Making Custom Stuff is FUN!

What’s fun about making custom stuff is the constant challenge it presents, especially when dealing with designs or materials that are applied towards novel applications.

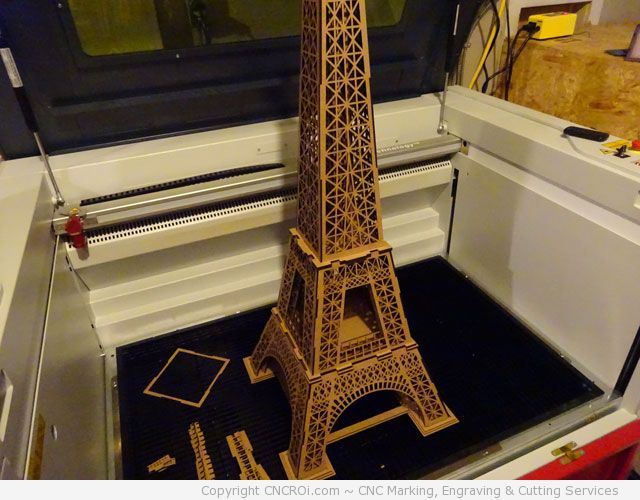

A great example of this kind of challenge is developing and producing flat packed 2D models that form 3D models such as the Medieval Castle above.

There is quite a difference between developing a model in 3D and testing it virtually and actually building it.

Bigger models may be thought of as easy but they are just as challenging as smaller models, each has its quirks that only become evident during the physical building process.

In the virtual environment, things have no weight and I don’t have to follow the laws of physics where two items CANNOT take-up the same space.

So when it comes to putting it all together in the real life, that’s when a 3D model comes to life in the real world and real world issues come to play that must be contended with.

You have models that have sliding or rolling items, others have very tight tolerances or sometimes I end-up building models that really can’t be built at all because part A is in the way of part B but generally, these are quickly resolved.

Regardless of the challenges, coming-up with through to building these 3D models is quite fun and a great class in furthering my learning of how to efficiently put things together.

You may think that making a model using hundreds of pieces as being hard to put together but it’s quite easy if the model we designed is well made and designed to be easily built together.

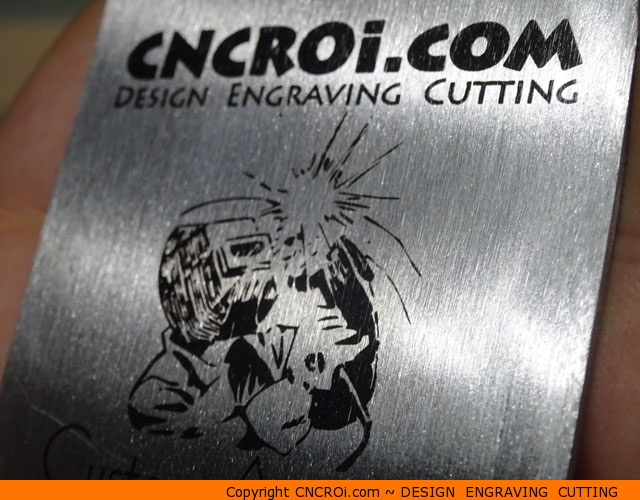

At the other end of the spectrum are lots of custom tags and plates for a wide variety of purposes, machines through welding tags.

Having a huge variety of metal capabilities allows CNCROi.com to offer custom services to a huge variety of manufacturers, some want colorful anodized aluminum plates while others want solid quarter-inch 316 stainless steel.

This is quite different from the 3D models, the work is more straight forward but it’s a precision volume game more than anything else.

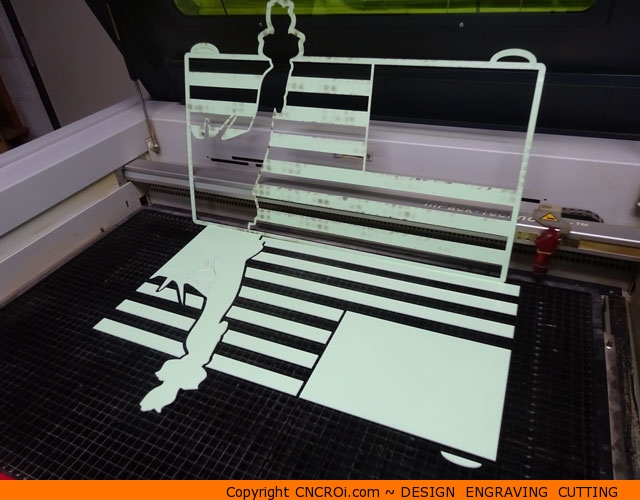

Other areas that are challenging include custom inlays when the materials are the same or at different specs.

Regardless of the project CNCROi.com is commissioned to do, from custom corporate awards to plaques and name badges, we put just as much effort in producing something amazing for our clients regardless of the volume or spec requirements.

Another area that’s fun to do is testing and making all these hundreds of videos that showcase our findings.

It’s great to have some fun too, trying new processes and materials and seeing how things come together.

It’s great to be able to show a customer who has a question that we have thought of that before and here are the results of our hard work.

Another thing I like to do is doing the “same design” across multiple materials to show customers just how different things can look using the same process but for another application.

For instance, custom name badges made out of resawed oak or lamacoids look incredibly different and have their own niche.

So, if you are looking for a company that can produce totally custom projects, start to finish or within a larger cog in your wheel, contact CNCROi.com because are passionate about making custom stuff!