Why is (insert material here) so expensive?

I often get asked by other companies who are looking for raw materials to purchase from CNCROi.com why is (insert material here) so expensive, we’ll review some of them now.

Why is Corian so expensive?

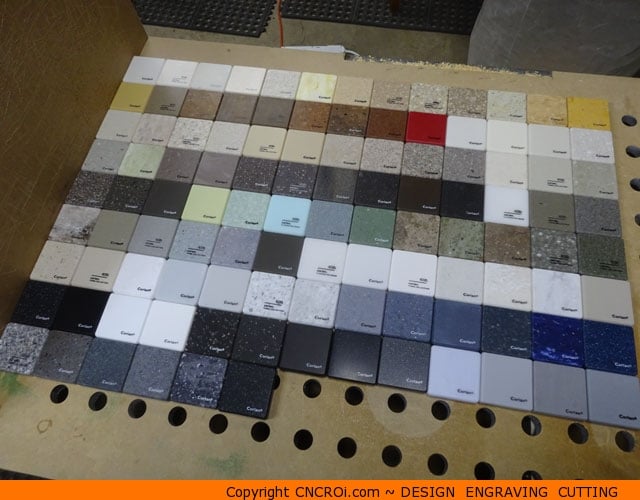

CNCROi.com does lots of Corian work, it’s available in over a hundred color combinations and is incredibly easy to sand, machine and laser engrave.

So it’s no surprise that many people are looking at us to provide them with CHEAP off-cuts from our production runs but what they don’t realize is that Corian off-cuts aren’t really a cost savings.

Why is that? Because if you want a specific color of Corian

- Custom Corian Color Options

We have to buy a full sheet of it! In other words, your little 14″ square “off-cut” really is a full sheet that we have to cut to size for you… and Corian itself is very expensive!

Now, of course CNCROi.com does have a very limited inventory of Corian in stock so flexibility in design and color options will give you a better price but at the end of the day, Corian is also very heavy, so you get hit by both the price of raw materials plus shipping.

Just something to keep in mind, we are not in the business of competing with the dollar store where prices are artificially low due to huge production runs in the hundreds of thousands, as such, your “one” is absolutely going to cost more.

Why is metal so expensive?

Just like Corian, if you are looking at CNCROi.com providing you off-cuts, the more flexibility you have the more affordable options we can provide to you.

If you are looking for one small plate that’s 4″ square out of any type of thickness or only a very few pre-cut tags, we of course can help you but they will be more expensive as a per unit price than an actual production run of 50 to 100 units that we typically do.

Metal, like Corian and just about every other material out there including lamacoids requires volume to bring the price down.

What a lot of people fail to realize is that it takes the same amount of time to set-up and cut 1 custom metal plate as it does 1 000 so cutting 1 you pay for EVERYTHING in that one unit, from raw sheet to machine, electricity, handling etc.

With some materials, this is far less extreme or if we can batch your project with another customer who has similar raw material requirements, but in those cases, timelines may need to be a bit more flexible.

Why is real wood so expensive?

One type of wood we are definitely doing more and more of is live edge, it looks great, very easy to work with and allows for a lot of creative options.

One thing people need to keep in mind is that unlike Corian or metal, live edge wood is totally natural so wanting a spec that’s DEAD ON will be far more than something that’s “roughly” what you are after.

The reason for that is that nature doesn’t make things to spec and neither us nor our suppliers will go through LOTS OF BOARD to find something dead-on as it doesn’t exist.

This is why a lot of our quotes when it comes to live-edge are within a few units range rather than dead on like most of our other work.

Take for instance the big chunk of walnut above, if you said “that looks great but I only want it 3 inches square, then we can cut it but good luck finding a 3” square piece of walnut with a live edge, it would need to be cut out of a bigger piece but even then, “square” is a very relative term.

Another issue is that sometimes customers confuse the pricing for material they see at the dollar store (bamboo being one of them) and think it’s cheap as a result.

Bamboo is incredibly expensive in North America in sheet form, I lived in Australia and China, there, not so much but it isn’t a natively grown tree here, as a result, it costs far more than say, their Maple or Oak equivalent that does grow natively.

Here again, flexibility on the type of wood species you want CNCROi.com to produce something on your behalf will save you time and money as an order of Bamboo is generally a custom order while Oak can be bought at the local lumber store.

Flexibility is Key

Just yesterday for instance, we had a customer who wanted only 4 units of a custom metal tag, their spec was extremely close to something we keep in stock, because they were able to be flexible, they got a good price on them while otherwise, they were looking at an exponentially larger bill.

CNCROi.com is a very efficient and relatively fast custom production facility, we never really know what’s coming through the door on any given day but generally, we know about a week out that XYZ using ABC material may be coming in.

As a result, if you aren’t in too much a rush and your specs are somewhat malleable, we can get your stuff done “at the same time” as another customer’s and save you money and us production time as all that set-up is bundled-up into a larger project.

Of course, flexibility can also mean material alternatives, if you want something that looks like steel but without the budget for steel, going with a lamacoid instead offers far more flexibility in both turnaround and design options than a “one-off” made of copper or 304SS.

The Bottom Line

With custom production there are a lot of variables involved, volume, raw materials, equipment use and so forth.

The more flexibility you have in your specs, the more efficient the entire process goes and the better a price CNCROi.com can offer you.