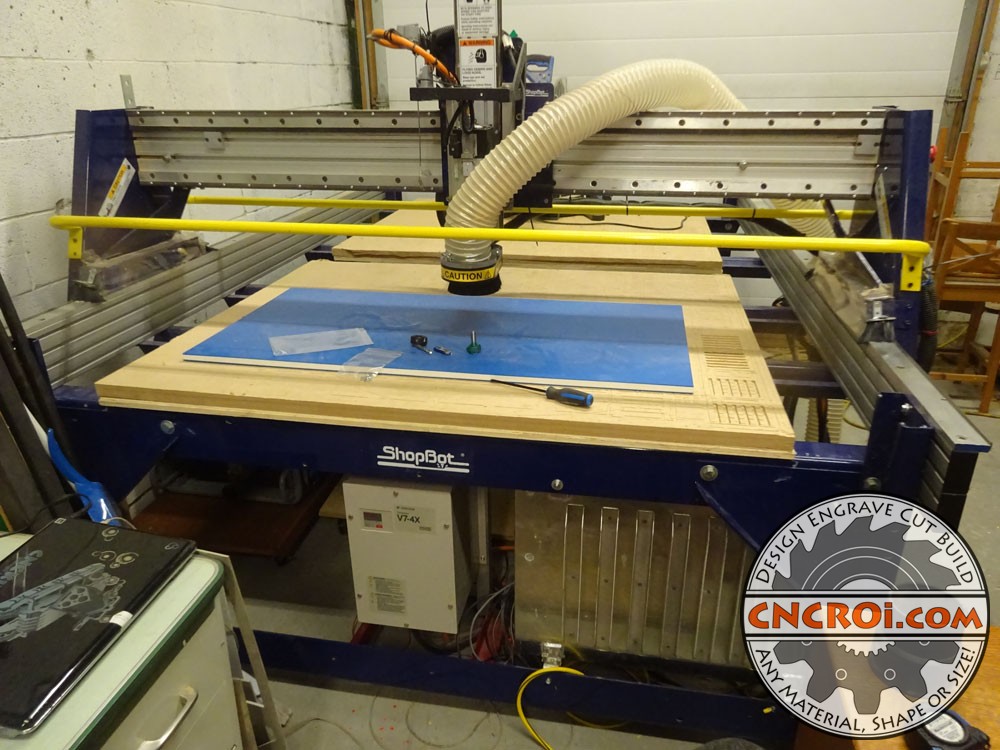

Full Size 96″ x 60″ x 8″ ShopBot PRSAlpha CNC Router

I’m happy to announce I’m just about done building my full size 96″ x 60″ x 8″ ShopBot PRSAlpha CNC router and WOW is it a major upgrade in capabilities at CNCROi.com!

I’ve shared hundreds of videos of me making stuff for my other website CNCKing.com, mostly wooden toys and unique furniture pieces and even my wooden big wheels but what’s surprising in hindsight, is just how much I was able to do with such a small platform, the ShopBot Desktop!

I knew eventually, as my projects got more complex and most notably, bigger in size, that I’d have to get a bigger CNC router!

But luckily in the CNCROi.com shop I also have a really big industrial Trotec Speedy 400 flexx laser, so it’s been my “go-to” for projects that didn’t fit on my ShopBot Desktop so I wasn’t totally without equipment to cut bigger pieces of wood but there is no substitute for the ShopBot PRSAlpha!

But there was one severe drawback to using my laser to cut what, honestly, should have been done with a bigger CNC router, and that is focus.

A laser is only as powerful as the focus of the beam, an unfocused 1KW beam has far less cutting power than a focused 100W beam and that’s the problem with having thicker and harder material to work with in the shop, laser cutting was really precise but incredibly SLOW.

With a CNC router, it’s a completely different story, you’re only limited really by the bit diameter and cutting area of your gantry.

Luckily, the vast majority of CNCROi.com‘s bigger projects could be cut using either our ShopBot Desktop, CNC laser or the Waterjet CNC but reality, none of them really totally replace the capability of our full size 96″ x 60″ x 8″ ShopBot PRSAlpha CNC router.

ShopBot PRSAlpha CNC Router Specs

I’m still very much setting things up, from power requirements to bits and the like for upcoming projects with the ShopBot PRSAlpha CNC router but here’s a video showing you what I had to play with for the past 8 years… and still works totally fine to this day and yes, I’m keeping it for projects!

So let’s take a look at the hard numbers comparing our ShopBot PRSAlpha to the ShopBot Desktop CNC router.

Cut/Movement Area:

105” x 61” x 8” (2.67m x 1.55m x .2m) VS 24″ x 18″ x 5.5″ .61m x .46m x .14m

Positional repeatability:

The ShopBot PRSAlpha has closed loop steppers with constant positional feedback to the drivers, if an obstruction is hit or cutting too fast it will try to fix the discrepancy realtime before stopping telling me things are a bit off, the ShopBot Desktop has no such mechanism.

Jogging Speed:

30” (760mm) per second VS 6 inches per second (150mm/sec) though for positioning, the ShopBot PRSAlpha has a XY Positioning Speed at a mind bending 1800” (45.7m) per minute!

HSD Industrial Spindle:

4 hp vs 1hp

Things I didn’t get but can easily upgrade to in the future for my ShopBot PRSAlpha:

- Vacuum Table: I’ve been using screws and clamps for 8 years, although I can very much appreciate the benefits of a vacuum, it isn’t worth the investment at the current time for my shop and it’s easy enough to “add” quickly should a project come along needing it.

- Rotary Indexer: This would allow CNCROi.com to make round things and either etch them at the same time or allow us to do the same using our CNC laser, an easy upgrade down the line that’s not really needed right now.

- Automatic Tool Changer: For the same reason as the vacuum table, it’s a nice luxury but not needed at this point and time for the projects current on hand, manually changing bits is pretty easy.

The CNCROi.com Difference

Having many different CNC machine types and auxiliary equipment allows CNCROi.com to really to amazing work that’s optimized for each machine.

I’ve shown many videos of how the CNC waterjet compliments the CNC laser…

But here’s an idea of what CNC laser can do to compliment the CNC router but that can now be done at a far larger industrial scale.

Imagine having custom shop furniture custom designed and cut full-scale using the CNC router with laser branding on the surface areas using the laser and added metal components for structural or esthetic appeal using the CNC waterjet.

The possibilities are now truly endless across so many applications now that even I have a tough time thinking of what we can make for CNCROi.com customers down the line!

As CNCROi.com‘s capabilities keep expanding, I look forward to the possibilities these kinds of capital investments will bring to the table for our customers, from full 3D rendering and animations through to final production, if you need something custom, contact us right now!