Drill Bit Annealing: Permanent Metal Branding

Although I’m permanently metal branding this regular drill bit, it’s actually a useful fill-in for some of our customer’s needs when it comes to annealing rods and other “rounded” objects.

This isn’t the first CNCROi.com video I’ve done using drills, a while back I used our CNC fiber laser source to color change plastic on the very drill we use these bits for.

And more recently, a custom dead-simple table for our drill press but this time, using our CO2 laser source, although we aren’t metal branding, having both a CO2 and Fiber laser source in our Austrian Trotec CNC laser does have incredible advantages well beyond metal branding.

We’ve done lots of rounded and angular type work when it comes to custom metal branding, for this drill bit, we’ll go super simple, just stick it on a grid to stop it from rolling around from the compressed air shooting down.

Custom metal branding can only be done using a fiber laser source, we can technically do it with our CO2 but the results aren’t as nice and as high contrast and we NEVER use ceramic bonding processes to achieve an “anneal” like results for our customers as it comes right off.

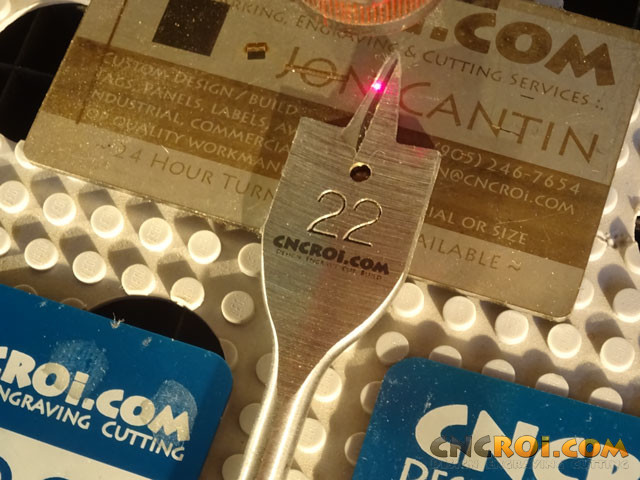

If you are wondering about how annealing looks like on a flat surface, here’s one of our famous metal business cards being custom metal branding using annealing from our fiber laser source.

And if you are wondering about the ultimate durability of the annealing process, check out my material testing on etched, annealed and deep etched stainless steel, with anodized aluminium thrown-in for comparison.

The same toughness and durability is just as true on rounded or curved edges as with flat, but keep in mind that there is an extremely tight tolerance envelope when it comes to annealing.

Going out of “annealing focus” ends-up etching the metal, for a bit that’s roughly a quarter-inch or 6 mm in diameter, we have about 4 mm of annealing possible, with the rest being etched due to falling out of tolerance.

After the work is finished, the laser points to its handy work and is ready (if this was a production run) to do a million more!

That’s the advantage to having an industrial machine to do this type of work, it’s wickedly overbuilt so a lot less can go wrong.

You’ll also notice that I etched a palm tree, I scaled it right down but as the lines are so fine, it was very hard to photograph it with the right light.

Custom metal branding looks great in real life but hard to photograph due to reflections of the metal, something that isn’t an issue with anodized aluminium but is with especially shiny stainless steel.

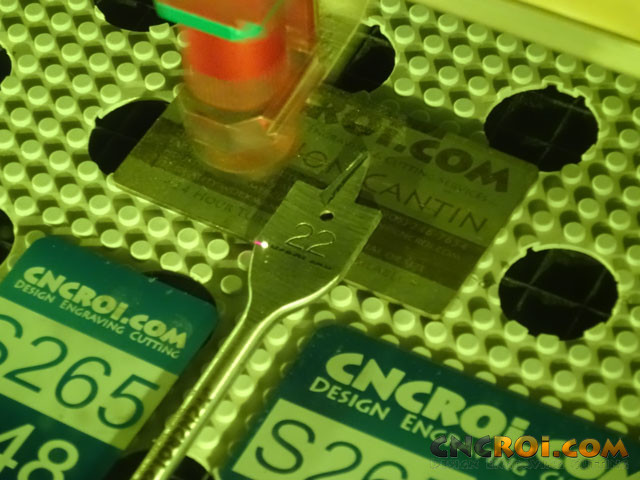

Here’s a closer look at the shaft, you can see at the very bottom, I was starting to etch a bit into the bit, it was falling out of tolerance, and the same with the absolute top of this metal branding sample.

Before cleaning it, you can see how the etching and annealing produce a different surface result as well, one is oxidation using highly precisely focused heat and the other is actually vaporizing into the metal, for the ultimate permanent metal branding!

I had so much fun metal branding the shaft, I decided to also anneal the drill bit itself at the business end.

Again, flat surface works best but in this case, the space is very small, so the logo and text are actually smaller than they were on the shaft!

Metal branding can be done up to a thousand DPI so even very small text or fine details come out nice and clear using CNCROi.com‘s industrial wide-format laser.

CO2 or Fiber laser sources, makes no difference when it come to annealing details on material that can support it with enough density to benefit from this high level of Austrian engineering.

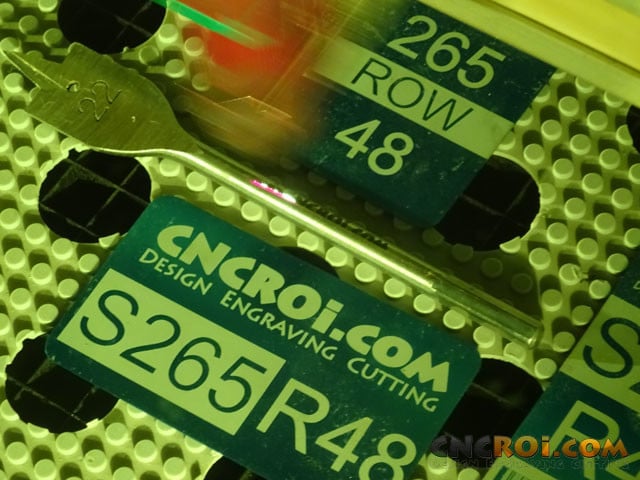

Sadly, none of the photographs came out in focus while annealing the end of this drill bit, the metal branding is still nice and sharp, the light was just too bright which is why I have all the other tags in this photo and video to help the camera focus on “something”.

Here’s a closer look, the 22 was not etched by CNCROi.com but the logo below it and the tag line even lower was custom metal branded by our shop.

Again, it’s hard to properly photograph metal so here are the end-results using a few different angles to help you see.

The drill bit by the way is a size 22, so if you are into mill work or have a shop of your own, this gives you an accurate sizing reference to see the quality of CNCROi.com‘s metal branding services.

What’s interesting is that in real life, our annealing is more clear than the etching you see above, you can see how jagged the “22” is and compare it to the precise lines and unjaggedness of our logo.

If we were etching, something I’ll do in another video later, you still wouldn’t see that ruggedness.

Here’s what deep metal etching looks like after being cleaned-up by CNCROi.com‘s industrial sand blaster for a quick comparison.

Notice how sharp everything is, from etching to annealing, custom metal branding by CNCROi.com is accurate, repeatable and yes, we can also do sequential or random alphanumerics if you so desired on any surface, including metal.

After the custom metal branding of this bit, you can see I have many more to play with, I’ll do those at a later date but as these are actively used, I can do a follow-up in a year or two and I can easily predict that the marking will not have peeled, faded or cracked.

The only way to get rid of metal branding done by CNCROi.com is to remove the surface of the metal, either by sand blasting or vigorous sanding or an angle grinder.

Annealing is also not affected by the environment as there was nothing added or removed from the surface, it was just oxidized under high heat.

Need custom metal branding? Contact CNCROi.com right now!