Maple Pill Tray Counters: Custom CNC Woodworking

Custom Maple pill tray counters… even four years after starting CNCROi.com, I still have projects come-up making things I never made before!

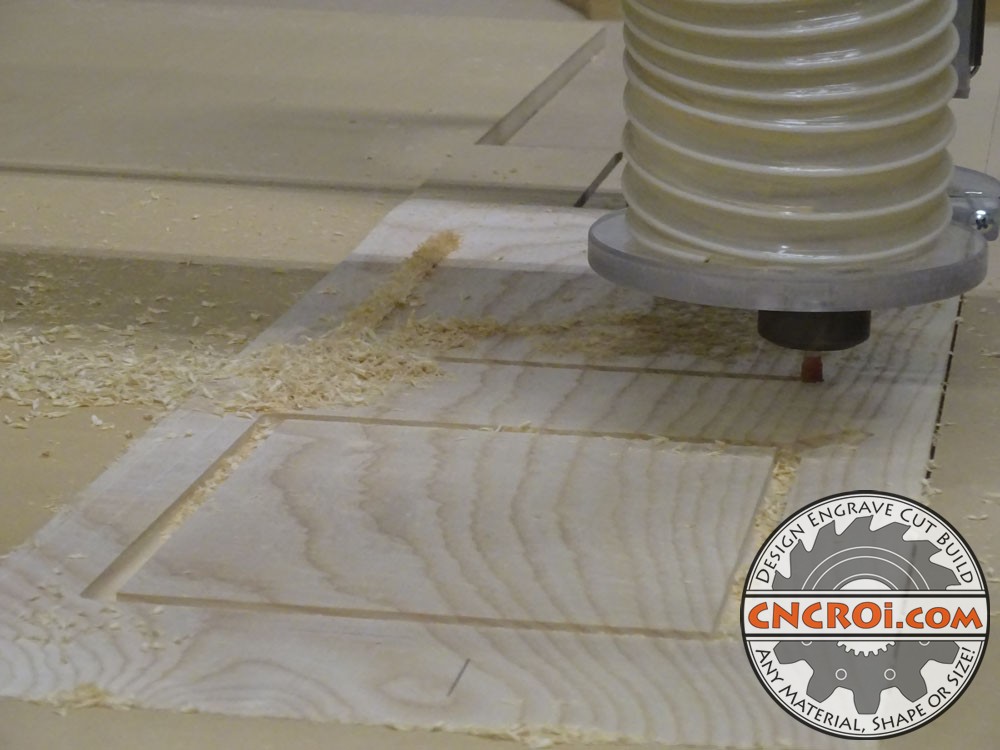

Before we do any carving or cutting using our ShopBot PRSAlpha, we got to flatten the table after doing a few more custom kitchen cabinets the last bit around as you can see from the groves in our sacrificial MDF table.

Flattening our table will both remove debris from the surface and help with hold-down tremendously as there is perfect contact without very thinly carved areas where we can lose suction onto this small slab of Maple.

On the left is the “old surface” and on the right the new one, perfectly flat without any imperfections, this is what will produce almost hand-out quality custom Maple pill tray counters, if we do this project using a non-totally-flat table, then a lot more sanding will be required.

I’ve been using CNC routers for a very long time, here’s one of my first projects with our smaller machine before we upgraded about a month ago to this awesome beast of a CNC router!

As we are going to use REAL WOOD to make these custom pill tray counters, not only do we need our CNC router to be flat but the wood too, planing will clean-up the surface and make it flat at the same time.

You can see how wonderful the Maple looks after it has been planed, not, it isn’t totally flat, but it’s dramatically flatter than it was in its raw form, the vacuum table will suck it down to make it flat so that CNCROi.com can machine out custom Maple pill tray counters out of it.

To make sure I have total suction on the piece of Maple, I layed out melamine scraps around it so that all the vacuum power in that zone will be focused on the board.

Melamine is MDF with a paper backing that doesn’t allow anything to get through it, as such, it makes for a wonderful material focus the vacuum table when dealing with very small pieces of wood for CNC routering.

What makes these custom Maple pill tray counters unique is that they are made out of a solid piece of REAL WOOD, there is no glue or other adhesives holding it together, just one solid machined piece of lumber becoming something very useful for a pharmacy.

What you see happening in these pictures is the first rounding along the edges, rather than have sharp 90 degree edges which are hard to keep clean, rounding them out means no dirt or debris gets stuck in the corners of these custom Maple pill tray counters.

If you aren’t familiar with CNC routers and what they can make, here’s a good video I made years ago explaining how they work and their capabilities… they are not better or worse than other CNC machine types, just different.

Due to CNCROi.com‘s on-demand approach towards mass production, making custom Maple pill tray counters out of any material, any size or shape is no problem, they all count as volume for us and whether they are all the same or different really doesn’t affect production in the slightest.

The pictures and video are messy on purpose, during production, CNCROi.com has the dust collector working but for esthetics sake, I left the boot off the machine so that you could see the actual machining happening, otherwise, there isn’t a spec of dust that escapes and the custom Maple pill counter trays would have been ready to ship once the process is done with little to no clean-up.

When it comes to woodworking, CNCROi.com has a full wood shop which means we aren’t just a CNC job shop but a custom fabrication shop that can take projects start to finish or just take them to a certain point and you can finish them up if you wish.

These custom Maple pill tray counters could have easily been laser engraved and additional details added to them quite easily, but for this project, the customer wanted to put their own finishing on it so I left it in the state right off the CNC router.

I really love our ShopBot PRSAlpha, it does amazing work, the same as it’s smaller cousin, the ShopBot Desktop which I’ve had for almost a decade and still works fine to this day.

There is incredibly versatility, flexibility and synergy by having more than one CNC machine type at CNCROi.com, it gives us a lot of production options that allows us to choose the best tool for the job, regardless of material or other limitations that may be present in the customer’s design specs.

I’ve seen a lot of plastic and cheap pill tray counters out there through my life, but these are by far the most beautiful and polished I’ve ever seen… and once the customer finishes them, they will look truly amazing!

Although a totally unnecessary step as I could have cut these out at CNCROi.com without requiring our bandsaw or associated sanding, I thought it would be fun to mix it up a bit as I really love using my bandsaw along with all the other equipment we have in the shop.

Like our other equipment, the bandsaw doesn’t replace our CNC equipment, it just compliments it.

CNCROi.com has an ever-growing list of equipment, both CNC and traditional hand and power tooling and as things progress over time, our capabilities just keep on expanding, making these custom Maple pill counter trays were a breeze because of these ongoing investments into the shop.

And the finished results speak for themselves, these will be sanded by the customer and finished but wow, what a great base to start-off with at their end, only minimal sanding is required on these beautiful custom Maple pill tray counters.

Have a custom woodworking job?

Contact CNCROi.com!