Custom Wood Veneers: White Oak, Hard Maple, Basswood, Cherry, Walnut, Bloodwood

CNCROi.com uses a lot of custom wood veneer species, today we’ll review what a laser does to White Oak, Hard Maple, Basswood, Cherry, Walnut and Bloodwood.

If you want to review other videos we’ve done outlining various custom wood veneers we use here, check out the following videos.

Yellow Heart, Alder, Butternut, Mahogany and Red Cedar: Real Veneer Wood Laser Engraving & Cutting

And Custom Laser Engraved & Cut Poplar, Wenge, Ash, Zebrawood & Padauk veneers.

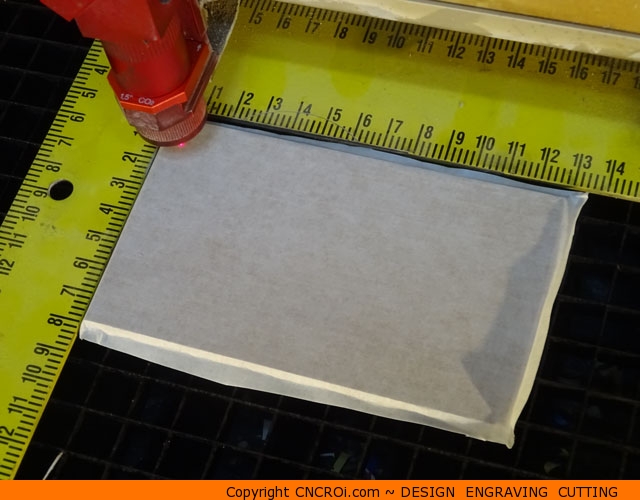

Now that we have that out-of-the-way, let’s take a closer look at today’s custom veneers starting with white oak wood veneer.

Like the other two bunches of wood species I’ve reviewed earlier and posted the video of on this blog post, white oak is also available in a large variety of thicknesses from extremely thin veneers to an inch thick and anything in between.

White oak provides very nice contrast from the laser cutting and is hard enough to take a good sanding to remove any resin and smoke that may deposit on the surface.

It is also a pretty dense wood, so masking white oak works very well and cost wise, it’s pretty affordable compared to the more exotic woods we have at CNCROi.com such as wenge and zebrawood.

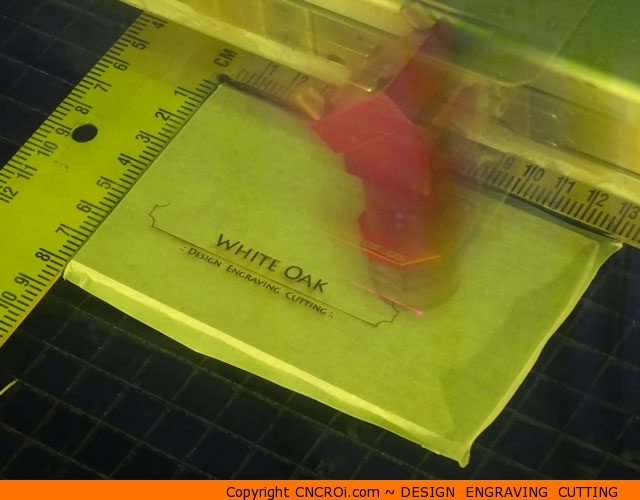

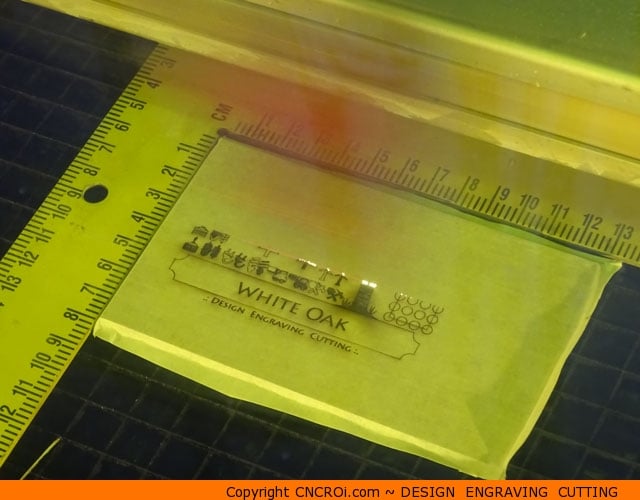

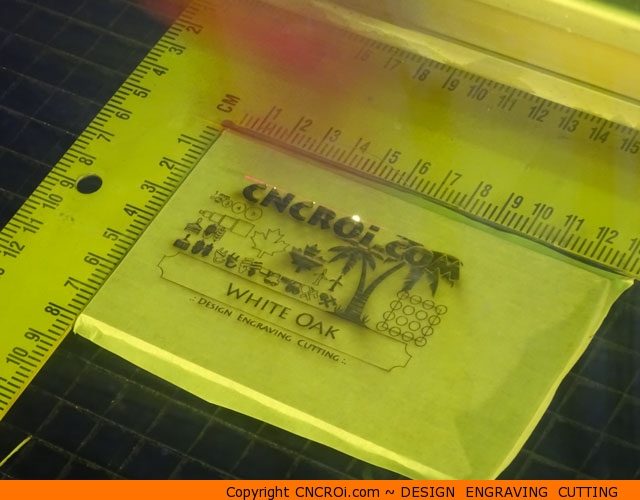

A really nice feature of white oak is that the grain is nice and deep in color, it contrasts nicely against the non-laser engraved surface and as you can see from the mask, it does have a fair amount of resin in it.

Without any sanding, you can see how wonderful this wood looks, you have a lot of the benefits of zebrawood but not as extreme and far more affordable with our white oak alternative.

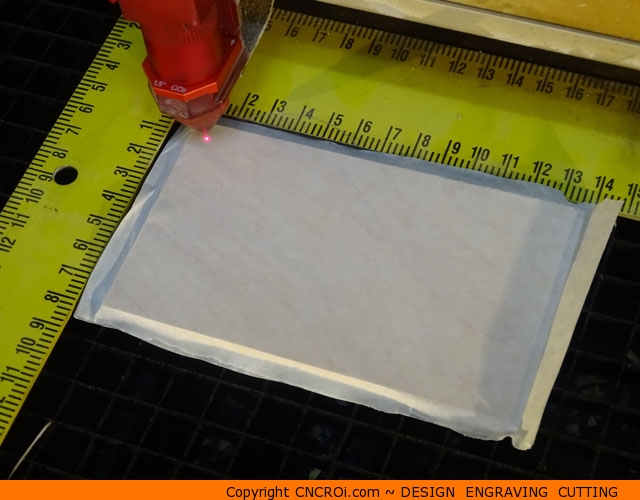

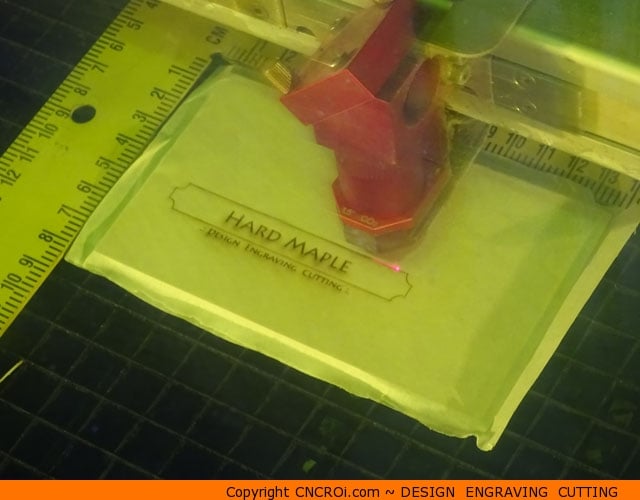

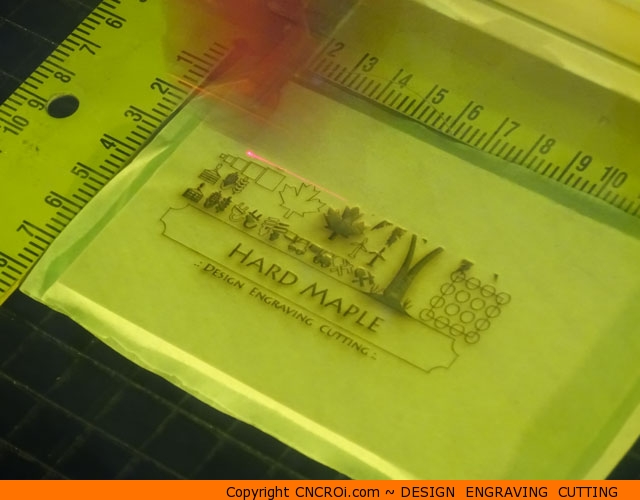

Next up is hard maple, a very nice wood that’s widely available being based out of North America, it’s like every second tree is some type of maple!

Unlike the white oak we say above, the engraving results on hard maple are a bit more subdued, depending on the application and the desired outcome, this is where good veneer selection is important from the very beginning.

If you are, for instance, looking at having CNCROi.com make custom business cards for you out of wood veneer, white oak is a wonderful wood for a more bold presentation while mahogany or zebrawood wenge is a more “prestigious” look and hard maple, a bit more, not as much, in your face result.

Like white oak and many other species reviewed, my favorite is still red cedar because it provides amazing contrast and a wonderful smell, it’s my go-to wood for quite a few custom wood veneer applications that we build and design things for at CNCROi.com.

As you can see, the surface quality of hard maple is very consistent, you don’t have the striking details in the grain or surface that you saw in the custom white oak veneer and the brown is a nice contrasting shade.

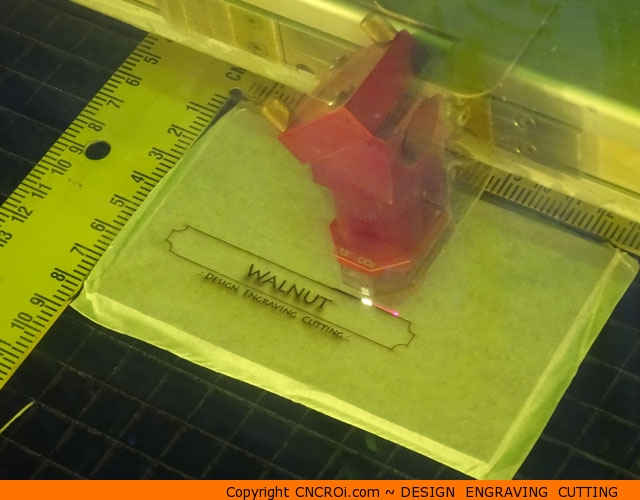

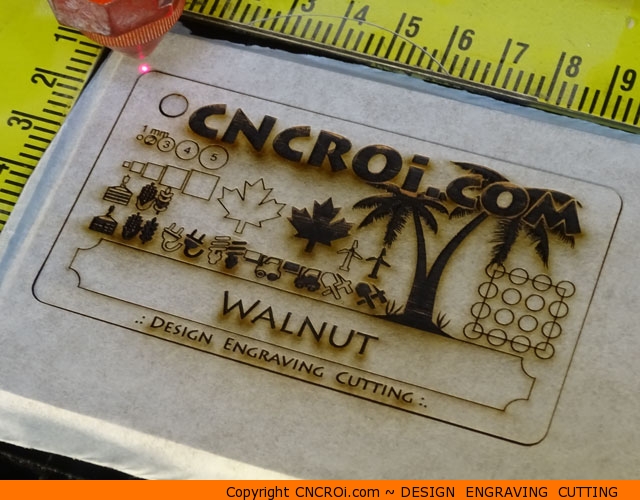

Next up is custom walnut wood veneer. Walnut is a wonderful wood species for inlays because it’s incredibly hard (and durable), consistent in density and best of all, provides a fantastic contrast to most other woods.

The engraving details are nice and dark as well, this is why you see a lot of heavy use wood items being made out of walnut because this wood species is so hard and durable verses, say, very lightweight and foam like density of basswood.

I really like the deep rich color that walnut wood veneer gives to projects, it has wonderful characteristics for so many projects we do at CNCROi.com that suit it so well from custom coasters through banks and even custom walnut furniture.

There is no mistaking the very consistent grain patterns and surface characteristics of walnut wood veneer, even very fine details come out nice and sharp due to the high density and weight of this wood.

Even without any sanding, walnut is almost ready to go from laser to custom applications for our customers around the world. Look at the leaves of the palm below, wow, you can easily make them out and the fraction of a mm spacing between the COM and the tree behind it. All very clear and distinctive.

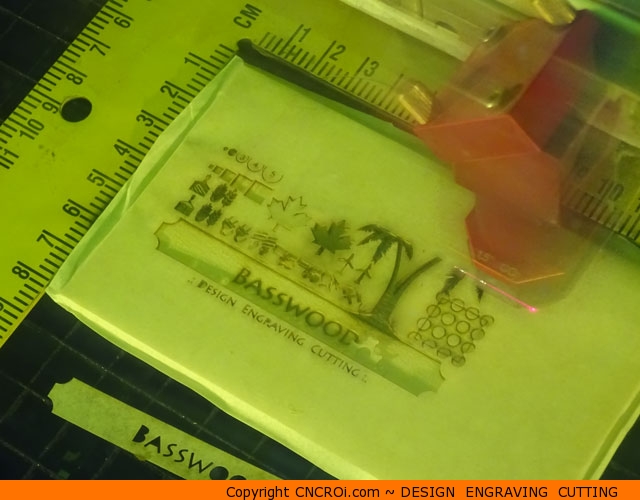

Basswood custom wood veneer is wonderful if you want something extremely light in weight and the application doesn’t call for anything particularly strong or durable.

Basswood is quickly sanded down and not a lot of laser power is required or CNC router power for that matter, to make something pretty neat out of this incredibly light in density wood,

You can see just how lightweight this material really is just by comparing the smoke vapor settling on this vs the walnut wood veneer above. This is a tough wood to mask as there isn’t that much surface cohesion. Wonderful for model airplanes, awful for structural elements in a custom model.

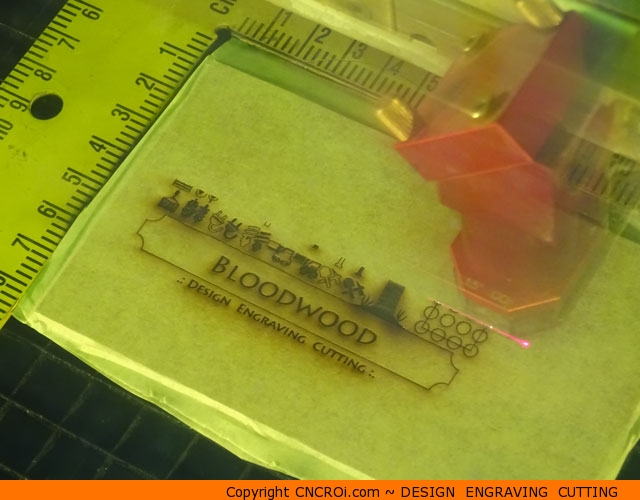

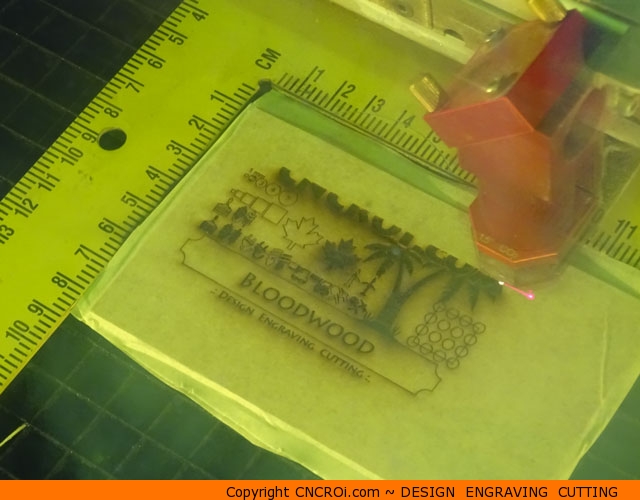

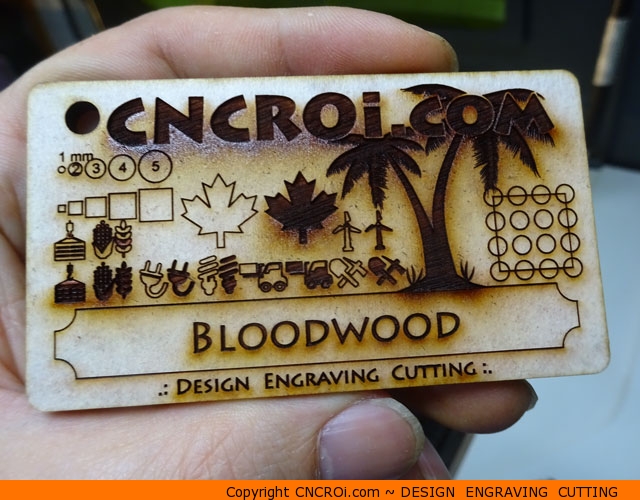

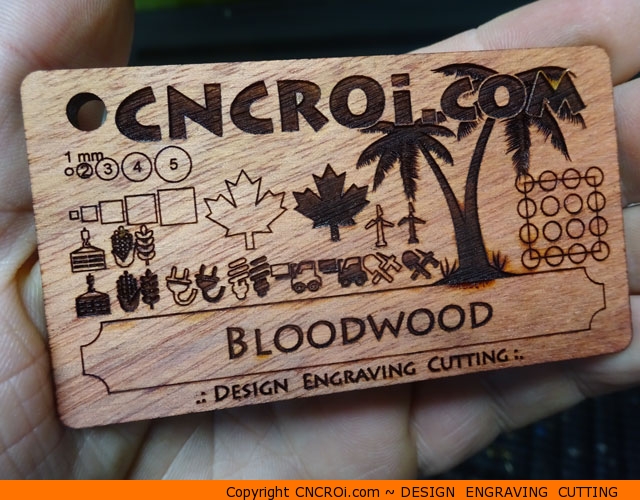

Bloodwood is a lot like padauk in color and somewhat close to red cedar, it has a deep rich color that also makes it deal for custom inlay applications and is relatively strong wood as well, so it can be used for structural elements, though it is also quite expensive.

There is a huge variety of colors and surface properties available in the wood veneers I’ve reviewed, so much so, that applications where you don’t want any paint or tint added to wood but want strong contrasts, it’s totally possible especially when you mix-in the capabilities we have with both our industrial CNC laser and CNC router.

Similar to walnut in surface density, you can see how the laser reveals a very consistent and dark wood grain but it isn’t as strong as the white oak in strength.

Even without any sanding, the results look fantastic, again, denser woods provide higher contrast and clarity when it comes to custom engraving applications.

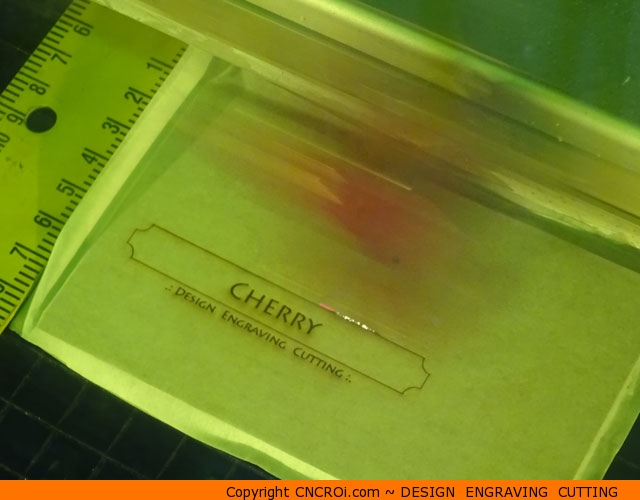

The last custom wood veneer we’ll take a look at is cherry. This wood is also pretty dense which makes it idea for lots of projects and applications that require strength and a strong contrasting engraving.

Cherry is a mid-range wood regarding costs but for some applications, the deep rich color that this wood species provides is tough to beat, throw-in its strength and durability and it’s a very good combination and stains very well too!

We’ve done a lot of custom name badges out of cherry, it’s a very well-known and popular wood species that works very well and can be easily sealed for a nice shiny look.

Like the walnut, only minor touch-ups are required after being processed with our Austrian industrial laser. Cherry also does wonders with custom engraving and cutting applications when it comes to our industrial CNC router as well.

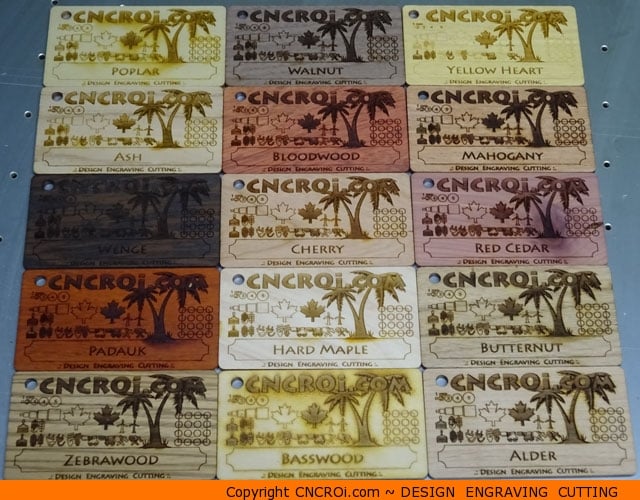

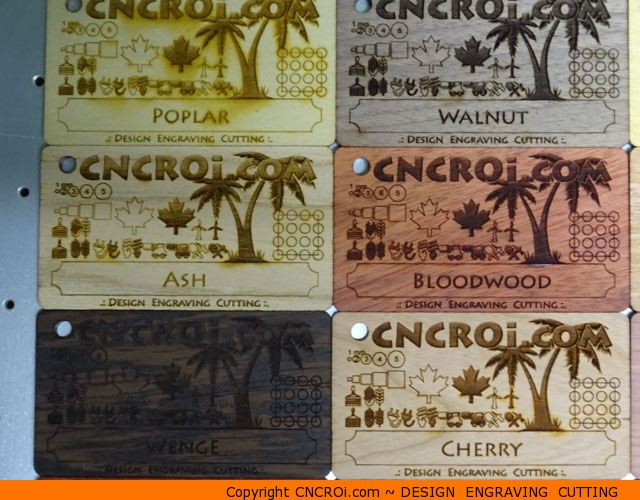

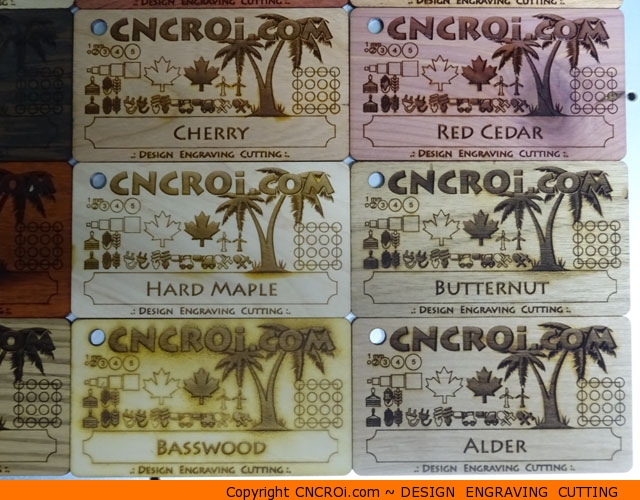

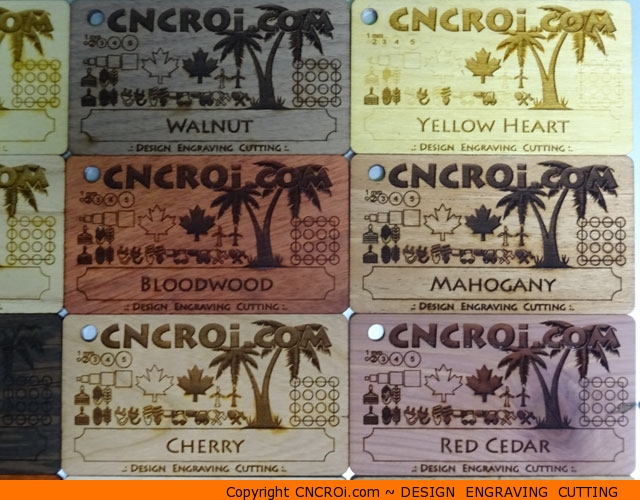

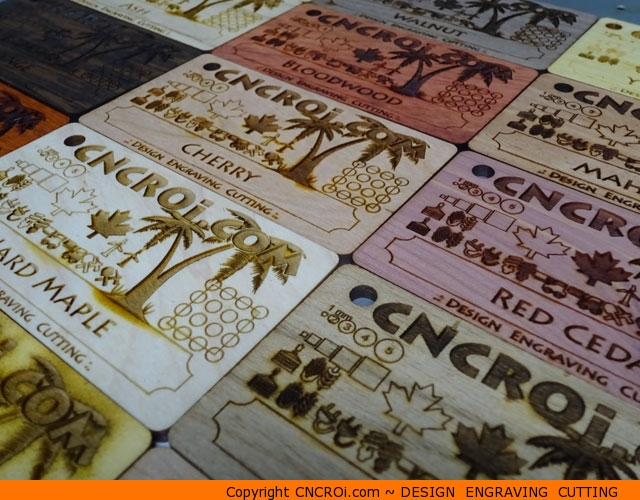

To help you see the contrasts between the various wood species I’ve showcased on CNCROi.com, here are some pictures of some of what we have available side by side.

Looking at these custom wood veneers from a few different angles, you can quickly see what shades may work best for your application and budget.

These were not sanded on purpose to help illustrate the differences of the composition of each of these woods, essentially, the harder woods are the easier to clean-up and work well with sanding.

Our industrial CNC laser engraves nice and deep so sanding the surface DOES NOT erase the results achieved by our equipment.

There is quite a wide variety of shades of color, picking inlays, even 3 or 4 different wood veneer options that work together is easy and due to the precision of our industrial CNC laser, custom cut inlays are perfect.

The engraving can also happen across inlays, so if you had a huge picture made-up of a whole bunch of different color variances, we can do that for you at CNCROi.com!

CNCROi.com works on a variety of projects to meet your needs using a lot of different wood species, contact us anytime to get a quote with the volume and budget you are trying to accomplish your goal with.

We have extensive experience with woods of all characteristics, big or small, we are here to help you!

Poplar, ash, wenge, zebrawood, padauk…

Hard maple, walnut, bloodwood, basswood, cherry…

and anything else you need done, contact us right now!