Material Testing Metal Laminate

Although CNCROi.com does a lot of metal work, we are increasingly getting projects focused entirely on CNC laser engraving laminate… and it’s a very different animal!

Why go with metal laminate instead of stainless steel or anodized aluminium?

Although stainless steel and anodized aluminium are fantastic materials to work with, they do have their drawbacks in the area of pricing. Making something out of laminate is a fraction of the cost from cutting through and annealing stainless steel or fiber marking anodized aluminium. This does come at a cost though, longevity.

While our metal work will last for a human generation if not longer if well maintained, laminate will take the same approach but in dog years. Laminates are more prone to scratching, delamination and direct sunlight, even the UV stable stuff, will eventually get the best of it.

Material Testing

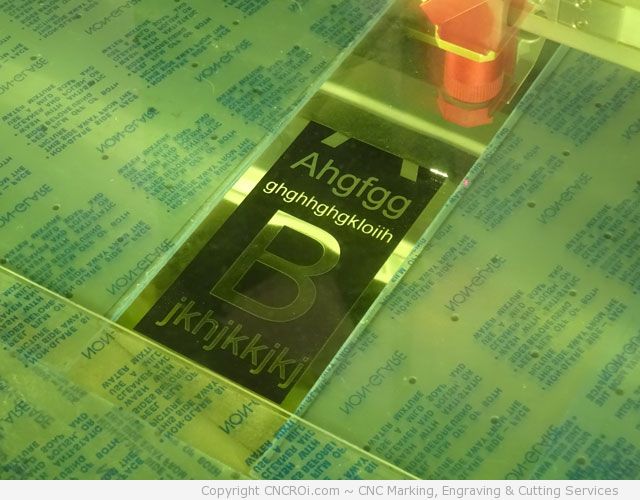

Generally for these blog posts, I know exactly what I’m going to do and the article that will follow but in this case, I just happen to be in the shop looking at some metal laminate and decided to play around with it, it was never planned hence the letters instead of our traditional CNCROi.com logo across everything we do.

What you will notice is our bed seems to be full of acrylic sheets around this sample, the reason behind that is quite simple, I wanted to get maximum extraction from the top as I wasn’t using my air compressor to throw-off the vapors our Austrian Trotec Speedy 400 flexx generally produces. This creates more “vacuum” to hold material down while at the same time, dramatically increasing exhaust power overhead.

For this, I was looking to see how clearly the edges were coming out, hence the easiest way to see edges from a variety of angles was to just use letters from the alphabet… you have round, straight, angles… the alphabet is wonderful for material testing!

There was another reason why I used these acrylic sheets too, it was to hold the edges of the material down, as I was doing a lot of plastic heating going back and forth up a thin sheet, it tends to get hot and “curl”. By using my vacuum table in this manner, I was using the acrylic to hold this down quite well during this process. Like I mentioned, I was never intending to do a blog post about this so the visuals aren’t as polished as normal.

The results were great though, laminate is a challenging material, each CNC laser operator – even with years of experience – have their own “secret” to producing the best results and what I find interesting is that these can be rather contrary! Without delving too much into what I’ve been told to do, thus divulging “industry secrets”, I can easily attest that there is more than one way to achieve a pretty damn good result on laminate. It is a material that does take some patience and time to understand though… and by far laminate is the material that has caused me to produce the most expensive scrap from any material.

Why do material testing?

If you have a CNC router (like we do), you are trying to maximize chip production, too small you end-up creating powder, too big and you are really wearing down your bit. CNC lasers are no different, you are trying to get maximum speed out of the laser while still producing extremely good results… if you go too slow, you end-up creating lots of fire and ash, if you go to fast, you end-up literally doing NOTHING. Laminate is a strange animal because it’s extremely finicky regarding heating. For instance if you pass over an area too “fast” and it still has some heat built-up in the material, you will end-up with a different finish than at a spot that had a few more seconds to cool down.

I’ve noticed I get this a little with metal annealing but nowhere near the same extreme as on laminate… that’s why I enjoy wood so much as it just doesn’t keep any heat and is soooooo easy to work with in contrast on both the heat generation and the focus tolerances. With metal, you have a fraction of a mm to produce a good result but with wood, you can be way off and still produce great work.

Here’s the video of the laser engraving process… filming was a last minute decision hence starting well into the project.

CNCROi.com for laminates too!

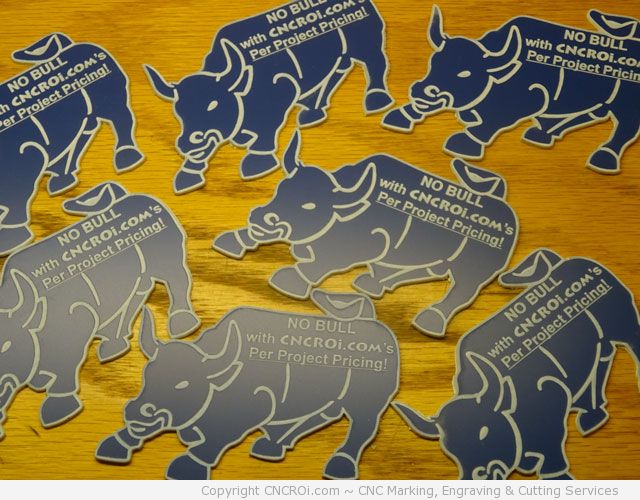

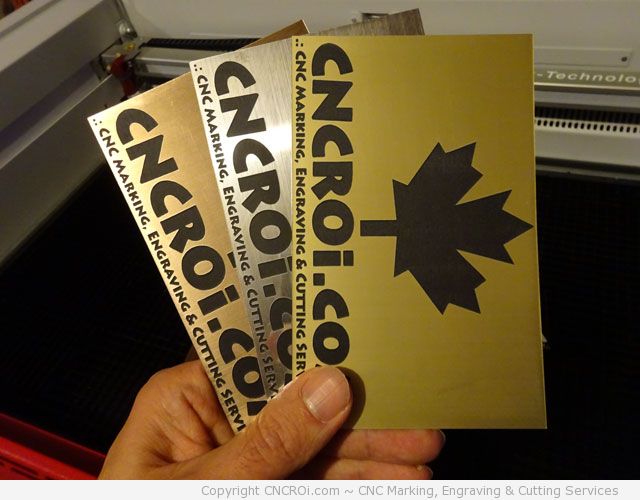

Have a project needing some laminates? CNCROi.com is here to help! Here are a few pictures of some of the projects we’ve done previously to get your wheels spinning as to the possibilities that laminates can provide your business. From signage to unique gifting, laminate has a well deserved position in a CNC engraving company.

Metal laminate.