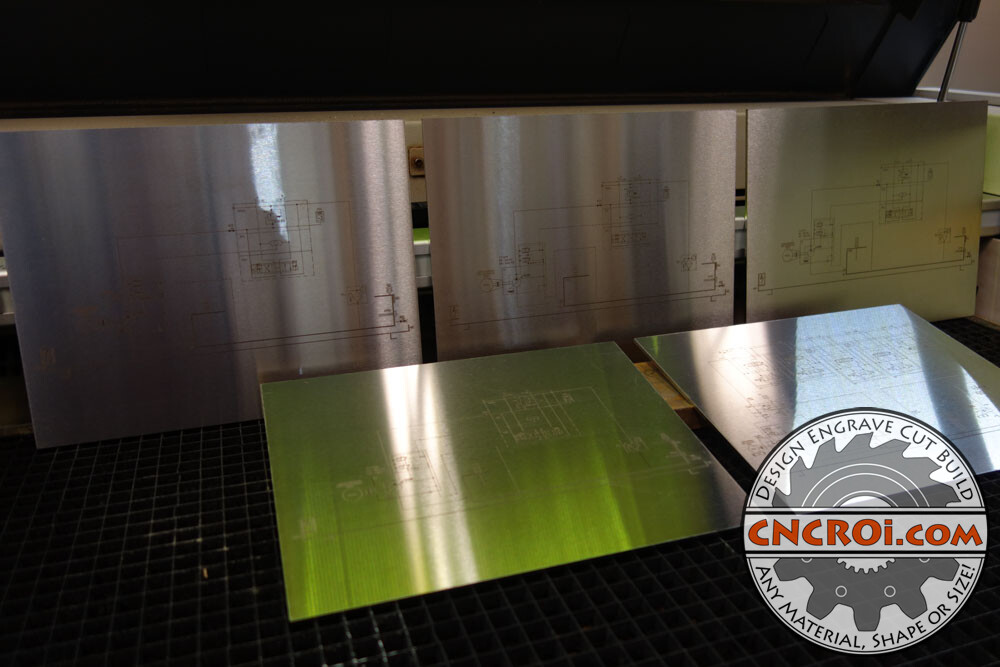

Electrical Enclosure Plates: 316SS #4 Finish

Custom electrical enclosure plates made by CNCROi.com can be fabricated using any size or type of metal (or plastic) with just about anything you want etched onto said plates.

https://www.youtube.com/watch?v=0mRZmOSD7f4/settings

Custom electrical enclosure plates play a crucial role in providing protection, organization, and accessibility for electrical components.

Whether you are building a control panel, automation system, or electrical distribution unit, designing and fabricating custom enclosure plates allows you to create a tailored solution that meets your specific needs.

Before starting the design process, it is essential to assess your needs and specifications for the custom electrical enclosure plates while considering the purpose of the enclosure and the specific components and equipment you need to accommodate.

We have a variety of equipment in our shop, power to CNC, so just about anything can be cut by us.

Keep in mind that CNCROi.com has years of custom fabrication experience, so we can accommodate just about any spec you come-up with but generally for custom electrical enclosure plates, the choice is either between 304 or 316 stainless steel.

When selecting materials for custom electrical enclosure plates, consider factors such as durability, electrical insulation properties, and compatibility with your application.

Don’t forget, CNCROi.com can also product custom components and accessories to go with your enclosure plate.

Choose a material suitable for your specific application, considering factors such as environmental conditions, chemical resistance, and desired appearance, is it worth spending more for a material that’s too durable or not enough for something that won’t last beyond a chemical wash down?

Unless the application for within a lab without chemical wash downs or within harsh environments, lamacoids (plastics) are not a good choice, they are cheaper, and CNCROi.com can produce all the tags you want out of it, but plastic regardless of what the sales brochures tell you, will not last.

Determine the appropriate thickness of the material based on the structural requirements and weight constraints of the enclosure, generally the thicker materials provide increased rigidity and strength but this comes at a price for financially and application flexibility.

Of course, not all our applications at CNCROi.com are industrial in nature, here’s a picture of my son on 316SS #4 finish that will outlast his great great great great grand children.

Attach the enclosure plates to the enclosure body using appropriate hardware, such as screws or bolts but to prevent galvanic corrosion, use the same metal type or better yet, have it spot welded.

For most industrial applications, our customers have gone with 11 or 12 ga stainless steel, it’s easy to come-by, incredibly durable and as you see, CNCROi.com can permanently fiber etch whatever you need onto it, so no paint or dyes will fade, crack or peel off over time.

CNCROi.com can also produce just about any lamacoid stick-on solution you want as well, we have more then enough equipment and expertise in that domain, but do keep in mind that although cheaper short term, long term, it will not last, they tend to break down, the harsher the environment, the faster this degradation occurs.

When I first started CNCROi.com, my goal was to create and fabricate items that were not just incredibly durable but way above spec, our customers have come to appreciate this, this is why we are using a fiber laser instead of a ceramic bond paste with CO2 for these application, it does cost more, take way longer… but it will last for EONS!

I can’t begin to tell you how many projects CNCROi.com has taken over from customers that went cheap and learned the hard way that nothing beats the gold standard, and that’s why I invested heavily in time and resources, to bring this to our customers.

The same holds true with CNCROi.com plates, we custom fabricate them to spec, these are not off-the-shelf components, sure they cost more that mass produced ones, but you can narrow down your spec to get EXACTLY what you require!

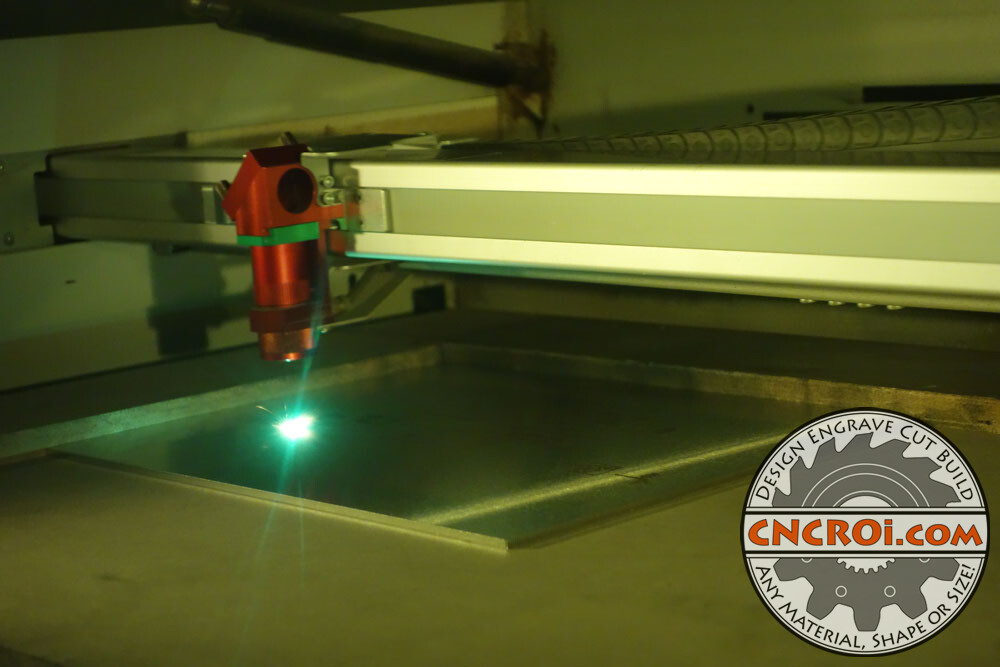

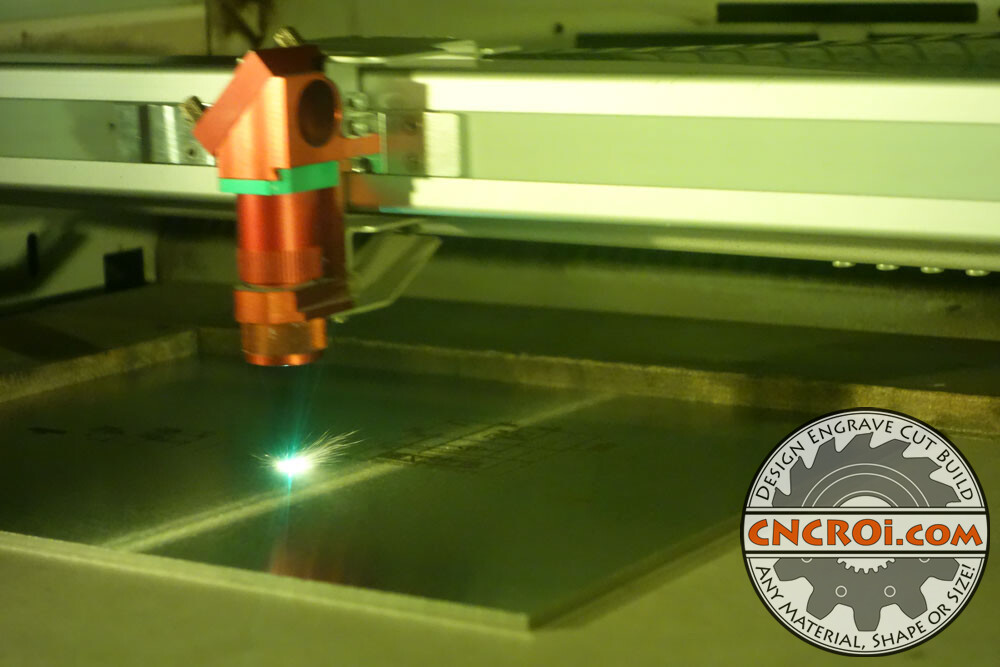

CNCROi.com has both a gantry style fiber laser and a galvo based one, they are both the same regarding the effect but different in their applications and their limitations, you can’t just have one.

Basically, the technology we use for large industrial customers, we also use for smaller businesses like mechanics and welders, once they see and feel the difference, they can never go back to stickers.

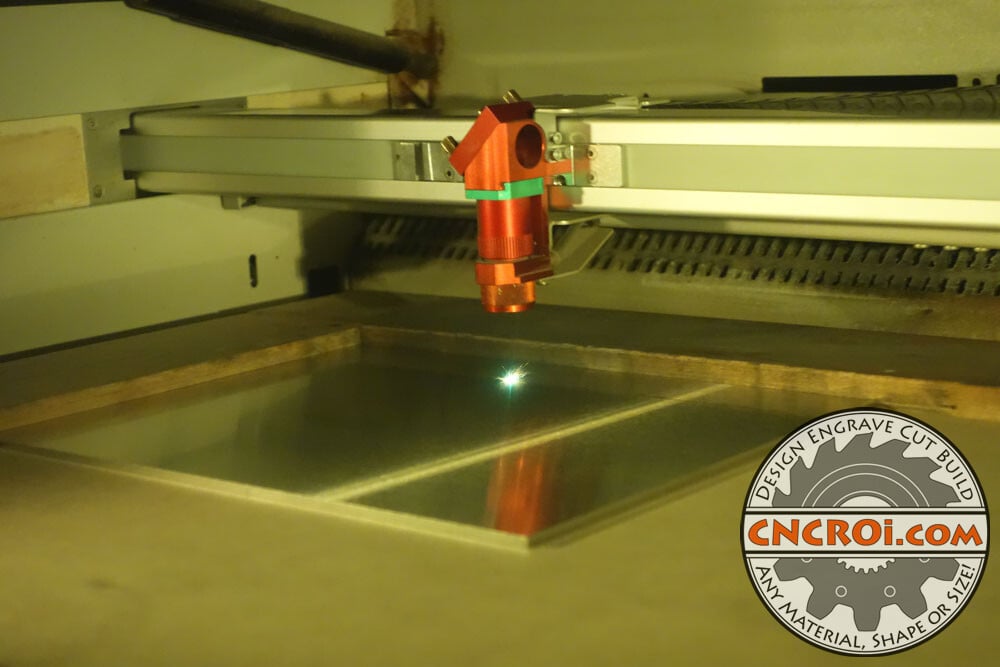

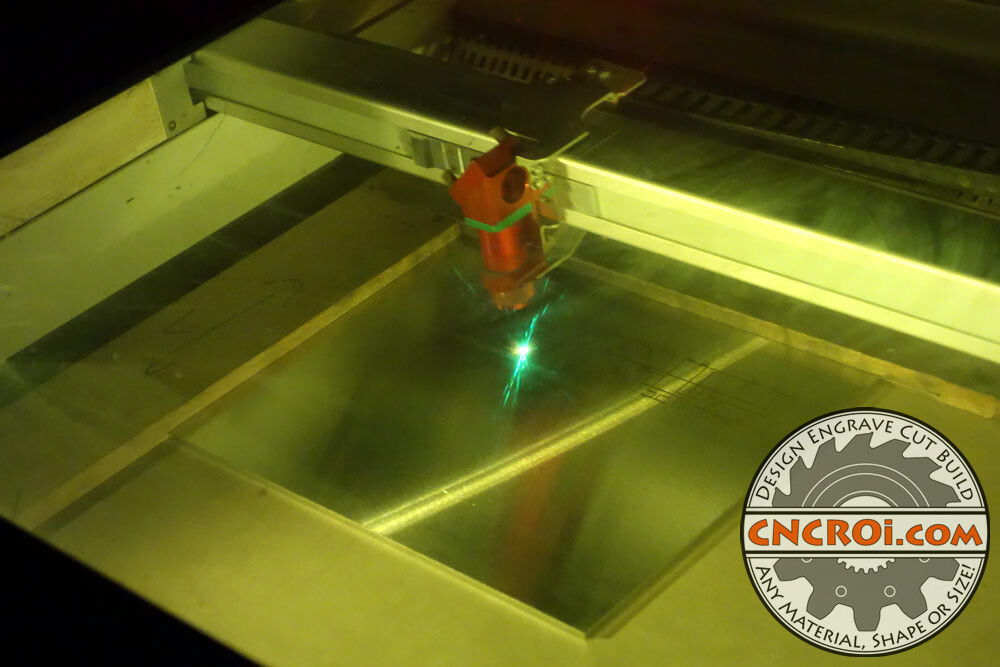

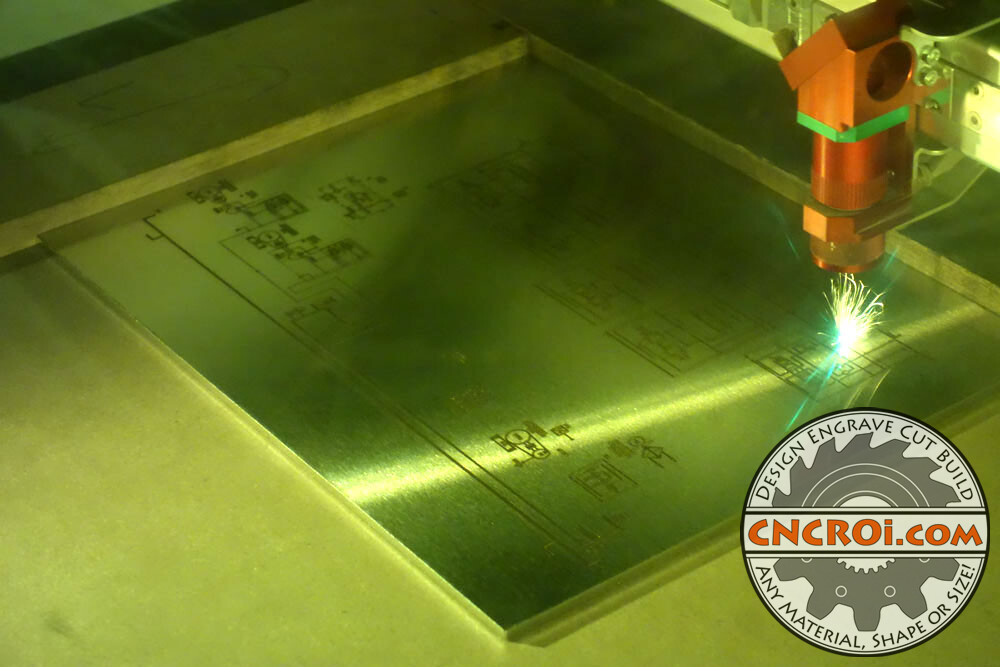

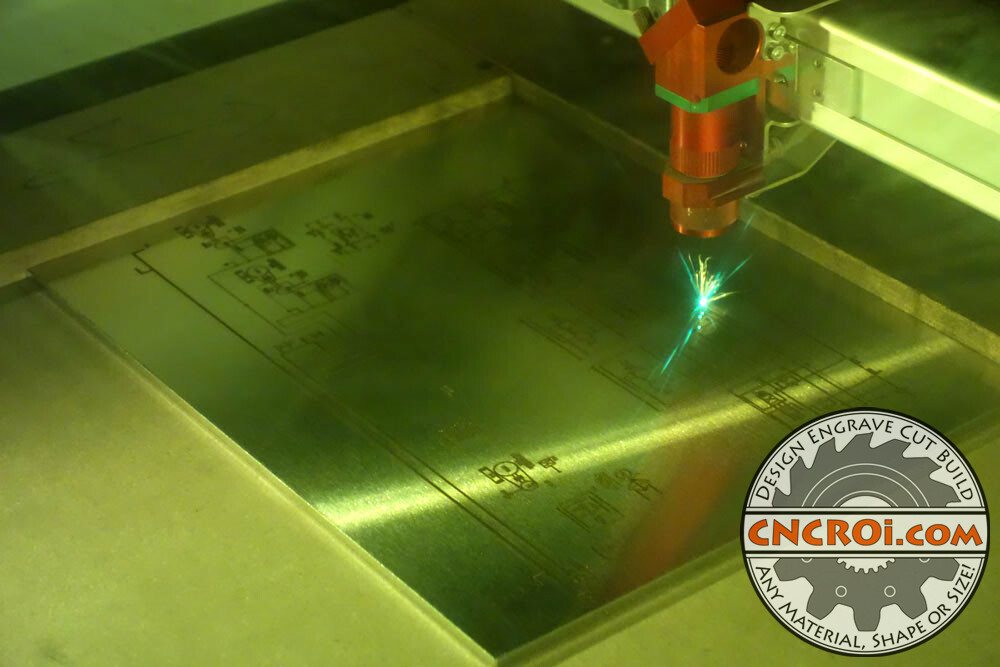

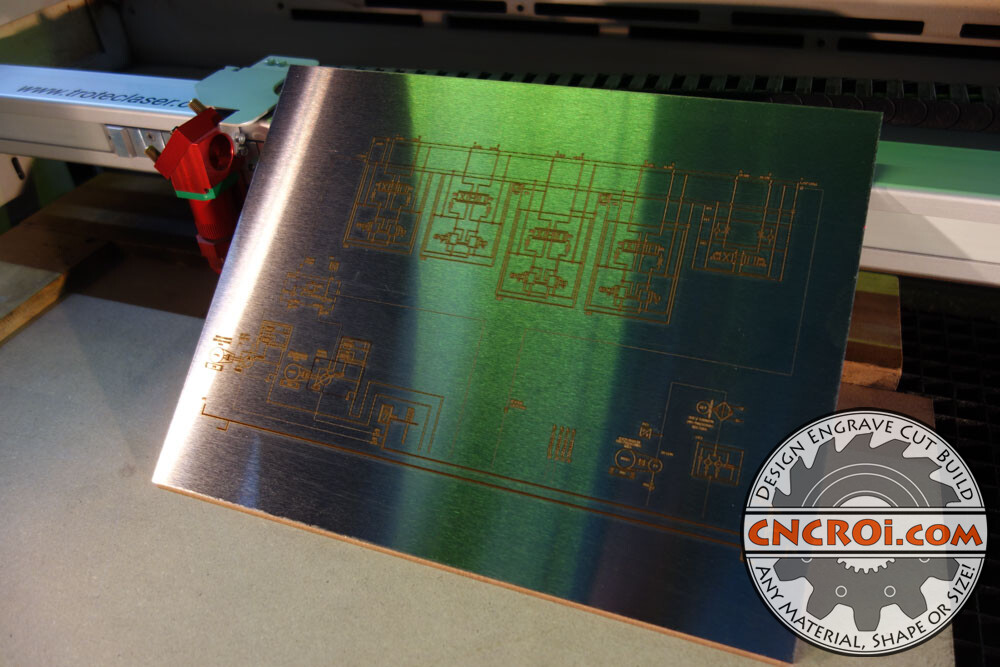

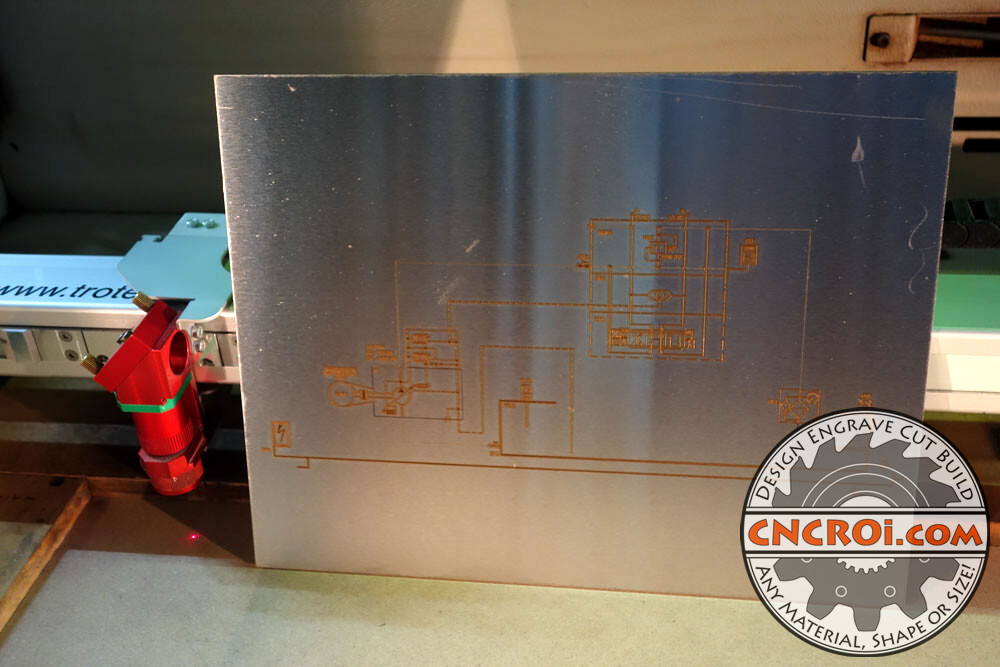

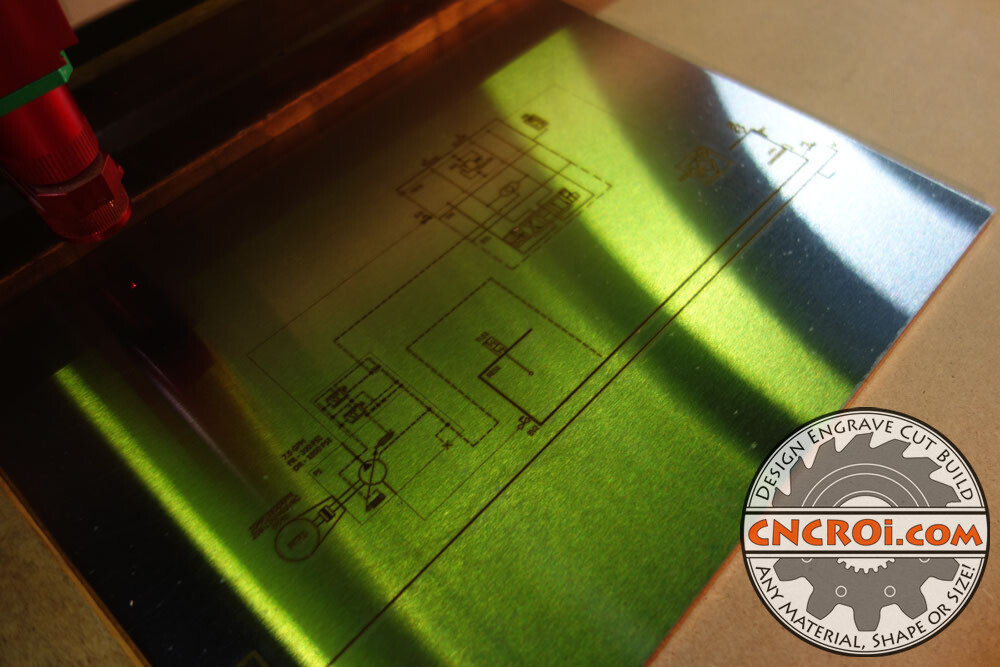

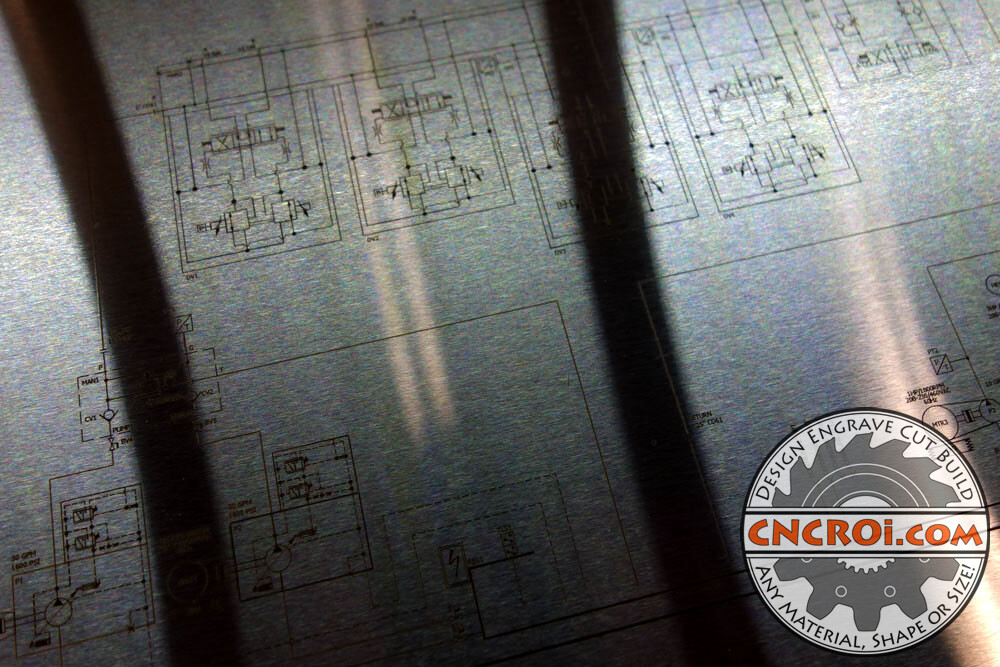

You’ll notice the picture underneath shows a heavy brown tinge to it, this is straight off the machine, there is some oxidation and heat tempering that occurs on the top surface of the plate, the etching is underneath, but this is easily removed to reveal the incredible brilliance and sharpness of the fiber etching process CNCROi.com employs at our shop.

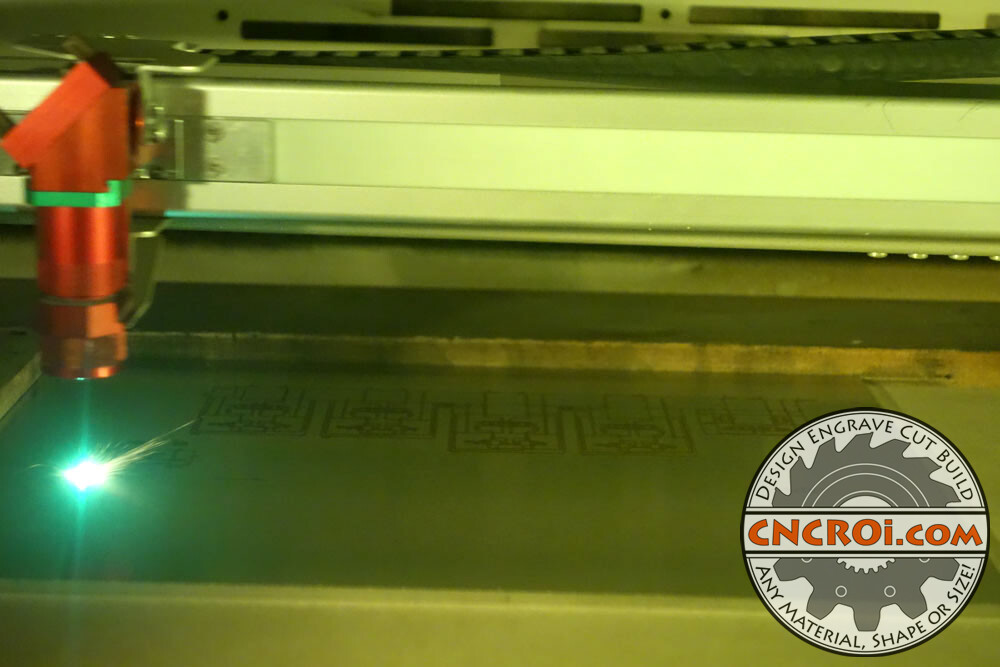

If you are wondering what deep etching is and how we do that at CNCROi.com, here’s a great video showcasing it, the galvo fiber laser is great for smaller items, plates this size wouldn’t be possible as they would take so long and as a result, cost so much to produce, that their cost benefit ratio is out of wack.

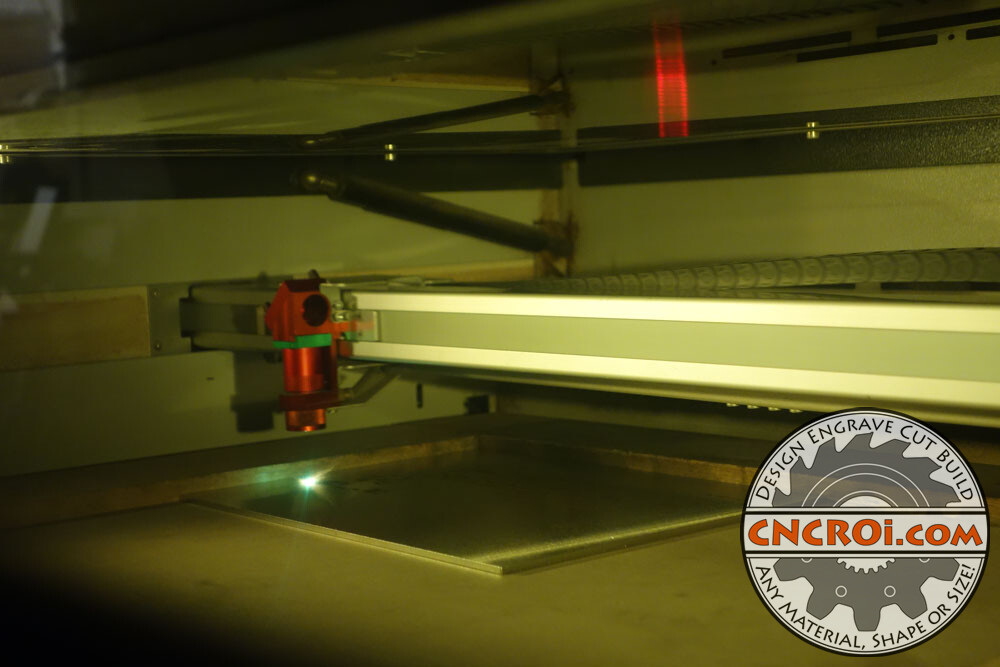

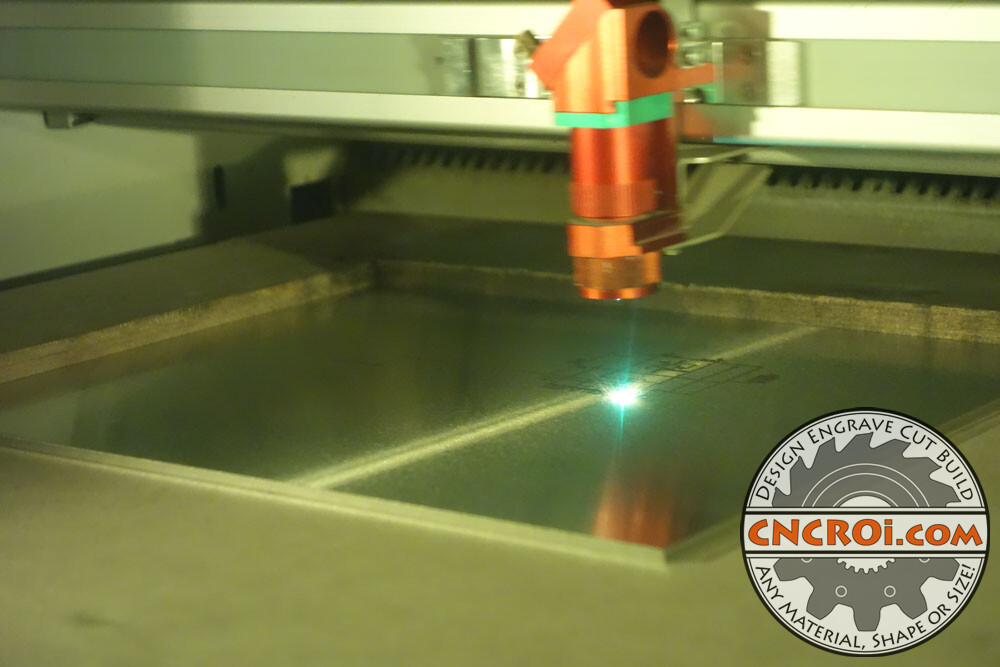

Once one of these custom electrical enclosure plates is finished, I just load-up the next into our machine to begin the process yet again, it’s slow, it’s methodical but the results are spectacular after cleaning them up.

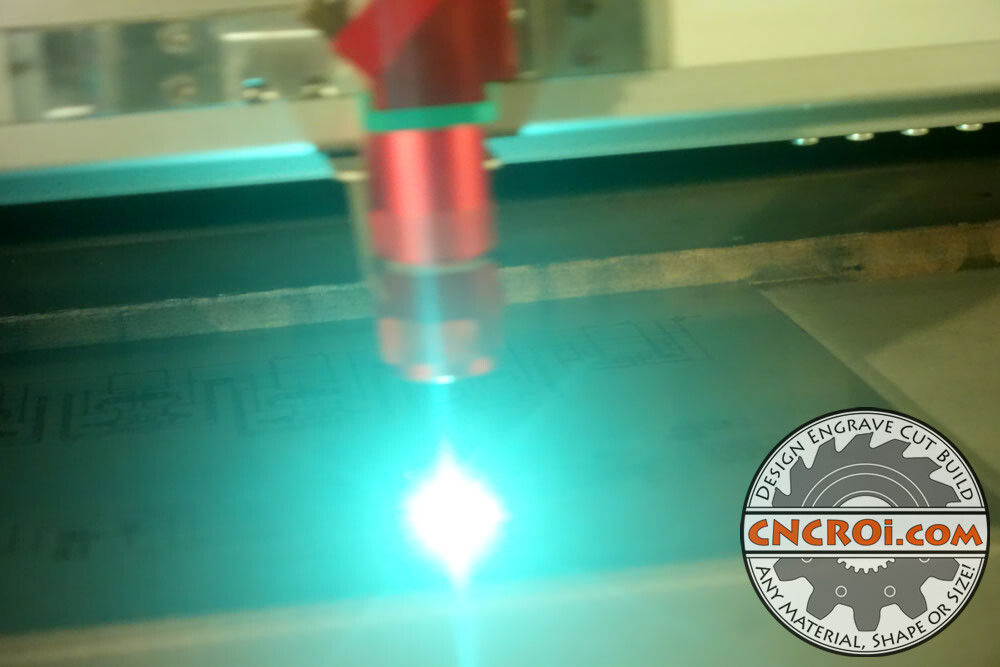

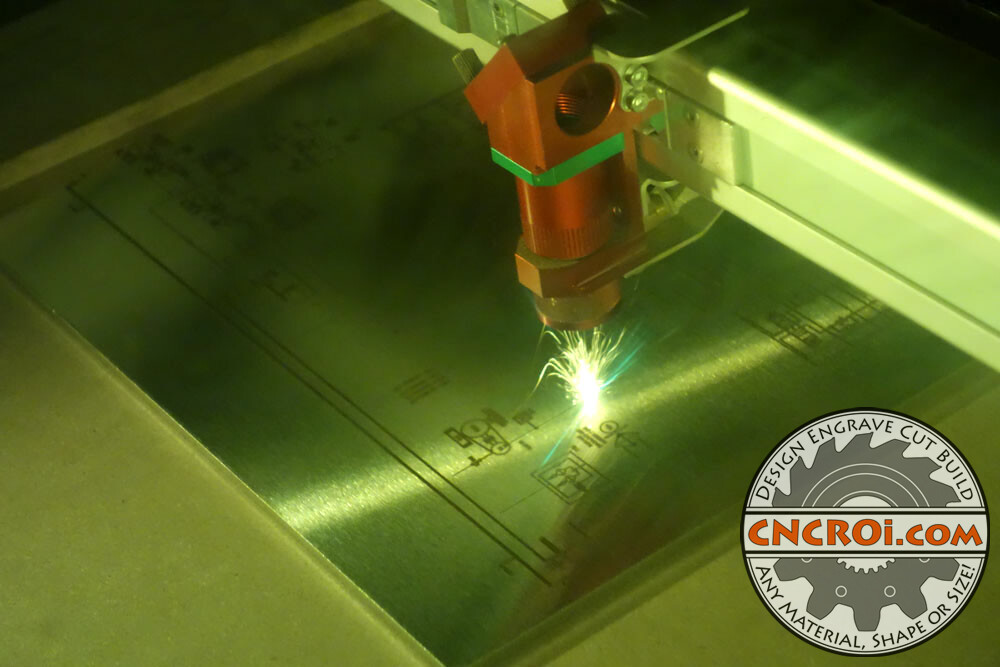

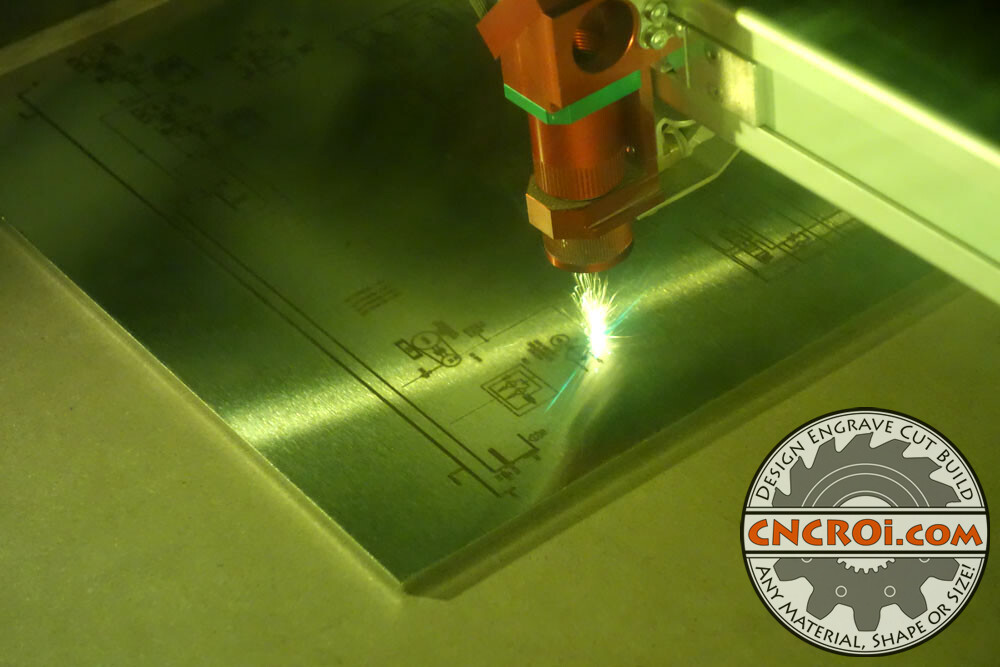

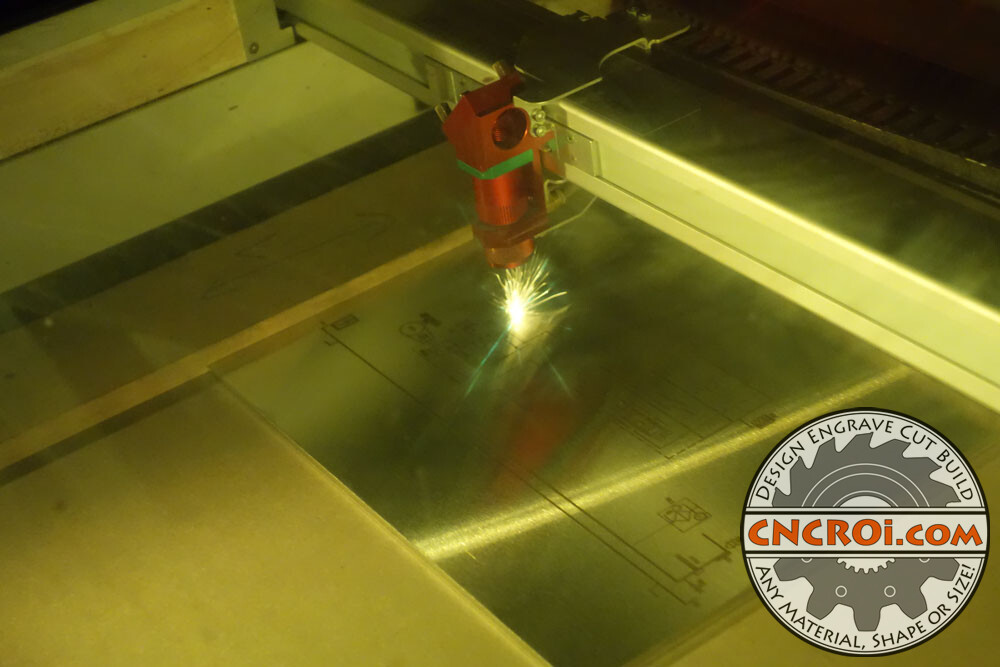

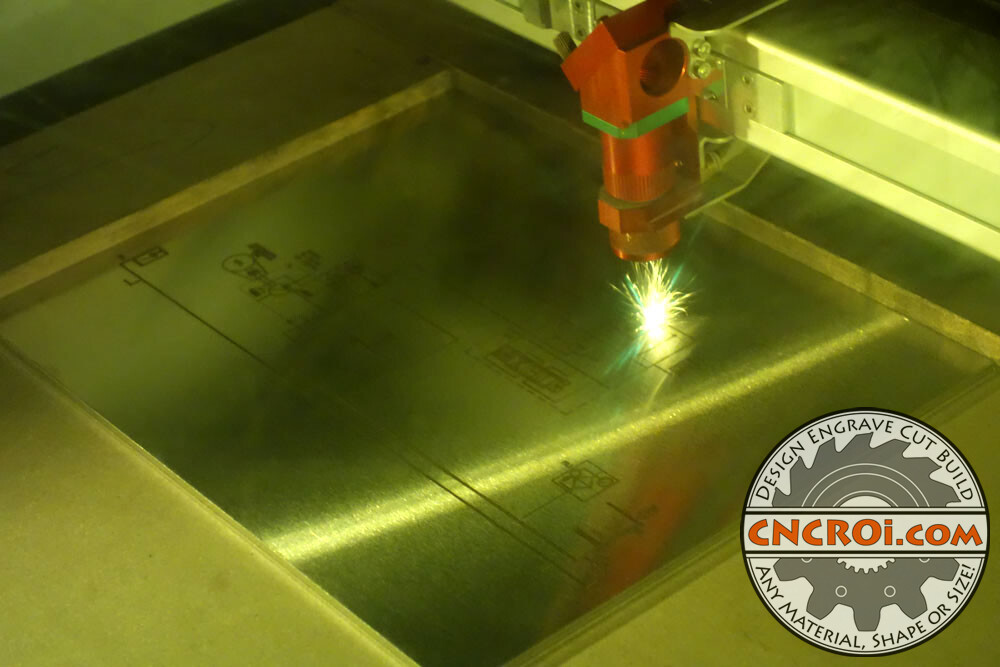

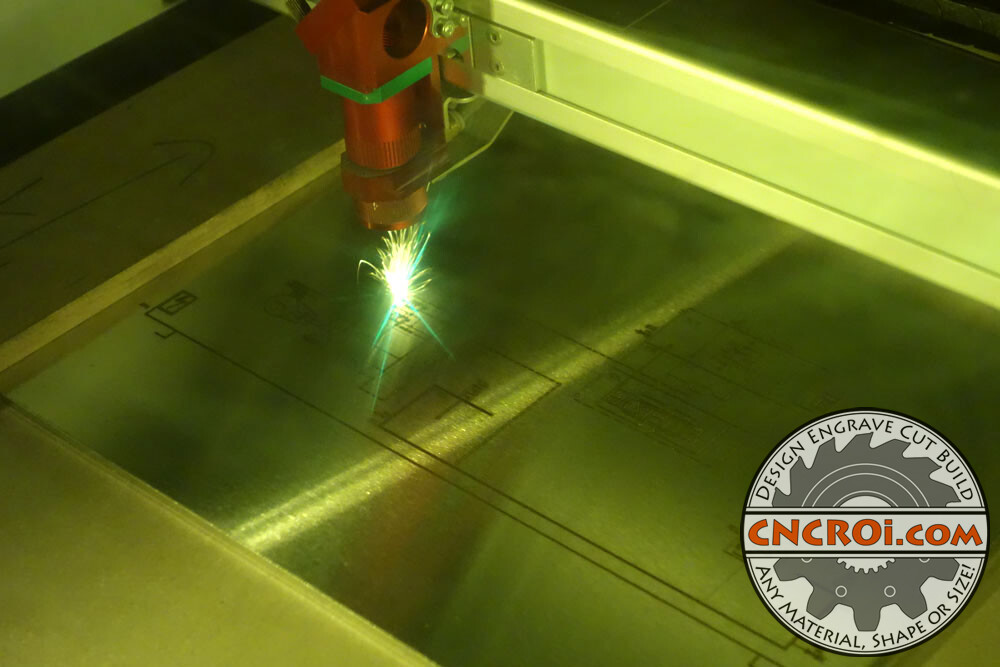

The sparks you see are the results of the fiber laser hitting the surface of the, in this case, 316SS #4 finished plates, the fiber laser beam itself is completely invisible, hence why you don’t see anything leading into and out of the laser head.

Now that the final custom electrical enclosure plates in this short production run at CNCROi.com is cut, you can more clearly see the results, again, stainless steel is awful to photograph and video, it has a shine to it that causes a lot of focusing issues so although the plate below looks a little muddy, it’s actually very sharp.

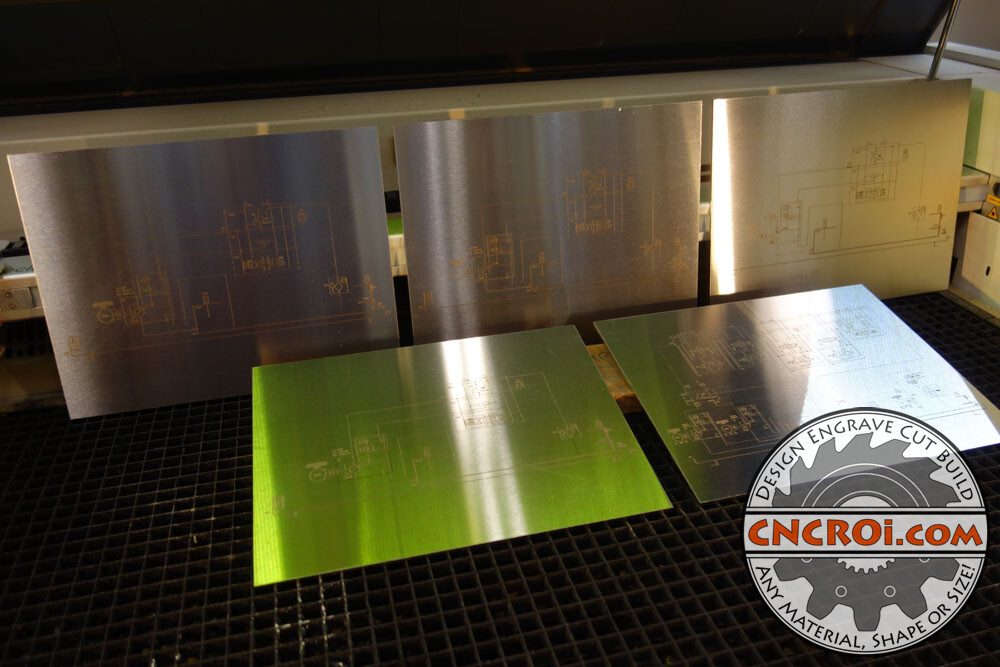

Below are what the custom electrical enclosure plates look like before clean-up, even just like this, they look better than anything else in the market but one cleaned-up, their true brilliance comes out which is sadly hard to photograph properly.

Stainless steel is very hard to beat, it looks absolutely stunning after fiber laser etching the surface and indoors or out, industrial or for public use, nothing really beats it.

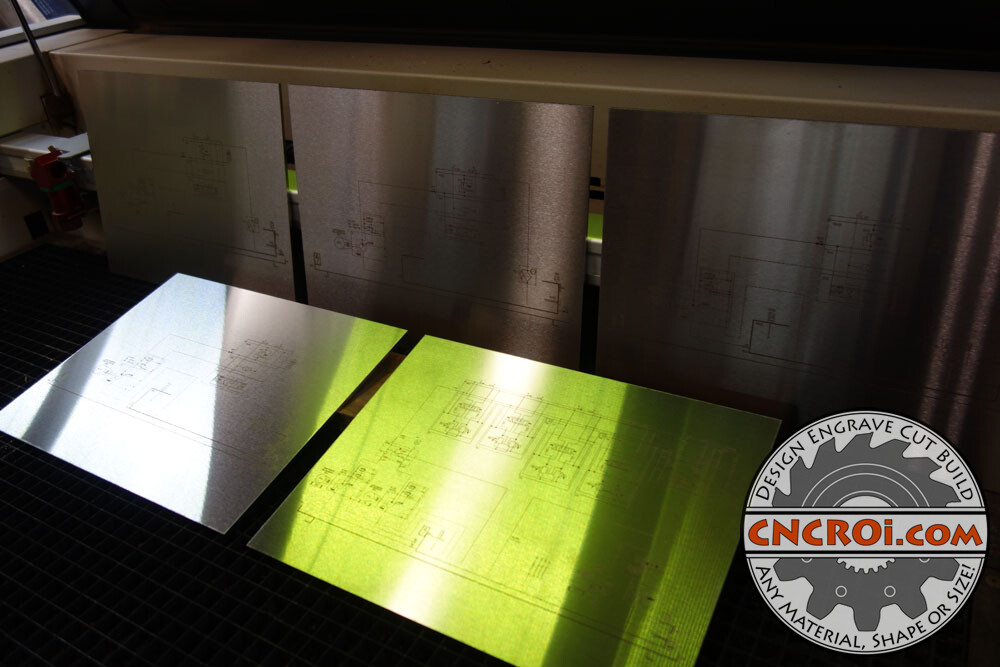

I took some pictures at a few different angles to try to reveal the results more clearly of the fiber laser etching on these custom electrical enclosure plates at CNCROi.com.

You can see how the plates change color based on how light reflects on them, the camera greatly accentuates this effect, it isn’t anywhere near as bad in real life.

Here’s the best close-up I managed on one of the custom electrical enclosure plates, even this one ends-up being a little fuzzy due to camera focusing issues from the reflectivity of the surface.

Need custom electrical enclosure plates? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=S4Qx6w0og9o/settings