Laser Etching Glass

If you have some high quality glass that needs to be laser etched – we can do it too! For laser glass etching, the challenge is finding a laser quality glass to work with, not all glass is created equal and this can cause some production related issues so sourcing the best stuff isn’t cheap but it will have less flaws which give a better frosting result.

The advantage of glass using lasers is that it’s a one step process relative to traditional sand blasting. We can also etch far finer and complex patterns than are possible using pretty much any other process out there. What the laser actually does to the glass is shatter it at the microscopic level which causes the frosting effect you see rather than abrasion caused by sandblasting. They are very different methods for creating essentially the same effect at a distance.

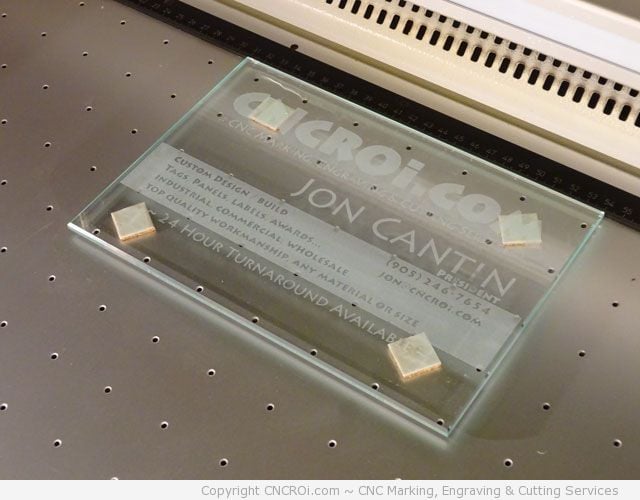

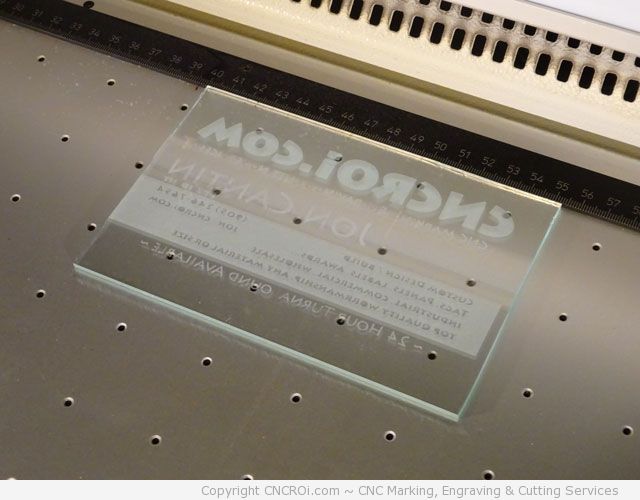

Generally for corporate awards or glass etching, you want to reverse etch the underside so that the front is flush, this makes cleaning a breeze and also give it a more polished and better looking esthetic regardless of where you place or hang it. This works great for wine bottles as well, you can keep the wine in the bottle as only the very top surface will be etched which releases no heat into the lower layers of the glass material. Of course, CNCROi.com has a rotary system with our Trotec Speedy 400 flexx so each wine bottle can have text going around the wine bottle if required by the customer.