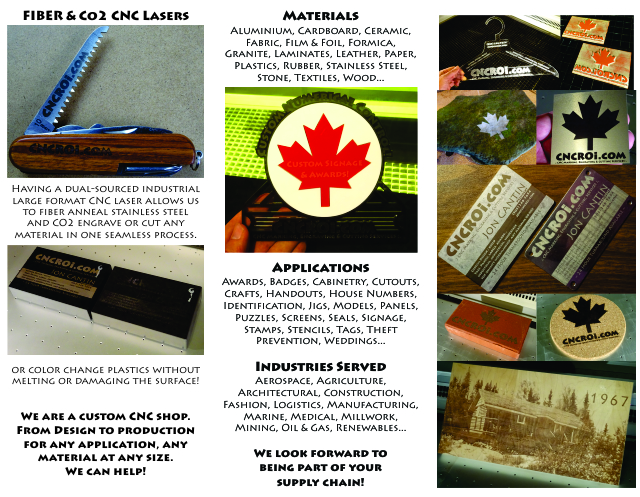

Formica Inlays (engrave & cut sharp inner corners!)

The millworking industry has been good to CNCROi.com as we expand the capabilities that our customers have beyond using a CNC router.

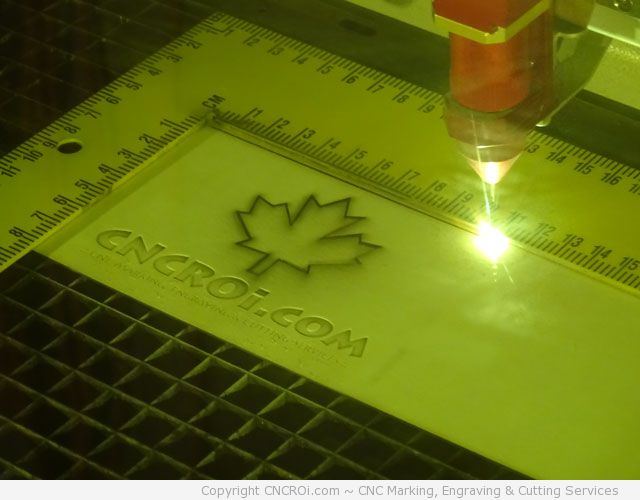

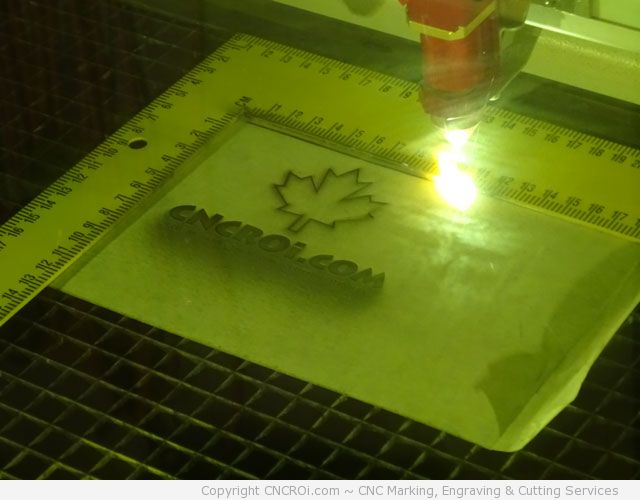

CNC routers are awesome machines, no millworking shop can exist today on a commercial-scale without them, we have one too, but they do have disadvantages by design, the round bit used for cutting. That very fact, regardless of how “small” your bit is, produces round inner corners, using CNCROi.com’s wide format Austrian CNC laser, that issue is no longer one. This is PERFECT for SHARP corporate logos, SHARP text and even Formica inlays (or inlays using any other materials).

At CNCROi.com though, we take thing further… like the capability to not just cut Formica several meters long and a meter wide but also engraving it! Yep, we are able to engrave Formica using our industrial CNC laser!

Now, you may ask yourself, why would you want to engrave Formica? Well, for installations, we can great tabs so your “part number” can be quickly sorted for complex installations or murals. The good thing about Formica is how brittle it is, these can be easily broken off upon installation into the right place.

We are also able to precisely cut Formica into any shape you require, whether it’s a thousand round circles or a complex silhouette that would make even Pablo Picasso question your sanity. Not only that, they will all be identical and if you really want to go nuts, we can then engrave each one with a unique alpha numeric or anything else you throw at is found in a database. CNCROi.com truly frees your creative spirit!

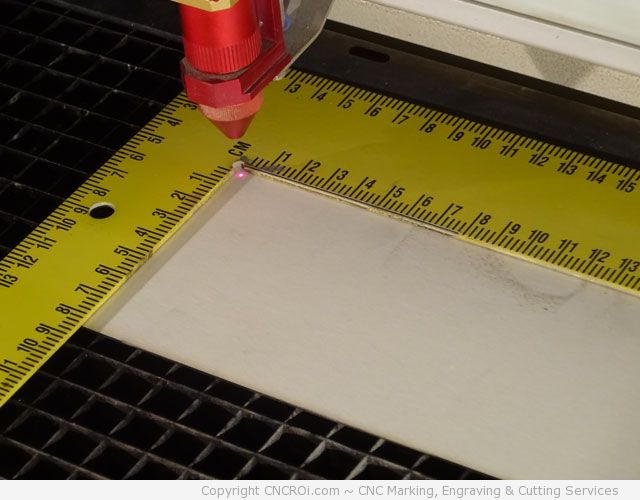

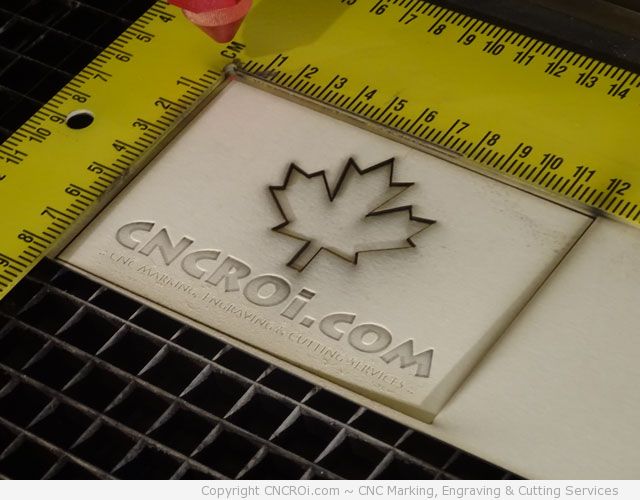

Looking at the above picture, you might say “that looks horrible, I don’t want that on my counter top or on as part of a wall. True, but we applied a mask on this bad boy, so all the smoke damage and soot you see in the above picture is easily removed by us or on-site (it protects it from scratches during transport) and the results, well, they are BEAUTIFUL!

Please note that I forgot to remove the masking in the inner parts of the engraving underneath with the smaller letters, that’s why they look a bit odd. This is WHITE Formica, as you can see, all that nasty stuff is GONE and the Formica is still white!

You can see a part of the masking still on the “O” part of the .com in the above picture. The engraving process obliterated the upper laminate, leaving the bottom there completely intact.

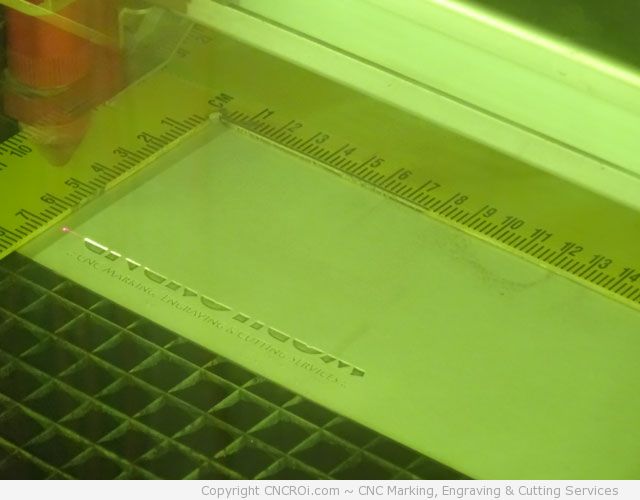

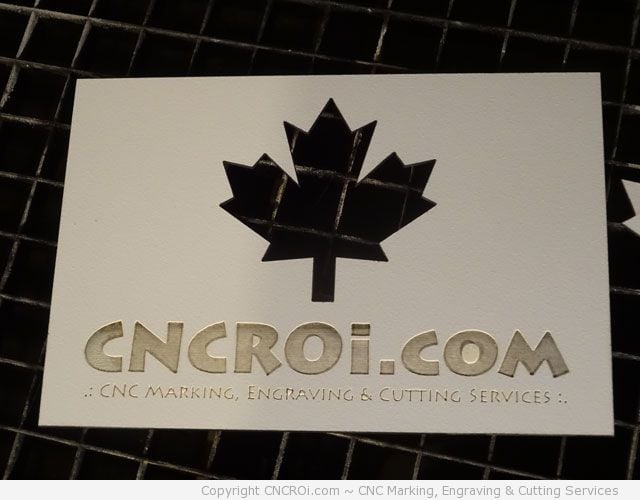

Looking more closely, you’ll notice the maple leaf, what you see here is IMPOSSIBLE to do with a CNC router, the corners are dead-on SHARP, but let’s take an even closer look and see how they fit into one another.

That’s less than a mm of material removed all the way around the maple leaf cut through the Formica. I also had some black Formica in the shop so let’s do the exact same file again using that and compare the two shall we?

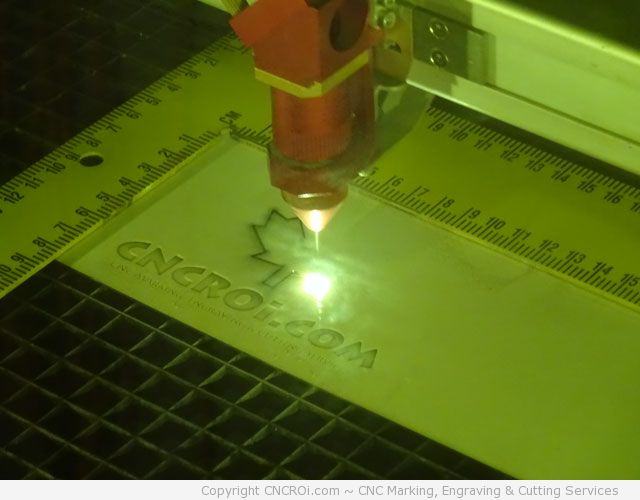

The cutting process was very much the same, you can really see the BLACKNESS of the Formica coming out onto the masking, this is why cutting Formica is a specialized process, you need an industrial machine for precision and to quickly handle all the debris flying around. The optics in our machine are well protected and we have premium features built right into our Trotec Speedy 400 flexx machine that allows us to do what most shops would run away from. A powerful extraction system and gas kit!

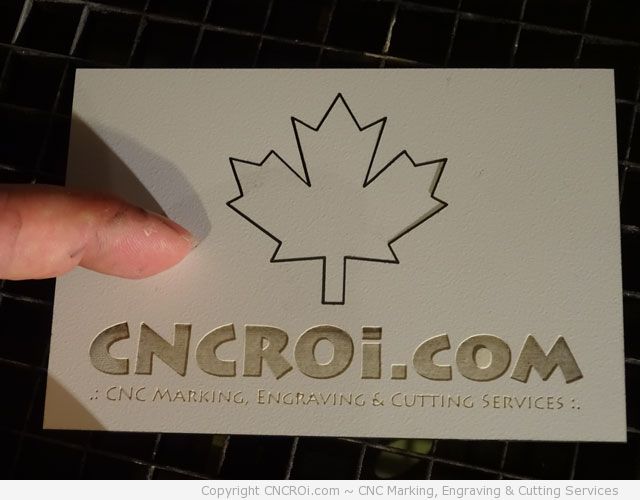

So, putting the maple leaf of the black Formica into the white Formica, creating an inlay in the process, shows you how precise our machine is. Let’s do this again but in the other way.

The black Formica had a bit of a bend to it so I had to hold it down, the fit is PERFECT! Here is a bit more Formica porn for you millworking companies to see how well these go together.

Watch the video of each of these Formicas being cut in our shop!

ONE STEP FURTHER!

You may be wondering to yourself, why would I want to go through the trouble of making Formica inlays? Here are a few reasons.

- extremely easy to clean

- extremely easy to install

- lasts forever – try kicking or ripping it off once glued in place

- well understood material, widely available in endless textures, colors and patterns

Purely an acrylic inlay.

Not only that, CNCROi.com can do inlays with pretty much ANY material! You want stainless steel inlays within hardboard or acrylic that fit just as well as this example? NO PROBLEM! You want to mix hardwood and softwoods for signage, NO PROBLEM! You want to use paper inlays into stone… well, you get it! NO PROBLEM!

Wood and acrylic inlay with Chicago screws.

As we tell our customers, we do not have a catalog of options, we use our creative potential to come-up with a solution tailored PERFECTLY to your application.

Corian paint filled (but can just as easily be an inlay).

Contact CNCROi.com today!