Importance of Budgets

The biggest challenge of running a custom CNC shop is generally focused around completely custom work where the client has no idea what they want or how much they wish to spend with us. CNCROi.com is a custom CNC shop, we can design and build to YOUR specs and budget.

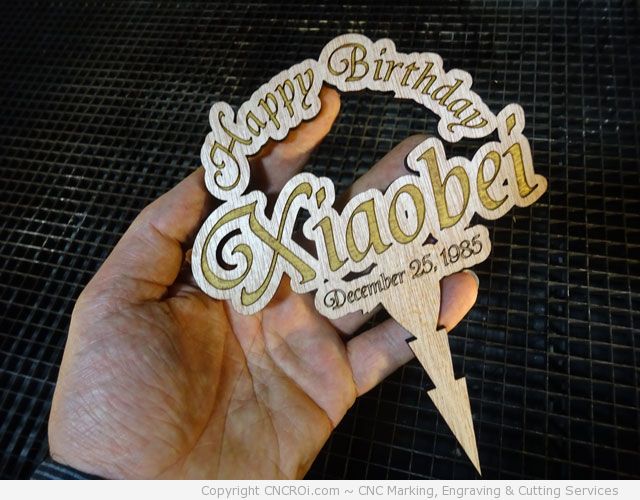

Take for instance these custom cake toppers, the price is dictated by laser engraving and cutting time. There are a lot of details in these that can be modified to hit specific price points. For ease, let’s say this is worth X$. If your budget is 50$, then we can achieve this “savings” in a number of different matters, the easiest is scale, so scaling the entire cake topper down by 20% will save on materials, engraving and cutting time. Furthermore, making the date smaller like you see in the picture below will also provide additional savings.

Additionally, volume also plays a role, if you had a budget of Y$ but wanted everything the “same”, well ordering more than one, like 10 units at once, would allow you to gain that price advantage – whether they were all the same or with different dates and names makes no difference.

Things that are not really affected by the price are things like engraving depth (within reason) as our industrial wide format Austrian CNC laser goes the same speed whether it’s engraving with 100% power or 50% power. The above custom cake toppers are made out of 3 mm birch plywood, so going to 2 mm wouldn’t make any difference though if you wanted to go to 6 mm or 1/4 inch, the price would go up, not due to engraving but cutting times would be slightly slower.

Let’s say you wanted the custom cake topper at the top of this page to be cut out of half-inch MDF, again, the cost would be more than 6 mm plywood or 3 mm plywood, hence the price would be more. You don’t want these cut out of MDF by the way – go with acrylic. 6 mm or 3 mm makes little difference as our CNC laser cuts through acrylic like butter.

Why are we so flexible on pricing?

CNCROi.com is a custom mass-production capable CNC shop, this means that we design, cut and assemble your project in-house. The massive advantage to this is you get EXACTLY what you want and the customization options are truly endless.

The difficulty for us is when you have “no idea price or quantity” and just want a ballpark without any design established, what do I say? 75$ for a cake topper or 50$ or 20$? There is no set price for our services as they are tailored to your specific needs. It’s not like we are importing a thousand mass-produced widgets from China, we are custom designing to the specs we both establish. This means prototyping as part of our quoting process generally, so the customer can touch and feel (and change) what their end-product will be.

Generally, we use plywood for our prototyping because it’s a wonderful material to work with on so many levels.

Custom Signage

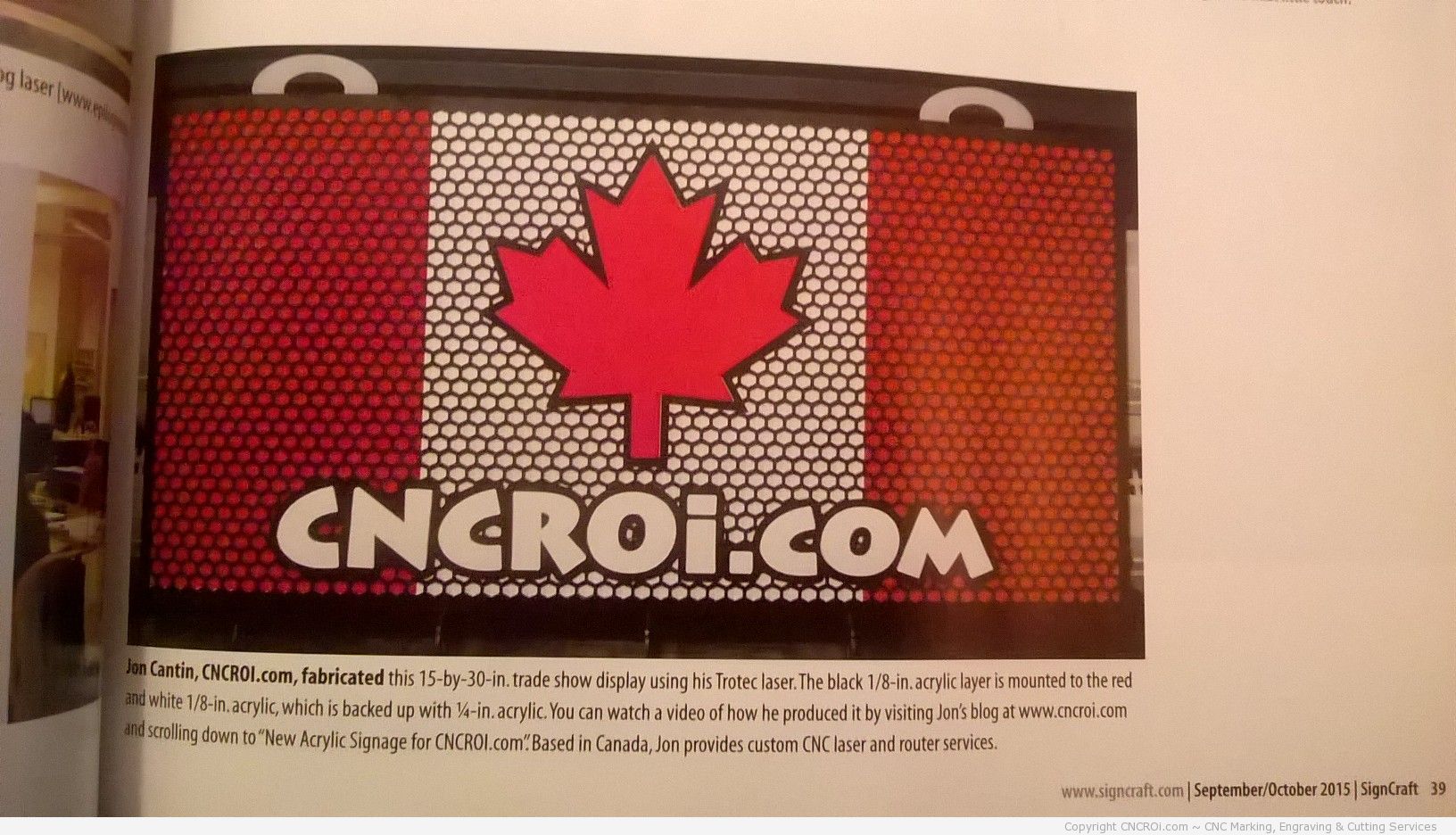

Take for instance our signage that appeared in SignCraft Magazine, if you wanted to cut the price down dramatically on this project, the first order of business would be to make the little hexagons either BIGGER (to reduce cutting time) or get rid of them completely. Alternatively, we didn’t need to make the sign so big.

Whether this CNCROi.com sign was made out of plywood or acrylic would make very little difference at the end of the day in price. Of course, we could have dropped a layer or used thinner material to produce faster cutting times – there is no engraving in this sign at all – but then you’d have something that wasn’t as sturdy.

Another area that is highly depending on price is annealing stainless steel. There are different levels of blackness we can achieve with our CNC laser. At the absolute max black fiber laser annealing, it takes about 5-10x longer to produce than a lighter annealing that’s not as “black”. The level of blackness is dictated by price and budget.

The absolute black looks just like vinyl printing on stainless steel, it’s quite incredible, but rarely is that level of annealing required for applications, most of the time, we do something like the above picture, it’s black but not absolute pitch black. Compare the above “blackness” to our business card.

Quite a difference huh? The fiber annealing on our business card plaque was so hot it was actually bending the metal, while the opener above got hot but not to that extent. Again, budget will dictate whether this is required or not, it depends on the application and need.

There is no other way around pitch black annealing, you may see some shops offering “cheap” annealing, it’s done using ceramic bonding, yes, we can do that here too… but we don’t because it doesn’t last, it fades, cracks and comes off with time. The aluminum maple leaf below was done using this method as fiber marking aluminum, due to the lack of carbon, just fibers white instead of black like stainless steel.

Alternatively, there are products out there that produce black out of aluminum, again, using a CO2 tube, which is what you can see here.

But though you save time and money going this route, it isn’t annealing and depending on the application, may not be worthwhile to pursuit. There is a reason why CNCROi.com invested in both a fiber and CO2 laser tube in our Trotec Laser, it’s because we want to offer you the absolute best in quality and durability regardless of application.

So, with each option you decide upon, there is a cost attached to it either monetary, material or design wise. We certainly DO NOT expect you to try to juggle all these balls in your head, that’s out job… which is why knowing a budget ahead of time will guide us to produce the best results for your particular need.