Dark Laser Engraving Bamboo

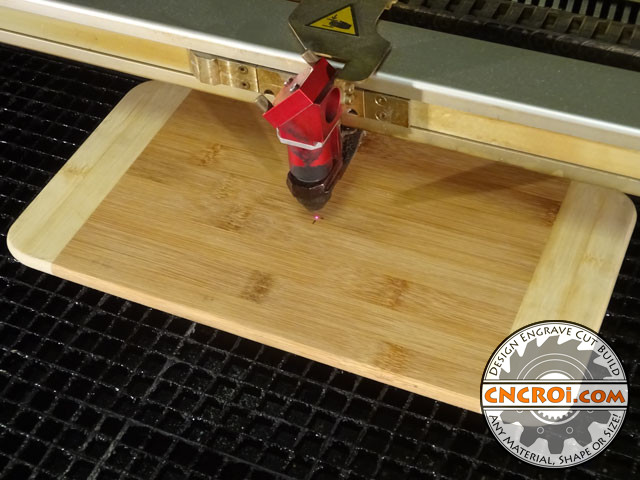

CNCROi.com will be engraving bamboo today, we’ll show you how dark we can achieve a permanent result onto this medium and how clear and precise it is.

To refresh your memory, here’s a video of the results achieved on the other side of this bamboo cutting board.

And here’s the results we were trying to closely achieve onto bamboo as we did with this walnut wood species, different wood, different results, always being careful not to overdue things as you just end-up burning the wood to the point where it becomes useless.

All that I did for this project was flip the bamboo cutting board over, so you can see what a typical engraving looks like then a dark laser engraving compares to it.

It’s quite a difference, but it requires a lot more time and precision to pull-off so it’s very much a “budget depending” kinda option when it comes to CNCROi.com producing something comparable for you.

Now that I have a logo, it’s time to start adding it to a bunch of different materials and producing results that really stand out for our customers to review.

The nice thing about engraving bamboo is that it’s a very dense material, comparable to oak or maple, as a result, everything is nice, strong and crisp even when engraved.

The purpose of the first engraving bamboo pass is to create some depth, we can go a lot deeper of course, but our goal here isn’t to go through the board but to create enough depth so that it’s interesting but not so much as it becomes a distraction.

CNCROi.com has extensive experience with materials of all kinds, including bamboo and veneers of every species you can think of.

There is a lot of smoke produced during the first pass, it’s not an issue but for filming and photography sake, I did so without using or applying a mask over the surface, just to show you what it looks like right on the raw bamboo.

This is not a bamboo laminate by the way, its solid bamboo that’s formed in sheets with pressure and heat, similar to how MDF is made, but dramatically more resilient.

If you want to compare apples to apples, check out this video of my logo being engraved, similar process to this but slightly smaller, on a solid piece of real oak.

There is a lot of work involved behind the scenes, from resawing through to finishing, but second only to metal, wood is one of my favorite materials due to the incredible diversity of species and design options possible with it.

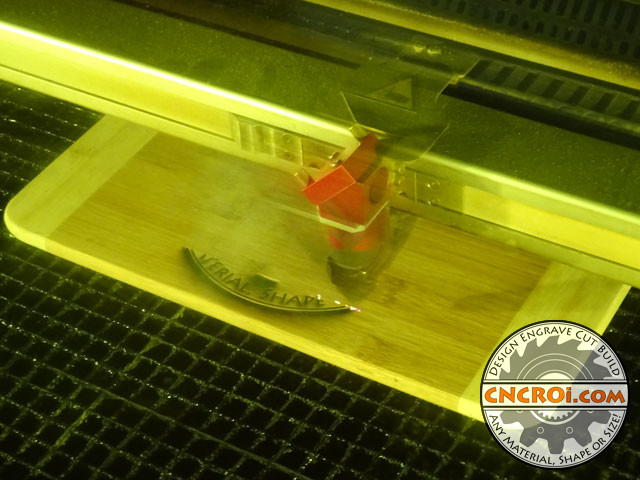

Engraving bamboo is also a messy process, you can see all the soot building-up on the surface and sticky resins, this just gets worse the deeper and more passes you do, almost regardless of the wood species stuck under the CNC laser gantry of our Austrian wide-format industrial laser.

Although this can be used to our advantage in the shop as well, there is no bad, just how you approach a result.

Engraving bamboo takes longer than softer woods because more power is required in any given point on the surface to produce a “similar depth” and the same goes with darkening the surface after it’s engraved.

There are endless options when it comes to wood, so just think of this engraving bamboo blog post as one of many choices that are depending on volume, budget and project specs you submit to CNCROi.com.

Where there is more material vaporized, that’s where more resin and smoke build-up on the surface, it’s quite interesting though because once sanded, the results look nothing like the messy results you see in these photos.

Even the more sharp inner letters or small details are produced by our industrial laser, anybody can engrave a piece once, but high quality machinery really shines when you need to go over the same piece AGAIN!

Why? Because if anything is “off” with the hardware or software, going over a workpiece that doesn’t go over the exact same places as the previous pass ruins the entire illusion and precision of the work.

Not a problem for CNCROi.com‘s Austrian equipment!

It’s a little hard to see but we are now doing a secondary pass, the goal of which is to darken the engraved bamboo, though a little additional depth is also achieved as a result.

Engraving bamboo requires different settings than darkening it, otherwise, you are only getting deeper into the wood, not darker.

It’s a little hard to see in these CNCROi.com photos, but the secondary dark pass into the engraved bamboo really kicks it down quite a few notches, it’s similar to teeth whitening.

You don’t go from yellow teeth to white, you go from yellow to lighter shades, and wood is the same thing.

What’s great about darkening woods using our industrial laser is that the results are permanent, unlike paint or other processes and yes, it can be sealed just as well as the rest of the wood.

As CNCROi.com didn’t add anything to the wood to achieve this result, there is nothing to remove!

Compare the above photo of the engraved bamboo to the darkened one, you can see quite a big difference.

Now that the bamboo cutting board is finished with our industrial laser, it’s time to sand it to remove all the soot and resin that built-up over the surface.

Luckily, I’m also a designer of things, so we use our custom sanding table, which was also laser cut, to achieve this.

This custom downdraft table has been absolutely amazing here in the shop, it’s probably one of the most useful pieces of furniture short of a chair that we have at CNCROi.com and it performs just as wonderfully now as it did way back when it was first laser cut and assembled by me!

Before we move ahead with the sanding, let’s take a few pictures so you have a point of comparison before and after this engraved bamboo is finished.

The play of light with the depth is just perfect, it looks a little messy now but the sanding will take care of it, a head-on picture though looks amazing, it looks “branded” which isn’t the look I’m looking for this time around, I want it to look SHARP.

This is why I’m sanding this bamboo cutting board that has the engraved CNCROi.com logo in it.

What really filled-up with resin in these photos are the inner details, so the growth rings inside the saw and the holes in the CNCROi.com cog wheel.

Already, you can see how clear the bamboo cutting board has become in the image below, even with the saw dust, compared to the messy photo above.

This is always the fun part of our job, do all the work and then see what it looks like at the very end when all the junk is removed.

And here are the finished results, it looks amazing, the inner growth rings in the saw and holes in the cog really pop and this project isn’t even finished yet!

What I like about lacquer and other finishing sprays and paints it they really make something amazing into something awesome!

And here is the finished piece, we started with a blank board and ended-up with something that belongs in a museum!

The shine really helps to add additional contrast to the CNCROi.com logo, as the engraving doesn’t shine.

How about a close-up?

Everything is sharp, everything is precise and everything is dead-on perfect!

The natural wood grain of the bamboo also helps tremendously to add additional details.

Do you have a need for something custom? Bamboo or metal, lamacoid or leather, makes no difference, contact CNCROi.com right now!