FDM 3D Printed PLA Lens Caps

Let’s make some FDM 3D printed PLA lens caps that are custom-fit, lightweight and provide durable lens protection at CNCROi.com.

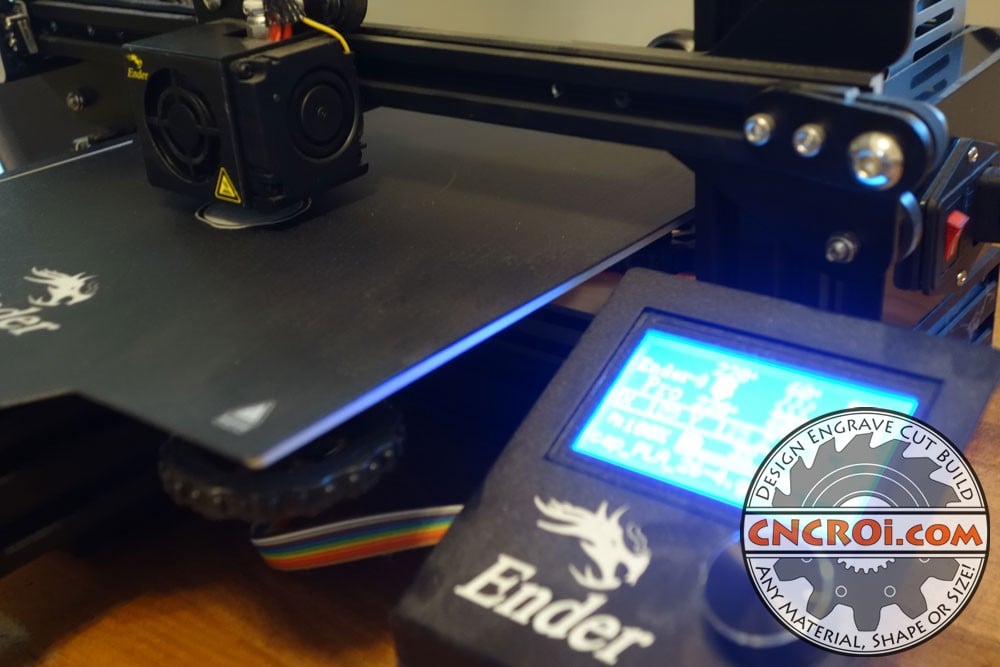

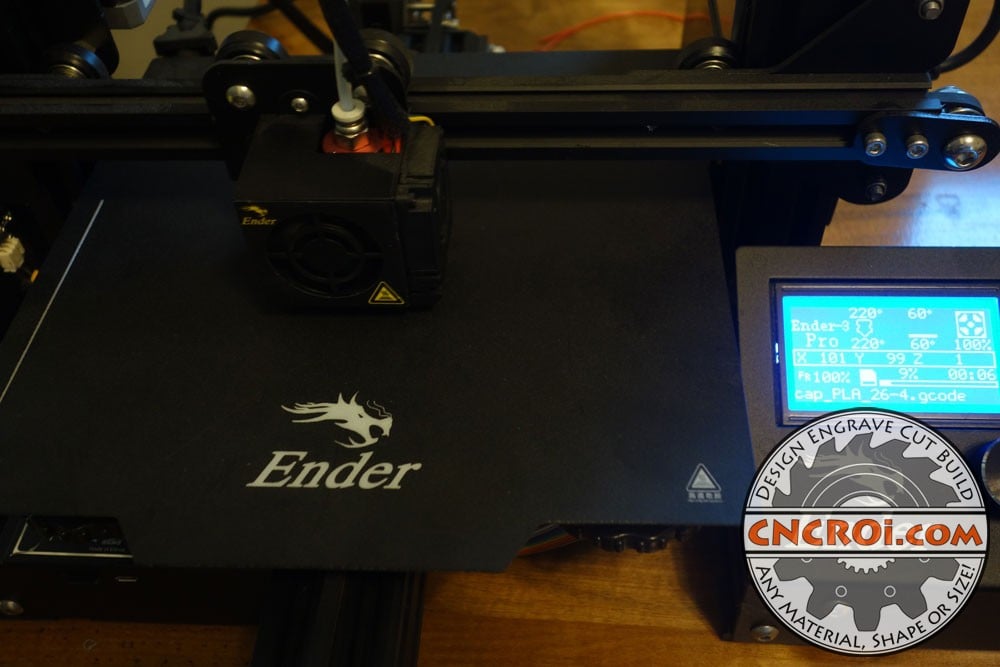

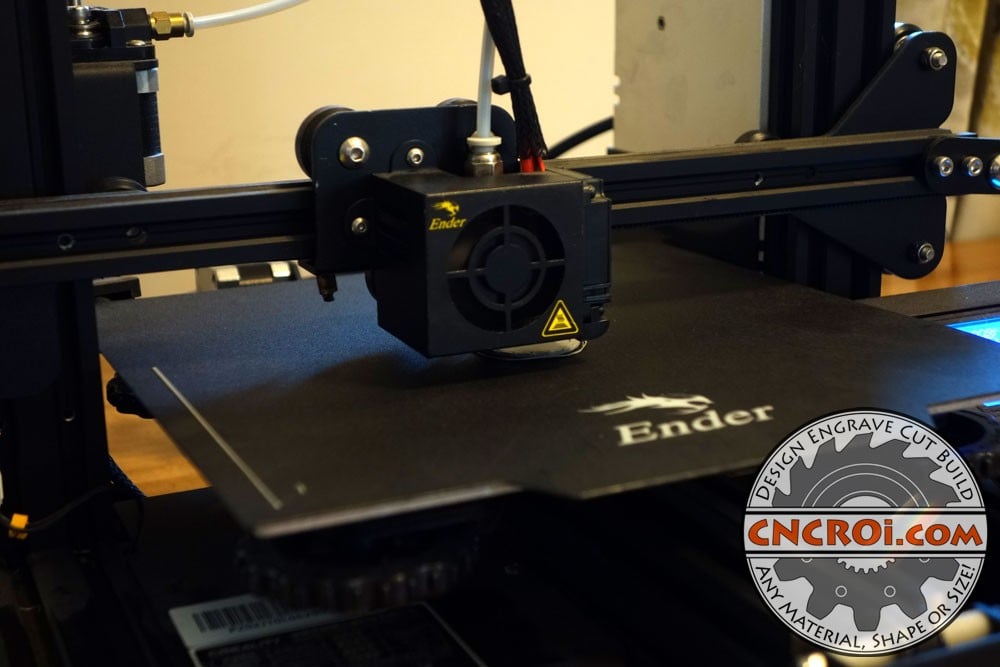

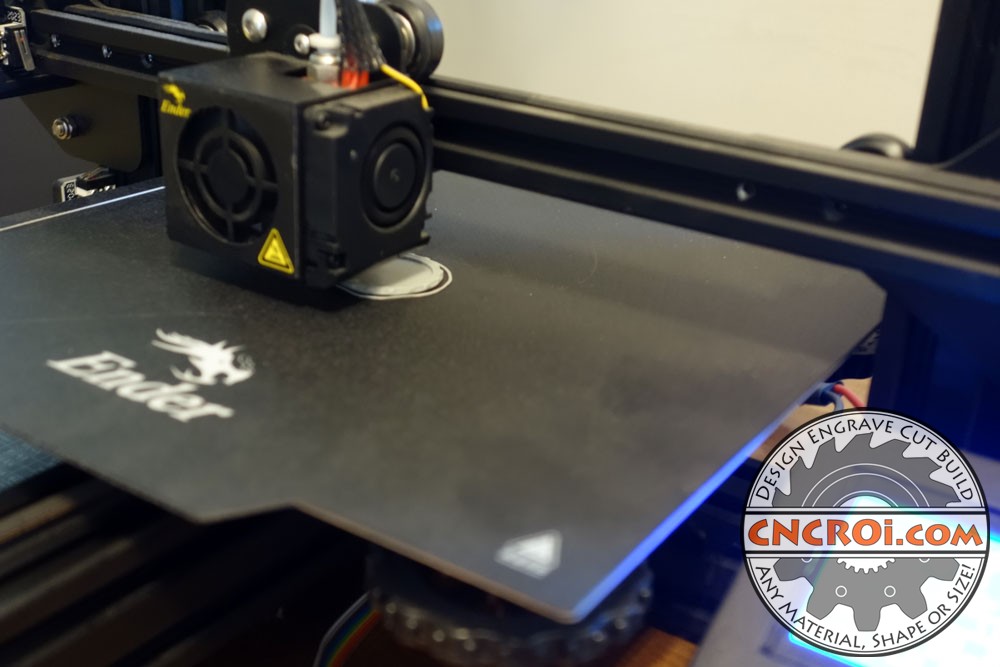

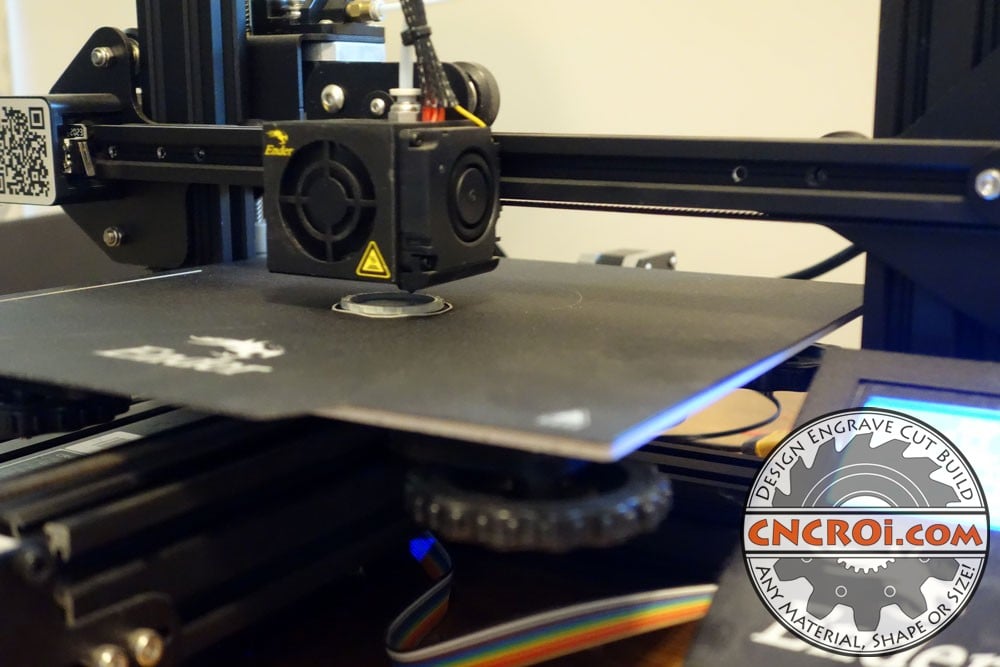

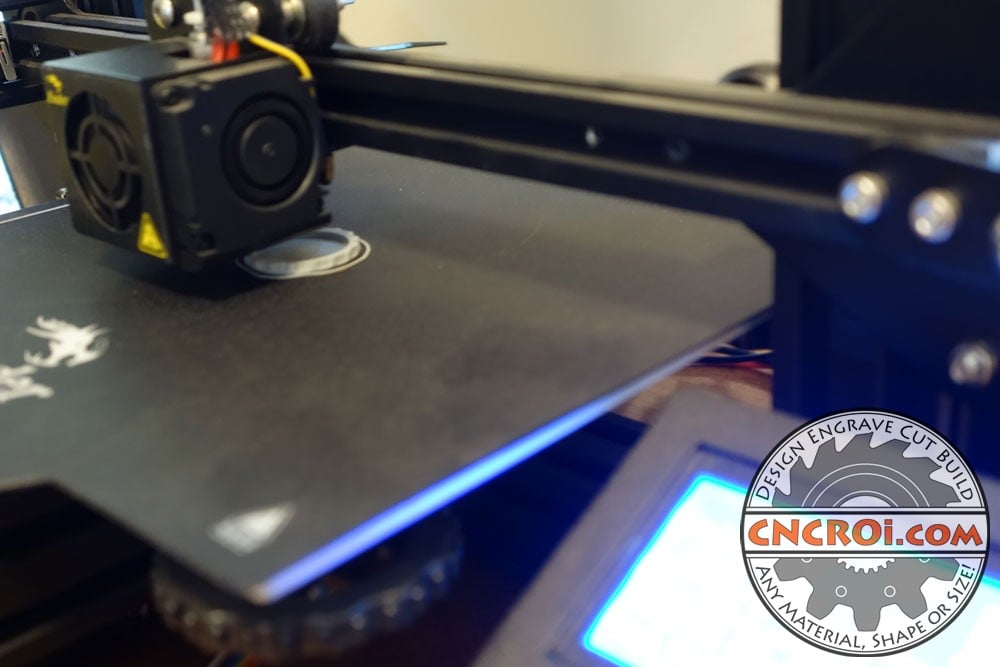

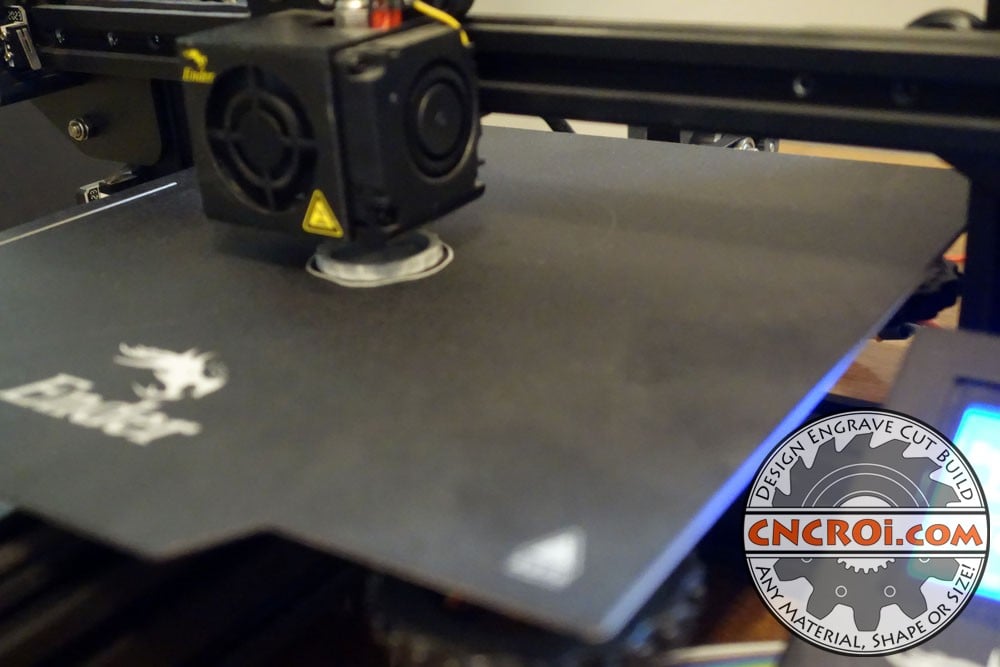

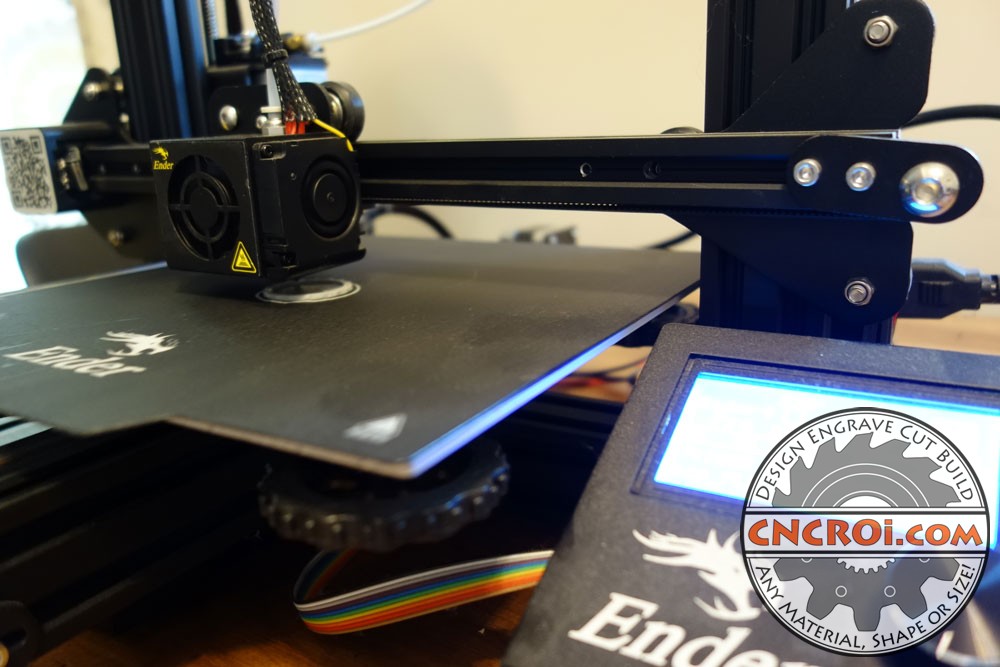

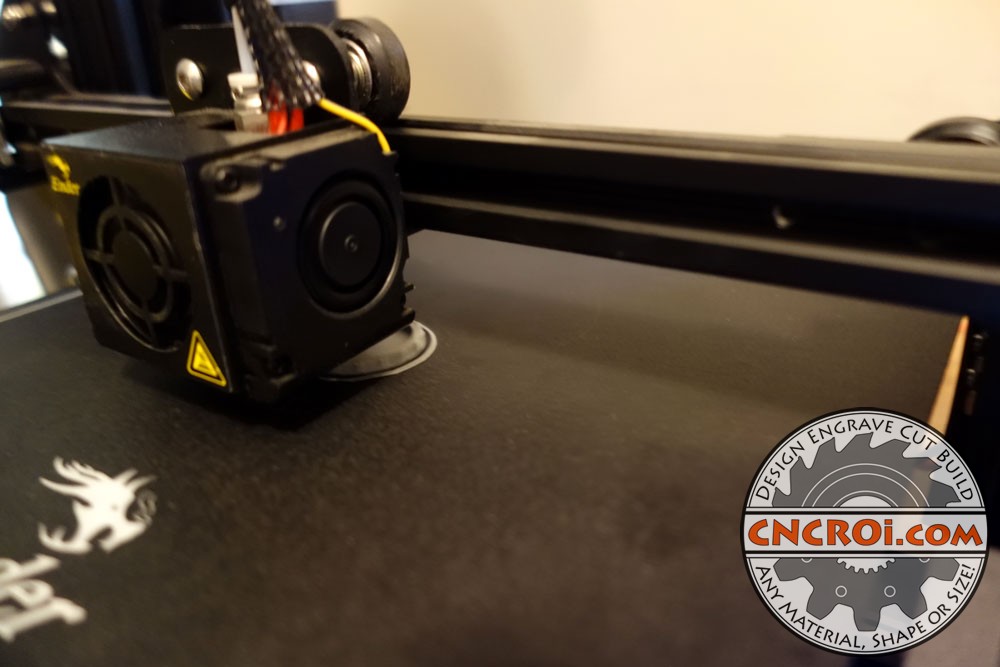

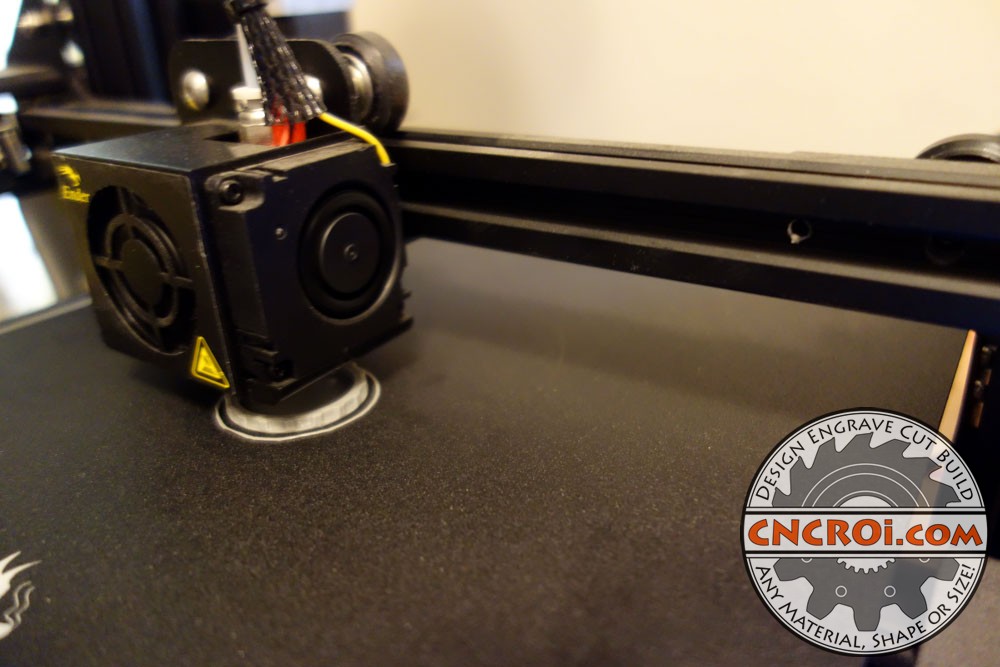

Jon from CNCROi.com decided to return to 3D printing after taking a ten-year break. Back when he first explored it, the technology wasn’t quite where he needed it to be—too expensive, too finicky, and frankly, too frustrating for the grand ideas he had brewing. Fast forward a decade, and the landscape had shifted dramatically. With machines now boasting far better precision, reliability, and affordability, it reignited Jon’s passion for additive manufacturing at CNCROi.com. The videos tied to this project show Jon’s mindset from a decade ago, but with today’s advanced tools, those same ideas finally have the platform they deserve.

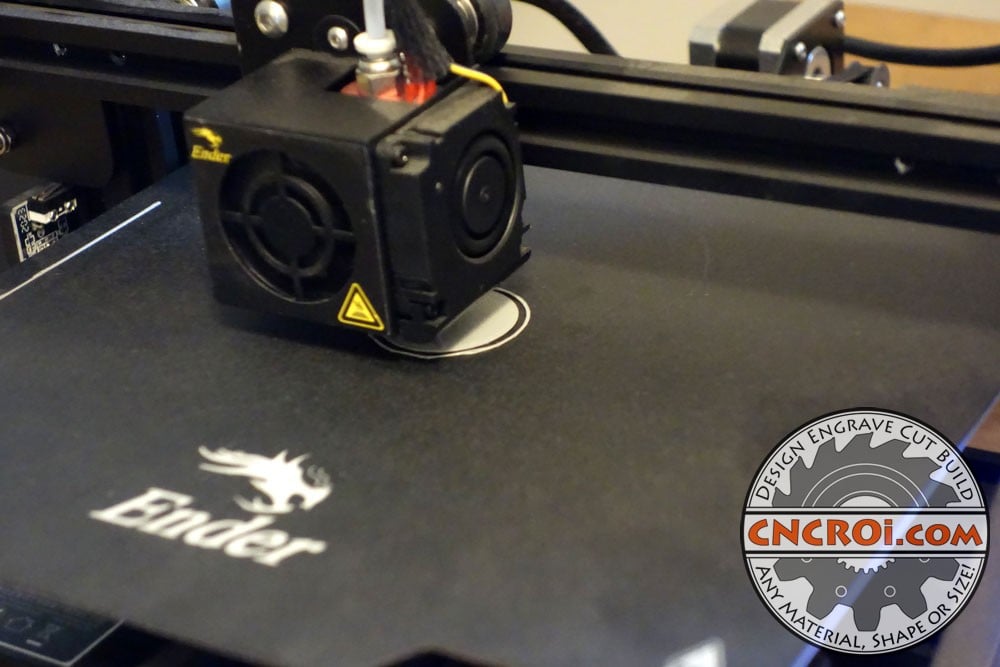

Jon from CNCROi.com found himself facing an interesting customer problem: hundreds of PLA lens caps, all different sizes and thread patterns, needed reliable replacements. Originally, the customer asked if CNCROi.com could fabricate aluminum caps for them. After an in-depth review, Jon concluded that wasn’t the best way forward. Sure, aluminum caps could be precision-made, but the diversity in sizes and the need for small batch quantities would quickly become an organizational and manufacturing nightmare—not to mention costly. The smarter solution was clear: 3D printing PLA lens caps.

Aluminum parts interfacing with aluminum threads would wear out quickly. Even though CNCROi.com could certainly machine each one to perfection, the continual wear and the inefficiency of small-run metal manufacturing would make this a fool’s errand. Jon proposed using plastic PLA lens caps instead. Lightweight, non-damaging to existing threads, quick to fabricate, and best of all, customizable at the push of a button. CNCROi.com’s experience with 3D printing, even from a decade ago, provided the foundation needed to pivot toward this approach seamlessly.

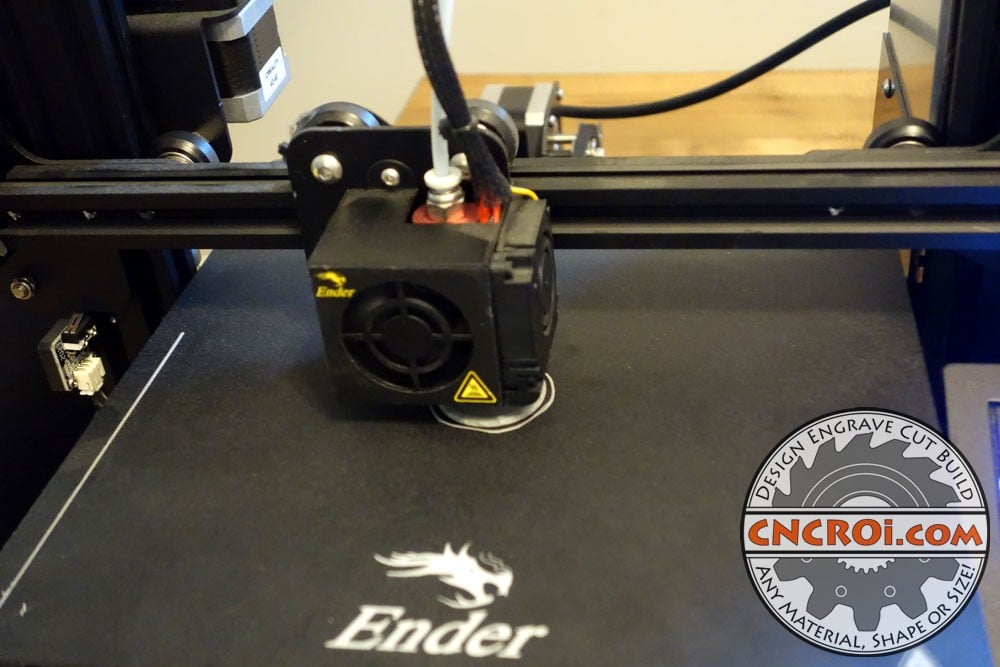

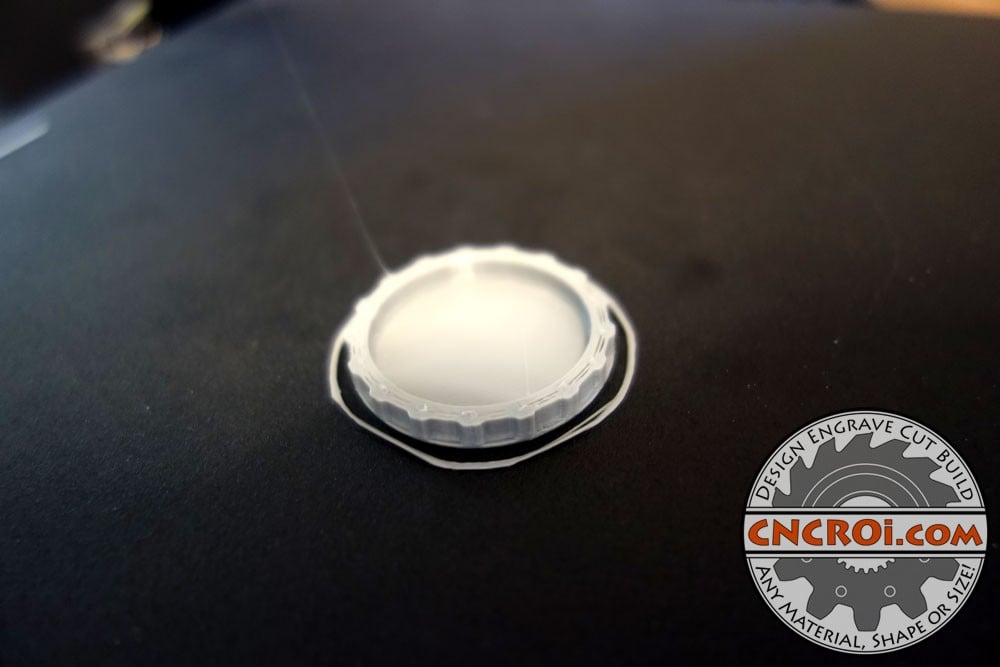

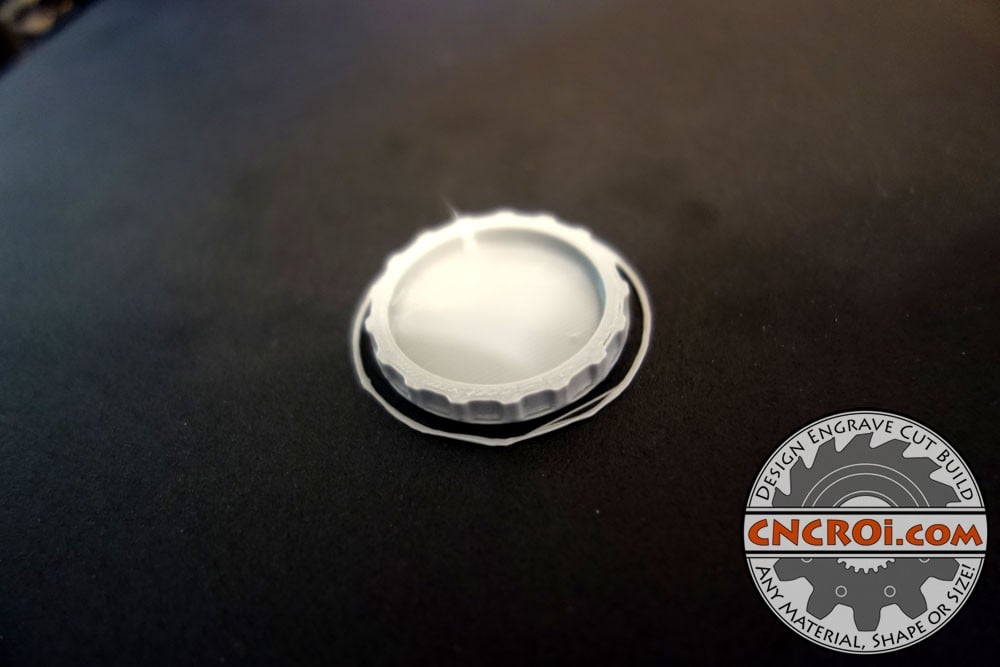

The first test cap was made from PLA, a common 3D printing material. Jon designed it to press-fit into the customer’s aluminum threads, and to his delight, the cap fit snugly without damaging the threads. While the aluminum caps would require absolute machining precision, 3D printing offered a unique benefit: just a slight press-fit was enough. Thanks to the flexibility of PLA and the precision of modern 3D printers, CNCROi.com was able to produce parts that were not just functional but also gentle on the existing hardware.

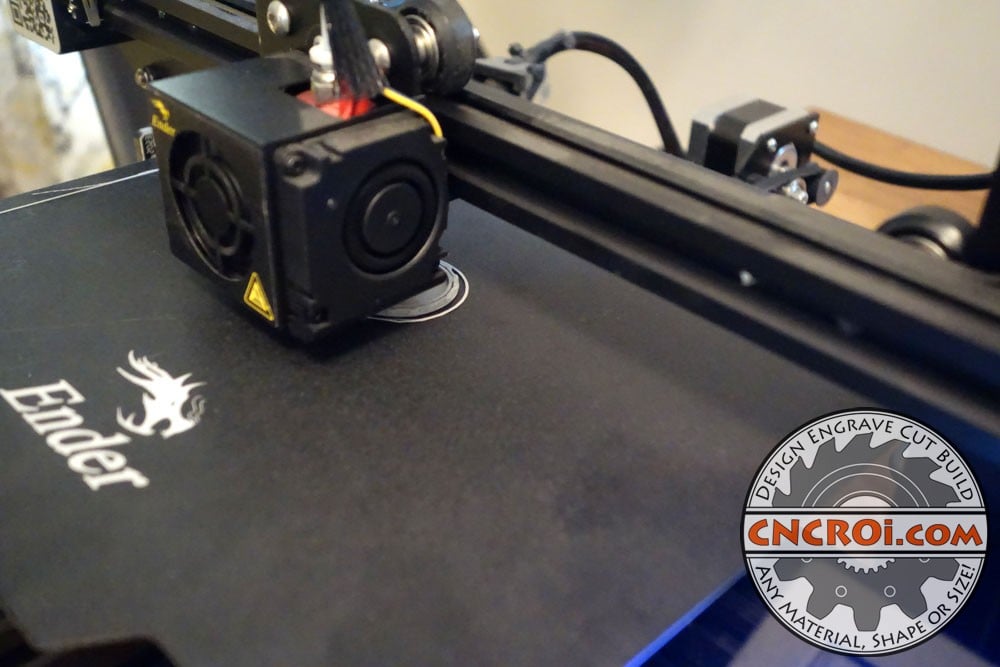

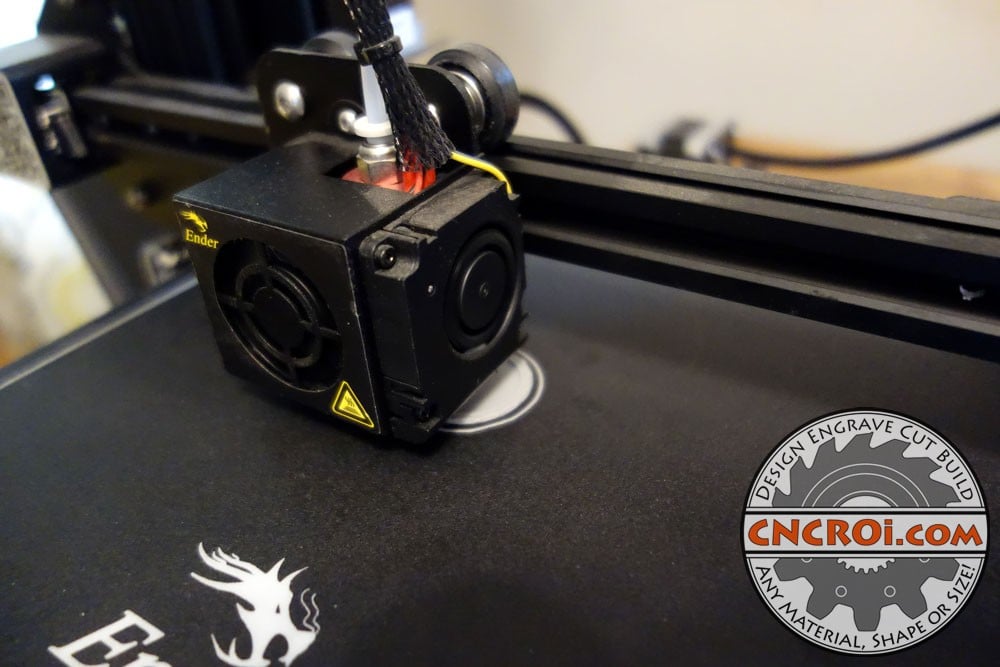

Jon emphasized at CNCROi.com how 3D printing is an additive process, starting at the bottom of a design and building upwards layer by layer. This contrasts with the subtractive methods CNCROi.com also specializes in, such as CNC routing and laser cutting, where material is removed to create the final shape. Each method has its place, but for this particular project, additive was king. The flexibility to tweak designs for tight tolerances without starting from scratch made all the difference.

After confirming that the general tolerances were accurate, Jon moved on to refining specific sizes. Using digital calipers, he measured a PLA lens caps’s internal diameter to 26.2 mm (about 1.03 inches) and adjusted designs accordingly. The resulting parts threaded on smoothly and securely, providing a custom fit that could be easily replicated across batches. However, a new challenge emerged—grip. The initial 3D printed PLA lens caps were perfectly cylindrical, making them slippery and tough to remove once threaded on.

The solution CNCROi.com developed was to add gripping surfaces to the design. These grip-enhanced caps allowed users to easily twist the caps on and off without struggling. Once the internal diameter tolerance was established at around 26.2 mm, adding external grip features like ridges or knurling patterns meant the caps were now both functional and ergonomic. All the customer needed to do was provide two simple measurements: the diameter and the height of the threaded section.

Because CNCROi.com already dialed in the tolerance adjustment needed for PLA’s behavior, producing custom-fit PLA lens caps on demand became remarkably efficient. Instead of managing an inventory of aluminum blanks and setting up CNC mills for each minor size variation, CNCROi.com could print caps as needed with near-zero waste. This on-demand manufacturing model meant faster turnaround times, lower costs, and the ability to easily adapt to the customer’s ever-changing inventory of thread sizes.

One of the major advantages of this approach for this PLA lens caps project, Jon explained at CNCROi.com, is that even an entry-level 3D printer—costing just a few hundred dollars—can achieve incredible precision. Tolerances were consistent even when tests were separated by days, with minor adjustments of just 0.1 mm (0.0039 inches) proving easily repeatable. This level of accuracy allowed CNCROi.com to confidently scale the project, knowing each new batch of caps would perform exactly like the last.

While the 3D printer Jon used was precise, it was also on the slower side. To optimize production speed without sacrificing quality, CNCROi.com plans to upgrade to faster, higher-capacity machines. However, for the initial phases of this project, the focus was squarely on verifying repeatability and quality—speed could come later. A perfect fit was the main priority, and thanks to modern 3D printing advancements, CNCROi.com hit that goal with ease.

Another key advantage for CNCROi.com was Jon’s ability to model parts digitally before fabrication. This digital-to-physical pipeline streamlined prototyping. Within a short time, Jon could tweak dimensions, test fits, adjust grips, and reprint without major downtime. This agility allowed CNCROi.com to solve client problems quickly, ensuring satisfaction while minimizing wasted effort.

It’s important to note that every CNC technology has its strengths. CNCROi.com uses CNC routers for large-scale wood or plastic cuts, fiber lasers for precision metal engraving, and now 3D printers for complex or low-volume plastic part production. Each machine fits into the workflow strategically. In this case, Jon knew 3D printing was not just an option; it was the best option by far for the customer’s PLA lens caps needs.

At CNCROi.com, it’s all about matching the technology to the problem, not forcing the problem to match the technology. If the project had required metal-on-metal wear resistance, aluminum might have remained on the table. But for protecting delicate threads, keeping costs down, and adapting to dozens of unique part sizes, 3D printed PLA lens caps were the ultimate solution.

The beauty of 3D printing at CNCROi.com is the scalability. Need one PLA lens cap? No problem. Need ten? A hundred? Easy. It’s just a matter of starting more prints or setting up a small production queue. Jon emphasized how this flexibility is nearly impossible with traditional subtractive manufacturing unless you have extremely deep pockets or infinite patience—neither of which most customers are thrilled to offer.

Another often-overlooked benefit of additive manufacturing is the ability to iterate designs quickly. If CNCROi.com needed to modify the grip texture, thread start point, or even add logos to the caps, it could be done digitally with minimal impact on the production timeline. Traditional machining would require expensive retooling, jigs, and possibly reprogramming CNC machines for each small change.

Jon noted that while additive manufacturing isn’t perfect for every project, it’s uniquely suited for custom, low-volume, and complex parts like these caps. CNCROi.com has spent years refining an approach that doesn’t marry itself to one method but leverages the best aspects of many technologies. Whether it’s CNC laser cutting, CNC routing, waterjetting, fiber engraving, or 3D printing, the right tool is chosen for the right job.

Thanks to Jon’s decision at CNCROi.com to 3D print these parts, the customer now has a cost-effective, efficient, and scalable solution. No need for massive aluminum stockpiles, no need to worry about machining errors or misfits. Just precise, functional caps that protect the original threads without wearing them out or making them difficult to use.

The feedback from the customer was overwhelmingly positive. They were thrilled not only with the quality and fit of the parts but also with the speed at which CNCROi.com was able to deliver them. Instead of months-long lead times typical for custom metal work, they had functional prototypes within days and full batches shortly thereafter.

Moving forward, CNCROi.com is exploring even more material options for 3D printing projects, including flexible materials like TPU for impact resistance and stronger options like PETG for tougher environments. Each material opens up new possibilities for custom projects tailored precisely to customer needs.

CNCROi.com is also planning to expand its 3D printing services into multi-material printing, combining hard and soft plastics into a single part where needed. This opens up opportunities for even more creative solutions that blend flexibility, durability, and custom geometry—something subtractive manufacturing can rarely achieve easily.

Jon emphasized again that CNCROi.com isn’t abandoning traditional CNC manufacturing anytime soon. There will always be projects better suited for laser cutting, waterjet cutting, CNC routing, or fiber laser engraving. But adding serious 3D printing capabilities allows CNCROi.com to offer customers an even wider toolbox of solutions.

At the end of the day, CNCROi.com’s mission is to solve customer problems effectively. Whether it’s one part or a thousand, simple designs or complex geometries, metal, plastic, or anything else, the priority is delivering high-quality results efficiently and affordably. 3D printing is just another powerful weapon in that arsenal.

Jon encourages anyone facing manufacturing challenges—whether they involve replacement parts, custom assemblies, promotional items, or even fully customized products—to reach out to CNCROi.com. The team thrives on creative challenges and is always ready to find the best solution, even if it involves blending multiple technologies.

In the modern custom manufacturing world, versatility is king. CNCROi.com has the experience, equipment, and creativity to bring ideas to life, whether through CNC routing, fiber laser engraving, or, as proven here, highly detailed and accurate 3D printing. Contact CNCROi.com today to make your next project a reality.

As CNCROi.com continues to expand its service offerings, integrating more advanced 3D printers capable of faster speeds, higher resolutions, and broader material compatibility is a top priority. This ongoing investment ensures that customers can always rely on CNCROi.com for cutting-edge solutions tailored exactly to their specifications. Whether a project demands the heat resistance of ABS, the flexibility of TPU, or the toughness of PETG, CNCROi.com can match the perfect material to the perfect application without compromising quality or functionality.

Jon and the team at CNCROi.com firmly believe that manufacturing should be exciting, accessible, and innovative. They are passionate about making the impossible possible, whether it’s through layering dreams one filament at a time or carving reality out of solid material blocks. If you have an idea—whether it’s a single part or a complete system—CNCROi.com is ready to bring it to life with a mixture of experience, creativity, and the right CNC or 3D printing technology. Reach out today and see just how far your project can go.

Have a custom project in mind? Contact CNCROi.com right now!