High Quality CNC Laser Cut Fretwork

There are a lot of cool things we do here at CNCROi.com but among the cooler things we can do with our Austrian CNC laser, CNC laser cut fretwork is easily among the top of my personal favorites list.

Very few things show how precise our industrial wide-format CNC laser like custom designed and cut fretwork. Why spend hours doing fretwork with a scroll saw when you have a company that can cut it out faster and more accurately than you could ever dream?

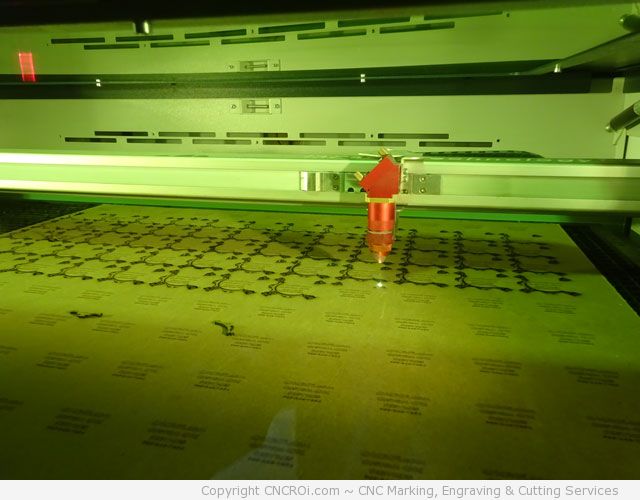

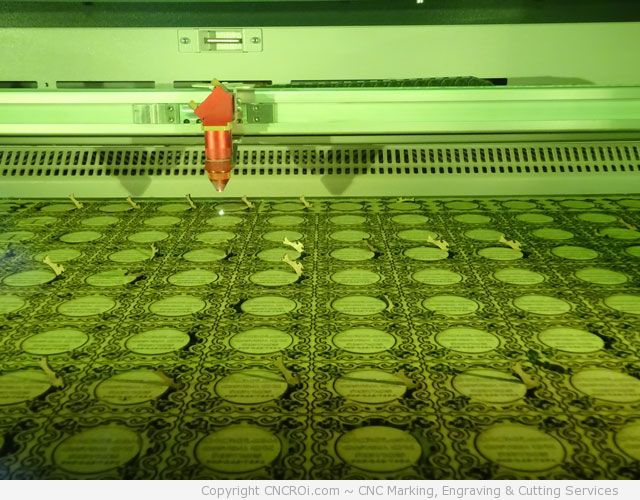

In this case, we had some 3 mm hardboard in the shop that was due for an upgrade so I stuck it on the laser bed (our working platform is 1 m x 61 cm and using passthrough, 1 meter x infinite). Our customers always want to have samples of our work so I strive to give them what they want, in this case, it will be a sample fretwork token.

After the initial pass of laser scoring the wood with the words we want on these samples, your name, quick tag line and phone number, it was time to start cutting through the hardboard!

This was done in several passes to limit the amount of soot and vapor we’d have settling on the work. Each CNC laser pass cut through, just in different areas as I didn’t want to mask this, I was looking for a slight coloring around the edges for this sample, and in this case, the glue and resin in the hardboard would do double-duty.

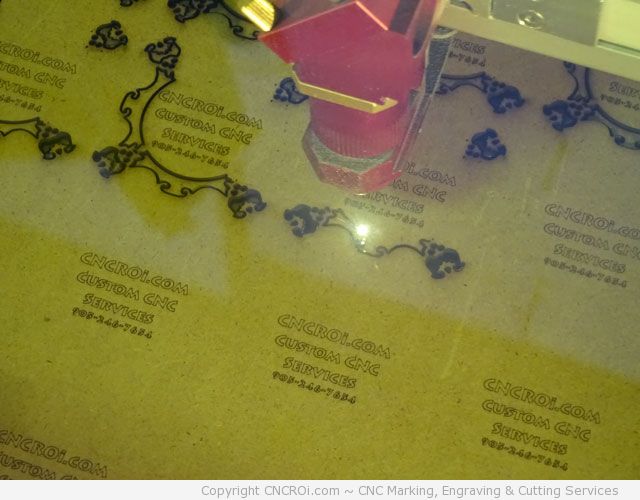

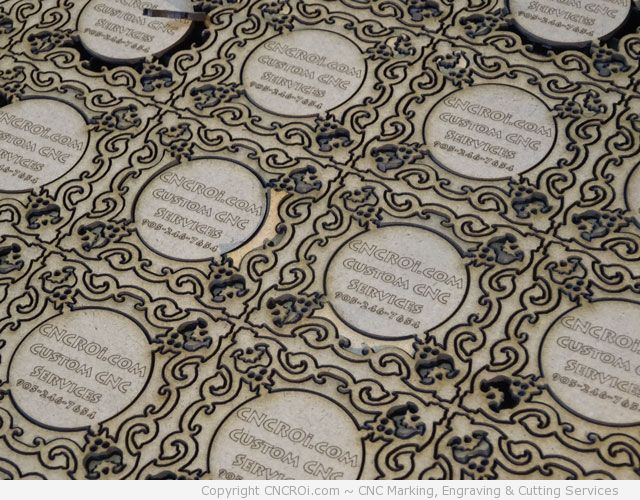

You may be wondering why we didn’t engrave the information on our hardboard fretwork sample? The reason is we want to outline the precision we can achieve and the fine beam we are working with. Engraving is easy, producing a fine beam is easy too… IF YOU HAVE THE RIGHT AUSTRIAN EQUIPMENT!

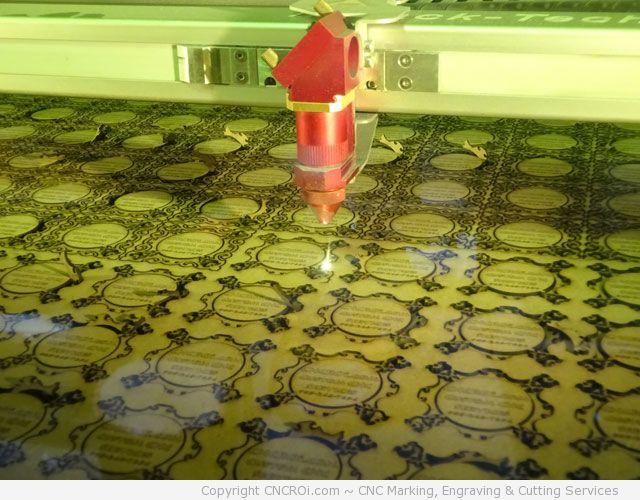

In this run, we made well over a hundred identical frework samples. Doing work like this makes me question why I even bother printing business cards anymore, I guess they each have their place but to me, this is far nicer than a paper card, even if it is full color on-demand printing.

You’ll notice there are three samples with a black marker going across them in the top image. I wanted to test the precision of the laser during production, the best way to do this is to do two (or more) passes on the same area using a fine cut line. The results? Other than being a bit darker from the double CNC laser pass, all the letters were scored perfectly. I don’t just buy the best laser on the market, I test it randomly throughout production to make sure our customers get the absolute best results from it!

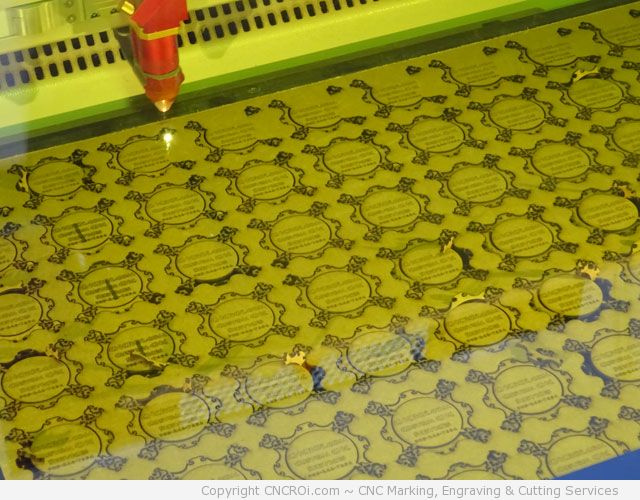

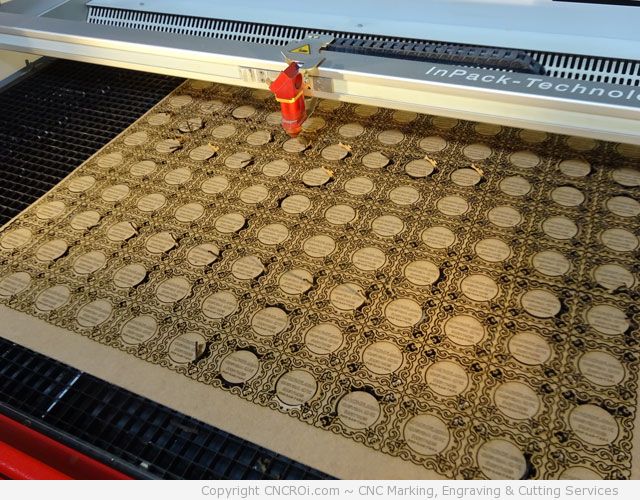

After the scoring and cutting the insides, the next step for this custom CNC laser designed fretwork was cutting them out. We have some major air going down on the piece which is why you see some small parts flying out of the way when the head approaches them and strong vacuum table sucking the smoke out as soon as it goes through.

It really looks awesome when you have a repeated pattern cut across what use to be a very boring piece of 3 mm thick hardboard. If the laser was out of alignment in the X or Y axis, you’d see any faults in this pattern immediately with your eyes. No faults here!

Our Austrian CNC laser is a fully capable production powerhouse, able to engrave, etch, cut and score thousands of units, each the same or different, makes no difference. That’s why we have this machine, to help our customers with their on-demand production needs.

Those little parts you see sticking up are the inner parts of the fretwork that were raised due to their position on our underlying grid table being at just the right spot with the air compressor pushing air down to lift them up vertically. We have tons of clearance even with this issue so it’s of no concern though it looks cool.

The reason why we can get such a large project done efficiently is because our laser is capable of moving up to 355 cm / second with acceleration up to 4g. Basically, if you were small enough so sit on the head, you’d pass out in a matter of seconds, don’t worry, with our powerful extraction system, you’d most likely be sucked right out the machine before the fumes got to you or worse, the laser got you.

That’s only PART of the story though, there is no point having a fast machine if it can’t be accurate. Our Austrian CNC has addressable accuracy of 5μm and static repeat accuracy of < ±15μm. What does this mean? Regardless of application or material, we are hitting the target when it comes to meeting stringent spec work.

Maybe it doesn’t matter to have such overkill accuracy and speed for fretwork like this but when your reputation is on the line and deadlines count, you want something that can do the job right the first time. EVERY TIME. Looking at the pictures closely, you can see how added depth has been added to the fretwork by allowing the smoke and glue to adhere to the edges – sometimes you turn a “bad thing” into a feature!

There is a reason why we get to do aerospace, military and government work here at CNCROi.com. We are passionate and have the equipment and skills to backup what we say we can do. Notice the absolute accuracy of the scoring lines that make-up the text. It’s straight, dead-on and readable. The circle on the inside is about the size of a quarter.

From anodized aluminum to stainless steel, polycarbonate to high density foam, laminate to hardwood… we can get it done fast, accurately and right. We don’t feature customer projects on our site because we value their privacy. We aren’t in the business of showing-off “here’s what we did for XYZ”, we are in the business of professional CNC custom work.

As you can see, everything was cut perfectly, removing the “scrap” board none of the pieces moved, I began removing the fretwork samples in the top left corner… this stuff is routine here at CNCROi.com… but wanted to show you a picture of what the results are like.

Looking for a passionate company for all your custom CNC needs? Contact us today!