Generational Banks Business

As I continue down my journey of creating generational banks for my on-demand business over at SandboxRanch.com, you can see how the evolution of processes, optimized after every production run, has bared fruit not just for that business but also CNCROi.com.

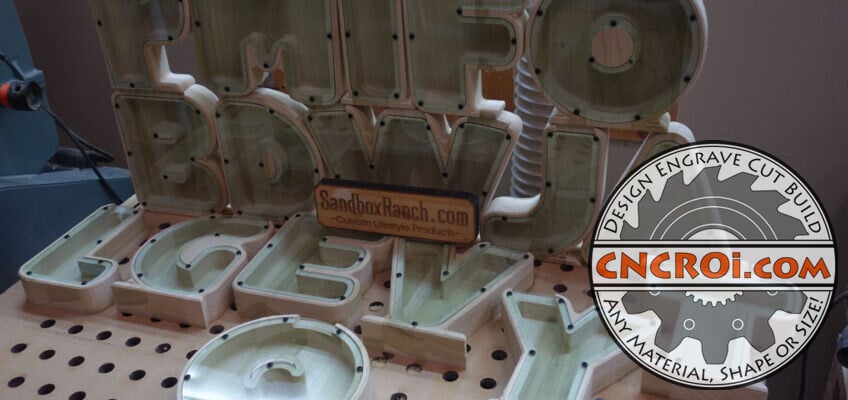

Before we delve too deeply into those endless amount of very positive changes, let’s look at my most recent production run of making V2 of my generational banks.

I’m currently in the process of revamping the other square style of banks over at SandboxRanch.com too, using the lessons I’ve learned over the past year to make an even better product for my customers there.

Now you might say, that looks pretty good, compare that to roughly a year ago, how I made these custom generational banks back then. To give you an idea, the banks below took 4x longer to fabricate than the ones above and the most recent revision are dramatically higher quality in every way.

It took hours to sand things previously, now, only a few minor touch-ups are required before shipping the banks out!

It’s astonishing just how much has changed at CNCROi.com not just in process but also equipment and most importantly, experience!

Starting SandboxRanch.com caused me to establish a shipping department to do all out own packaging and ship things directly from the shop, no more endless queues at couriers to do this for me… that alone, along with my Thermwood of course, allowed me to leapfrog the equivalent of years into the future!

Of course, SandboxRanch.com wouldn’t exit before my old tea light business which taught me all about craft shows, serial custom production and endless design challenges which all helped me become a far better laser operator and designer.

This was a great experience as I’m now talking with a few offline distributors about getting my generational banks into physical stores, all those craft shows got me comfortable with negotiations and reading people.

If you are wondering how I got my start in all things CNC router, here’s my very first CNC router doing among my very first projects that I designed myself 11 years ago for the business that would eventually become CNCKing.com.

I’ve been doing custom designing though fabrication for a few years, the equipment has gotten bigger, far more powerful but also a lot more expensive but I still very much enjoy watching the process of creation, whether it’s for my stuff or that of others.

I remember when I’d buy bits for my little Shopbot Desktop machine, awesome by the way and will be what my son will use to learn how to CNC himself when the time is right, and they’d be under 10$, now I feel like I’m getting a deal if they are under 200$ each!

Upgrade or Leapfrog?

Looking back to early 2022, I certainly knew the limitations of my “big” Shopbot PRSAlpha, like any machine, you certainly know when you’ve outgrown it, but for 95% of the projects I was making for CNCROi.com customers, I could make things work well within the tolerances inherent in the projects I was taking on.

That 5% though, I’d just have to let those opportunities pass me by, so if you run a business at 95%, that’s still pretty good in my book but when I started developing and making these generational banks, every one of those 5% limitations were literally getting in my way towards fulfilling those dreams.

I knew right there and then, that it was either time to do a major upgrade in my CNC router to bring it up to snuff, or jump to something that would allow me to leapfrog over those limitations.

After doing the financial assessment of whether to upgrade or leapfrog, I realized that if I upgraded, I’d just raise the ceiling until I hit my head against it again and then would need to leapfrog so I bit the bullet, spent a lot of money and time, and jumped to my 20 year old Thermwood CNC router.

Although a brand new Thermwood would have been great, the costs involved not just with the machine but everything else around the machine, was just too fat a cannonball to swallow currently.

What’s surprising is that both the ShopBot PRSAlpha and the Thermwood were roughly the same age, but “new”, the Thermwood was in orders of magnitude more expensive at the time it was fabricated, it also weighed 12 000 pounds vs the Shopbot being a fraction of that, with a rigid gantry no less.

https://vimeo.com/728205113

It certainly wasn’t a seamless transition, there was A LOT to learn using a totally new platform and truth be told, only now, a year later, am I finally comfortable with understand it’s nuances and working it to the best of my capabilities… that leapfrog was worth it, even with all the headaches it caused.

So what are generational banks?

My goal with SandboxRanch.com specifically, was to develop an affordable line of banks, made-to-order and customizable, that weren’t just throw-away items, they are built STRONG, are actually useful as banks for kids and adults and best of all, could be passed down.

This takes quite a mind shift design wise because the endless compromises that could be made because there was no point in making banks that were bullet proof (though they are available with a bullet proof window) if they cost an absolute fortune and nobody could afford to have a little custom in their lives, which is my ultimate goal with SandboxRanch.com.

So during the past year of learning how to and not to do things, constantly improving on processes and equipment, I’ve finally come to the point where I can design and fabricate a perfect wooden bank, regardless of wood species or size or combinations of specs thereof, perfectly, right off the machine without going through the days and weeks of fine tuning things.

Better CNC designer and Operator

Like teaching myself how to design kids toys over a decade ago after teaching myself how to do 3D animation even earlier than that, each skill compounds onto the other, there would be no CNCROi.com if it wasn’t for ShopBot existing, there would be no Thermwood in any shop neither – I have no idea what I’d be doing now in that alternative timeline where I didn’t teach myself animation as a teenager which has lead me down the path I’m on now.

All I can say though is I’m a vastly better CNC designer and operator after turning this vision of custom generational banks into reality over the past year for SandboxRanch.com, most custom projects seem like child’s play to me now as I took on a massive challenge and got through this self-imposed gauntlet victorious!

Custom GitHub Arctic Code Vault Fabrication

3-axis CNCs are all the same

On a daily basis now at CNCROi.com, I jump from metal projects to wooden ones, plastic to rubber for clients across North America and sometimes beyond. Shipping prices outside of NA are a major hurdle that I can’t overcome.

Whether it’s a custom project for CNC laser, CNC waterjet, CNC router or CNC plasma, in my mind, I’ve done enough of all of them to know instinctively which machine is best for the given application and can design within the optimal tolerances of each.

Our newest capabilities now include fiber laser cutting which means we can, after YEARS of headaches, fabricate our own custom anodized aluminum tags for our control panel and electrical customers.

https://www.youtube.com/watch?v=DMCVOf9IXqQ/settings

This comes on the heels of making custom thermoforming molds which just wouldn’t be possible with my old CNC router, which itself is a whole new line of business opportunities for CNCROi.com so again, leapfrog was the perfect choice at the end of the day.

Each new machine I acquire for CNCROi.com or challenge I impose onto myself to get through, only helps to elevate my capabilities, my customers benefit as 9 times out of 10, you guessed it, I’ve done it before and for those 1 in 10 projects, I have more than enough experience to see the project through.

For the past 20 years, my entire life has been dedicated towards custom fabrication, at first, virtually, and now pixels to dust (or smoke).

I look forward with helping you turn your product into reality.