Deep Etching Stainless Steel

CNCROi.com does a lot of deep etching stainless steel, in this case, the customer provided the parts you see in this blog post as they have internal cutting capabilities but we could have cut this as well using a variety of equipment in our shop.

https://www.youtube.com/watch?v=CxuDTZxXNrM/

When it comes to fiber laser cutting and etching, there are two main systems that CNCROi.com employs, a galvo and a gantry system, both etch, but for small items, the galvo is dramatically faster.

The reason for deep etching these stainless steel plaques is because the client will be painting these, and they want the etching to show though the paint, this also covers them for when the paint eventually comes off as the etching will remain permanently into the plate.

For CNCROi.com, deep etching stainless steel is a process that involves fiber lasers to create intricate designs and patterns into the surface of stainless steel, we use this technique for many applications in a variety of industries, from aerospace and automotive.

When it comes to deep etching, we can go through the plate if required, though it’s a very slow process that’s prone to warping, especially for larger surface area etchings.

The process of deep etching stainless steel begins with the selection of a high-quality piece of stainless steel, the steel is thoroughly cleaned and polished to ensure that the surface is free from any debris or contaminants, if oils for instance are present on the plaque, they may scatter the power of the fiber laser beam, and produce an inconsistent result.

There are many benefits to using deep etching stainless steel in various industries. For example, in the aerospace industry, deep etching can be used to create high-precision components that are lightweight and strong.

The etching that CNCROi.com produces is also completely permanent, unlike UV or any other printing method, it’s actually part of the metal so if the metal is bent, the etching is bent as well.

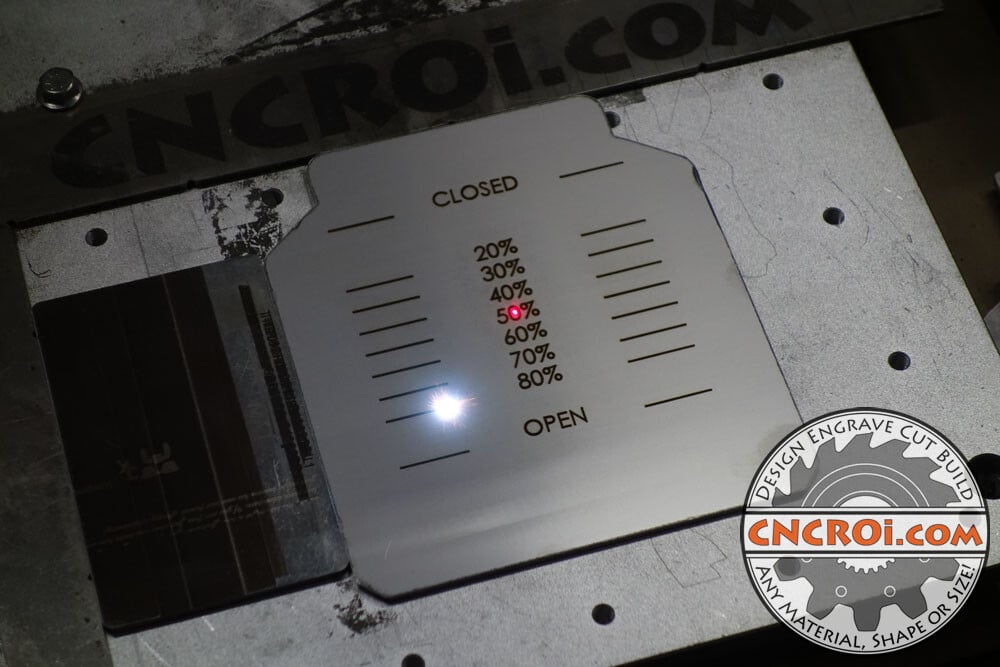

Here’s what the gantry method of deep etching looks like, not as exciting as the galvo but it has its place, we do a lot of that also at CNCROi.com, just for larger items or things that don’t fit in the galvo fiber laser.

The ability to create intricate designs and patterns into the surface of stainless steel allows for the creation of parts that have specific mechanical properties and are resistant to corrosion and other forms of damage.

In the automotive industry, deep etching stainless steel can be used to create decorative or functional components for cars and other vehicles such as emblems or logos for a car’s exterior, or it can be used to create intricate components for the interior of the vehicle.

In the jewelry industry, deep etching stainless steel can create unique and intricate designs that are both beautiful and durable, without adding any weight to the finished piece.

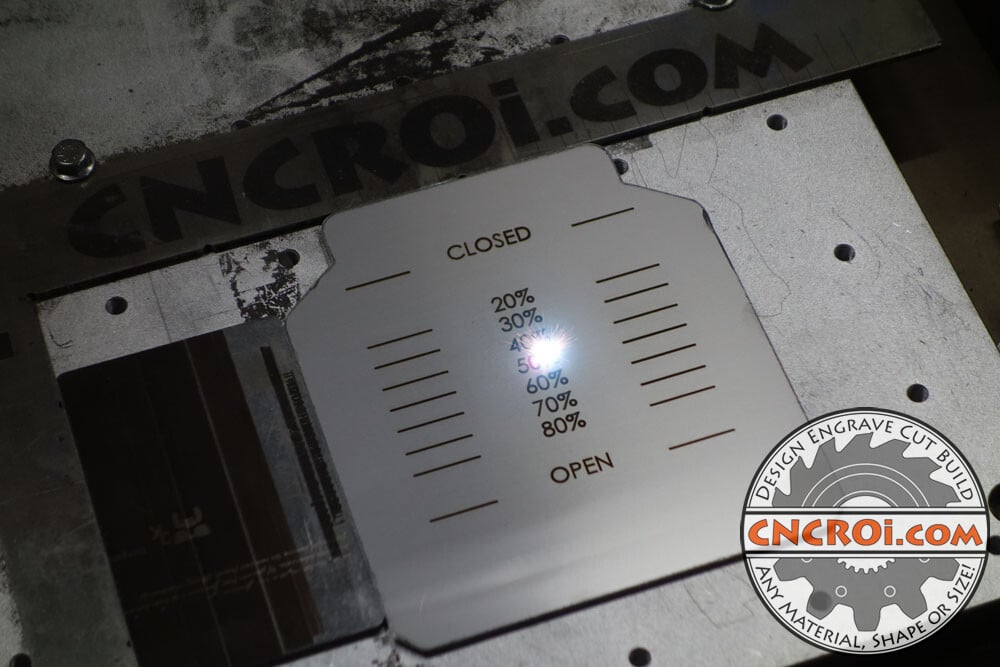

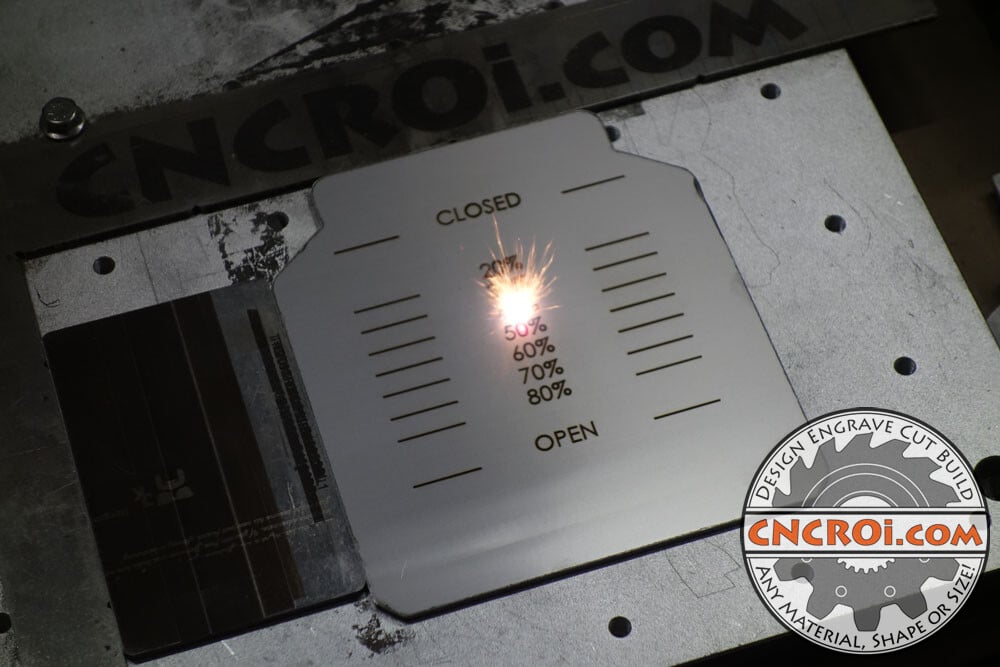

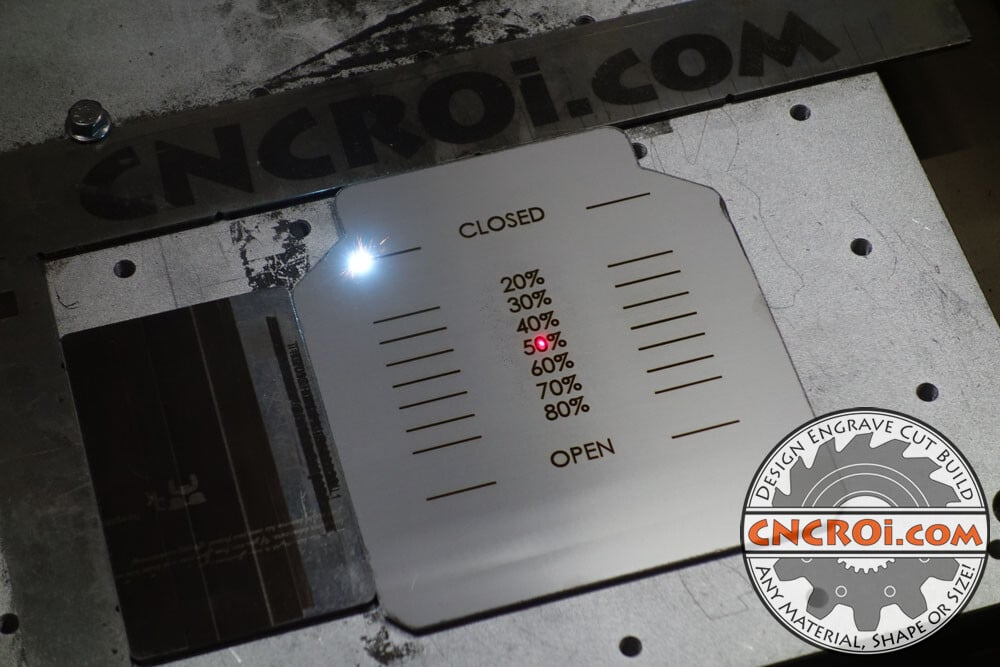

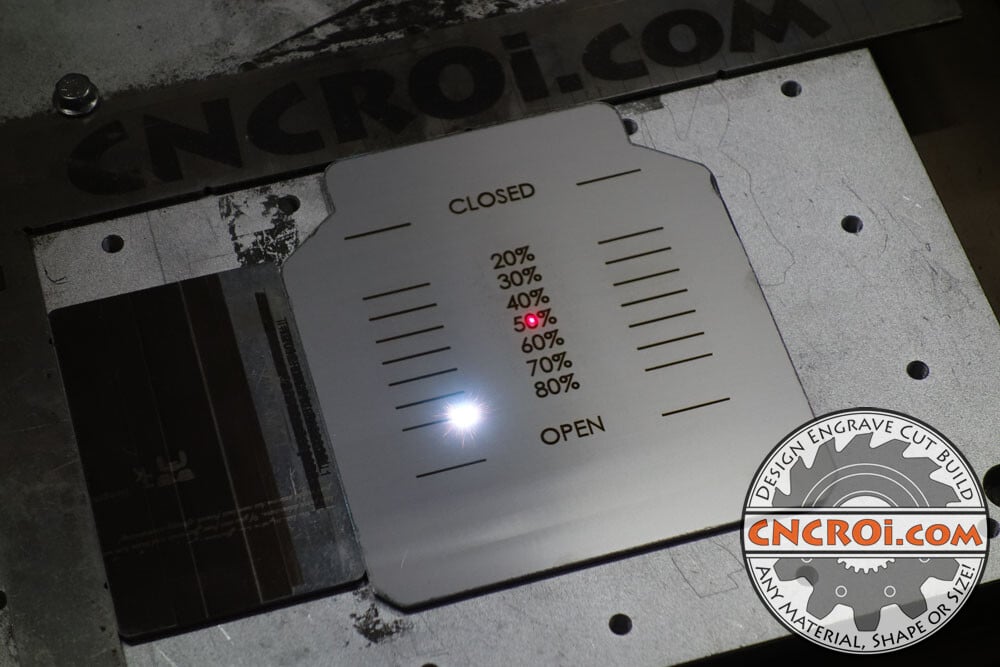

You’ll notice two things during the deep etching stainless steel process that’s more evident in the video than these photos, the first, that the fiber laser goes over the same places multiple times, this is part of the excavation process, removing a minuscule layer one at a time from the plate until the desired depth is achieved.

By far the most etching that we actually do at CNCROi.com involves our gantry system over large surface areas for a variety of applications.

The second thing you’ll notice is the build-up of debris not only next to the etching but on the plate itself, this is the excavated stainless steel that builds-up on the surface of the plate, the more CNCROi.com deep etches the stainless steel, the more debris builds-up on the plate.

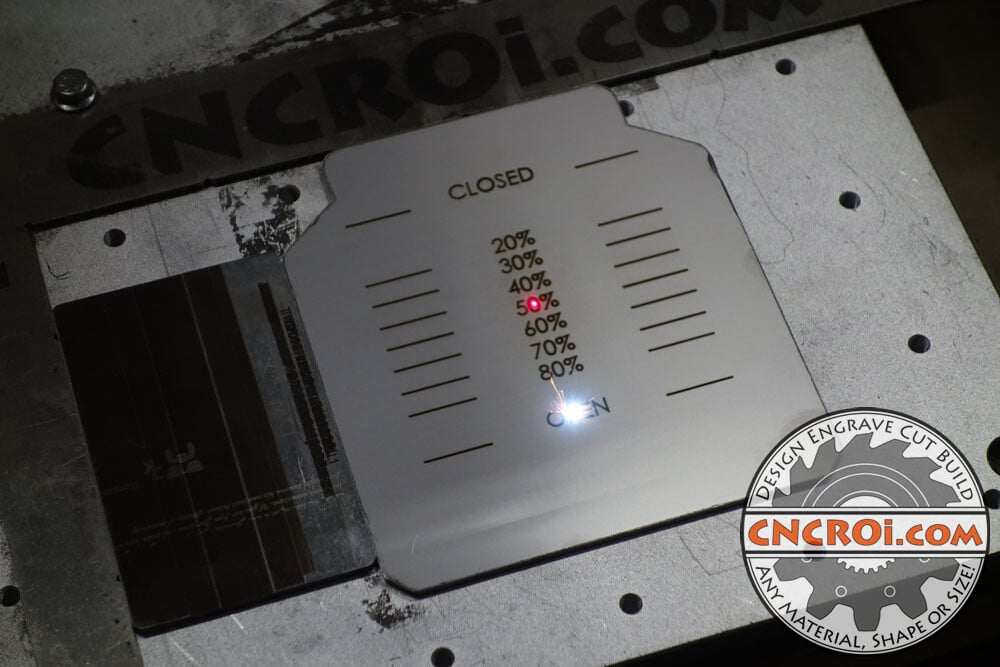

The red light you see on the plate is actually what I use to manually focus the beam, for some projects that involved deep etching stainless steel, we need to go a lot deeper, as a result, I need to refocus the beam mid-production at CNCROi.com to get as much power hitting the plate as possible so that the excavation process continues.

When it comes to deep etching stainless steel, just about any vector image works and most fonts as well, as long as we are dealing with black and white “things”, then the laser is either on or off in that area and as such, able to perform the deep etching process at CNCROi.com.

Annealing is a different process than deep etching stainless steel, its only on the very top surface and thus, maintains the reflectivity of the base metal, unlike etching, which removes the shinny coat.

There is something that I watch for when doing deep etching stainless steel especially, the first is head build-up, if the plate gets too hot, then it starts to warp and as such, can start to move around on the base plate of the fiber laser machine, to avoid this, I use compressed air to cool it down as it’s being etched at CNCROi.com.

For this plate, there isn’t much surface overall being etched and it’s spread-out, as a result, just he ambient air in the shop is fine.

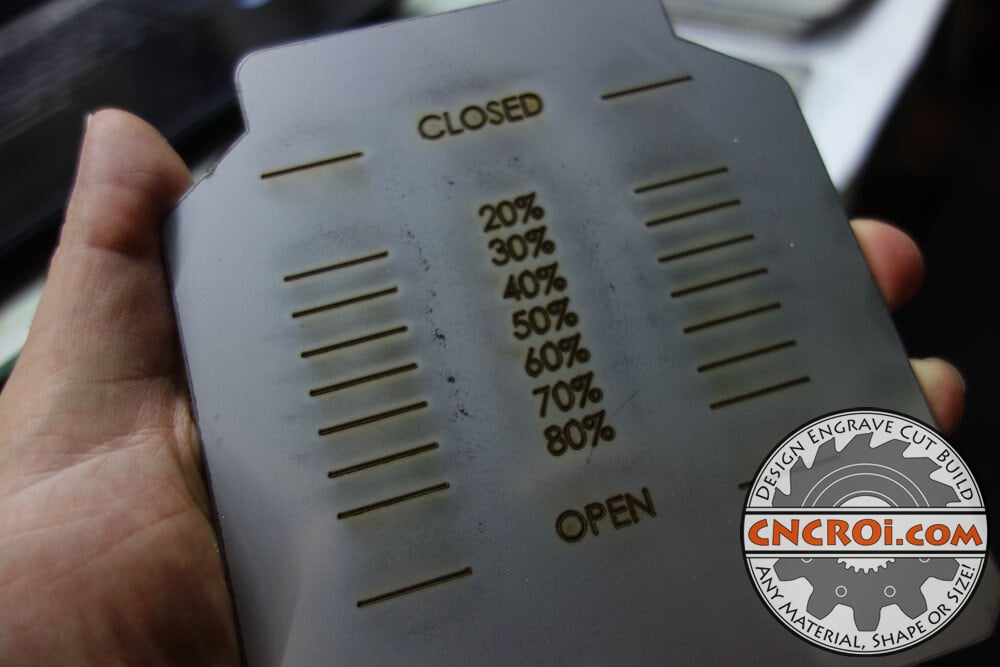

The 12 ga 304 stainless steel with 2B finish below becomes the finished plate above after more than an hour of etching, you can see the spread-out of the debris that use to be inside of the plate that’s been liberated onto the surface of it by CNCROi.com.

Etching vs annealing, etching is better as it’s into the metal rather than on the surface, removes the reflectivity of the metal and has a higher focal tolerance during production.

After a quick clean-up, you can compare the deep etched stainless steel plate right off the machine to the finished one that will be painted, this is why I prefer deep etching over annealing, it’s more durable as it goes into the plate rather than only on the very top surface.

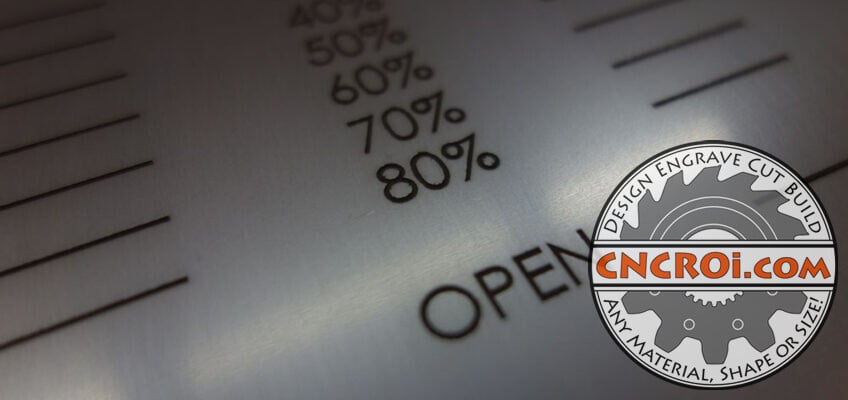

Again, here’s a close-up of the etching right off the machine below, you can see everything is sharp and at a very high degree of detail, far more than can be achieved using a chemical process.

And after cleaning it up at CNCROi.com, the deep etched stainless steel not only looks spectacular but you can also feel the etching as you run your fingers over it.

Need custom deep etched stainless steel? Contact CNCROi.com right now!