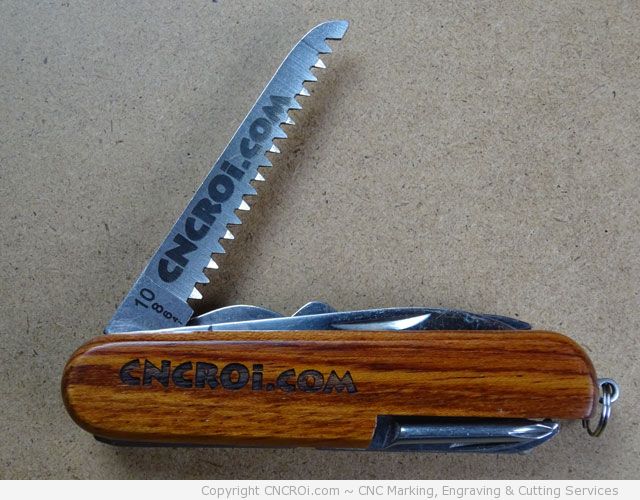

Engraving and Annealing a Pocket Knife

When I decided to follow through and purchase the CNC laser we use here at CNCROi.com – a Trotec Speedy 400 flexx – I knew it has to have both a CO2 and Fiber laser source? Why? Well, look at the picture below… this was done in a fraction of the time thanks to a dual source laser vs one that’s only CO2 as you’d have to clean this knife blade, apply toxic paste, wait for it to dry for 10 minutes, laser bond the paste into the stainless steel THEN clean it off and wash it. I skipped all of that!

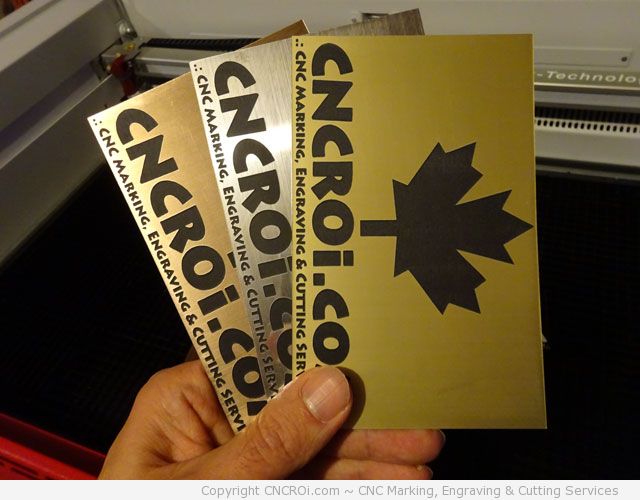

Laser engraved wood, laser annealed blade. Those numbers represent font point size, clearly visible and readable down to 1! All done in one process thanks to our dual source laser.

The other major advantage to having a dual source other than a massive time and money savings for both our shop and the customer is that we can do things, like really small parts, that simply wouldn’t be possible any other way. We are doing laser marking and annealing of some small aerospace widgets and guess what, I couldn’t even imagine the headaches involved if we didn’t have our fiber laser source. This is why I bought the best damn equipment in the market and why everyday, I enjoy the power it brings to our customers.

Let’s watch some awesome video of the entire process – I cut them into two videos to keep them short but they could have all gone together in one take.

CNCROi.com: Laser Engraving a Pocket Knife (Corporate Gift Ideas)

CNCROi.com: Laser Annealing a Pocket Knife (Corporate Gift Ideas)

With September in full swing – now’s the time to start thinking of gift ideas for your employees or customers – if we can make a regular knife look like a million bucks – imagine what we can do for you! Instead of presenting you with a catalog of what we could get to you, it’s easier for you to tell us your budget and what you have in mind… if we can’t find it, we can always build it in-house using our products or YOURS!