Dinosaur Family: Model Making 101

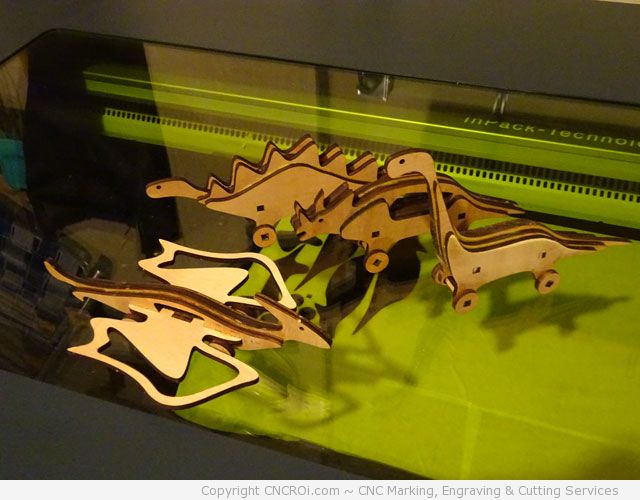

CNCROi.com has its beginnings in model making – the laser is one of the best tools to accomplish highly detailed models of all sizes as the beam is so narrow. Just recently, I completed a series of dinosaurs, very simple and straight forward designs!

So, if you want to get into model making, you can design and we can cut them out from just about any material you can think of… I actually have plans to make one out of solid steel using a kw CNC laser we have access to. Before you jump into the model making world though, I’d strongly suggest, even before you buy software to make them, learn from my mistakes! I wrote a book after years of self-taught model making that will save you YEARS of headaches that I went though.

Condensing my last book of over 450 pages (CNCKing.com Volume 4: Rise of the CNC – Ultimate CNC Design Course) into a few lines is bound to be missing a few important points but let’s get your feet wet with some of the bigger concepts.

Start from the bottom

With all my designs that have wheels or legs, I always started the design process from the bottom up. This allows you to directly control the length, width and indirectly height of your model before you start so if you need something to fit in a specific space, this is the way to make sure it will before you get too far along the design process!

Generic to specialized

Don’t worry about the fine details until you have an outline of your model – spending hours on a detail that you later discover doesn’t fit well with the rest of the design could have been discovered when you had an outline of it without the details! Use progressive refinement on your model, look at weak points, and improve upon them… continuously until it’s done!

Software and hardware aren’t important

A good model can be cut using any technology out there, scroll saws (if you are very adventurous) to CNC laser / router / plasma and across a ton of different materials – so don’t get bogged down by the details. Do keep in mind though that each of these tools have limitations, you can’t have 90 degree inner corners using a CNC router (due to round bit), you can’t have intricate small details or engraving using a CNC plasma (resolution isn’t like a laser) and so on. Learn these limitations and design accordingly but give yourself room to easily adapt it to other cutting technologies with a few minor adjustments.

Don’t give up!

The worse thing you can do when starting something is giving up! Your first designs WILL suck, they WILL have problems and they WILL cause you headaches but all this stuff can be learned and adapted overtime… your mistakes don’t disappear with experience, just get smaller (sometimes!)