Laser Engraving a Beer Can

Laser engraving a beer can isn’t something I’ve ever done with our wide-format industrial laser so I figured why not give it a try at CNCROi.com and see what happens!

This came about as I was engraving some wine bottles with our Austrian CNC laser and I realized that both wine and beer both come within cylindrical packaging.

CNCROi.com does lots of metal and aluminium work so I wasn’t quite sure what would happen when you hit this Sapporo beer with a high energy beam of light.

I knew this can wasn’t anodized so my guess is that its many layers of four-color printing using clear plastic so it could either melt or if I used too much power, go straight through the can.

I spent the better part of a decade abroad living in countries as far South as Australia and North as China, then down to the Philippines, South Korea, Malaysia and even Japan before coming back to North America to start CNCROi.com.

So, when it comes to food and drink, I’ve tried lots of stuff from all over.

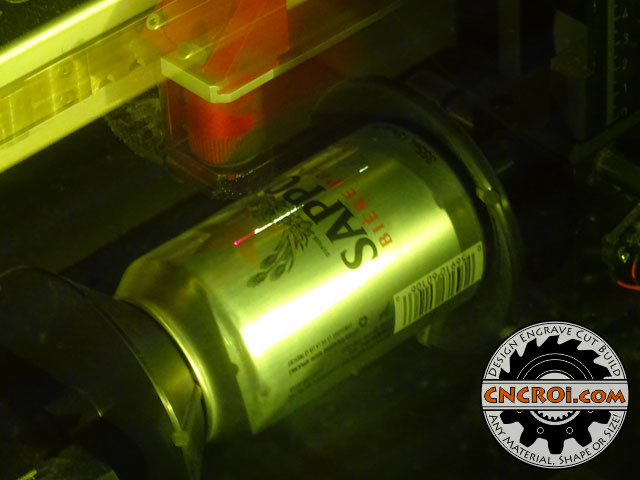

I wasn’t quite sure what I’d see from laser engraving this can, I was HOPING for the same results we achieve on anodized aluminium (video below) but I was surprised that even after multiple passes, I was only getting a polishing result instead.

Something was definitely being engraved and vaporized, you can see that from the photos that laser engraving a beer can is doing something for sure.

If you are curious about how they go about adding a label to beer cans, here’s a good video.

So it’s a pretty quick process, taking only seconds per beer can.

If you look closely, you can see the clear plastic film that’s applied to the can during the labeling process and that’s what I vaporized somewhat with our industrial CNC laser.

It’s always fun to try different things in our equipment as learning about different industrial processes and what we can do with those processes is an important part of CNCROi.com‘s understanding of how to make things.

You must know how something is made in order to understand how to make it.

Here’s another video of a cylindrical product demo to show you the design possibilities CNCROi.com can offer you as well.

This is the same design on cardboard as on the laser engraved beer can, so you can see the results of the same design across multiple materials and sizes.

Laser engraving a beer can will probably be the same regardless of it’s a Sapporo Premium beer can or a can of Coke, aluminium is very good at dissipating heat and the printing process must be an industry standard as well.

If you look at it in the right light, the polishing (more than engraving) that our Austrian laser has done to this laser engraved can of beer is pretty decent, the contrast is good depending on the angle.

What didn’t come out very well when engraving this beer can is wherever the color was, it tends to stay.

I did multiple passes and it didn’t seem to make a difference, the labeling on these beer cans is bullet proof!

Again, contrasting the engraved beer can above with what CNCROi.com achieves using anodized aluminium is night and day.

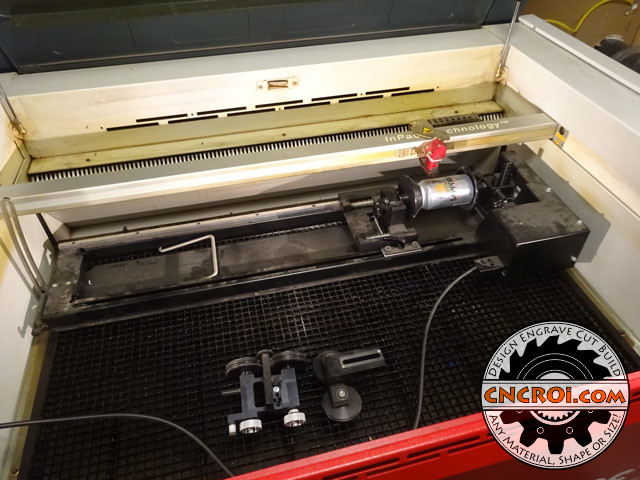

As you can see, we have plenty of room on our rotary system for a lot bigger items using our Austrian engineer and built rotary system.

What you see below the rotary system are rollers, sometimes rollers are better than a push and squish system we used for the wine bottles and the laser engraved beer can.

A close-up of the design on the laser engraved can of beer, again, the right angle and light, they look great, otherwise, they are hard to notice.

Even comparing that to stainless steel, you can see that the contrast of our industrial processes is what sells it, not much contrast, not much point in using a laser to do something on the base material.

Engraving a beer can, at least onto this can, produces sub-par results.

If you are looking for a passionate company to design and build something to your specs, contact CNCROi.com right now!