Laser Marking & Engraving Random Plastic

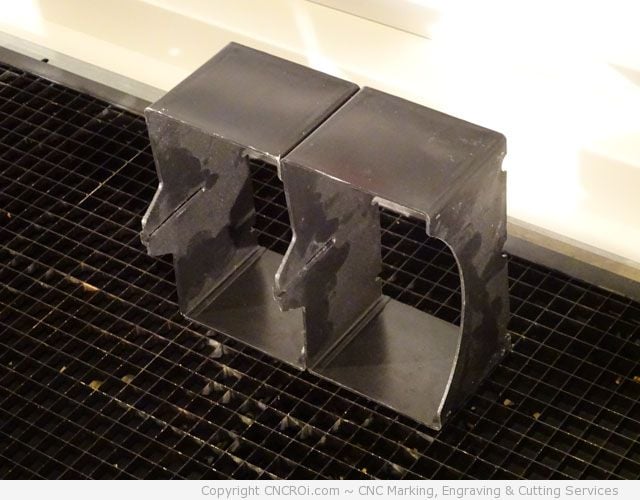

Got to love random plastic bits, there are so many different types each with their own material composition and densities that it’s always fun to see what the results are. In this case, these are IKEA (extra) vents that we didn’t have a use for anymore. I did this previously using hard drives but they were relatively “low” (pictured below) so this time around, let’s mark and engrave plastic components that are TALL!

Fiber marking on the left, CO2 laser engraving on the right. We can do both!

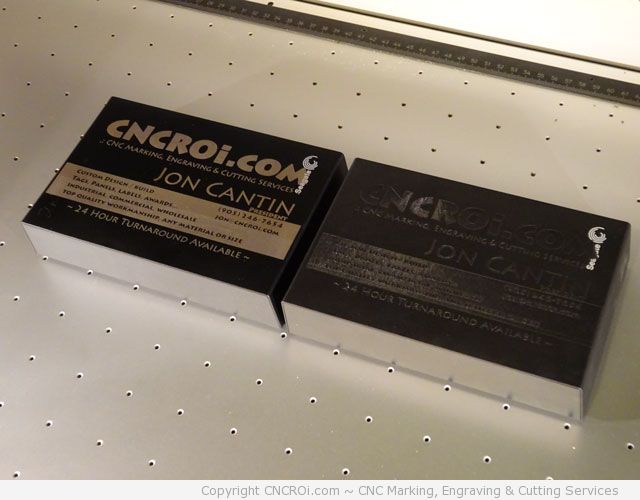

Thanks to our massive CNC laser bed, we can take-on projects that aren’t typically found in most custom CNC shops, this is a great example! Our bed measures a meter x 60 cm so just about anything we stick in it looks rather small.

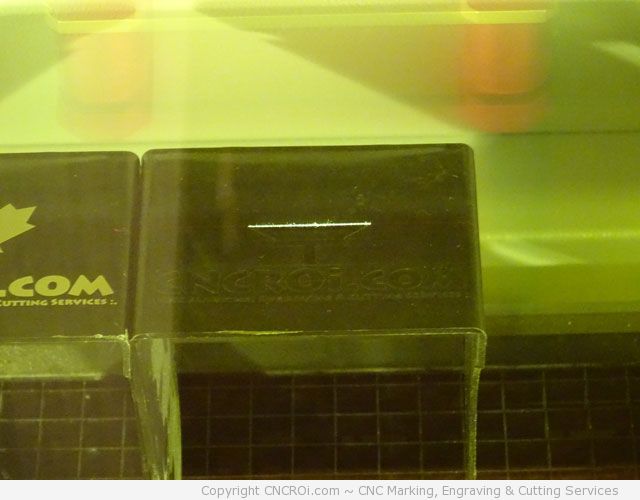

Zooming-in a bit more, you can see the plastic is rather soft and the surface is anything but flat… this would “traditionally” pose a problem when it comes to fiber marking as we’d quickly get out of tolerance which would produce uneven results but as we have a Trotec Speedy 400 flexx FIBER lens as well as our normal flexx lens, we can get this done quicker, better and faster.

So, once all the normal calculations are made, it was time to boot-up the computer and the machine and get some CNC laser marking going!

The results looked very promising contrast wise, and it only got better as the piece was fiber marked further.

This is about the best result I’ve ever gotten out of plastic, the contrast is awesome!

Now, I did the same but using our CO2 power source instead of our Fiber one… this necessitated a lens change and calculations to get everything the way it should be.

We aren’t getting a strong contrast like we did with our fiber laser tube on this plastic… the CO2 tends to melt plastic while our fiber color changes it.

After all is said and done, the fiber laser marking using our CNC laser is by far the better result. There is no damage to the plastic (zero depth) and it can be seen clearly from any angle even at a distance!

I put them into the light so you can more clearly see the effect, notice the melting on the right with some rounding while on the left, nothing.

Having the right tools for the job is what CNCROi.com is about, whether it’s plastics or metal, woods or ceramics, we invested in the best CNC laser in its class so that we can produce outstanding results for our clients. In this case, there is NO WAY of faking the results we got with our fiber laser source using a CO2 laser unless you plan on paint filling it.

As usual, I’ve included a video for your viewing and even included the one we did a while back of the two plastic hard drives, the results using the fiber laser source are similar but for the laser engraving CO2, this soft plastic produced far better results than the “hard” hard drive plastic.

CNCROi.com: Laser Marking & Engraving Random IKEA Plastic Vents

CNCROi.com: Effects of Fiber vs CO2 Laser on Hard Drive Plastic