Flatbed Printer Jigs: CNC Laser Cut Formica & MDF

CNCROi.com has a growing customer list requiring custom flatbed printer jigs because we can literally cut any material into any shape, any thickness for just about any specialized application you may have in mind.

Like all our other services that we provide, making custom flatbed printer jigs is something we use both internally for our own customers and externally for those with waterjets, UV printers, routers, flat

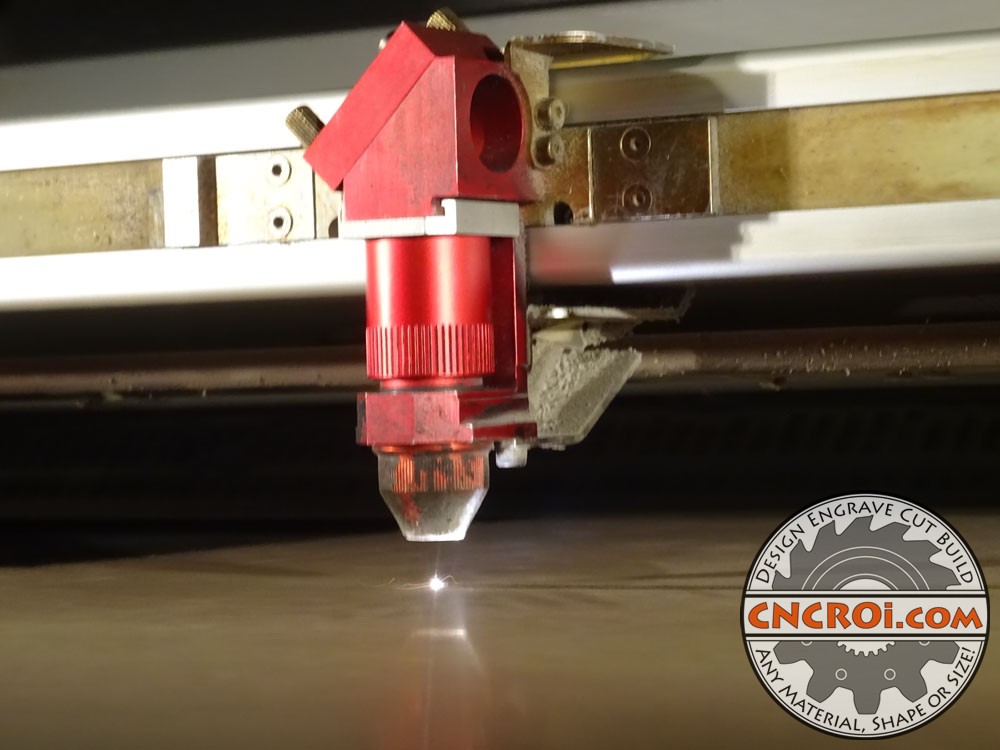

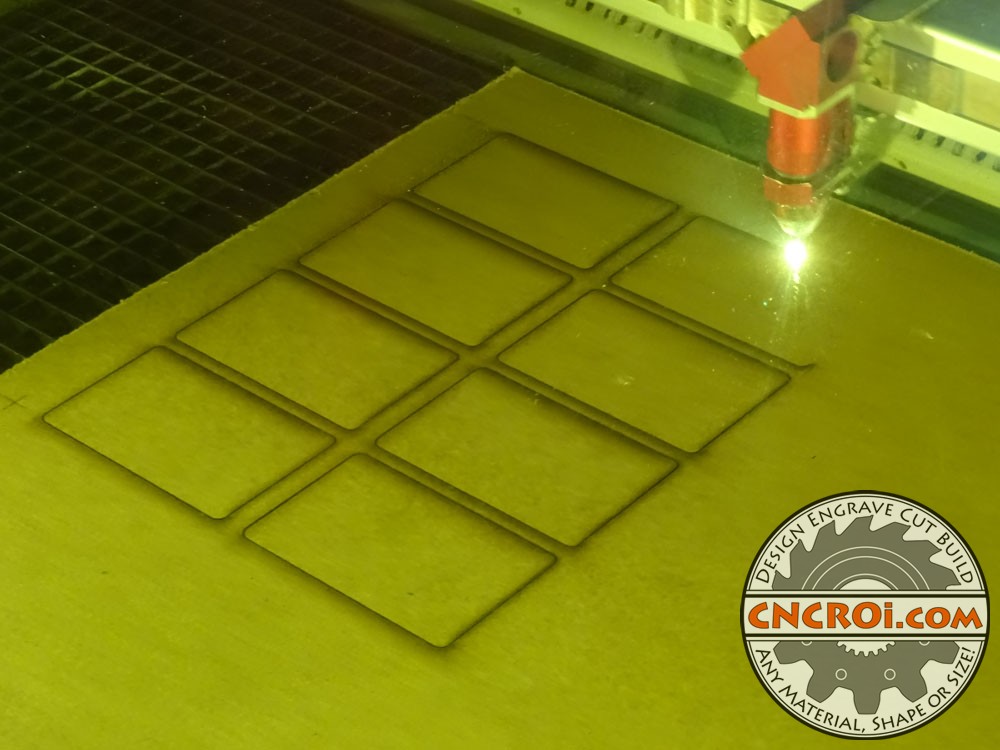

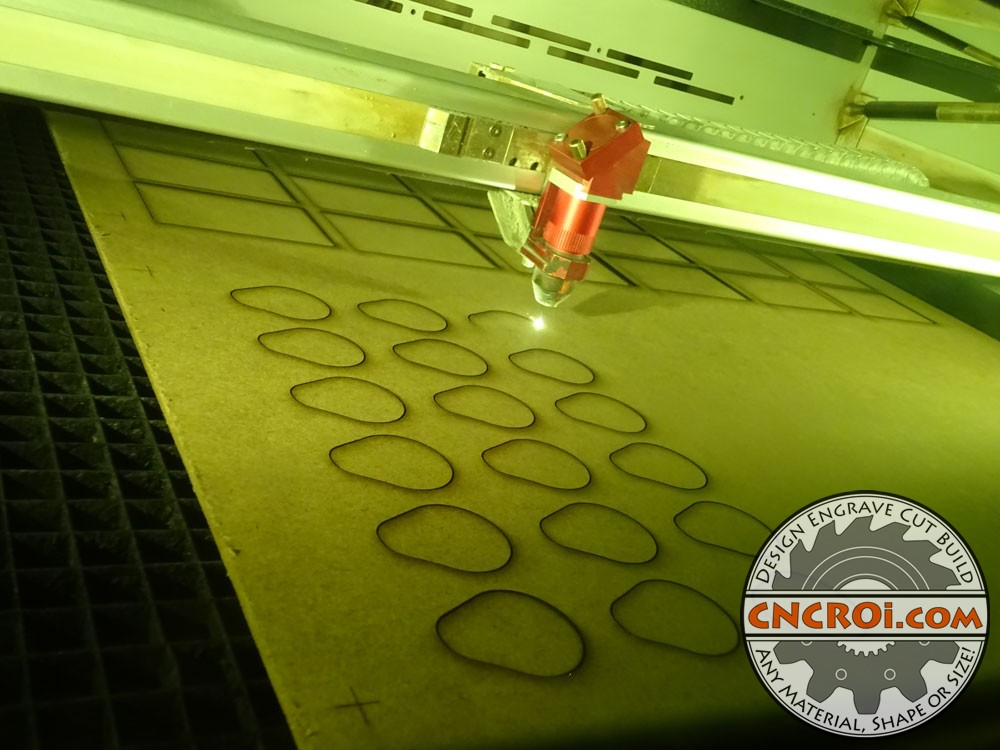

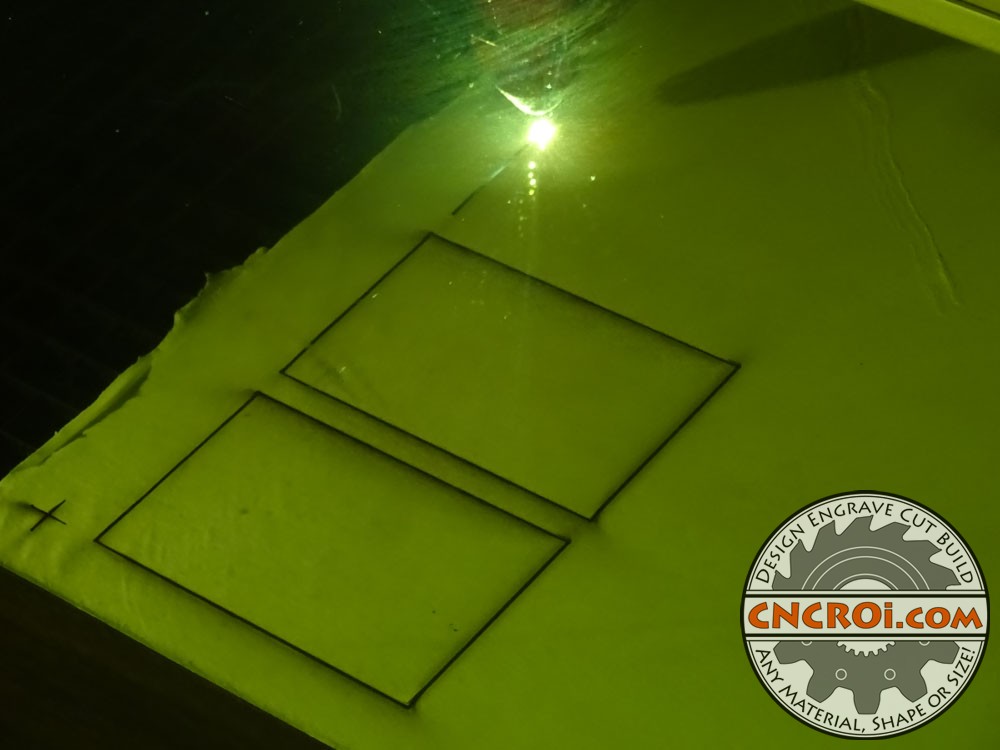

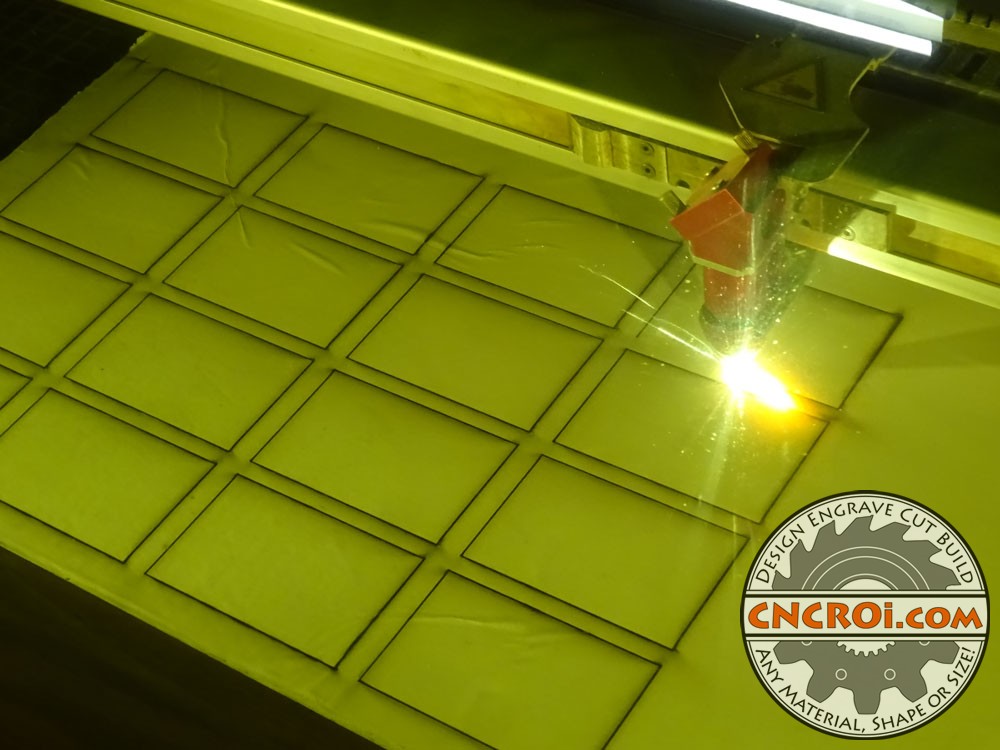

I take a lot of photos here and out of the thousands I’ve posted on CNCROi.com, the above is really one of my favorite, luck and opportunity made a really nice photo of a laser cutting something!

Acrylic makes for a wonderful jig material, each has their plus and minus but we’ve moved most of our internal jigs to MDF as over time, we’ve found they last longer and can be produces more cost effectively than acrylic.

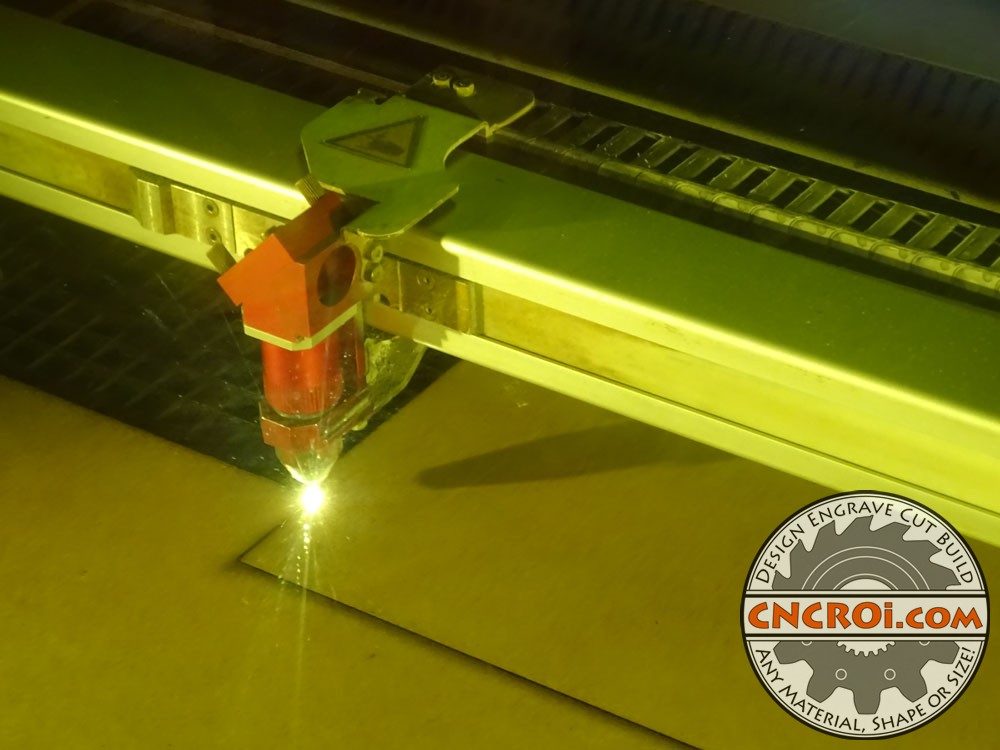

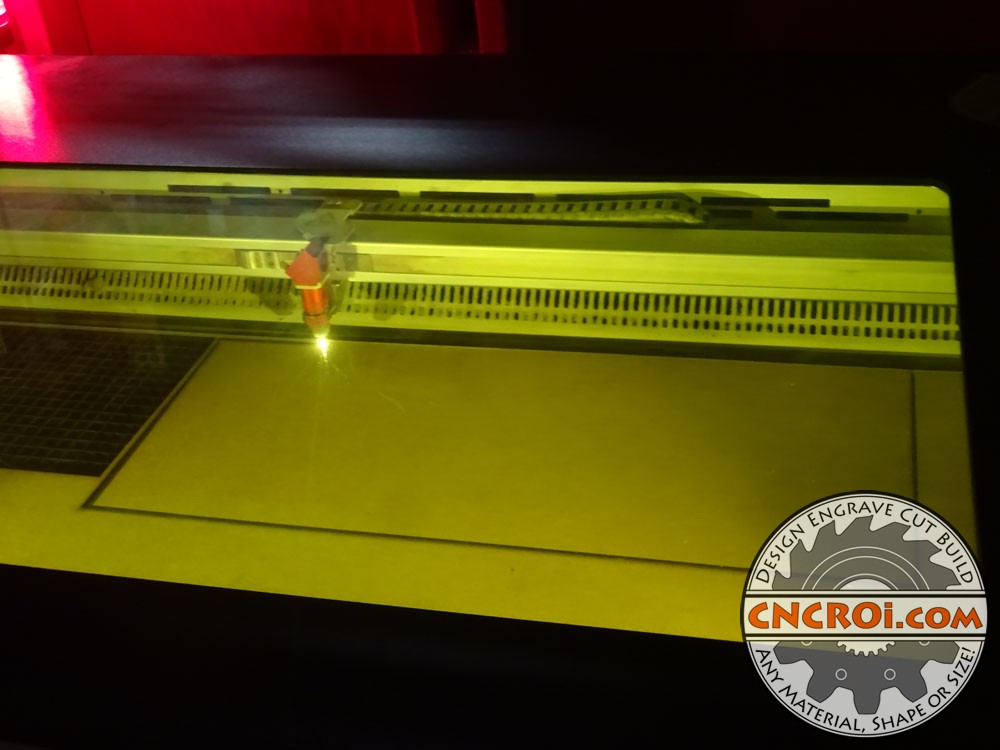

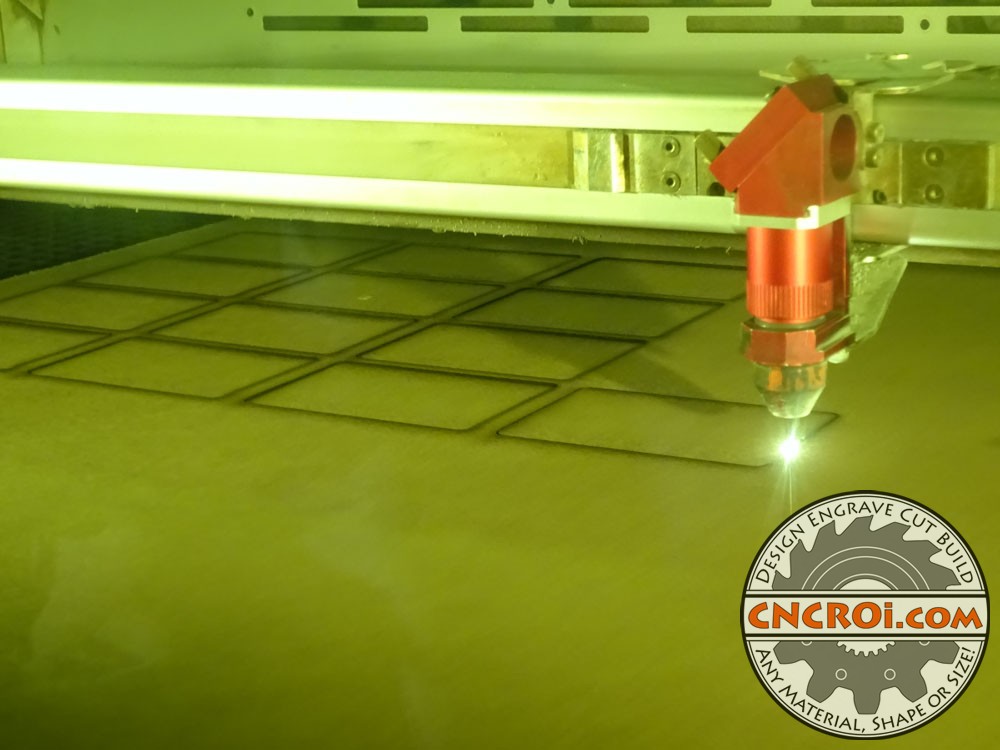

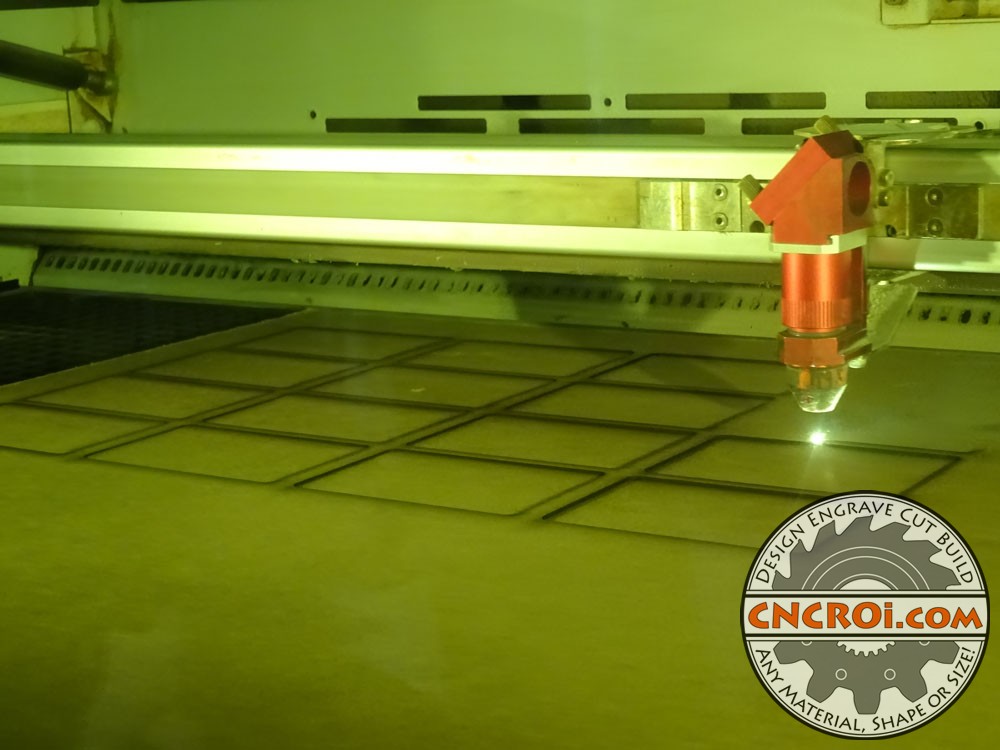

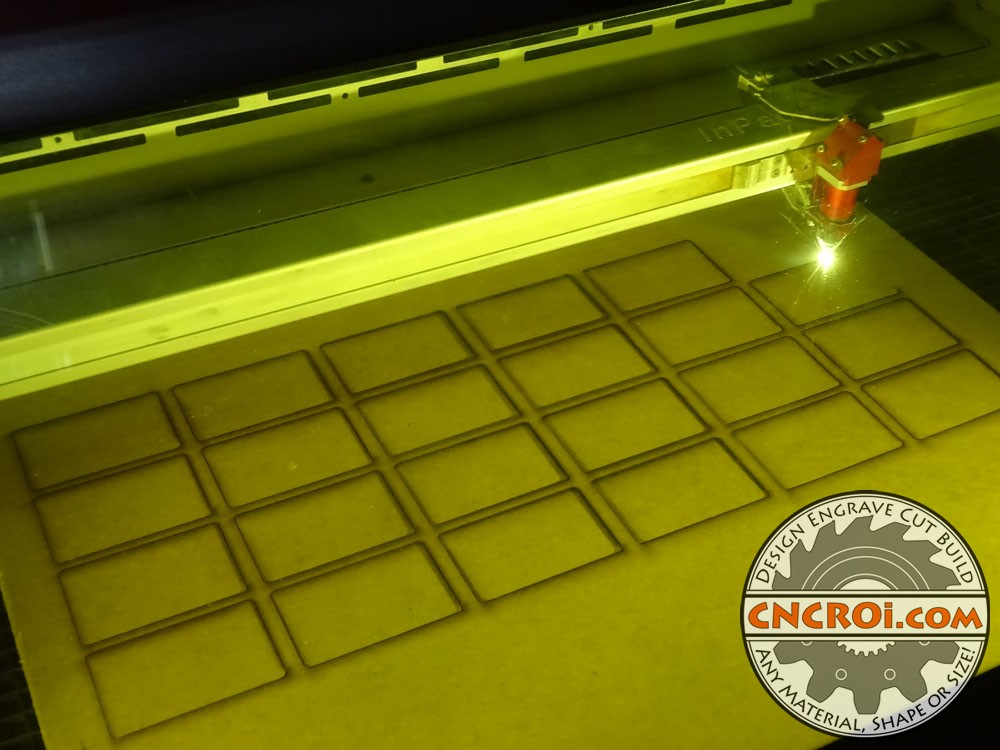

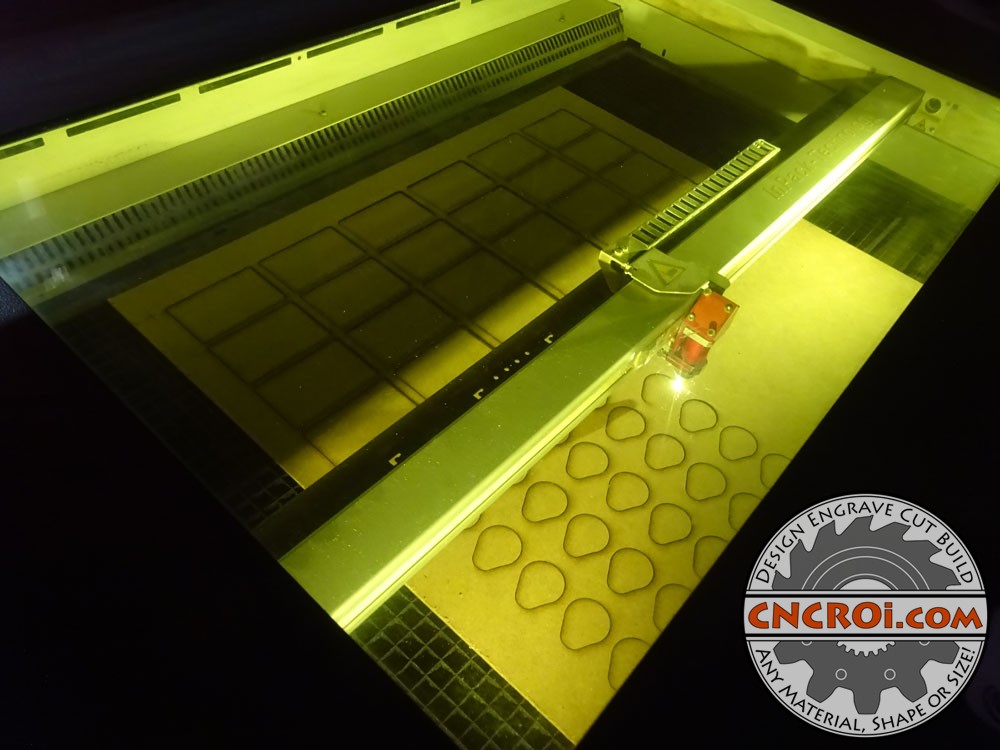

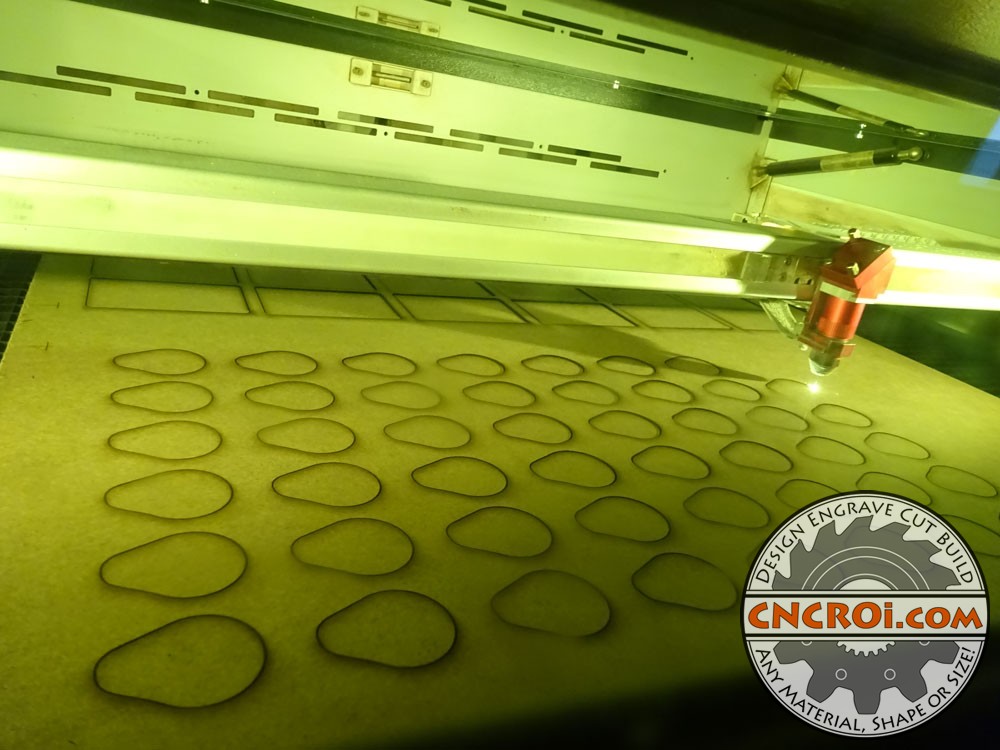

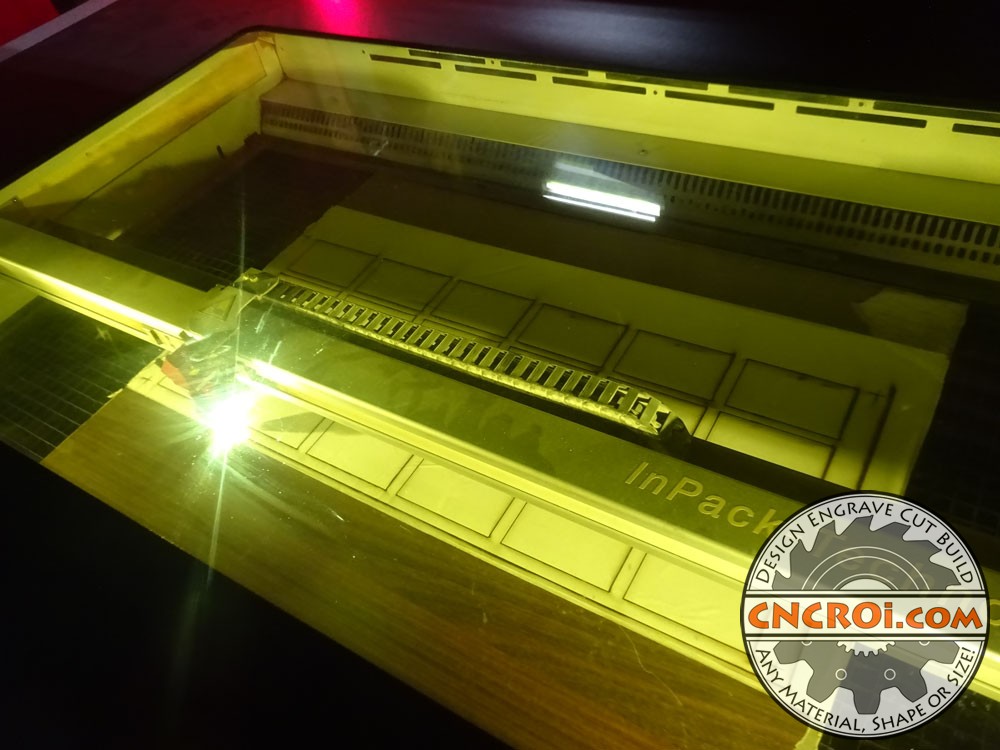

In this case, we are using 1/8″ or 3 mm MDF to produce the bottoms of the custom flatbed printer jigs we are making for a UV printer business that uses our jigs for their entire operation.

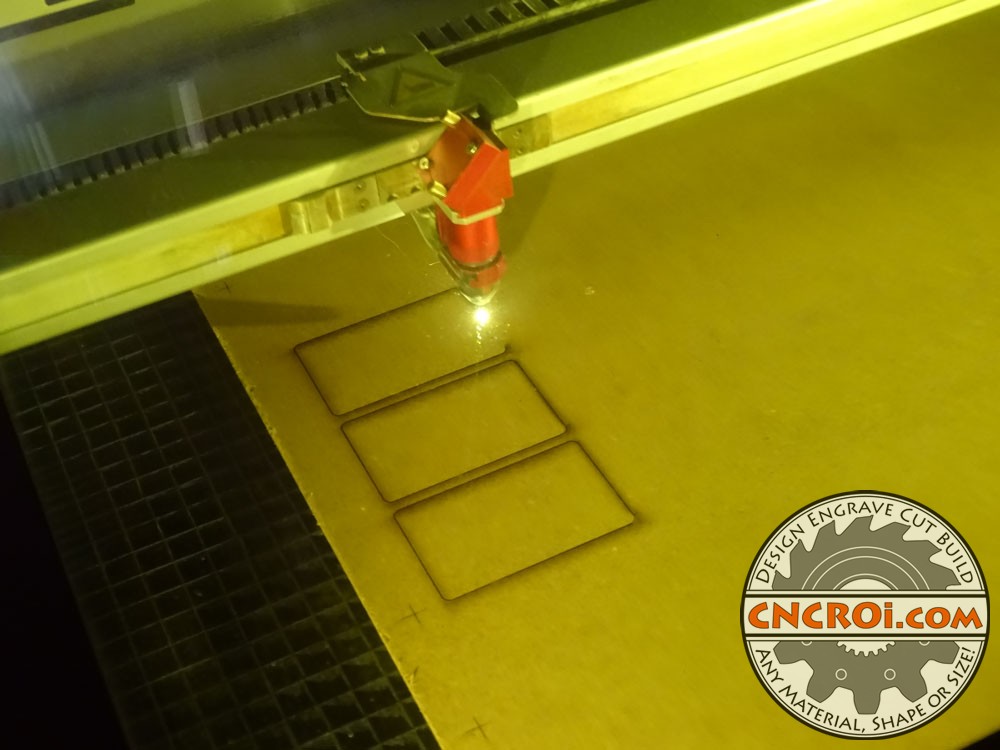

It’s easy to tell the bottom part of most jigs with the top, the bottom is generally flat with only an outline cut out while the top part you see below will have the outline and all the inside parts cut out of the custom flatbed printer jigs.

CNCROi.com can make custom flatbed printer jigsusing a variety of materials, from Corian through Delrin, plywood and MDF, even polycarbonate and Formica as you’ll see in this blog post.

Literally and shape you can think of, CNCROi.com can cut it out for use with your UV printer or other imprint technology.

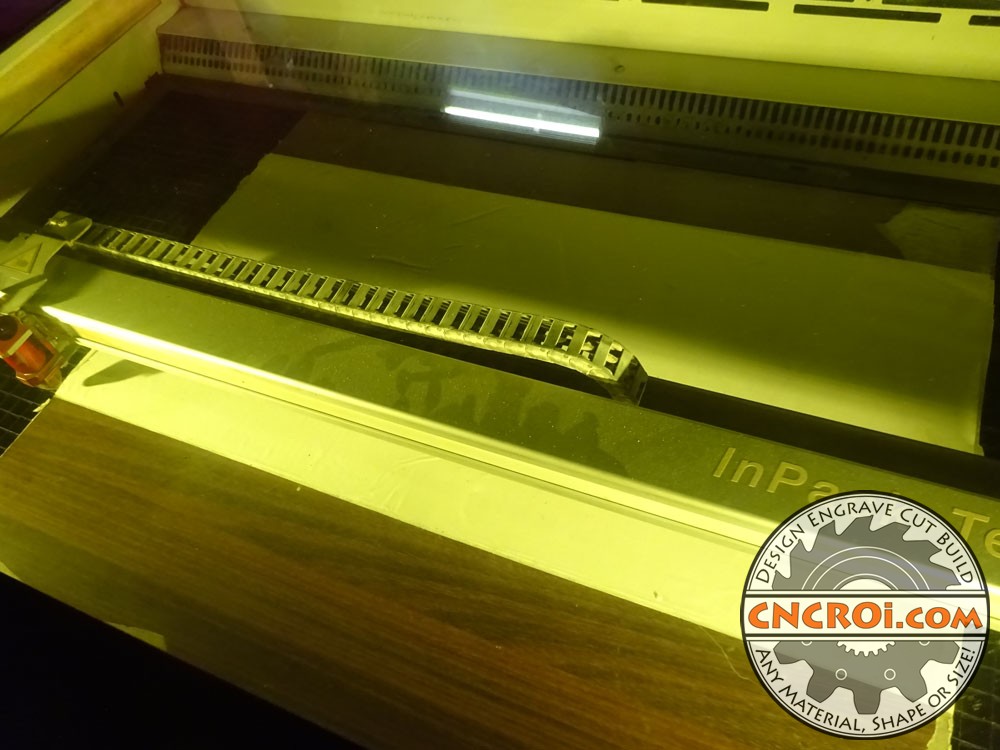

Cutting out custom flatbed printer jigs is a pretty straight forward process, we get the digital files from the customer and then convert it into a format CNCROi.com can use with our Austrian wide-format industrial CNC laser.

After the mock-up is approved, the custom flatbed printer jigs can then be cut out using whatever material at whatever thickness our customer requests and fits within their budget and timeline.

We often produce custom flatbed printer jigs with unique features for our customers, from dimensional information and branding so they know which jig is which hanging on the wall through specialized cuttings to suit various variations in part formats.

Jigs big or small, CNCROi.com makes them all!

We also produce custom flatbed printer jigs glued together or not, it all depends on what our customer wants us to make on their behalf.

What I especially like about making custom flatbed printer jigs for our customers is the sheer number of different products our customers come-up with for us to make a jig from, it’s as much fun making these jigs as guessing the part that goes into it.

What I tell all my CNCROi.com customers requesting custom flatbed printer jigs is to make the part fit perfectly digitally and then use the laser (if that’s the tool we use) vaporizing beam width on the line as your “give”.

Things to keep in mind when it comes to custom flatbed printer jigs is to give yourself room for tabs so you can easily grab the products from the jig.

When it comes to custom jig production, we are as much our own customer as a supplier to others who have come to reply on us to produce top quality jigs for their specialized applications.

And of course, get CNCROi.com to make more than one copy, that way, you can work on filling up or emptying the custom flatbed printer jig while the other is being worked on by your machine.

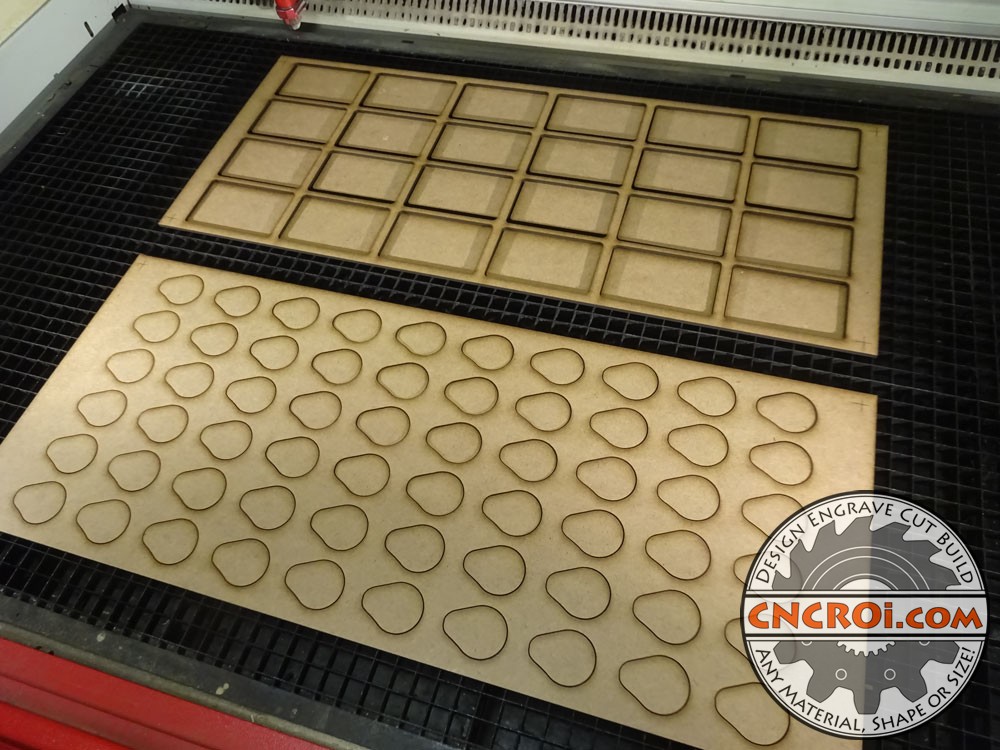

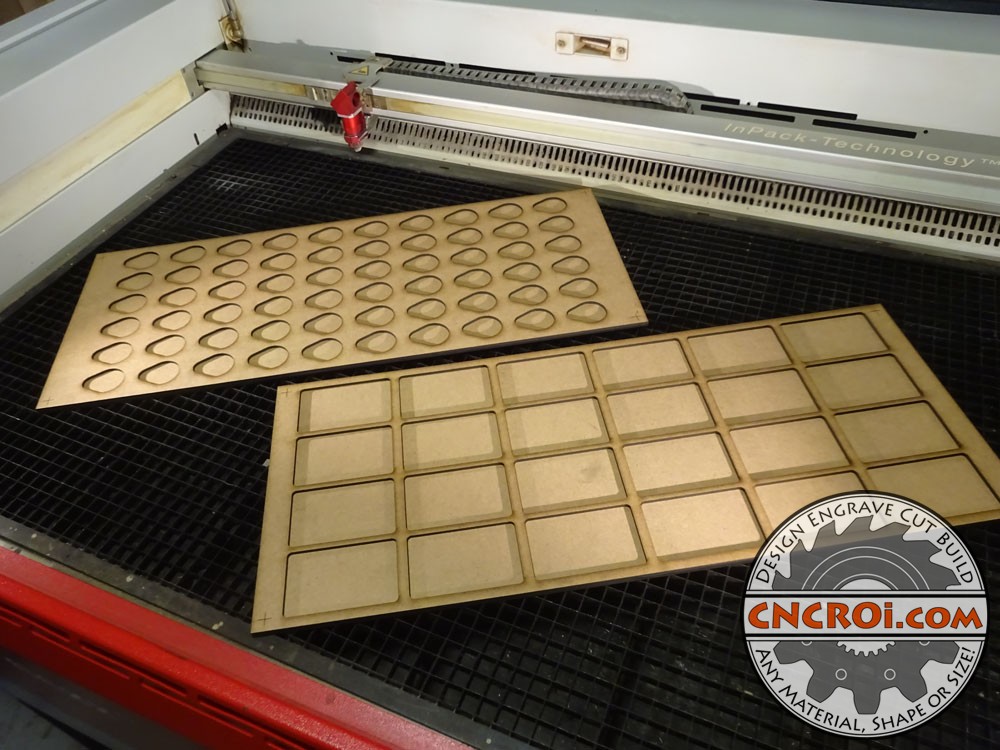

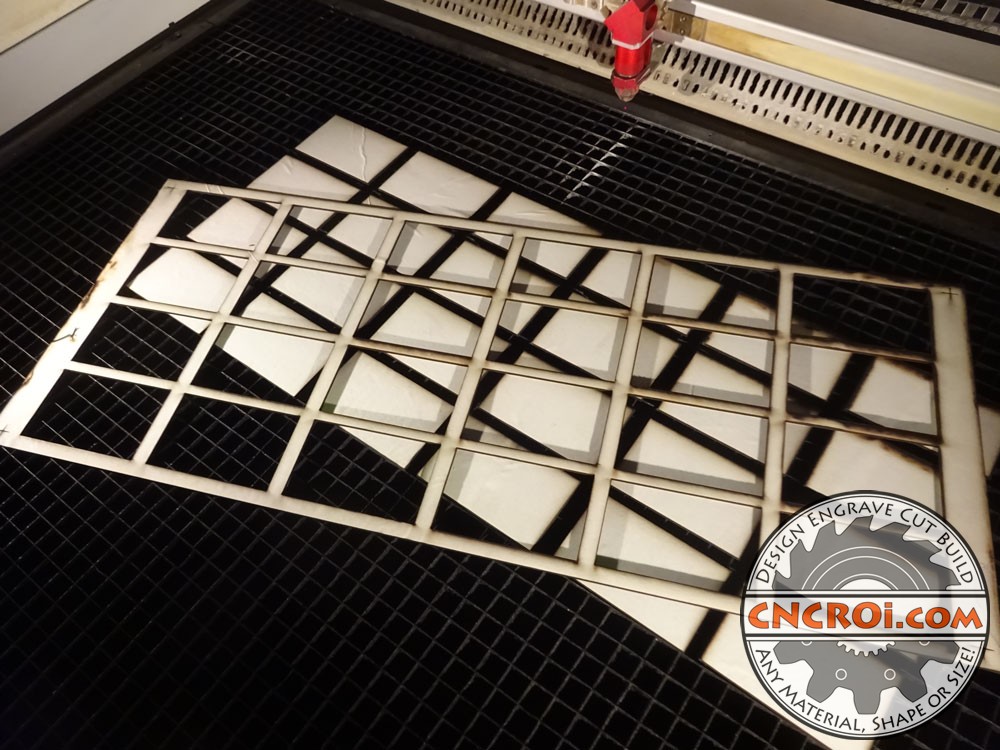

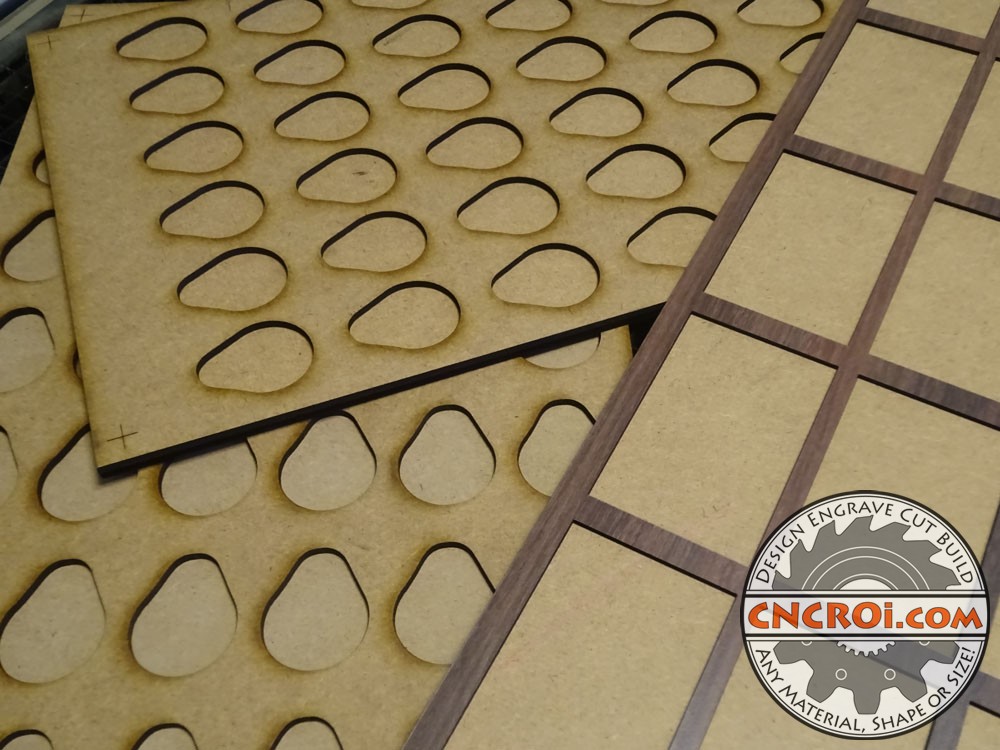

Here’s what the custom flatbed printer jigs look like after they have been CNC laser cut (in this case) out of 1/8″ or 3 mm MDF.

Removing the jig tops reveals the cutouts that our Austrian wide-format industrial laser cut out, this is scrap material that will find its way into our fire pit.

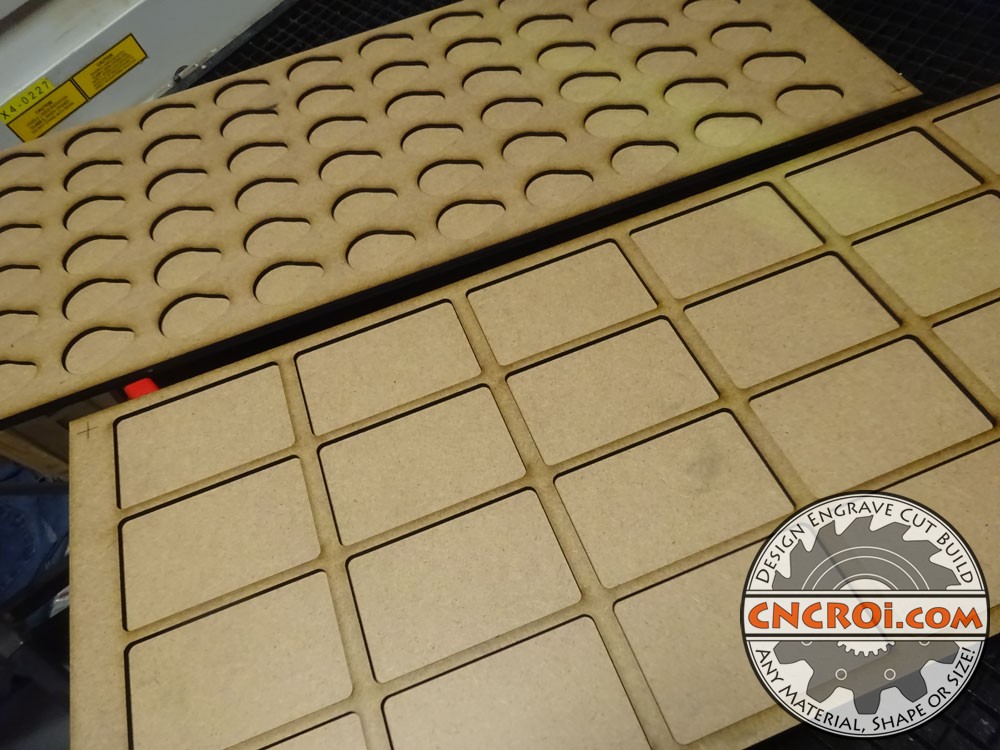

Doing a quick fit, you can see how the custom flatbed printer jigs fit perfectly because both were laser cut using our machine.

Looking at the MDF jigs from another angle, you can see how the top and bottom parts fit perfectly.

Generally all the inside parts of our jigs end-up going to our fire pit, so nothing is wasted as the heat generated is greatly appreciated at night with family and friends.

Our customer had a special request for a top part of the custom flatbed printer jigs, what they are UV printing is very thin and as such, a 1/8″ or 3 mm “top” would be too thick, so something half that thickness would be needed.

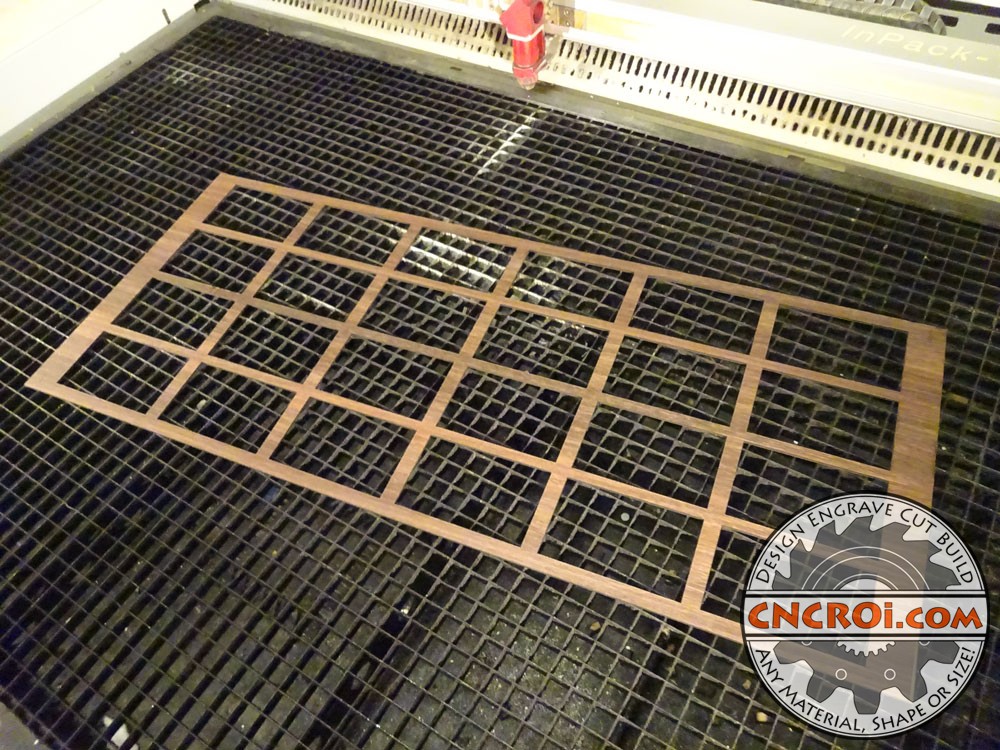

There were a number of options I looked at, there is steel CNCROi.com could cut using the waterjet or plywood veneers but at the end, I decided to use Formica as it’s strong, easy to clean and pretty strong stuff at this very thin gauge (thickness).

You really need a powerful CNC laser to cut through two layers, back to back, glued together, of Formica and luckily, CNCROi.com has just such machine.

CNCROi.com has a full wood and metal shop, as such, we do a huge variety of projects and jigs have become indispensible towards our goal of creating custom methods of mass production.

We couldn’t use waterjet to do this as the pressured water tends to separate laminated work, the laser was the best choice for these custom flatbed printer jigs.

Now that the Formica was CNC laser cut to perfection, it was time to remove the masking and yonder at the amazing capabilities CNCROi.com has for our customers far and wide.

This Formica custom flatbed printer jig looks amazing, perfect mix of strength and durability.

Taken as a whole, this was a good run of custom flatbed printer jigs for our customer, as we grow in capabilities and materials, CNCROi.com is here to help you with all your custom jig needs!

Want a custom jig made custom to your spec by a passionate company that lots making them for you and ship right to your door?

Contact CNCROi.com right now!