Laser Cutting Custom Dry-Erase Whiteboards

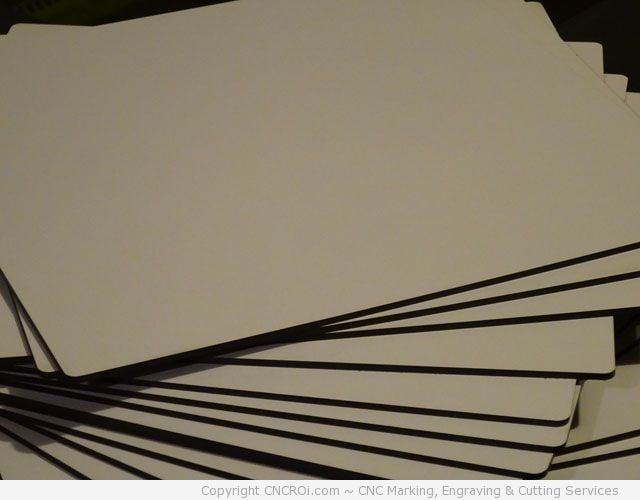

CNCROi.com was recently contracted to cut custom laser cut dry-erase whiteboards.

Our client was unhappy with the offerings found at retail outlets and after going through several rounds of cardboard backed dry-erase whiteboards, we provided them with a far more durable and stronger solution that had an MDF backing with a very solid and consistent non-magnetic surface for daily use.

Generally we put a masking agent over the surface of the materials we cut, sometimes just facing and other times front and back but in this case, none was required – the smoke was easily wiped off and our extraction from underneath did a wonderful job of quickly extracting the smoke before it had any time of settling either above or below the piece.

The smoke lines are so minimal as were flare-outs thanks to our gas kit which pushes highly compressed air along with the laser beam to dramatically reduce the chances of fires and vapor settling.

The results were precise, each board is identical to every other board and fit perfectly within the intended application.

In this case, CNCROi.com custom cut square boards but these can be made into any shape or size thanks to our pass through ability on our Austrian Trotec Speedy 400 flexx. Having a powerful and stable 110W tube also helps produce identical results time and again.

You can watch one board being cut to size in the video below – we left a bit of room around the boards as they were cut using a non-CNC tool.

We’ve learned that if something isn’t cut with a CNC, it won’t be identical so we prefer to create our own cut lines, the results look better and as you can see, material wastage is at a minimum.

Having two-way feedback on our CNC equipment is a fantastic way for us to ensure that job positioning fits across multiple boards and we can test these before any cut is made.