Laser Marking Dates & Part Numbers

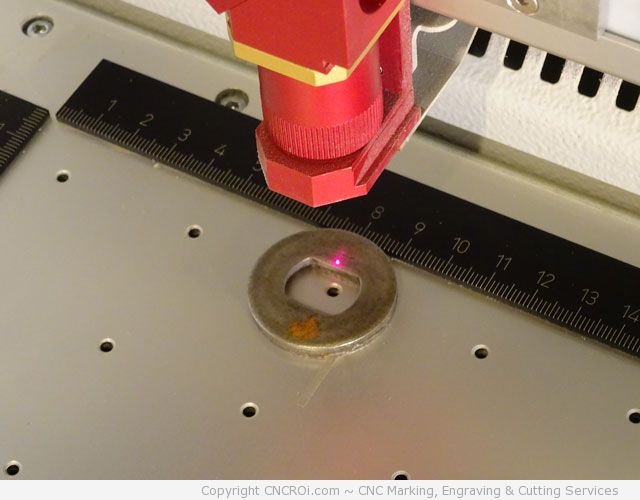

Lasers are a fine beam of energy and CNC laser machines allow precise control of where that beam of energy is directed. The beam is thinner than the width of a human hair and the one operated by CNCROi.com has two different sources sharing this awesome precision. What does this mean? We can etch, engrave, mark, anneal or cut pretty much any material known or unknown to man.

To give you an idea of scale and how small you can go (think anti-theft or logo marking if needed), I took a picture of a washer I annealed and put it on my business card. As you can see, the part numbers are extremely small and yes, I could go even smaller.

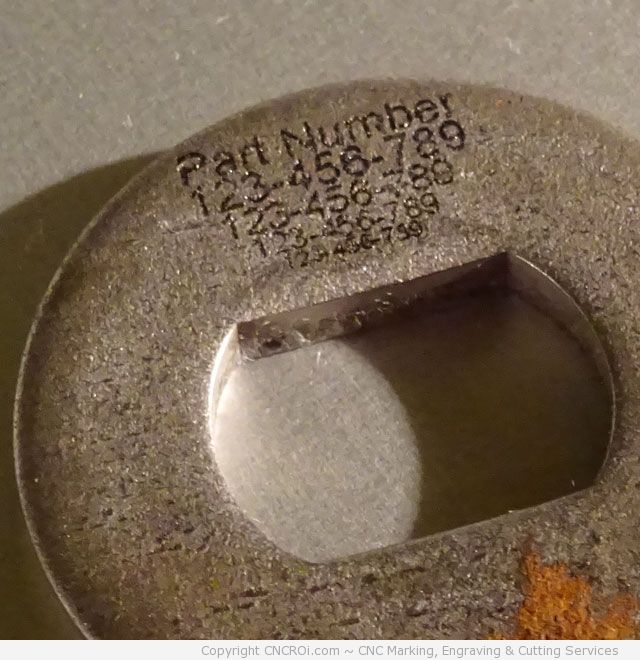

Looking at a closeup, you can see even more clearly how defined and clear the part numbers are on this random washer. This isn’t the cleanest washer in the shop and that’s the point – I wanted to show how, even in the WORSE of circumstances, you can still read a part number. As you can see, there is still PLENTY of room to put a lot more information such as the manufacturer’s logo, website, telephone number and if wanted, the first and last names of every employee at the plant.

This 3 cm (30 mm) washer can still be read by the naked eye down to font size of 2! Small parts like these are generally set-up in jigs where hundreds can be marked or annealed in one shot – this saves the customer a substantial amount of money and the operator a substantial amount of time. We both win!

In this case, something this small is perfect for industrial marking where they fit within other machinery and when the customer needs to order more or some spare parts, all they need to do is read off the part number found on the piece instead of doing endless measurements, sending pictures back and forth and then forgetting a decimal point and have to send the shipment right back. This part number is annealed, it will not come off and is a permanent fixture on this part.

Of course, different materials can be marked in different ways, if this was plastic, most likely this would have to be done using our fiber laser but if it was wood, our CO2 laser source. On some materials such as this, you can go almost to the microscopic level of detail while on others, to be seen clearly, you won’t be able to. This is why material testing is CRITICAL as part of the RFQ process.