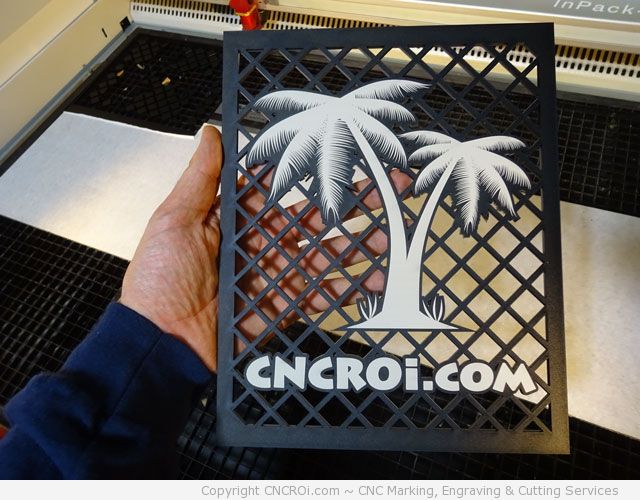

Acrylic

What’s to say about acrylic, it comes in a massive variety of colors, textures, transparencies and thicknesses… in addition, it can be bought in different grades to suit just about any application your business may need.

With just a little heat (or a lot) it can also be color changed, bent and folded!

Acrylic can be cut to just about any size using our Trotec Speedy 400 flexx’s CO2 laser source (we have a fiber as well) efficiently and cleanly.

The edges are always flame polished – something you can’t do using a CNC router or manual tool unless you go through a secondary process involving a flame thrower and a quick hand.

If you are looking for a custom jig, acrylic is also a wonderful material, they are precise, easy to build and last a very long time without being prone to warping due to humidity or temperature variations like MDF or other materials generally used for jig making.

Some applications best suited to acrylic:

- illuminated or neon advertising displays

- small personalized point of sale (POS/POP) displays

- unique name badges

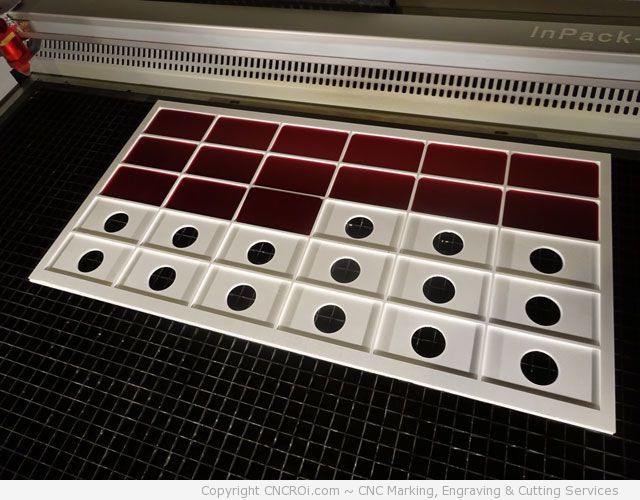

- custom poker chips

- individualized jewelry for short runs

- mass production of promotional tags of all sorts

- inserts and inlays

- … and the list goes on.

Including custom mirror production that can be paint filled!

As you can see, there are A LOT of applications where acrylic makes perfect sense!

For more information about acrylic visit http://cncroi.com/category/acrylic/.