Elephant Door Holders: Production Prototype (Part 2 of 2)

As CNCROi.com specializes in making things that weren’t made before, sometimes even I have doubts about how to best make something regardless of the design or material, so testing is required to confirm assumptions.

https://www.youtube.com/watch?v=N7CyP54yflw/

The above is the second part of this elephant door holder, to watch the first, the video is below.

https://www.youtube.com/watch?v=HUs1zMcwQfI/

The reason why I designed and made this elephant door holder was because I had doors open and close throughout the house from the summer winds, this solves the problem, but it was also a great case study as to what we generally do in the shop for customers (they aren’t door holders).

The first step towards prototyping is actually MAKING the item, that’s when you find out what works and what doesn’t, I’m sure you noticed what was wrong with the first version of the elephant door holder, some were obvious, some not, but then it came down to actually USING it for a week or two before hitting the drawing board again.

This lapse in time is also important, though CNCROi.com isn’t always given the luxury of time to see how things turn-out, it is wonderful to actually use and test and item for an extended period of time before jumping right into version 2.

https://www.youtube.com/watch?v=vVBR6oPZUQI/

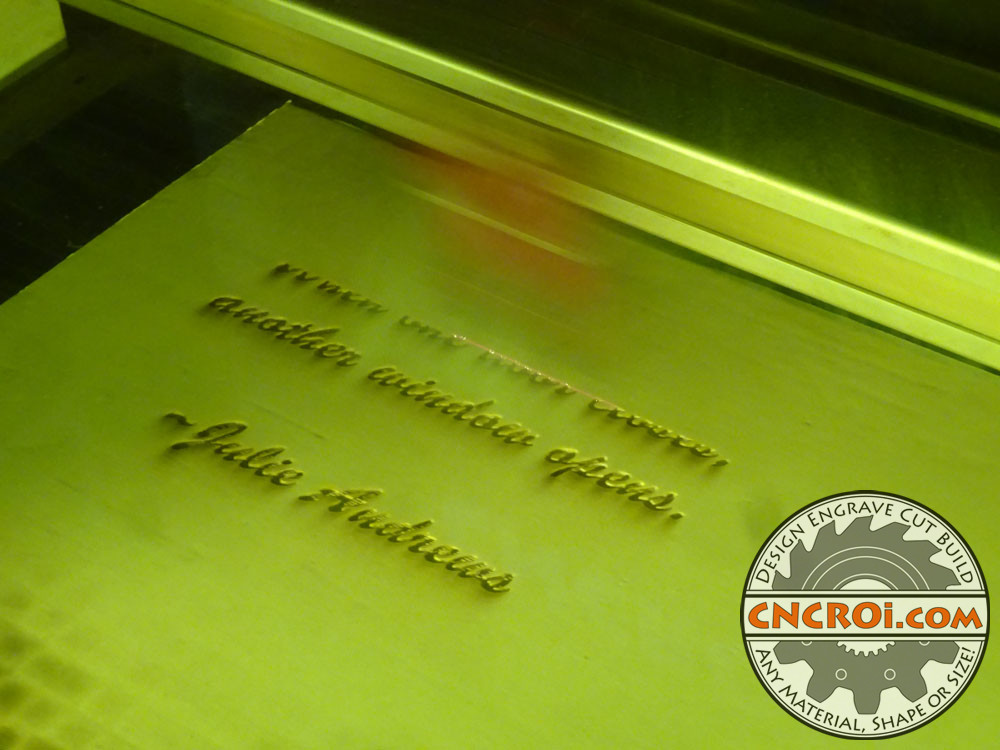

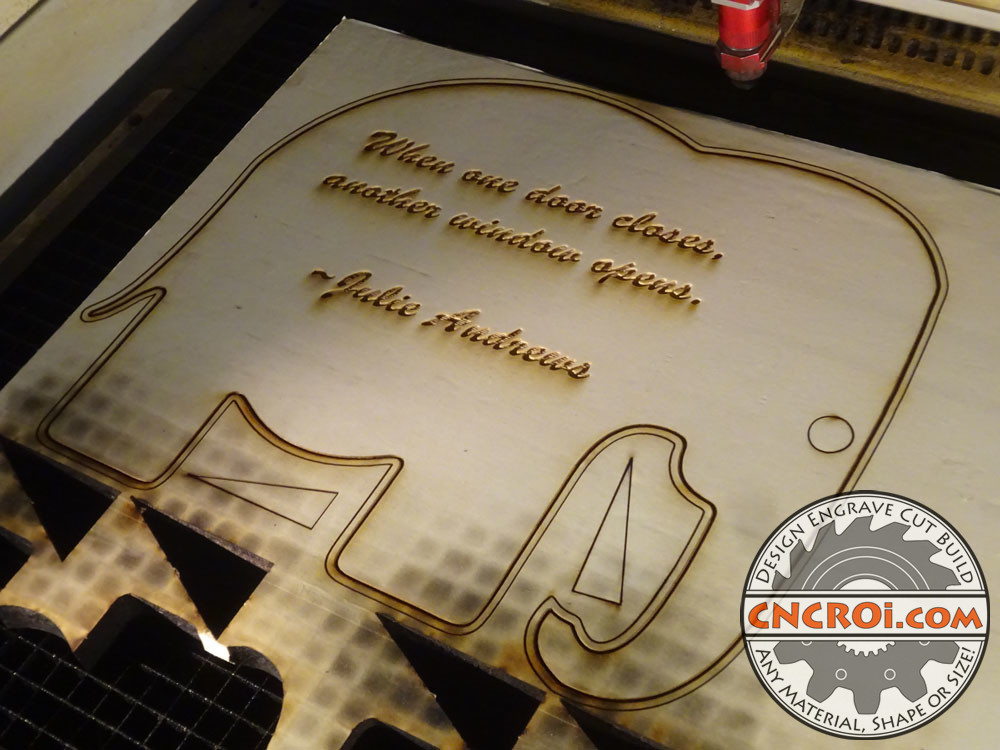

The resolution we can achieve on wood of pretty much any type is amazing, as a result, CNCROi.com makes custom wooden business cards through furniture using a variety of species.

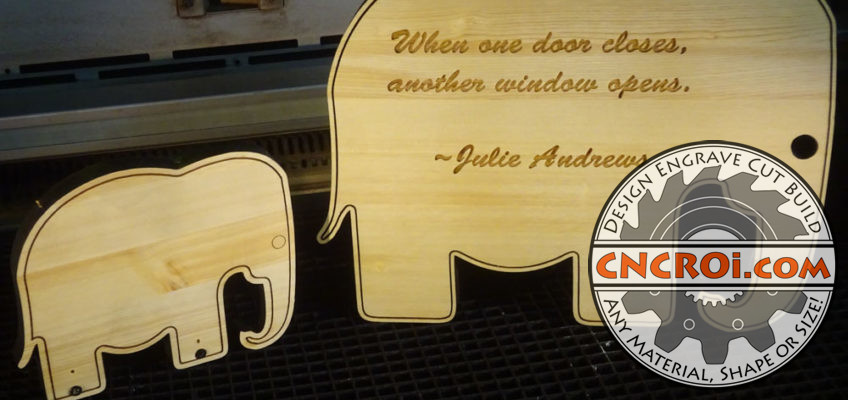

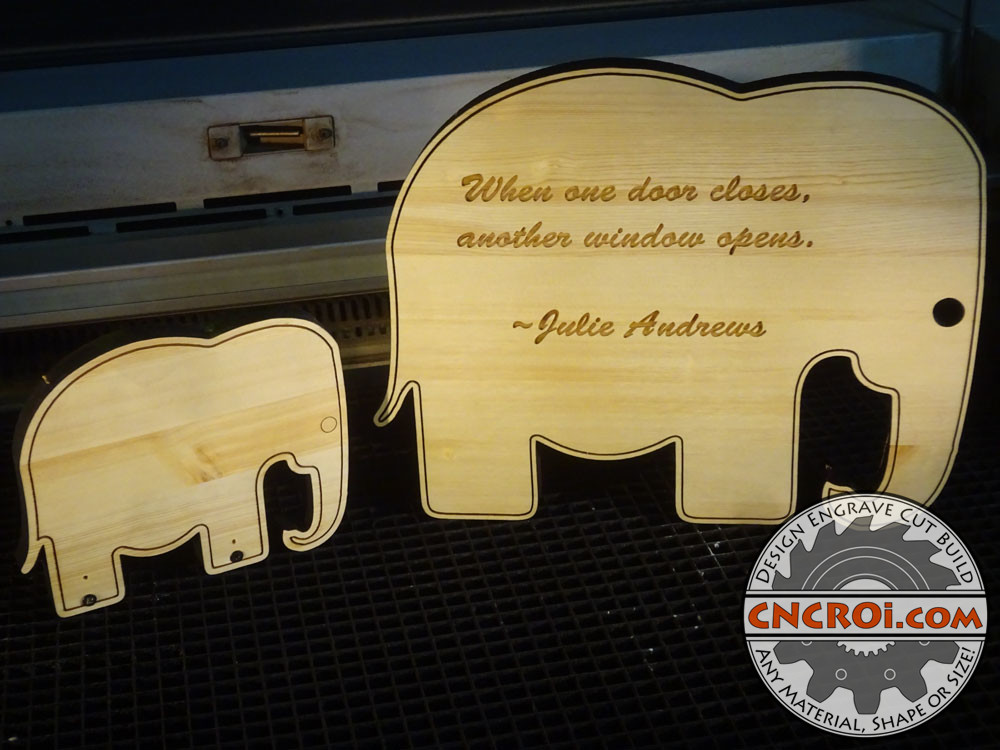

One of the first observations I made using the elephant door holder (version 1) was that it was too small, I kept forgetting it was there due to it’s diminutive stature, quickest fix to that was to scale it up 4x!

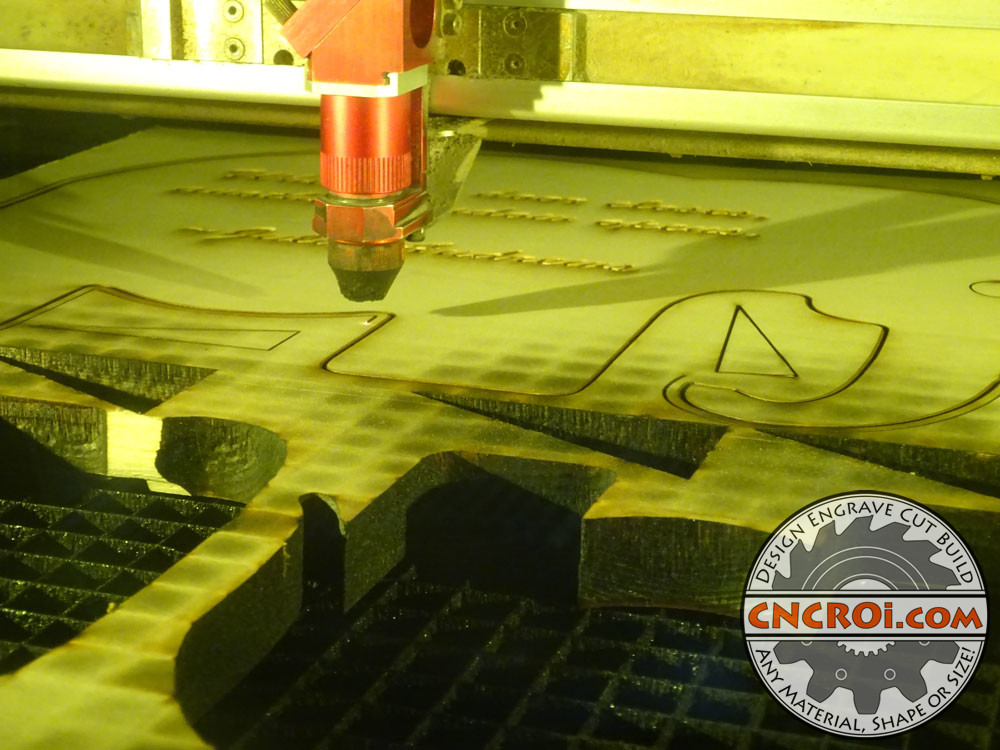

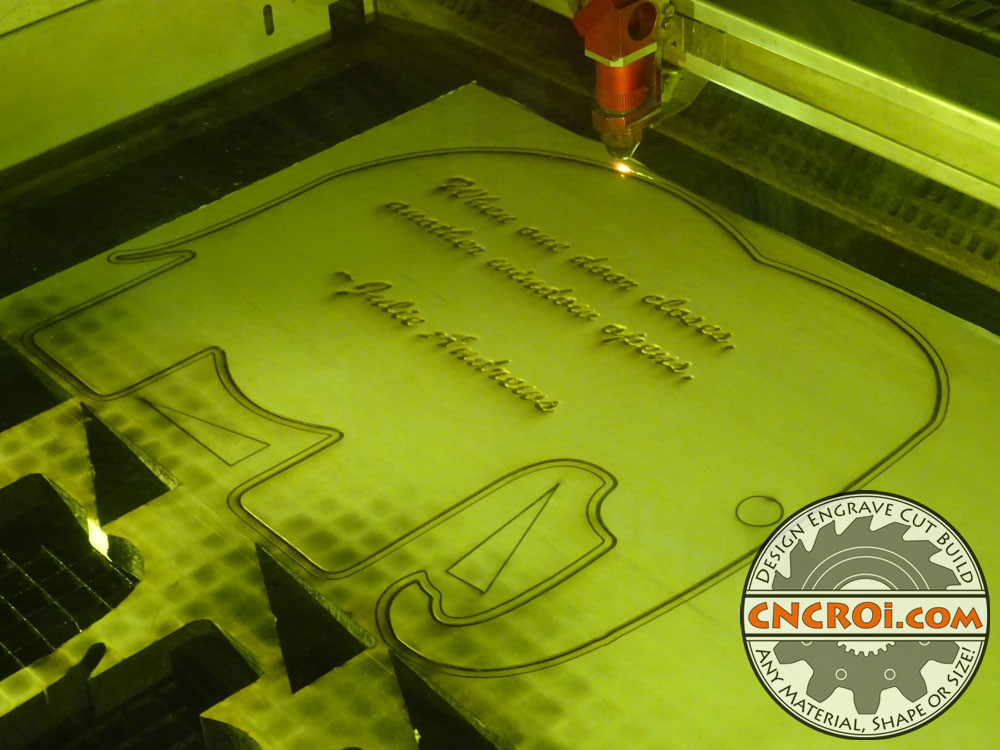

Having a much larger elephant posed some new issues though, the first was that I now had a HUGE surface area with nothing on it… so quickest fix to that was to put a motivational quote to fill the space!

When one door closes,

another window opens.

~Julie Andrews

Having access to a variety of capital equipment means we can optimize production to the project at hand.

https://www.youtube.com/watch?v=67DOfMCacBk/

Whether we jump from one machine to the other or do everything in one step like this elephant door holder at CNCROi.com, that flexibility offers us incredible design capabilities that no one machine can offer.

I also fixed-up a few nagging issues I had with the first version of this elephant door holder, the first was the eyes, I wanted to cut straight through, just the esthetics looks better and if I didn’t do this, I’d be reminded that I didn’t do this each time I looked at it.

CNCROi.com isn’t limited to just 2-D items either, we can build items using exclusively our laser, router or a combination of that and waterjet cutting (for metal) should the project lend it self to it.

https://www.youtube.com/watch?v=QLNaITMxayw/

The other issue that I really disliked about the original version were the screws, yes, they were a last minute addition and with glue, not totally required anyways, but I wanted to keep the strength they provided while at the same time, have them hidden.

At first, I made just a modified version of the extended triangles you see in the image below to prop-up the elephant door holder but then while building it, I realized that although this design element worked great when it was smaller, not so much it it’s new super sized version.

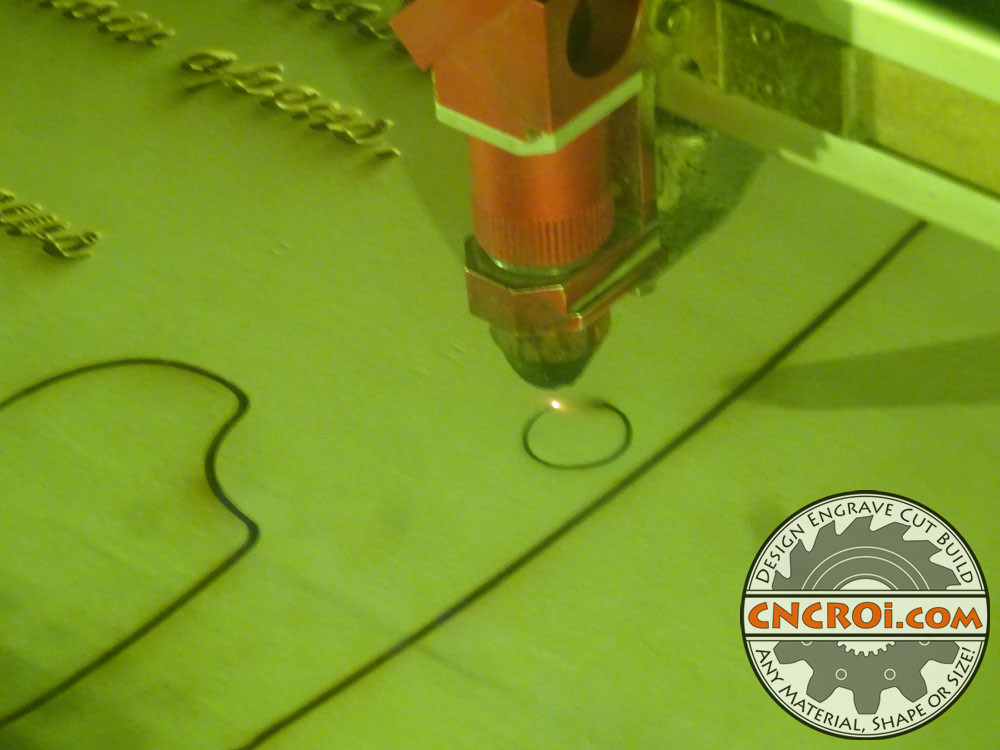

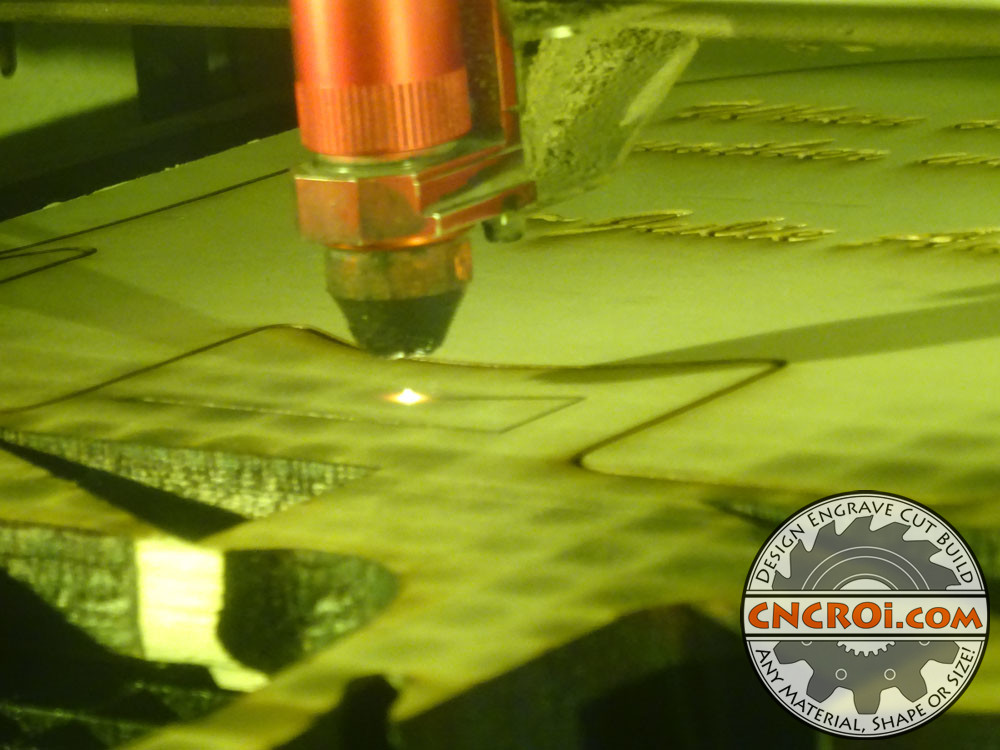

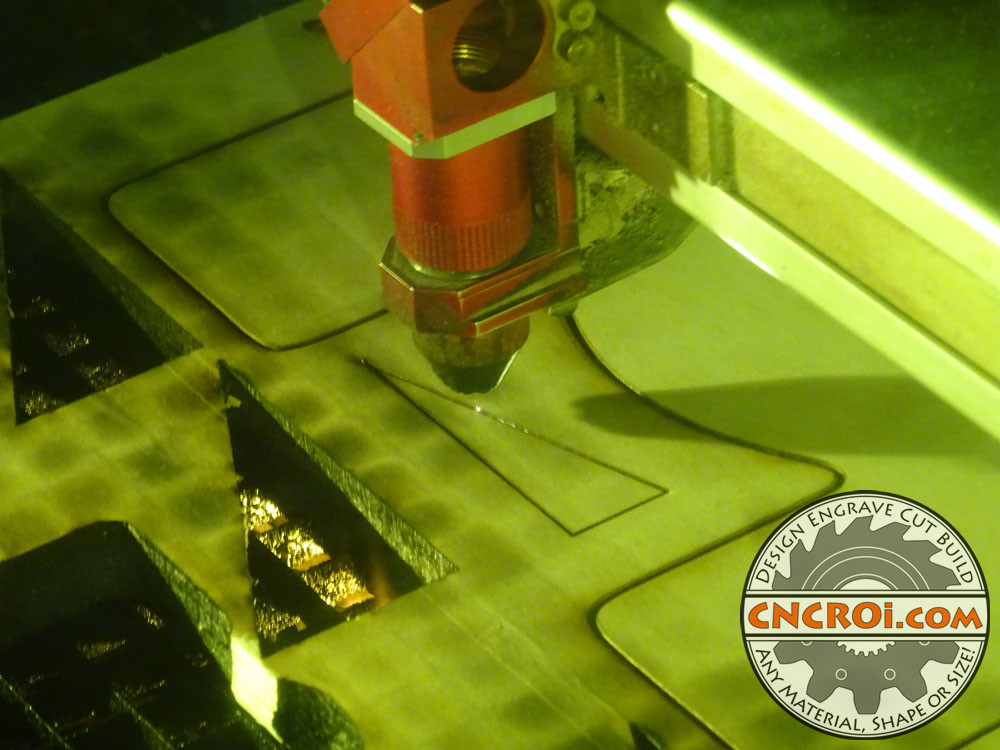

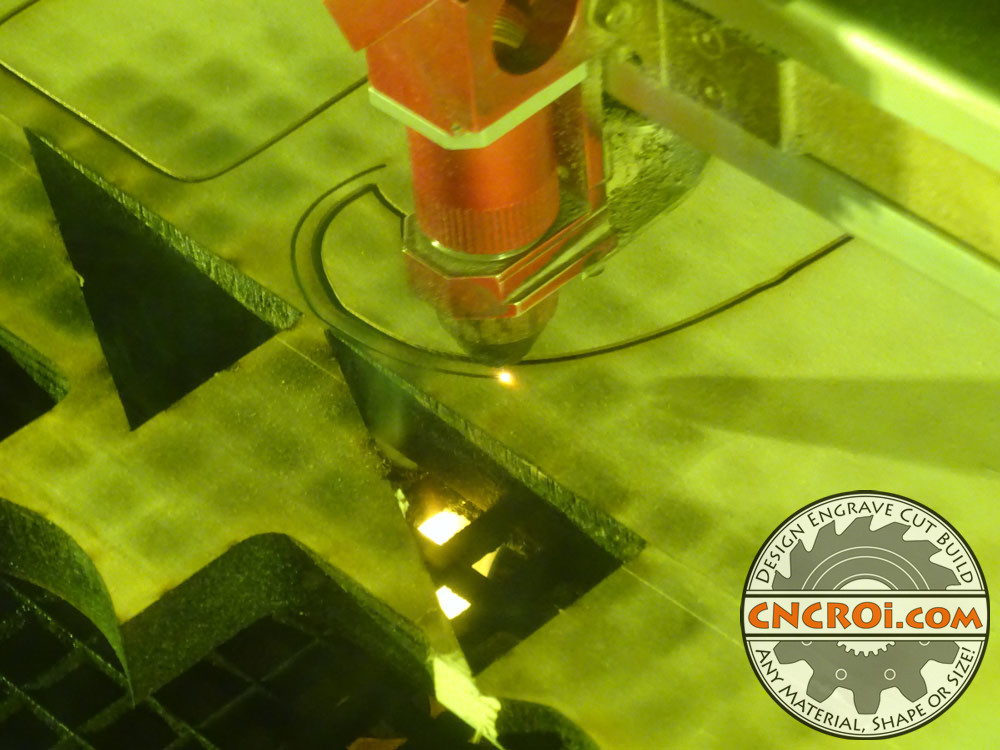

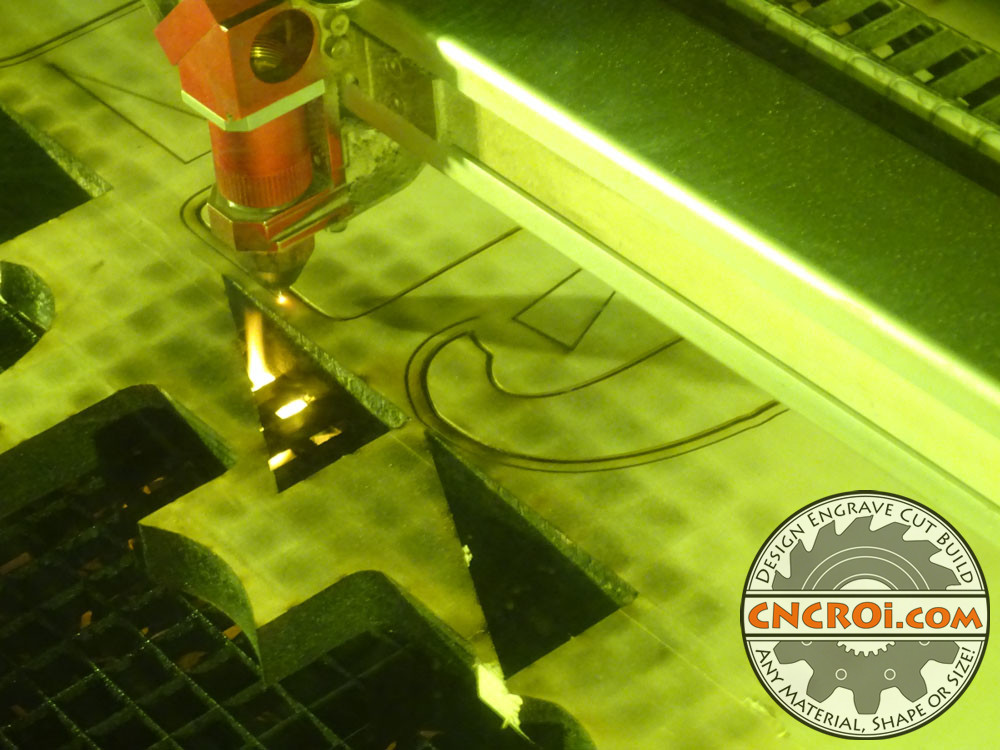

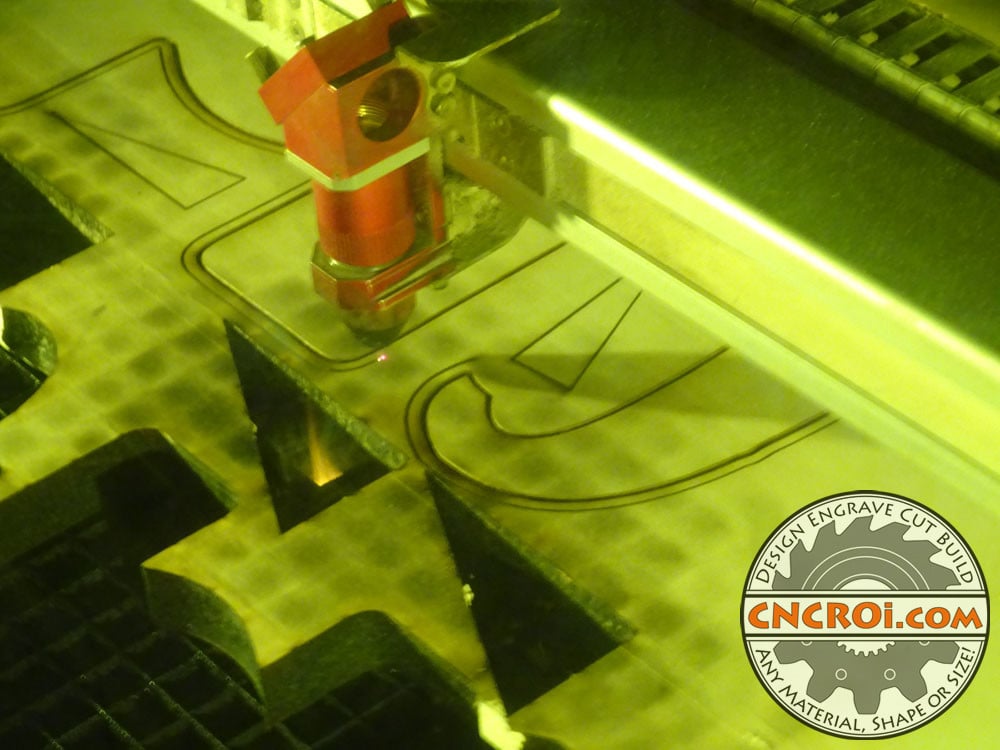

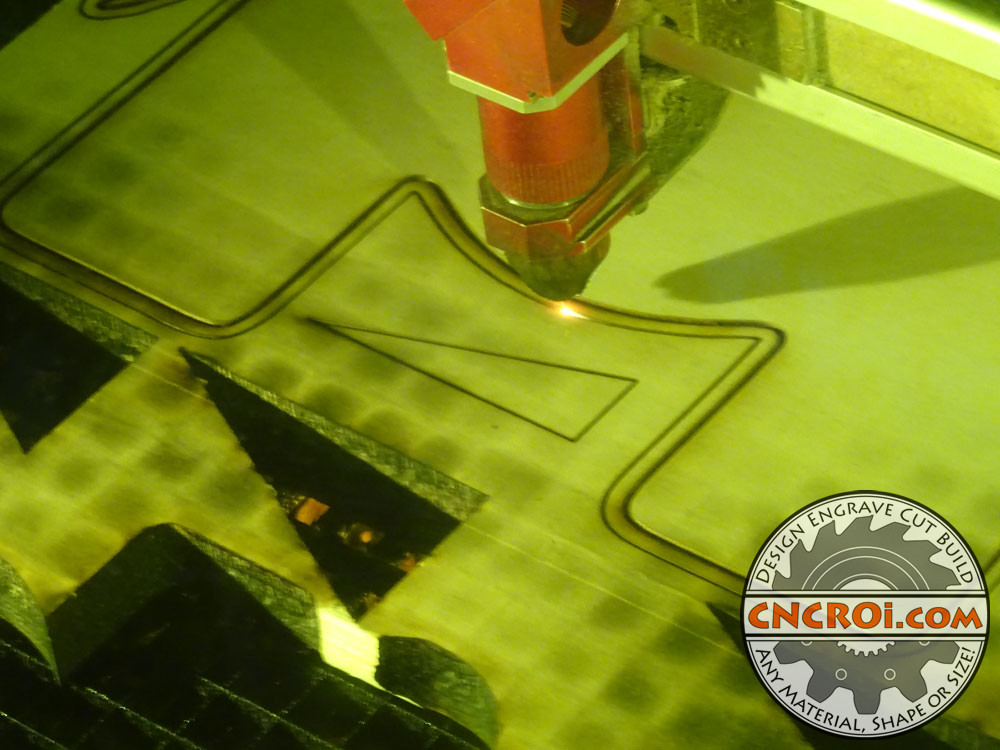

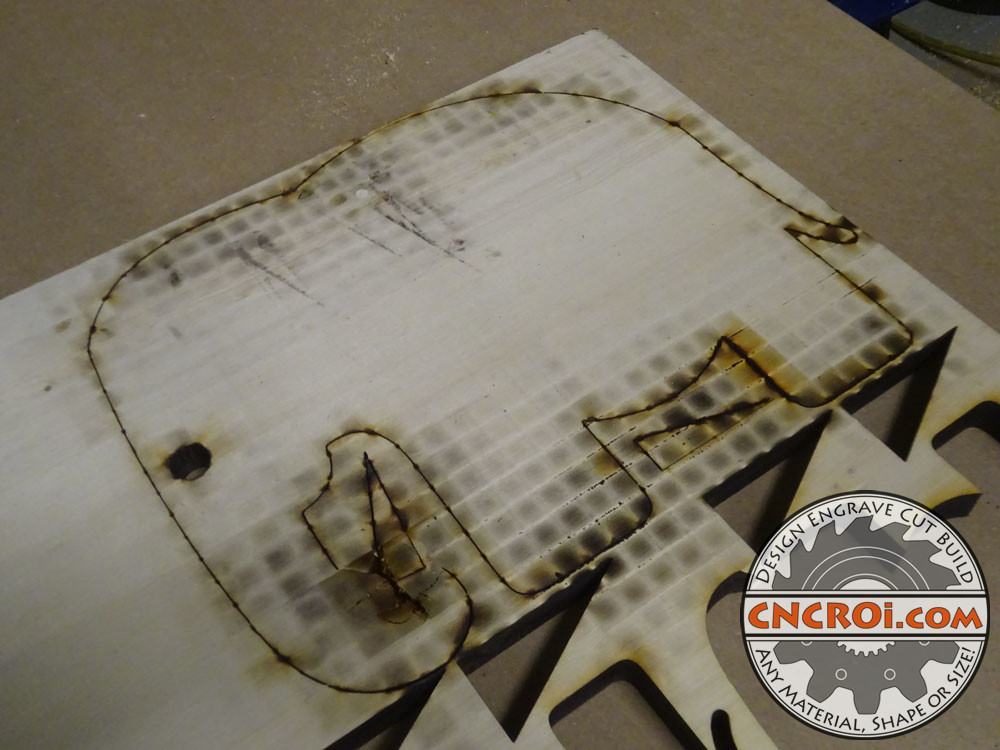

As you can see from these photos, the laser cutting process is very much a fire burning process, that’s how the contrast is created along the edges of this elephant door holder.

https://www.youtube.com/watch?v=PCZ7LBllXbI/

This isn’t the first nor the last item I make for around the house, I made a shoe holder that holds itself up totally fine since I’ve made it a few months ago, so I’m not only a supplier but also my own customer.

I’m always amazed at how literally photons of light are able to cut anything, we get hit by them all our lives but when concentrated, they can easily cut Pine and even steel!

Another popular item CNCROi.com makes a lot of are custom house and cottage signs using mostly wood though we can just as easily make it out of metal as well.

https://www.youtube.com/watch?v=iyDXD6pTj3s/

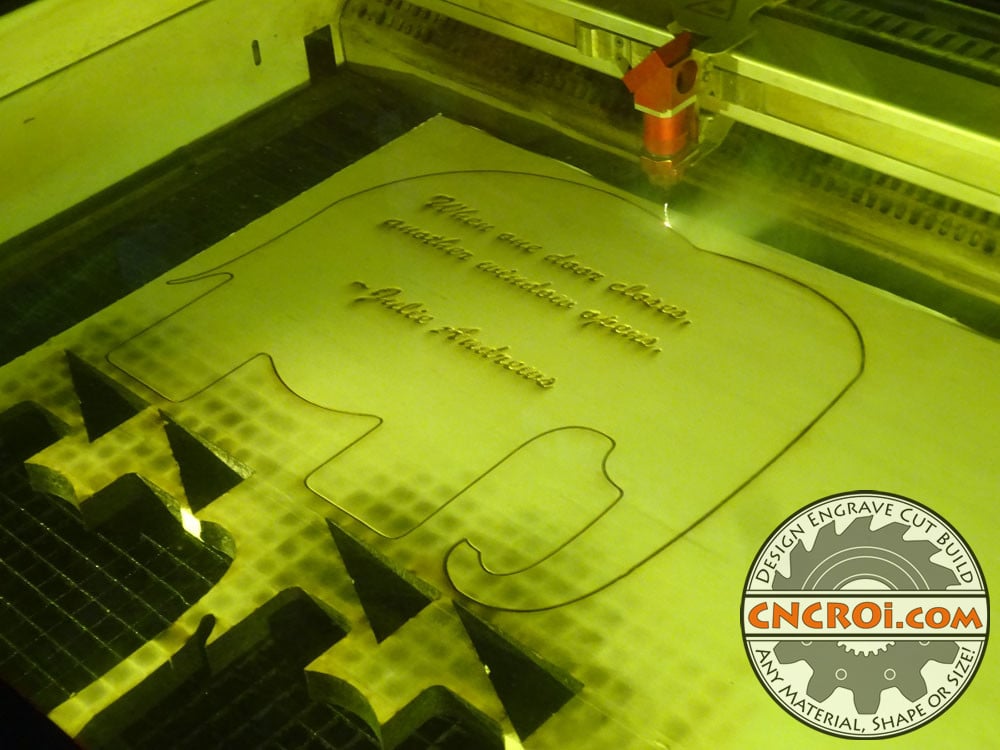

After the laser engraving of the Pine wooden elephant door holder, it was time to cut it out, this makes sure nothing moves from one process to the other, you want to keep the entire project as a full sheet as long as possible.

Unlike version 1 of this elephant door holder, I pretty did all the passes twice, the reason for this was to further darken the edges and the cut areas, remember I’m making charcoal here, the more burning I get, the more charcoal I produce and the darker it looks.

I could have easily cut this custom elephant door holder using our CNC router but I wanted to do this in one step rather than two as otherwise, I’d have to paint the contrast which the laser does for free.

The precision of our industrial laser is amazing, we can pass over the same area millions of times and still pass over the same original pass, we get the same precision with our CNC router by the way, just there is a higher chance of not hitting the same area as there is contact between the machine and the material which may slightly move things.

After the custom elephant door holder is done being cut, you can see the masking did a wonderful job of keeping smoke off of the surface, next step is sanding it and cleaning it up in the CNCROi.com shop.

House number signs are always fun, as are welcome signs, this elephant could easily be modified to become one.

https://www.youtube.com/watch?v=xr_QpXOyCHc/

You can see the back where the flames cooked the wood in many areas along the cut lines, this is fine, all of this is on the masking, not the underlying Pine wood.

Going back to the door holder tabs, I modified the design so that I could screw a screw directly through the back of one into the elephant with some glue, this posed a far stronger union and without the ugly esthetics of the original version 1 of the elephant door holder.

This design works far better and has been improved throughout, I consider this a production quality version of the elephant door holder, there are still a few tweeks I’d make but they are so minor as to not be relevant in this discussion.

Need something custom made out of wood? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=N3a1sBNi_H8/