Elephant Door Holders: Rapid Prototype (Part 1 of 2)

Making custom elephant door holders was something I’ve been wanting to make at my house for a while, it’s both my favorite animal and I’m tired of doors slamming shut with the wind during the summer.

https://www.youtube.com/watch?v=HUs1zMcwQfI/

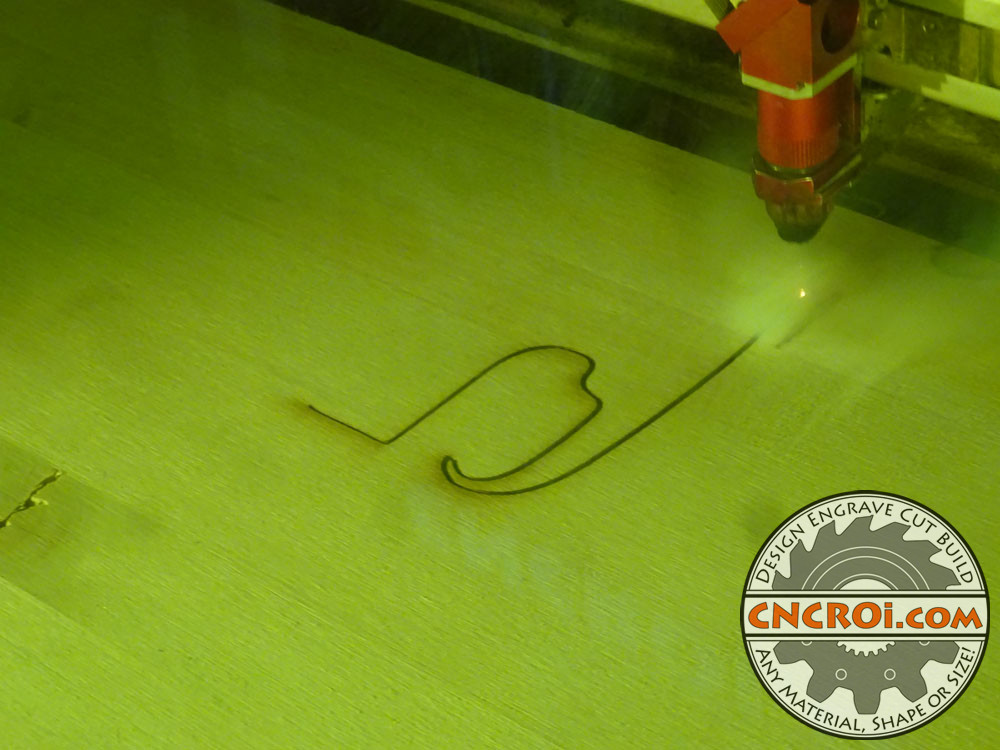

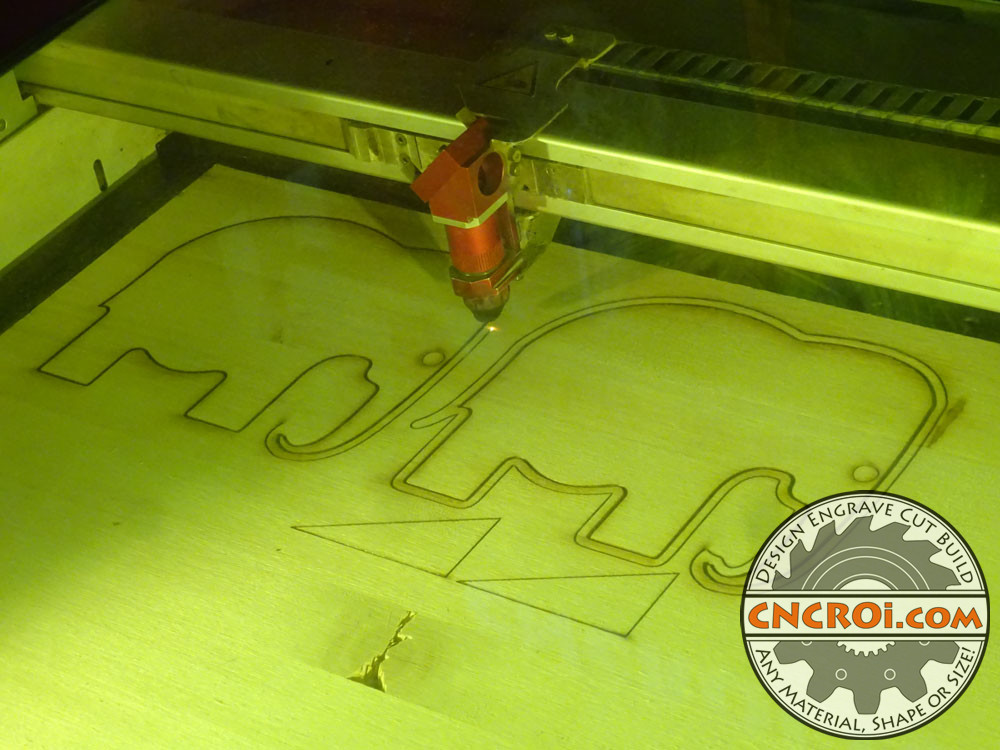

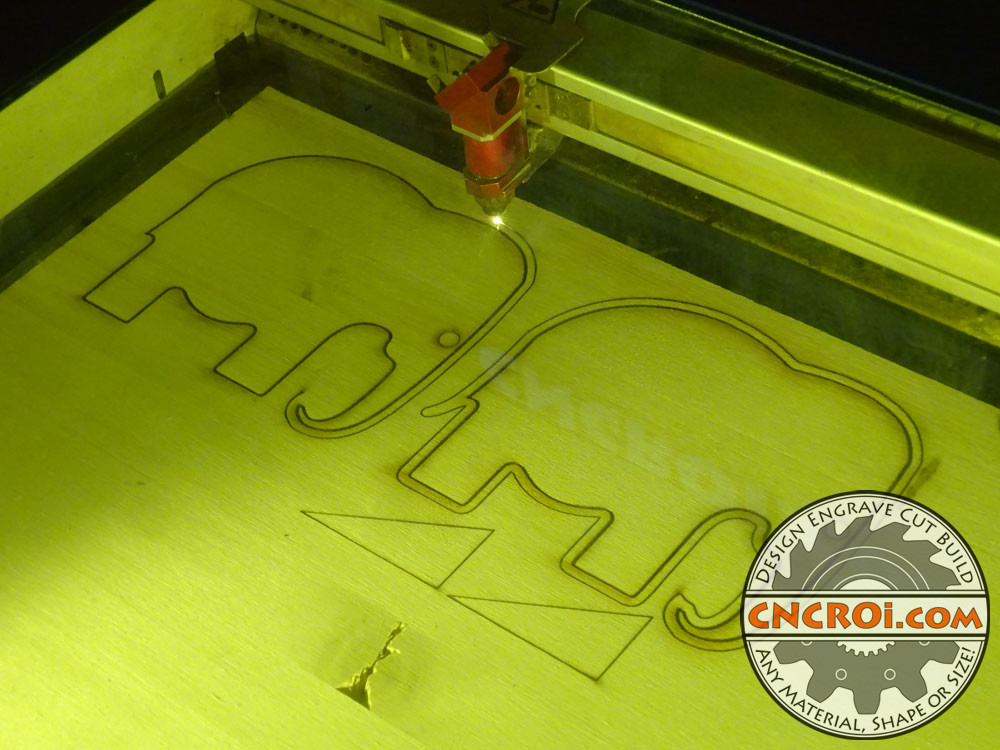

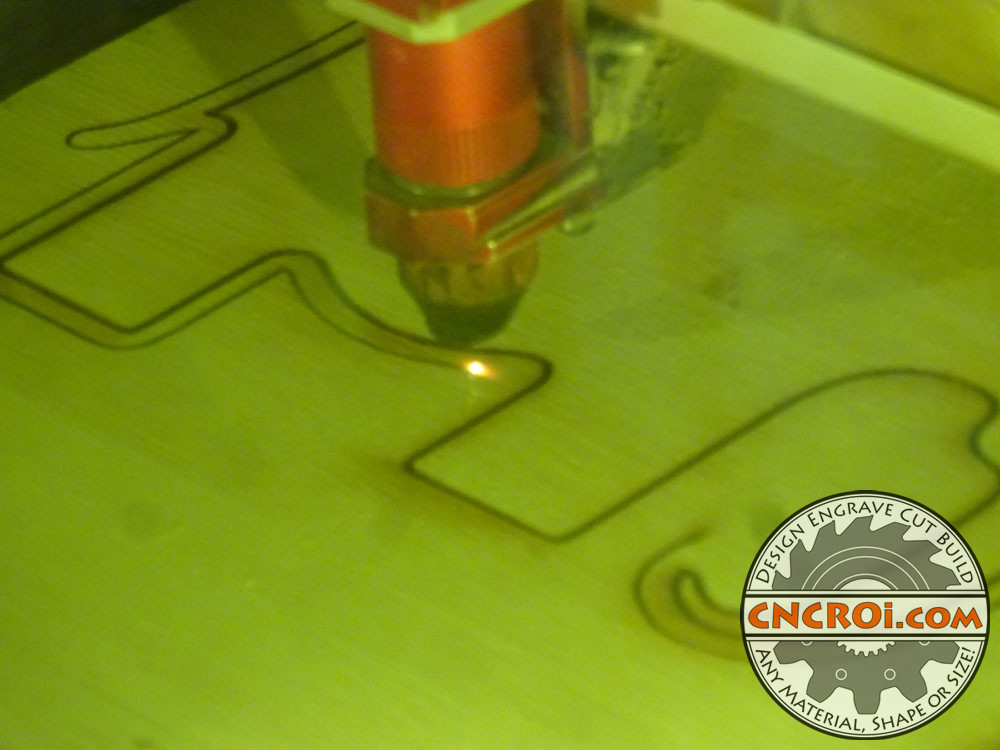

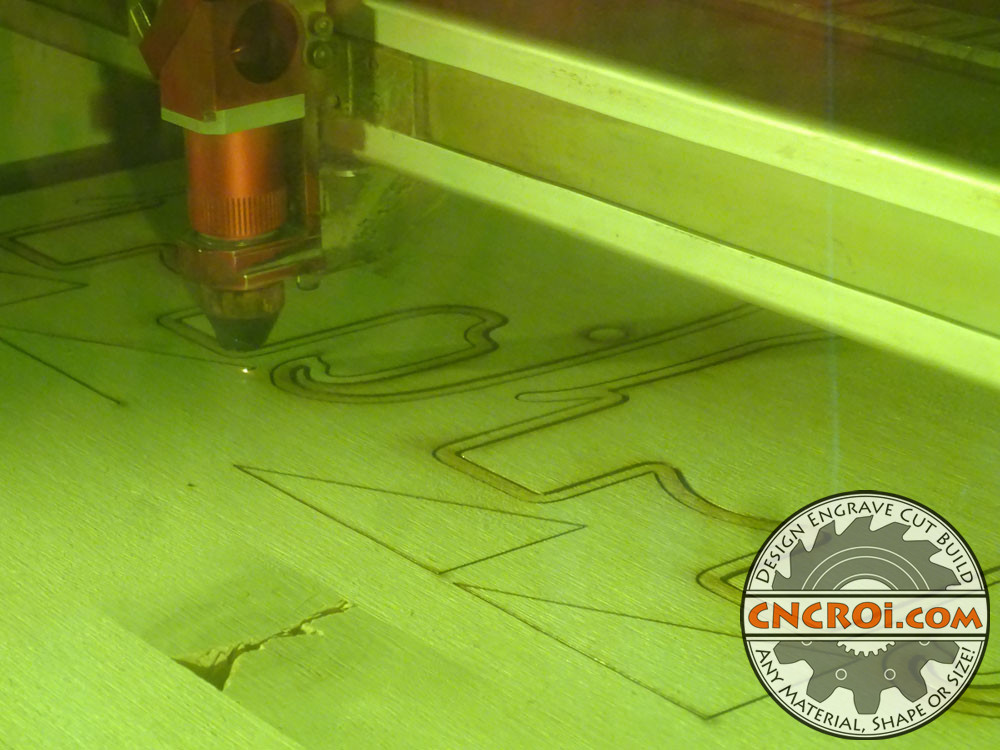

As such, I quickly designed-up custom elephant door holders using 3/4″ 18 mm Pine and went about testing out my initial design ideas – something I do a lot of in the shop for customers far and wide at CNCROi.com.

By far the easiest material to work with when it comes to prototyping is Pine, I wanted something nice and think for these custom elephant door holders so that I can play with a few ideas and concepts quickly and efficiently without having to pull out the big tooling I have access to.

I’m certainly not new to custom fabricating items using Pine at CNCROi.com, this is a simple pencil holder that went through the exact same process, try a few ideas out, see what works and what doesn’t, then make more!

https://www.youtube.com/watch?v=xz301R_Xpa0/

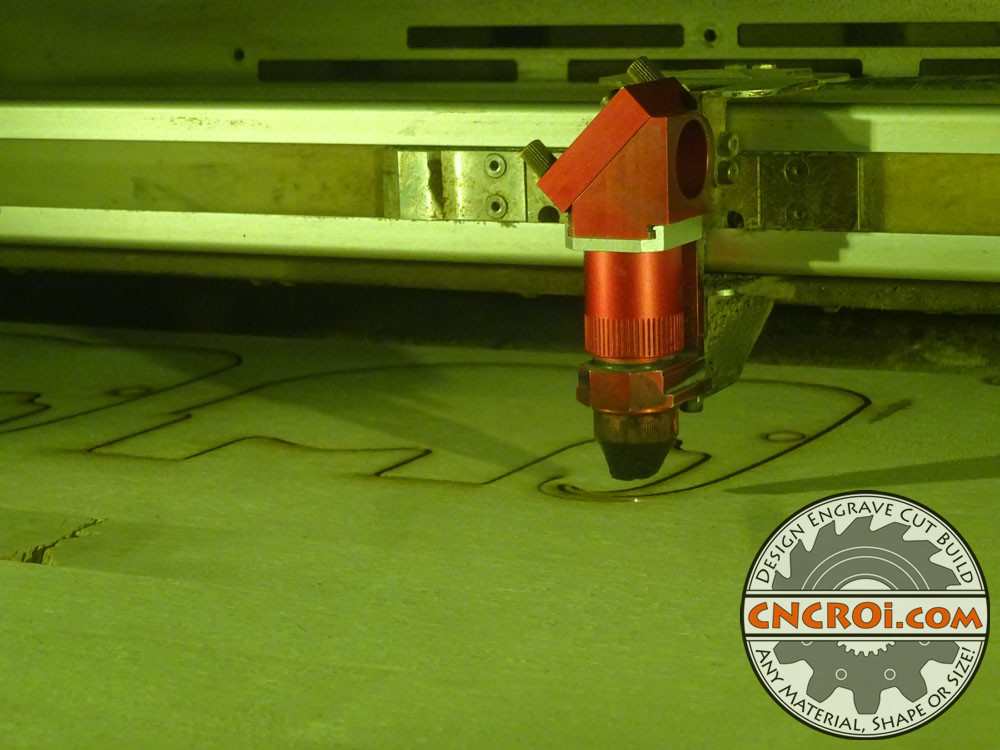

The laser is plenty strong to easily cut through the Pine, it also produces a wonderful contrast at the same time, which really helps to make the entire project pop that much more!

I really had no pre-conceived concept or design when it came to making these custom elephant door holders, I just wanted a simple design and a functional one at that but how it came together or was built didn’t really matter at this stage, it was for personal use and I was trying out different ideas as if I was about to go on a production run of thousands of these.

Pine is really a hugely underrated product, it sands and stains wonderfully and is very easy on machinery when it comes to making custom fabricated items out of it.

https://www.youtube.com/watch?v=L8rMyW7Am3M/

CNCROi.com does custom fabrication, one-offs to thousands of units, and as such, when it comes to personal projects such as these custom elephant door holders, I wanted to go through the steps – and share with you – the thought process as if I was going into a massive production of this product.

One of the first mistakes I realized while I was laser cutting these was that I should have made the screw holes at the same time as the laser engraving and cutting of the custom elephant door holders, it speeds things up, removes a process (drilling) and actually makes the end-result way more accurate in a production run.

Pine is actually a pretty durable wood if taken care of for the right application, what I really enjoy about Pine is the endless products that can be mixed and matched with it beautifully.

https://www.youtube.com/watch?v=gBCN5tmn8bg/

I laser engraved the front face just to give it a bit more contrast, as the edges are a dark brown, it’s nice to have a face following that for more visual appeal.

The second mistake I made when actually drilling these little guys out was that I made two drill holes instead of just one, things were going so well with the drill press I thought “why not” in a split second but once done, I regretted making them as they are totally unnecessary.

Pine also engraves WONDERFULLY, it’s a soft wood and the laser always does a wonderful job engraving into it producing a beautiful contrasting result.

https://www.youtube.com/watch?v=XGJGFMFwDmU/

Of course, engraving Pine can be done many different ways to produce unique wall plaques and imagery.

https://www.youtube.com/watch?v=poleEGELcPY/

Before drilling the holes in these custom elephant door holders though, I had to first clean the up after being laser engraved and cut, that involves sanding – something I rather enjoy doing at CNCROi.com.

After the sanding process, these custom elephant door holders are looking very nice, of course, then I realized that maybe it would look better if the eyes were cut through as well instead of just laser engraved!

Having a variety of equipment in the shop allows us to make other unique items, custom to spec that we’ve made lots of other items with through the years at CNCROi.com.

https://www.youtube.com/watch?v=puSpxd8eaZI/

Anyways, off to the drill press to do some redundant work, my initial thought in making two holes was so that the back part that goes under the door to hold it in place wouldn’t swivel, having two points of contact would prevent that immediately but then I realized after drilling that I’m applying glue anyways, so yep, not only was the drilling process redundant but so was making extra holes or actually, any at all!

Anyways, after making the holes and realizing my mistake, it was time to finish the models up, some good drywall screws will hold everything together forever with some glue.

Having a shop with lots of live edge also helps when it comes to producing unique products for our customers, from custom wooden cottage signs to full-on tables!

https://www.youtube.com/watch?v=iyDXD6pTj3s/

After final assembly, the custom elephant door holders are looking pretty good, next step is to seal the wood so that it looks nicer and if it gets wet, it won’t expand or rot.

After drenching them, I give them a light sand, it was night and I couldn’t really see how much seal I was applying to the finished custom elephant door holders.

CNCROi.com can also make dimensional wooden items, so we aren’t limited to strictly flat production.

https://www.youtube.com/watch?v=67DOfMCacBk/

Regardless, it’s easy enough to sand off excess sealant and the results still look fantastic, this was a prototype and I will be making another version of these based on everything I learned doing these two models.

If you are looking for something to be custom fabricated, contact CNCROi.com right now!

https://www.youtube.com/watch?v=EHtIEyWOG4k/