Don’t use the WRONG material for the application

Quite often, as part of the quoting process, I have potential customers asking me how much it costs to do something in material X when in reality, that material is totally wrong for the application and they should be using material Y instead.

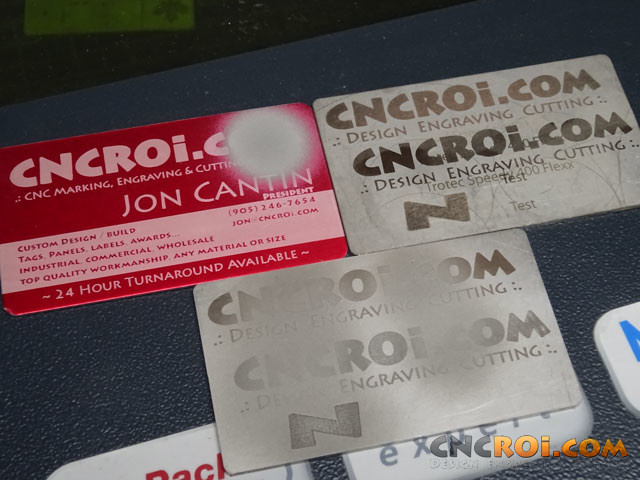

I’ve done a lot of material testing on behalf of my customers and out of personal curiosity here at CNCROi.com.

The video above was something I did just to confirm my thoughts and to show customers that there are some serious differences between anodized aluminium, stainless steel etching and stainless steel annealing.

It’s not scientific for reasons I’ve covered in my video but it gets the point across and really helps our customers understand the differences between all three processes that we do a lot of here at CNCROi.com.

This testing also leads to other processes, coatings and options for our customers too.

Sometimes you are using the WRONG MATERIAL!

I remember a job we were quoting for an architect who fell in love with a tile that they wanted CNCROi.com to engrave to form an outside mural, everything was great but there was a problem, they fell in love with very thin INTERIOR wall tile and they wanted to use it OUTSIDE where temperatures can fluctuate from -20C to +40C!

So, guess what happened each time we did material testing, it cracked, no matter what we did, so I made suggestions for other materials that would actually look better and last way longer but in the same “color scheme” as the architect wanted, instead of taking my advice, even trying other tiles made for outdoor use, they just kept trying to explain how they were right and we were wrong.

I followed-up a few months later, they found a company that took the job on (I refused the job) and guess what, cracks everywhere and there are already missing tiles – you don’t glue interior tile back together after it has been laser engraved then stick it on an outside wall!

Even UV printing instead of laser engraving (one of my suggestions though we don’t offer those services) would have been far superior to the mess they ended-up creating.

Just because you saw something look “nice” somewhere doesn’t mean it was made out of what you think it was made out of, or that it’s the right material for the application.

Cheap material due to low budgets

Another common issue of jobs I don’t take on for CNCROi.com are customers who want something “nice” but their budget is so low, that what we produce won’t last or worse, look awful.

They take a picture of something they love and want the same thing for a fraction of the price.

A great example are plaques, there are generally two choices when it comes to “metal plaques” and that is the lamacoid above with an MDF backing and the real stainless steel below.

These are totally different plaques though they may have a very similar finish.

You can put the 316 stainless steel plaque inside, outside, even on the Moon or to mark a gathering area a thousand years into the future and it would be totally happy and fine regardless of pretty much anything you throw at it environment wise but put the lamacoid plaque out in the rain for only a few minutes and bring it back inside and it will be ruined (due to MDF backing).

Yes, I could have made it with a more “durable” backing like acrylic but even then, THESE WILL NOT LAST OUTSIDE.

There is a reason why engineering customers of ours requests and has a budget for the 316 stainless steel plate and does not even consider the MDF backed lamacoid plaque to put down a mine shaft.

Lamacoids are great material, we use it all the time here at CNCROi.com for customer projects, but it isn’t always the best material for the application and just because your budget doesn’t allow for real metal, doesn’t mean that you can wish your lamacoid to be as strong and durable as metal under your intended application.

I’d even go with wood before steel or a lamacoid if the application made more sense to go in that direction.

Selective Understandings

When it comes to custom fabrication, most of our customers know exactly what they want, how they want it done and are knowledgeable enough to realize the best material for the job to fit their intended application.

Other people seem to have a very narrow view and selective understandings of how things should be and anything counter to that, which doesn’t fit into their world view, they completely ignore. They are more interested in proving that they are right rather than admit that maybe there are other options available that are better suited to their application.

Each time CNCROi.com gets approached for a custom job, regardless of the budget attached to it, the first question I ask is the application, it’s by far the most important question to ask as there is no point in doing a custom job and then a few weeks or months later, it falls apart then we are both dealing with the problems.

It really isn’t worth the lost time, materials and having to re-do a job just because “we” used the wrong material.

If there is any doubt regarding the best material for the application, I often do a job in several materials and ask the customer themselves to test to see which works best before any production run.

I’ll freely admit that I don’t know everything and am willing to try to prototype with the customer until we find something that fits their requirements and each time we’ve done that, not only have we gained a customer “for life” but it lead CNCROi.com to learn something that we can then use for other applications and customers.

Custom is Fun!

No two days are the same here at CNCROi.com, it’s always fun trying new things and getting feedback from customers as to how things went, positive or negative, so that I can keep on improving my understanding of materials and their related applications.

We’ve done some amazing stuff that nobody will ever know we’ve made and I’m totally fine with that, but the point is that I know we made that possible and for our customers, they know we cared enough to work with them to find the perfect solution to their problem.

At the end of the day, it makes no difference who is right or wrong, end users don’t care who had the biggest ego during the production of a job, they only care that the job was done RIGHT!

Life is a journey that’s worthwhile when new experiences, interactions and knowledge come into play and that’s exactly the attitude I maintain with my customers and within my company.