Laser + Plastics: What REALLY Happens?

As part of our ongoing blog series of what REALLY happens with CNC lasers, today we’ll focus on acrylics and plastics here on the CNCROi.com blog.

Freshly cut 3 mm thick acrylic on our cutting table.

Generally when we are talking about acrylic, what we are really talking about is a synthetic thermoplastic called Polymethyl methacylate (PMMA for short). Acrylic is available in both cast and extruded forms and to complicate things further, there are almost endless proprietary blends of acrylics available for an endless variety of applications. Here’s a short list of what I’ve been able to find.

- Acrylic glass

- Acrytuf®

- Altuglas®

- Astralon G®

- Casocryl®

- Degalan®

- Deglas®

- Dunova®

- Friacryl®

- Hesa-Glas®

- Limacryl®

- Lucite®

- Lucryl®

- Paraglas®

- Perspex®

- Plexiglas®

- Primal®

- Resarit®

- Setacryl®

- Satinglas®

- Setasand®

- Setaletter®

- Seta-LED®

- Metallic®

- Stone® Acrylic

- Setapan® Acrylic glass

- … and the list goes on and on and ON!

Now, if you want to jump into lets say polycarbonate, you have yet another list, each with their own proprietary blends.

- Anjacom®

- Anjaflam®

- Anjalon®

- Axxis®

- Decarglass

- Durolon®

- Latilon®

- Lexan®

- Makrofol®

- Makrolon®

- Polycarbonate

- Xantar®

- … and the list goes on and on and ON!

So which one do you want really? Well, it depends on the finish, heat, exposure, thickness, durability and even color (or lack thereof). For instance, Lexan® in that it’s extremely strong and produces a SOLID black reverse engraving with tough to remove yellowish edges which is great for applications requiring something transparent yet stronger than glass.

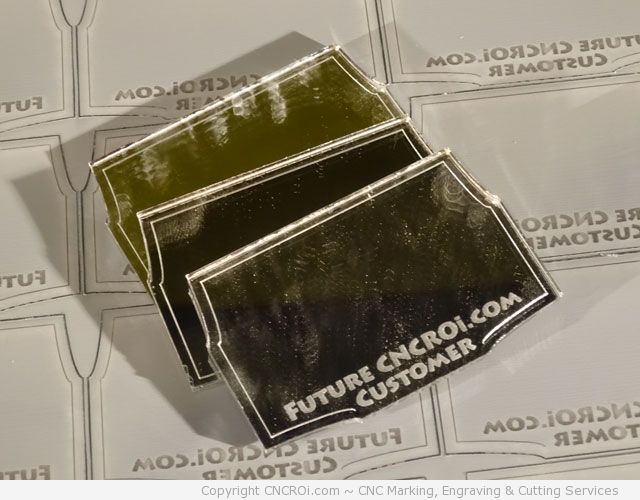

Lexan reverse CNC laser engraved (image not reversed).

The advantage of a thermoplastic is that it’s very malleable when warmed and with the CNC laser, the results are a nice flame polished edge rather than a rough one with CNC routers which then must be flame polished manually. Like wood, our Austrian large format CNC Trotec laser vaporizes this material during the engraving process but with cutting, combustion is a very real issue that must be controlled. This isn’t like a knife cutting through butter but a lighter cutting through solid petroleum.

Flame polished edges look great but things can get messy!

Unlike wood, acrylic is available in exponentially more textures, colors, transparencies and even densities which makes them a go-to material most of the time for us at CNCROi.com. Sure, I could make (and have made) jigs out of wood for certain applications but the cutting times using a similar thickness acrylic are much faster and the finish better. It also won’t expand or contract with temperature or humidity variances and is easily cleaned. The added benefit of acrylic is that it’s waterproof.

Resolution wise, we get essentially the same regardless of material as it’s more a factor of the material density than the material type with us as we have both a fiber and CO2 laser tube. The smell from wood engraving or cutting is pleasant while that from acrylic is anything but which is why having a strong extraction is essential when processing this material.

Laminates

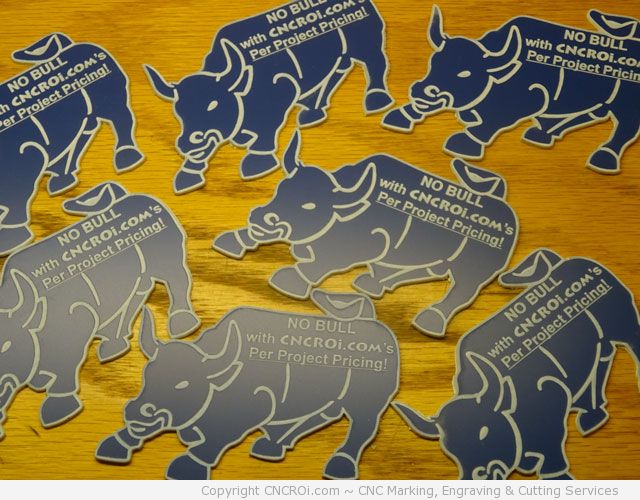

Like acrylics and other plastics, laminates also have their niche in the CNC laser engraving world. The advantage they have over polycarbonate is that you don’t have that awful staining that’s tough to remove unless you use methyl hydrate handy and you can get it multiple layers unlike most acrylics. Want a yellow sign with a black or red “background”, that calls for laminates unless you want us to bond two different pieces of acrylics together (depends on application yet again!)

What I really like about laminates is that the engraving is pretty consistent and the “fake metal” as I call it actually looks a lot like the real thing but without the hefty price tag or laser time. Don’t have money to anneal stainless steel for a sign? Use “fake stainless steel” laminate and engrave black. From afar, you’d be hard pressed to tell the difference and to be honest, the laminate will look better contrast wise but you do pay in durability. The REAL annealed stainless steel sign will last until the dinosaurs rule the Earth once again while the laminate would be hard pressed to outlast your house.

Plastics

Another nice quality of some plastics and acrylics is that they are color changeable under a fiber laser. As you see on the image below, the color change happened on the left hand side while the CO2 just engraved (melted) it. Depending on the application, you may require one reaction or the other to occur, regardless, both processes are permanent. Let’s take a look at some more specific plastic types.

Polyvinyl chloride (PVC)

I get this question often, why is Polyvinyl chloride (PVC) so bad for lasers? The quick answer is the C or chloride in the name, this is released during the laser cutting or engraving process which corrodes the machine and damages the lungs of the operator. Not to say we’ve never cut it, I’m sure we have here at CNCROi.com without knowing it BUT we aren’t talking about production day-in-day-out kinda stuff. It has a very distinctive smell and is the reason why we prefer to source our own materials than have customers drop off their plastics with files to us.

The tough part about identifying PVC (or any plastics) is that it’s also available in endless colors and transparencies, it isn’t just those black tubes you can buy at Home Depot BUT if you really want it cut, that’s what a CNC router was made for, it does a great job cutting and engraving PVC without the toxicity issues present with our Austrian CNC laser.

Polyester

Also known by the names of Fleece®, PES, Polarguard®, Thermolite® and Trevira®, polyester is used mostly by the fashion industry due to its high durability, low cost and light weight. They are also used in the industrial and building sectors for an endless variety of widgets. What I really like about cutting this in the CNCROi.com shop is that fashion designers don’t need to worry about loose threads in shapes that are simply impossible to achieve using an orbital blade. There is also no tearing of the material as our Trotec Laser never actually touches the material, hence, no need to hold it down either!

Although we can technically engrave this material, just like we can with paper, it’s better to cut this material and sew layers as the results are sharper and there is comparatively little fumes generated. Take the polyester fabric Velcro, why would you want to engrave that?

PETG

Also known as PET, VIVAK®, Eastar®, Vectan®, Spectar®, Quinn® or LUMEX®, Polyethylene Terephthalate Glycol is a thermoplastic polyester that’s used in applications where flame retardants, durability (it’s almost unbreakable) and chemical resistance is required. A surprising variety of everyday products are made with PETG including furniture and widgets used to protect machinery.

Delrin®

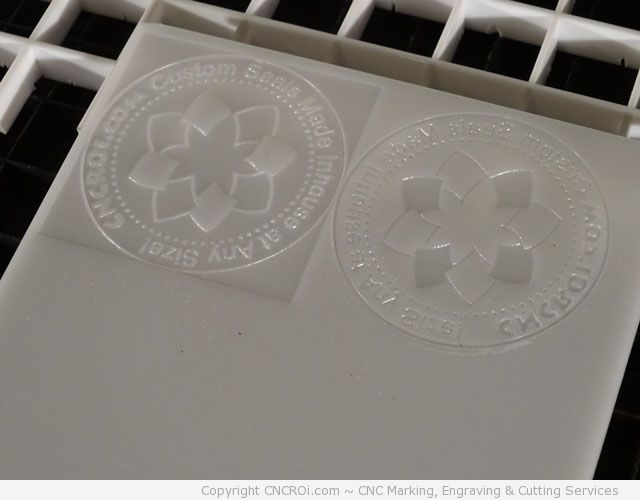

Also known as Polyaceta, Polyformaldehyd, Ultraform®, Hostaform® or Ertacetal®, Delrin is a very strong semi-crystalline thermoplastic resin that’s very resistant to wear and tear and it’s very rigid which means it can be used in a variety of applications where actual metal is. For instance, we use Delrin® here at CNCROi.com to make our custom seals!

It’s also heavily used in the industrial sector to replace metal bearings and packaging due to it’s ability to stay in one piece during travels from plant to shelf.

Kevlar®

Also known as Aramide, Aramid fiber, Aramid tissue, Nomex®, Teijinconex®, Twaron®, PTPA or Aromatic polyamide, Kevlar® is another thermoplastic used heavily where durability and strength (protection?) is required. Those bullet proof vests and high-end hiking boots use this material extensively as it’s incredibly difficult to pierce and yet, is very flexible with just the right amount of give. If you play any kinds of sports, I’m willing to bet there is some variant of this material in it – it’s found in everything from tennis balls to rackets, snow skies to strings.

Polyethylene

Although I could go on, let’s take a look at one last one, polyethylene which is also known by the names of PE, Polyethen, Alathon®, Dyneema®, Hostalen®, Lupolen®, Polythen®, Spectra®, Trolen®, Vestolen®, Luflexen® and Baylon®. Unlike the Delrin® you saw above this plastic has a very soft feel to its surface which makes it ideal for applications where you don’t want to scratch or “harm” the material being processed in industrial plants. It’s also used on cell phone displays where your finger wants something that feels comfortable with a bit of “grip” rather than using something that’s too rigid and hard.

How do you pick?

Generally with our customers, they will have a preference already at hand, for instance, an industrial company may needs some gasket mounts so they’ll have something they already use and we do a bit of research about it and cut or engrave away. Other times, the client says they want something like a custom plaque so acrylic is the default choice or they need a UV resistant sign, so laminates are the way to go. Like thermoplastics, there is a lot of choice out there but when you narrow it down, CNCROi.com engraves of cuts the same day in and out.