Fiber Laser Annealing VS Marking

A common question I get when talking to CNCROi.com clients (potential and current) who need some industrial annealing or marking of various items including custom laser cut tags is “what’s the difference between annealing and marking?”

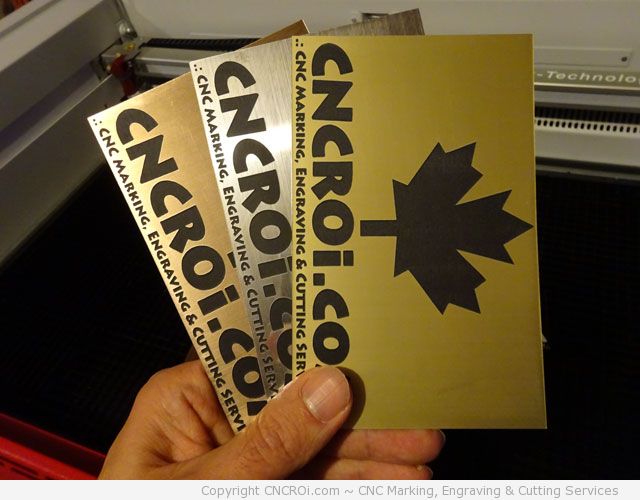

Steel (stainless in this case) annealing on the left costs more and takes longer to do but is more visible than marking.

From the above image, annealing looks a lot darker – it’s actually black – than the marking but this comes at great cost both financially and time wise. There is also a lot less tolerances involved with proper annealing when compared to simply marking. Generally speaking, the vast majority of applications can “get away” rather successfully with simply marking the metal instead of annealing it and sometimes it’s very hard to tell the difference when doing this at a very small scale.

If you contracted CNCROi.com to make machine tags at the back of your machines, something that may be viewed rarely, we sometimes suggest a laser setting in between annealing and marking, you get a darker marking but without the large expense of actual annealing though viewing angles does suffer by comparison. Annealing is black from all angles (light depending) while marking requires slightly more rotation to view properly but both are visible if you are looking for the industrial marking.

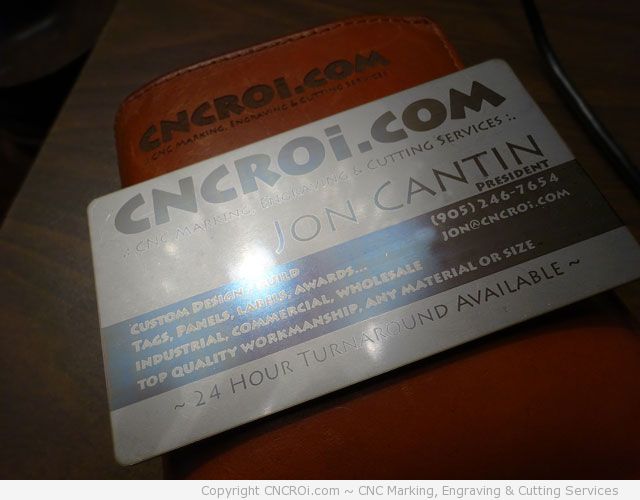

Annealed 304 Stainless Steel business card.

For applications such as part numbers where cost is a major issue, generally, marking is more than fine as, like the back of a machine, these are rarely looked upon but nice to have when it comes to ordering more of the same. So, what application would annealing be a worthy expense? Well, where visibility 100% of the time is absolutely essential – think steel house number plaques, life or death medical equipment identification, official commemorative plaques. If your applications requires annealing, you generally know it right away. Regardless of which process you decide upon, keep in mind that both laser fiber annealing and marking are permanent.

Of course, we have produced a video for your viewing pleasure to see both processes yourself!