How much does it cost?

A very direct question I get from customers is “how much does it cost?”, regarding either the project they want done by CNCROi.com or our CNC equipment. Both have the same answer, it depends.

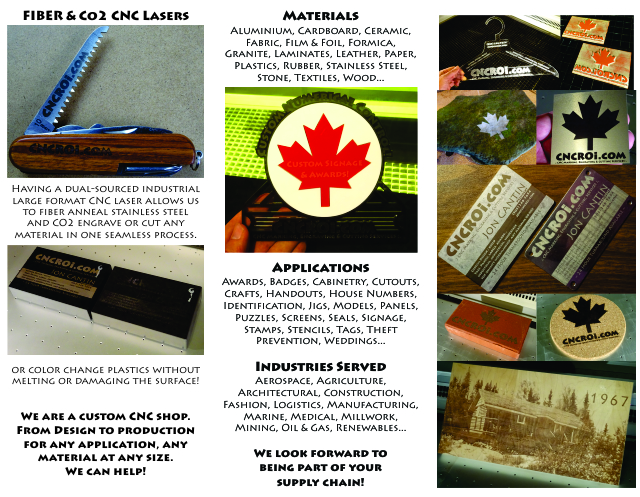

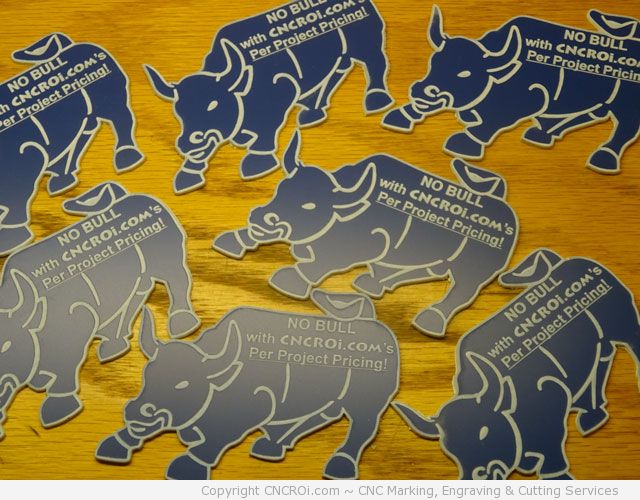

Take for instance a stencil such as the one above, the cost will range wildly depending on the material selection, volume and size. For instance, making this stencil about half the size would reduce the price in half but if you had, let’s say, 100 to be made, the price would drop by half anyways at the regular size. What makes us unique is that you can have each stencil with DIFFERENT INFORMATION and it wouldn’t matter to us!

Now for materials, making this out of stainless steel would cost far more than the plywood used or, by extension, it needed a secondary process as you decided you wanted these out of aluminum, using technologies like powder coating or anodizing would add to cost but also dramatically increase the lifespan.

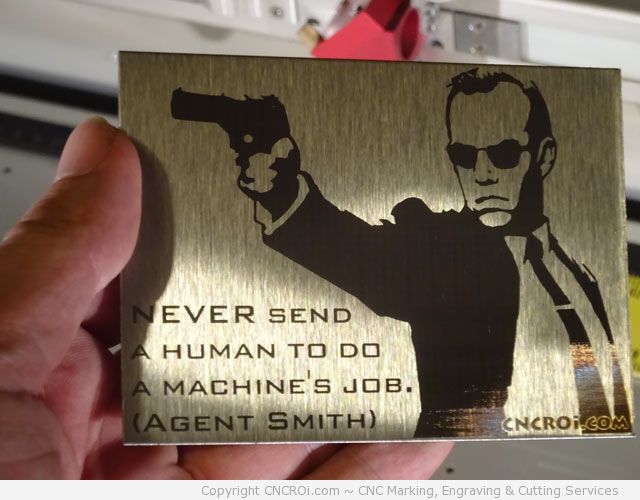

Agent Smith looks awesome, the price to make this BLACK as you see in the picture is very different from if you wanted it brown, which would be 2-4x faster production wise using our fiber laser… let’s say you only needed this to last ONE DAY, then we’d use Cermark and it would come off after a few days or weeks but cost significantly less than CNC laser annealing. If you made the text on ONE LINE at the bottom of the plaque instead of to the left as I have done, it would cost less even if the plaque was bigger! Interestingly, the same parallels regarding “darkness” can also be made with polycarbonate, almost to a T!

If you wanted the same Agent Smith on plywood, maple, oak or whatever, the cost would depend on the depth you wish the engraving to be, the quantity and desired post-processing (paint filled, hot stamping etc.) required.

Your company wants something awesome for a trade show display to attract visitors? You see the above and say “hey, I’d like that but we sell trucks, we want a custom design of that instead!”. That sounds great, your first question will be, how much? My first question will be “what’s your budget?” Let’s take a look at both.

How much is a useless question as I don’t even know the scale of the truck you want, say you want it to be the same as the image. Alright, what material, how many and what is your timelines? Let’s say you tell me MDF like the above and you have a month. Guess what, I still have NO IDEA what the price will be! Why?

- Do you have the design already made and ready to cut with our CNC laser and/or router? (most likely no)

- Do you want it to have any moving parts?

- Does it need to be designed to break apart or flat packed shipped?

- MDF won’t last long, I’d suggest something stronger like plywood, even birch of the same thickness would be dramatically better.

- I will need a drawing (CAD preferably) with JPGs of the truck you want designed.

- Your timeline is no problem but YOU need to make decisions fast, if I ask you a question, it can’t take a week for you to get back to me.

- and so on…

I won’t know the price until the design is done and approved, only then will I cut it up and know the cutting costs. From experience though, I’d tell you right off the bat that you are looking at a few thousand dollars but anything beyond that, I really don’t know. If your budget is a thousand dollars, this isn’t a project that will happen on either of our watches!

How much does your CNC cost?

Another question I get a lot of is how much does our CNC router or laser cost? Well, that depends. The reason you are asking me this is because I gave you a quote that you thought was a bit “high” and you think it’s cheaper to get your own OR you want to know what I’ve invested into this company! The investment in our Industrial wide-format Austrian CNC laser was significant, we could have went Chinese for sure and saved a bundle, but that wouldn’t have been good for our customers who required a service they can count on with incredible precision and repeatability.

CNCROi.com does do military, aerospace and architectural work, depending on the company, I give two different answers.

The general public, I tell them it costs as much as a house. Telling them the exact dollar figure is about as useless as me asking how much they paid for their car, it’s inconsequential. To heads of industry, I tell them how much I paid but I’m also quick to throw-in additional costs that go far beyond the price of the machine.

- These machines DO NOT RUN THEMSELVES, sure, I may make it look easy but like a carpenter with 30 years of experience building kitchens, if you try it yourself, the results will be nowhere near as good. So, you need an EXPERIENCED and ENTHUSIASTIC operator, you won’t get this at minimum wage.

- The ongoing costs, you got an operator, great, you have a machine, awesome, now, after this one widget production line is done, what will either do for the next few months until your next “logo on a widget” production line is required?

- Depreciation, the CNC world is a funny one, you want the machine to work 24/7 as that’s how you make money but such heavy use also depreciates the machine, laser tube to servos, all get used-up. So, the more you use it, the less the machine is worth so your goal has to be to make as much per hour WITH IT while it WORKS so that you have money to buy a new one once it because useless in the shop. If you charge too much, you get no projects, if you don’t charge enough, you won’t have money to buy another one or expand!

Keep in mind that during the life of our CNC laser alone, we will have spent more money on the employee than the machine by several folds, we would have spent more money on electricity than the price of the machine and several orders of magnitude in time finding customers than the price of the machine. The machine is the cheapest part of the equation!

CNC gambling

Anybody who knows me knows one thing, I don’t like going to casinos or playing the lottery, it’s actually quite boring, if you look at the above, you’ll notice there is A LOT of guess-work and essentially, gambling. There are so many variables involved that for many projects, you try to give numbers that make sense and “hope” you are right.

Some projects, the numbers are easy to come by and taking everything into account, all’s good… but being a CUSTOM CNC SHOP means that “custom” part can cost X now but dramatically more or less once you actually get the project. To me, this is the ultimate form of gambling, sometimes you win big and other times, lose just as much. One thing I have never done though, was go back to a client and extend my hat asking for more money. CNCROi.com operates on a per-project basis and as such, I stick to my quotes, good or bad.

Each project is unique, each project has challenges that produce scrap and that’s what makes it so much fun, the money to me always comes secondary, as long as at the end of the month there is more + and – so I can keep growing the company, I’m happy.

Contact CNCROi.com today!