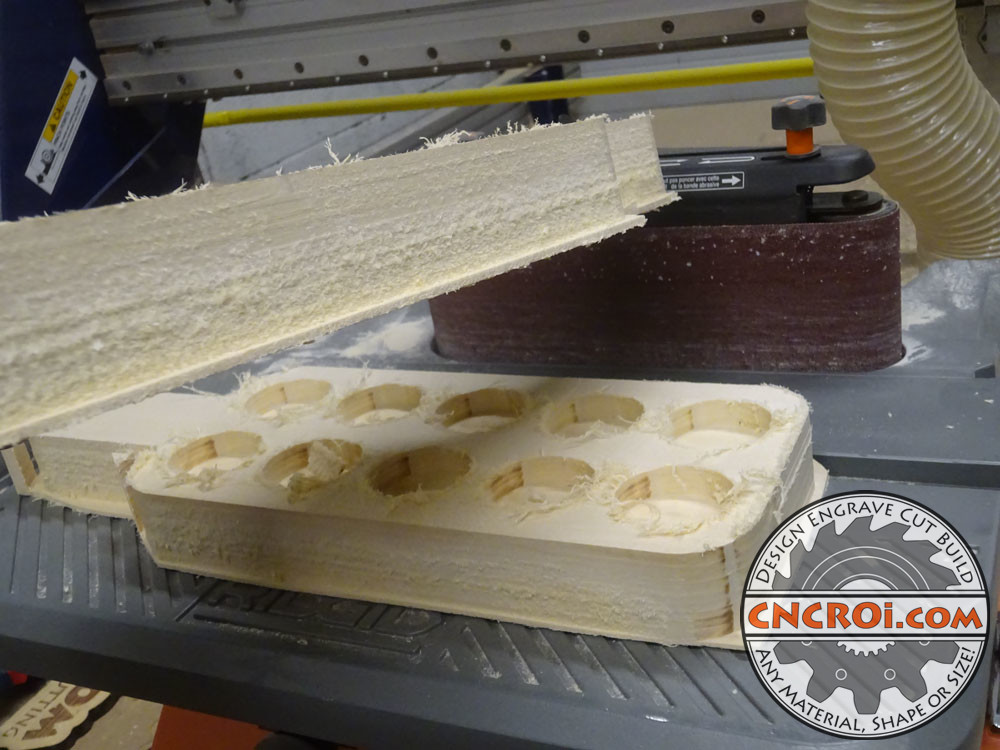

To keep things safe in the shop, I did give it a small ledge which requires a little cutting with my bandsaw before sanding flush, this prevents the wooden tray from becoming a bullet in the shop and makes big production cycles dead easy.

You can see clearly, this is a live edge sourced custom wood tray, notice the bark along the bottom, this will be cut off using the bandsaw but I prefer to use this approach over trying to make tabs and other hold down methods for the wood on our full sheet CNC router.

Wood trays generally all follow this approach which I’ve developed through trial and error, the more efficient the shop can be and the more flexible we can be in CNCROi.com‘s approach towards custom production, the better our services can be for our end customers.

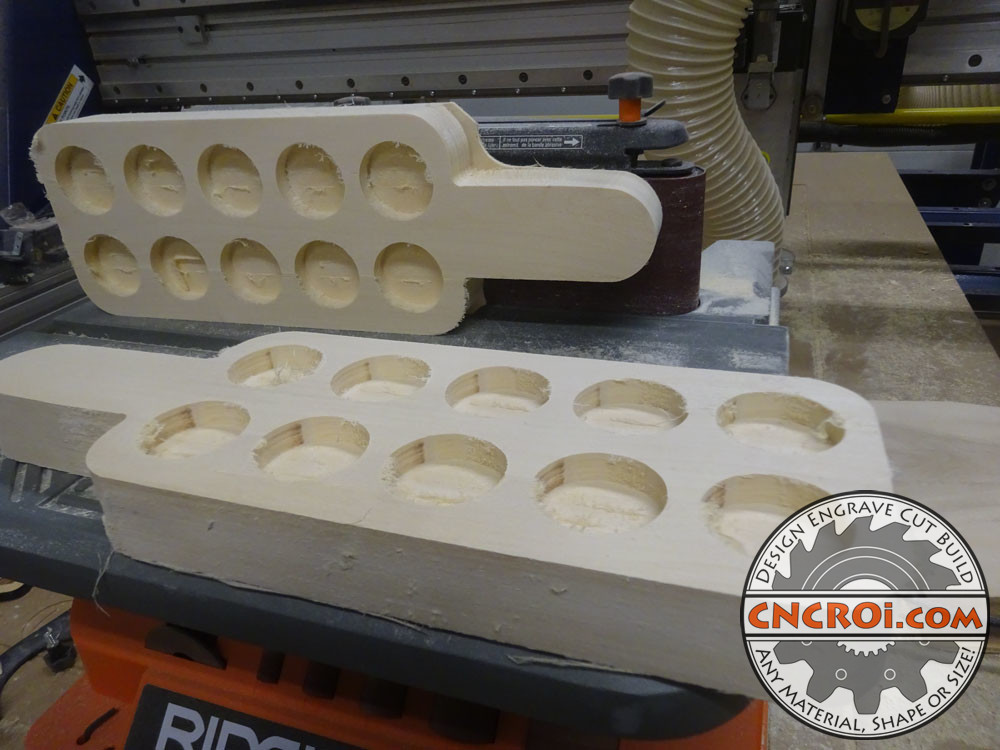

A little bit of preliminary sanding and this custom Poplar tray is ready for the finishing line, I’m always amazed at just how precise our production capabilities are and how much fun it is to make something out of a kiln dried slab.

Don’t forget, CNCROi.com has full 3D design and testing capabilities so if you want a design that’s going to be used as part of a larger project to show to your boss, we can make that too from simple designs like this bread crumb tray…

To something that has moving parts.

Just for fun, let’s make a few custom Poplar shooters using what’s left of the custom wood trays I made above, you’ll notice that although the design is very different, the approach is essentially the same.

The reason why I don’t have a dust boot during production of these trays is because I’m going pretty deep when it comes to almost cutting out the wood trays from the live edge Poplar, it would snag and cause problems.

For this job, the custom wood shooter trays are being made side by side, the left over to the right ended-up becoming my new cutting board for use at home and any scraps from all of these jobs will go into the fire pit.

You have to try to imagine that the shooter trays you see being custom fabricated here are the same design we made months ago for another customer, the nice thing about CNC production is that the designs can be made on-demand so you aren’t stuck with an inventory of thousands with your first initial order.

I really enjoy the process of custom woodworking, from the initial design specs our customers want to making the digital file then going into full production followed by finishing (not shown today).

If there was ANY doubt as to the origin of these custom shooter trays, yep, they are straight from kiln dried and CNC flattened live edge Poplar!

Like the tray above, the next step is the bandsaw to liberate these custom wood trays from their live edge slab origins, they are looking pretty good already but now it’s more a process of refinement instead of making.

Custom wood trays of any shape, size or design profile are made by CNCROi.com, we give you absolute flexibility, including material choice.

You can see the 1/8″ or 3 mm ledge along the bottom that kept everything where it was suppose to be during the CNC production aspect of these custom wood trays, again, easily sanded off.

When it comes to custom trays, the process start to finish is generally the same but the designs we pump out at CNCROi.com are amazing, our customers love the work we do for them and it shows when they receive their custom order through the mail.

These three trays are now finished the preliminary sanding process, next-up is the more refined sanding and finishing with a wood varnish or mineral oil.

Want custom trays of any size, shape, wood species or design?

Contact CNCROi.com right now!