CNC Router: Each Material & Technology has a + / –

A CNC router are awesome tools, but they can’t do everything, no CNC machine can, which is why we have a diversity of top of the line equipment to handle projects in the most efficient manner possible.

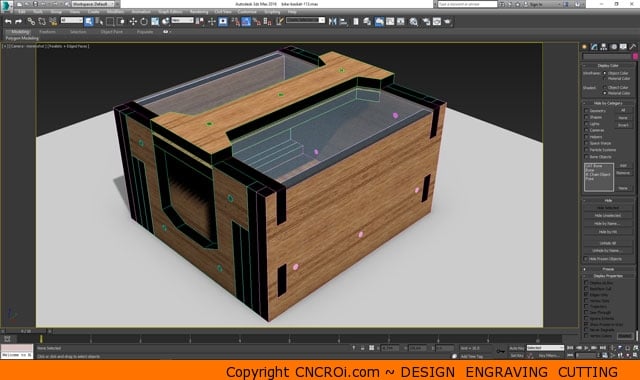

Due to the nature of the work we do here at CNCROi.com, we work with a number of different CNC tools across a huge variety of materials. The issues that each material presence is unique as is the machine used to engrave, etch or cut it out, something we don’t have to deal with when doing our 3D modeling.

CNC Technology walk-through

I made this video a while back to give you the basics, we’ll be covering additional technologies here but it should give you at least a background, if you don’t have one already. This is by no way a in-depth overview of the different technologies, just a very brief overview of what we have available for your custom project.

https://vimeo.com/204703236

CNC Router

CNC routers are great fun, it’s how I cut my teeth on in the CNC world that led-up to me getting into other CNC technology like laser, waterjet and plasma… etc.

CNC Router Good

- Can cut a huge variety of materials.

- Are fast, accurate and powerful.

- Massive number of router bit configurations.

- Precise X, Y and Z.

- Can produce beveled, under-hangs, pocket and other types of architectural or mill work details.

CNC Router Bad

- Bits break.

- Material needs to be held down.

- If you don’t have a tool changer, changing bits between job cycles can take-up valuable time.

- Plastics needs to be flame polished with a torch after cutting.

- Edge quality may need sanding or finishing.

CNC Laser

We have a dual-sourced Trotec Speedy 400 flexx wide-format industrial laser. It has both CO2 and fiber laser sources and with an accuracy of within 5 nanometers! Plenty of power, speed and precision.

CNC Laser Good

- Can cut a huge variety of materials.

- Can handle projects as long as you want, for instance, we regularly make signage that’s over 4 meters (13 feet) long!

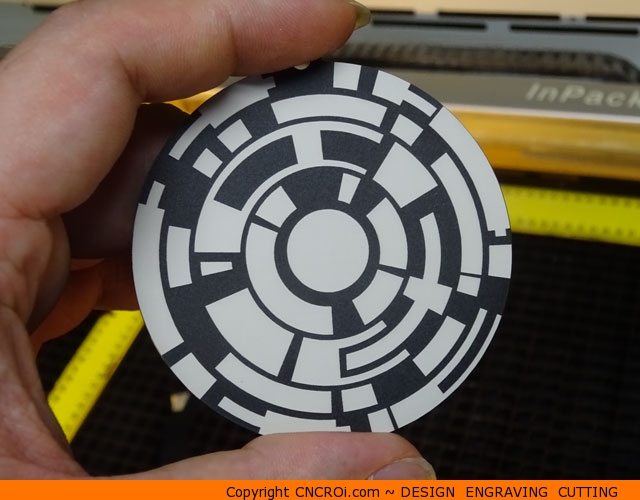

- Can permanently engrave, etch and anneal metals, plastics and woods in up to 1K DPI resolution.

- Precise X & Y axis.

- Nothing to break, it’s a contact free process.

CNC Laser Bad

- Although some jigs can be made, generally the cutting and engraving is 90 degrees (straight down).

- Bevels and other edges easy with a router are not efficient with a laser and not as precise.

- Now 2-way feedback, the router knows what depth to position the bit, the laser has no idea (Z axis not so precise)

- Produces smoke and resin and for some application, the heat causes issues.

- Free flame polished plastics – with router, the edges are frosty and chipped.

CNC Waterjet

We are getting more and more inquiries regarding waterjet capabilities, again, each CNC technology.

Waterjet Good

- Cuts can be done along 5 axis, meaning you can have angled cuts inside of parts not possible with a CNC laser and very tough to do even with a CNC router.

- As it’s also a “contact free” process other than the water and aggregate, you don’t have the vibrations and hold down issues present with a router bit pushing and pulling through the material.

- It’s fantastic for metals, plastics and woods as the edge is essentially sanded at the same time.

- Can cut through INCHES of metal without the heating issues present with laser or plasma which require secondary processing.

- Just as accurate as other CNC technologies.

Waterjet Bad

- Can’t be used with aluminium where anodization is required as the edge isn’t conductive to electricity (think power coating with heat, anodization with chemicals).

- Can cause de-lamination on some laminated materials though some of these issues can be reduced by proper design.

- Your material will get wet.

CNC Plasma

CNC plasma is essentially a torch hooked-up to a CNC machine that cuts out parts from an overhead gantry.

Plasma Good

- Can cut a wide variety of metals with excellent edge quality.

- It’s fast and accurate, similar to a CNC router in speed (material depending).

Plasma Bad

- Produces toxic fumes and dust.

- Parts can warp due to heat.

- Parts may require secondary processing to remove molten metal in the bottom.

CNC Overview

There is no PERFECT CNC machine out there, each has their costs and benefits, where a CNC laser doesn’t really have any consumables, CNC plasma, router and waterjet do which need to be accounted for. How do you know which is the best technology? It depends on the application, budget and design.

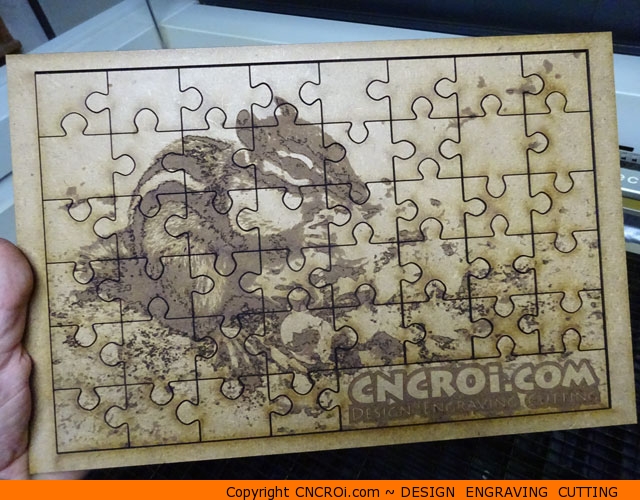

For instance, if you had to cut wood, plasma is out. If you needed it engraved, it may be more efficient to cut the parts with a CNC router and then laser engrave as the bit can’t make fine detail smaller than the diameter of a bit.

There is a lot of thought that goes into the work we do, for us, we specialize in CNC router and laser work though we have access to other machines and suppliers depending on the requirement.

Material Overview

To “complicate” things, materials all react different to CNC equipment used for it, for instance, where a CNC laser produces a burned edge (which is good or bad depending on application), you require secondary sanding if it’s cut using a CNC router. Where a waterjet would give you a nice sanded edge, you can’t make pockets like a CNC router can and making pockets using a CNC laser isn’t very accurate and incredibly slow by comparison.

Same thing with metal, let’s say you have a design that’s 2″ aluminium, it can be done with plasma or waterjet but if the application is such that material warping may be an issue due to the heat produced by the plasma, waterjet or CNC router may work. It depends on the design.

You don’t need to know this stuff!

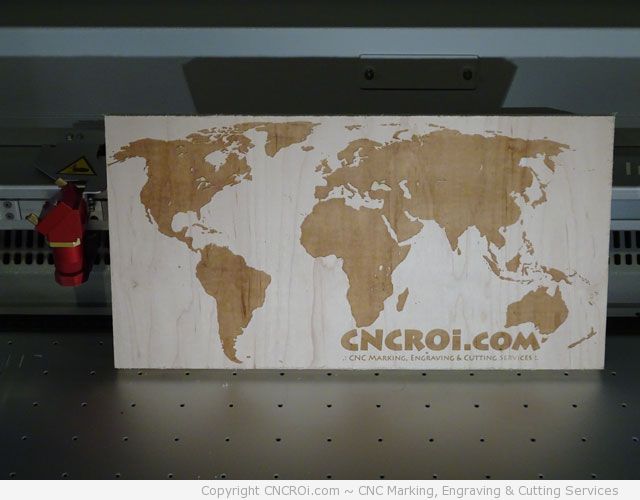

We use a huge variety of CNC equipment and processes at CNCROi.com, so just tell us the application and budget and volume and we’ll figure out the most efficient way forward. For instance, here’s a design I made a while back using a CNC router and you can see the edge quality requires sanding.

While doing a project with our laser produces a different edge requiring no sanding at all but a wiping of char.

https://vimeo.com/174571550

If this project was metal, a waterjet would have been a better tool at this thickness than router or plasma.

I could go on and with a lot more depth but that’s why I wrote a book about this stuff, actually, half a dozen of them which you can get HERE at our e-com store.

Long story short, you need something custom, contact CNCROi.com right now!