Hundreds of Custom Wooden Gears

Today we’ll review the process of custom CNC laser cutting hundreds of wooden gears, custom to spec ornaments that will be painted by children.

I had to take a week off this website to have enough time to get a lot of projects done along with getting new equipment in the shop and organizing things for even bigger commissions coming into the door.

Growing is great, but I always keep in mind that my space is always the same, so the more it fills-up, the less room I have for other stuff.

Unlike the above video, we’ll go in a different order of items that are being converted into custom wooden gears.

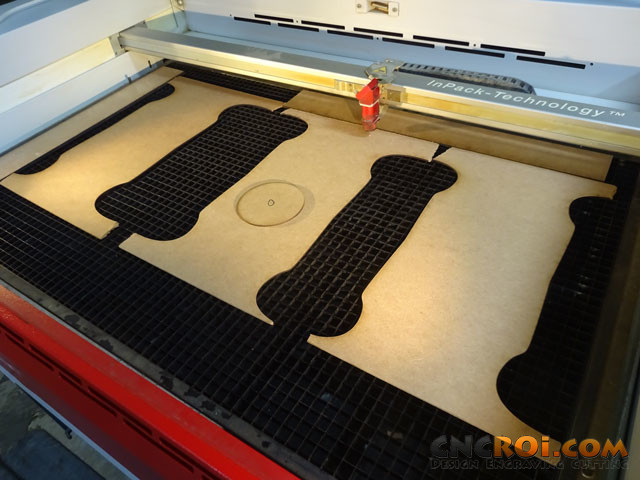

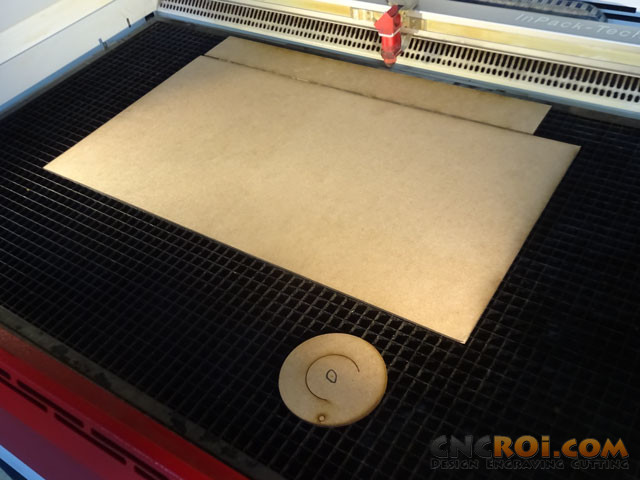

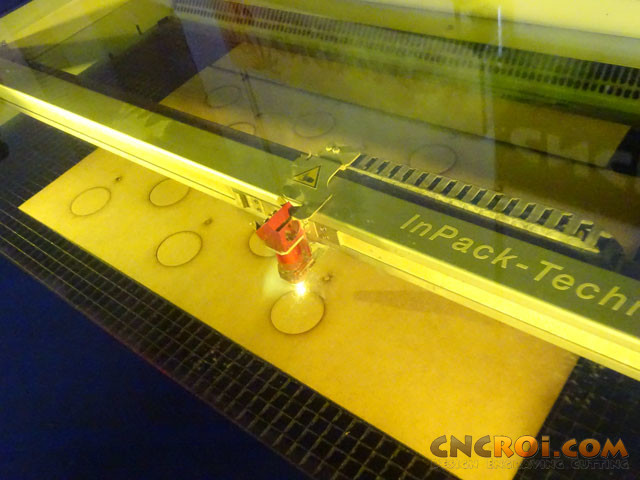

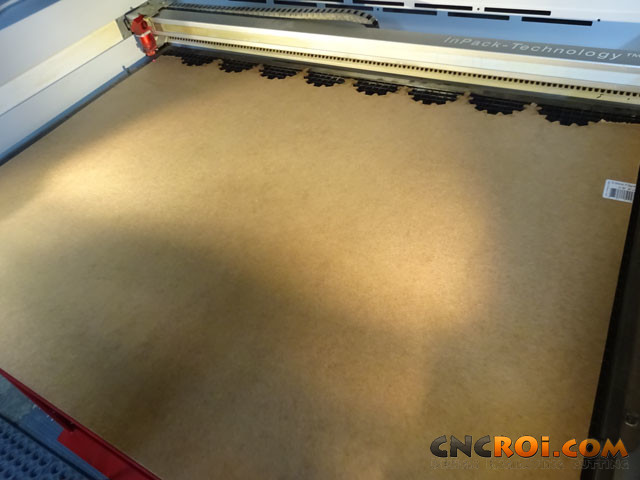

Generally, if the volume allows, we work from full sheets of materials that are fed into our Austrian wide-format industrial CNC laser as we always have off-cuts that can then be used to cut out other parts from to minimize material wastage.

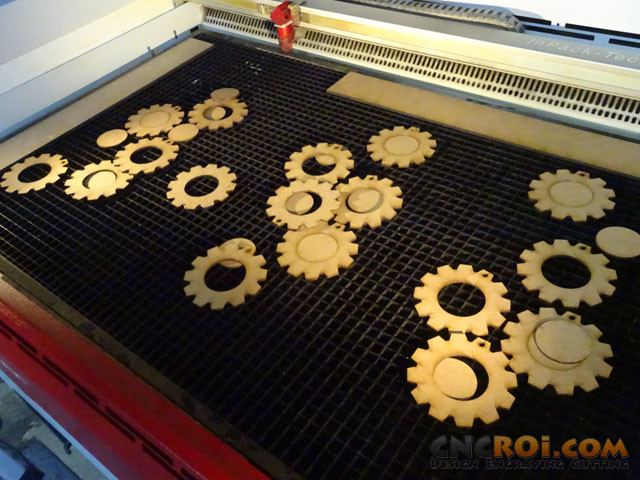

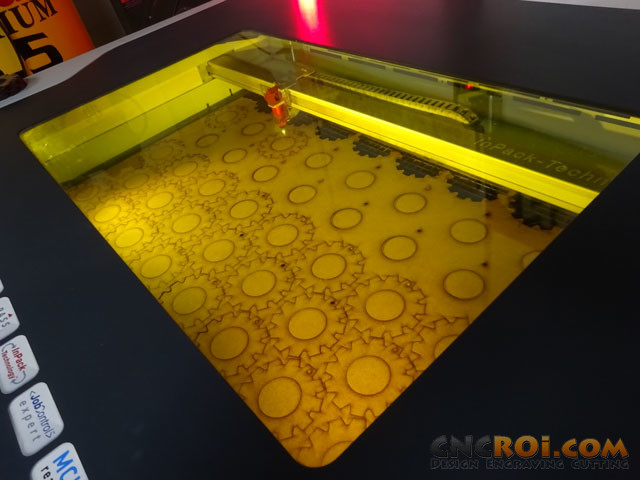

The nice thing about these small custom wooden gears is that they are relatively small, which allows us to really use-up the material as optimally as possible.

These custom wooden gears are made of MDF, 1/8th inch or 3 mm material, which works great with paint, is relatively inexpensive material and works well with our industrial laser.

These custom wooden gears as a result of using thin material cut pretty fast too, which means our customers get something totally custom in an affordable manner across huge volumes.

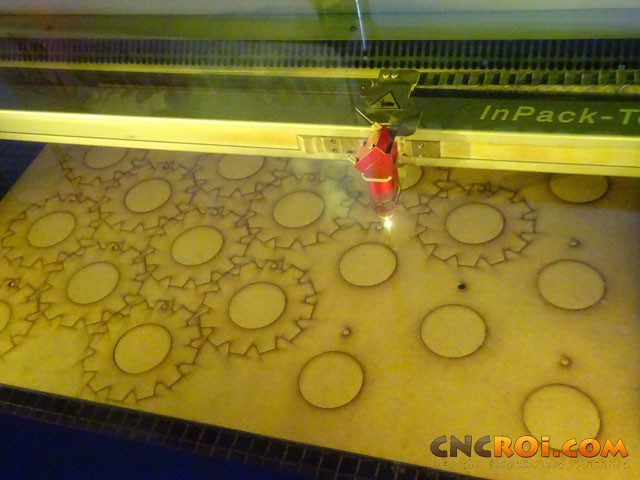

In this case, the customer wanted over 400 custom wooden gears, I didn’t take pictures of all the production but just enough to give you an idea in the video and photos as to what’s involved with production runs in the hundreds.

As you can see, everything is custom to spec and on-demand, this means that if you wanted custom wooden gears to all be of different shapes and sizes, we can just as easily do that as the “same”.

There is no difference to CNCROi.com, same goes with material variances, so if you wanted a bunch of custom wooden gears in a few different shades of acrylic, no problem either.

The ever-growing CNCROi.com Shapes Library doesn’t contain any gears but our focus isn’t to show you EVERYTHING that’s possible, but an idea of what is possible across a variety of materials.

Making custom shapes never ends, there is always another shape, silhouette or combination of the two to custom cut for any given application, cutting boards to novelty ornaments.

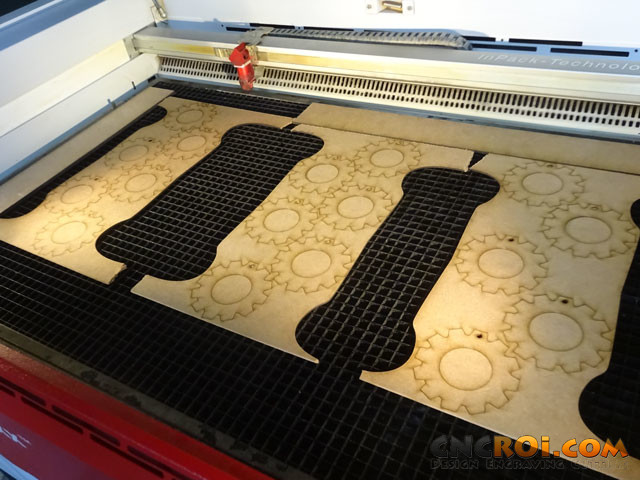

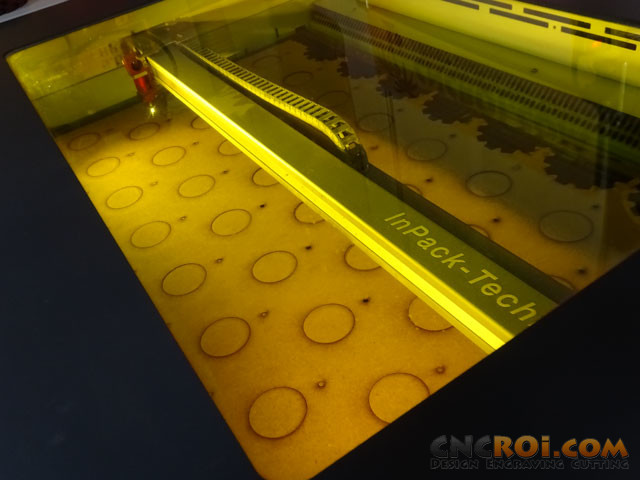

In these videos and photos, you can notice that CNCROi.com cuts out the inner holes first followed by the outer ones, this keeps everything precise as nothing moves during the entire production cycle for ultimate repeatability.

When it comes to custom production, ultimate flexibility in production and design allows our customers to really enjoy what we make for them, it’s how they want it, when they want it, at the price they dictate.

We have plenty of clearance as well, if you had a custom wooden gear that needed engraving that was 10 inches in thickness (high), then no problem either for CNCROi.com.

There are endless applications, working with designers who make their own designs that we cut for them or we help come-up with the final design, we work fine either way.

These aren’t meant to be actual working gears, these are custom ornaments to be painted without the need for them to interlock, hence having the custom wooden gears larger and fatter than they need to be.

CNCROi.com does have a gear generator, so if you have specific specs on that front, we can help you with that end of the design process just as easily as cutting them out.

Having a tight fit with less than a mm or 1/16th inch space between the custom wooden gears optimally uses material, if we were doing these out of Corian using our CNC router, we’d need to leave room for hold down but CNC lasers are a non-contact production method.

If you wanted your custom wooden gears to be painted by us, we can do that too by the way.

Here’s the most optimal nesting we could achieve on this piece of extra MDF board, there isn’t any room left to spare.

CNCROi.com does have nesting software though I did the ones below manually, if it’s all the same piece, I’ve found manual nesting to be more efficient than automated.

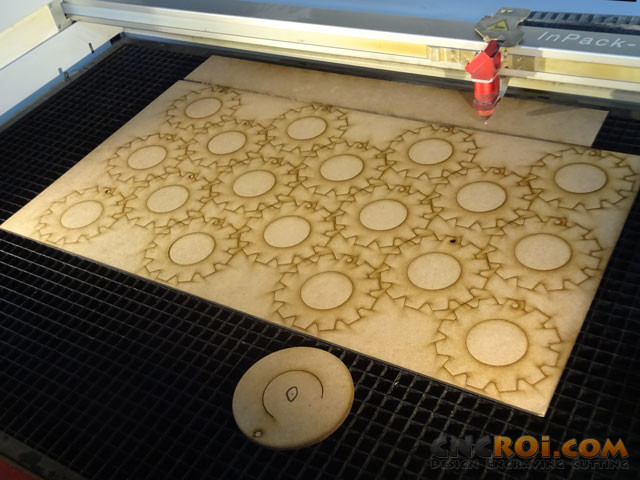

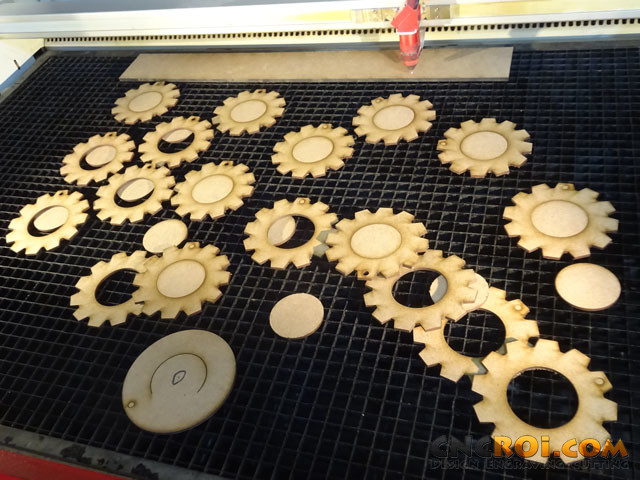

The custom wooden gears just come off the board by themselves thanks to gravity, how’s that for precision and optimal production!

All these photos and videos regarding these gears would be the same regardless of material, paper through stainless steel.

CNCROi.com could have also engraved onto each of these gears, the names of the students or any other identifying information, including a logo at the same time.

That’s the flexibility when it comes to ultimate customization that we offer our customers.

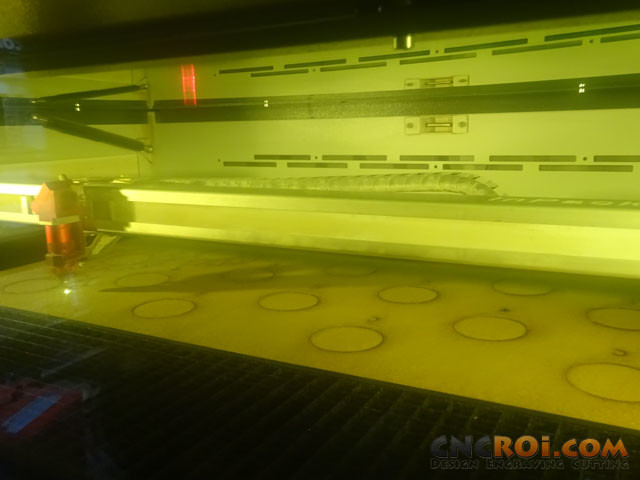

Now we’ll transform a full sheet of MDF into custom wooden gears for our customer.

Again, no different from scrap or awkward pieces, they are all the same, it’s just that we get faster production using a known size wise piece of wood than unknown.

Looking at the top, you can see the sign that we’ve fed this board into our machine, again, optimal use of material, making custom wooden gears keeps production fast and material wastage low.

You can see also that some of the inner pieces have dropped slightly, they just happen to fit within the holes of our vacuum grid table.

Lots of clearance, we have longer and shorter lenses, but we use optimal lens for given material thickness to produce the best results for our customers.

Making custom wooden gears is no different from any other shape, if you wanted hundreds of hearts, zebras or arrows, the process would be the same.

The board is now transformed into custom wooden gears, I wish production was as fast as typing the descriptions in these blog posts.

At the bottom of the sheet, you can see a bit of “white space”, CNCROi.com will just feed that through and transform that area as well into custom wooden gears.

A review of how tight the manual testing is, there is a little space just to ensure continuity but otherwise, very little is left over and it just breaks itself down.

It’s pretty nice when the “scrap” looks just as neat as the final product.

Here are all the custom wooden gears on our vacuum grid table, all done.

Next step is to prepare them for shipping from CNCROi.com to our customer.

Here’s how they are packed in a cardboard box.

There are so many of them that it’s hard to break any one of them as overall, their strength is combined when it comes to shipping custom wooden gears.

Need some custom wooden gears or any other shape regardless of size, shape or material? Contact CNCROi.com right now!