Plastics

We can work with other types of plastics including polycarbonate, plexiglass, polypropylene and polyethylene – some of the best results of laser engraving include ABS (Acrylonitrile butadiene styrene co-polymerisate), PA (Polyamide), PI (Polyimide), PES (Polyester) and PC (Polycarbonate) while cutting PP (Polypropylene), PET (Polyethylene terephthalate), PC, PMMA (Polymethyl-methacrylate), PS (Polystyrene), PES and PA come out awesome!

Please visit our Acrylic page for details about this specific plastic type as well as our Delrin/Depron page.

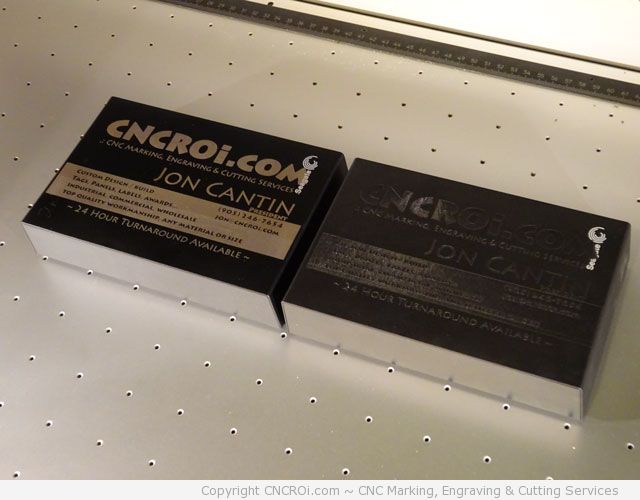

Fiber marking on the left, CO2 laser engraving on the right. We can do both!

Because we have both a CO2 and fiber laser, we can also mark materials instead of engraving them – meaning no material is removed during the laser marking process. Depending on the composition of your plastic, having this flexibility allows us to product the best results for your intended applications.

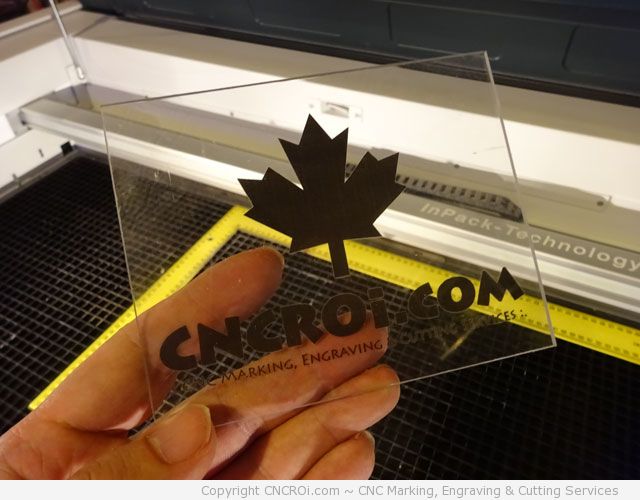

Some applications that can use either or both laser sources include personalization of cell phones, laptops, badges, computers, POS, gifts and the list goes on.

Our laser is more precise and faster than a cutting plotter as there is no material contact or resistance issues and we don’t need to replace dull blades that can leave marks or tear material. Our laser engraves, marks and cuts just as well on the first as the millionth!

ABS

An amorphous thermoplastic blend, ABS cuts very cleanly with our laser with a very nice polished finish.

Acrylic

Please visit our acrylic page for more information.

Delrin

Please visit our Delrin page for more information.

Fluoropolymers

Fluoropolymers in thin gauges cut very cleanly with our CNC laser, ideal for Teflon gaskets but also with a host of other applications in the automotive and aerospace industries. Our larger format machine allows us to efficiently and accurately plow through large production runs with consistent results.

Hypalon

A trademark of Dupont, its chemical name is chlorosulfonated polyethylene (CSPE) synthetic rubber (CSM), this synthetic rubber is used extensively in inflatable boat manufacturing process due to its resistance to chemicals, temperature extremes and UV stability.

Kapton

The results of CNC laser cutting Kapton are very clean, we can also engrave this material with incredible consistency even across large sheets.

PETG/PVC

PETG produces toxic fumes, just like vinyl that produces Chlorine gas so we generally opt for polyester or acrylic instead for safety reasons unless you have a very specialized application that requires it. The engraving and cutting are very corrosive to our equipment.

Polycarbonate

CNC laser cutting polycarbonate tends to discolor it, for thin material used in industrial processes, the results are consistent and clean but as the thickness increases, so does the likelihood of discoloration. The engraving results are pretty good though.

Generally, we suggest skipping polycarbonate and using acrylic or polyester for better results where fiber laser source color changing isn’t required.

Polyester

Polyester cuts cleanly with nice sealed edges and can also be engraved. Polyester is used heavily in the fashion industry for clothing and by interior designers for upholstery.

Polyethylene/Polypropylene

Please contact us if you must use polyethylene as generally we prefer using ABS or acrylic for better results using our CNC laser.

Polystyrene

Used heavily in the architectural field to make small models, the results from laser cutting are clean and consistent. Thin polystyrene cuts very nicely but if you get into thicker material, the results quickly become inconsistent with melting. Generally, acrylic produces better and cleaner results with only slightly more weight, which is what we suggest using instead.

Our laser doesn’t require any pressure to be exerted on the foam during the cutting process – there is no fixation which means even the most delicate foams or mats aren’t damaged.

Polysulfone

Not a nice material to cut or engrave generally using a CNC laser due to charring, use acrylic instead.

Polyurethane

A pretty nice material to use with our CNC laser for both cutting and engraving applications. We can cut open or closed cell polyurethane foam up to an inch thick though thinner material produces better results.

For more information about Plastics visit http://cncroi.com/category/plastic/.