Metal Tank Level Gauges: 12 ga 304 Stainless Steel

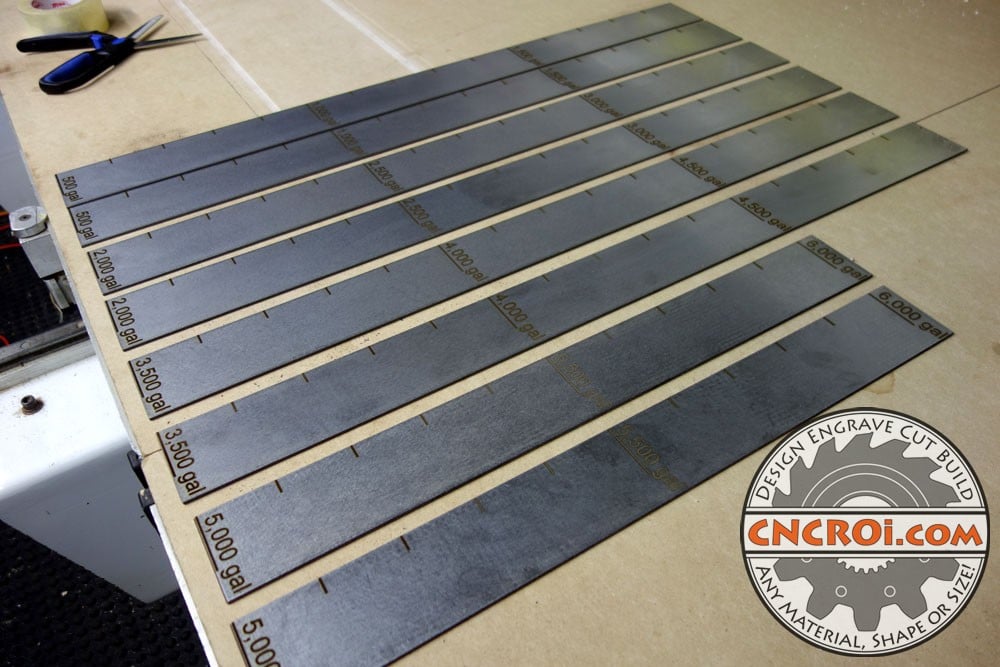

These custom metal tank level gauges were made at CNCROi.com using 12 ga 304 stainless steel with 2b finish that was then sanded to a more interesting polish.

What are custom metal tank level gauges? They are essentially a hard ruler that is next to a sight glass so the customer knows immediately what how much “stuff” is in the tank.

The goal of custom metal tank level gauges isn’t to be 100% precise down to the ml, it’s just a quick evaluation of roughly how much contents are in the tank.

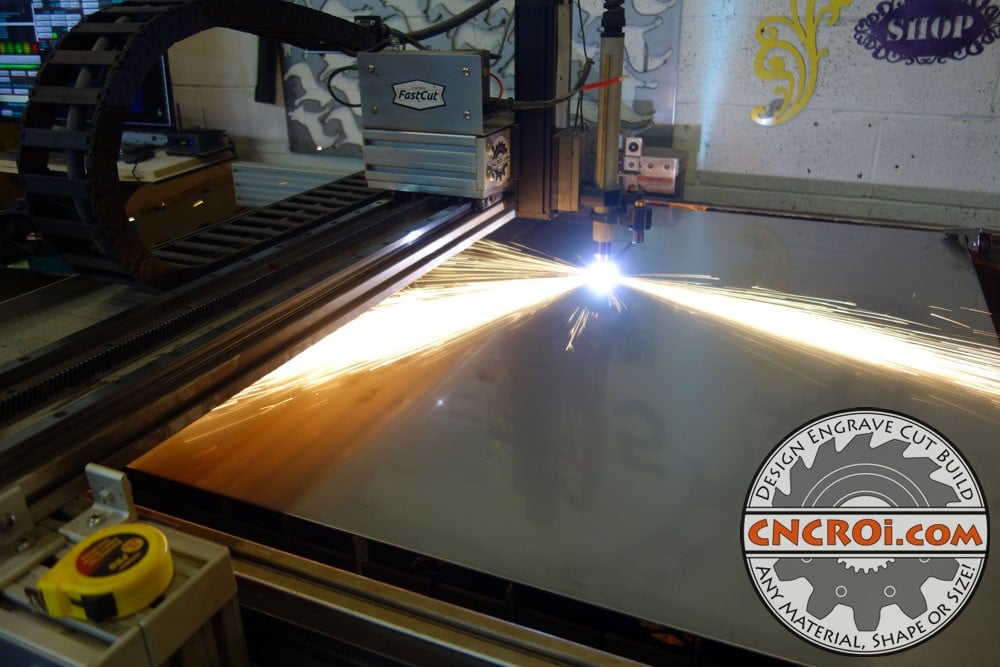

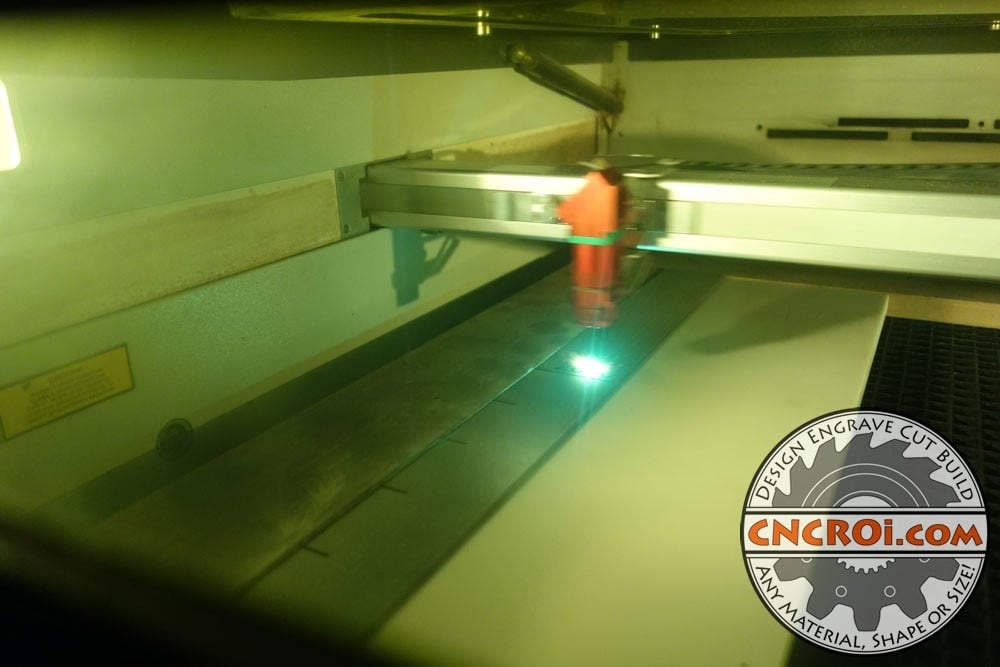

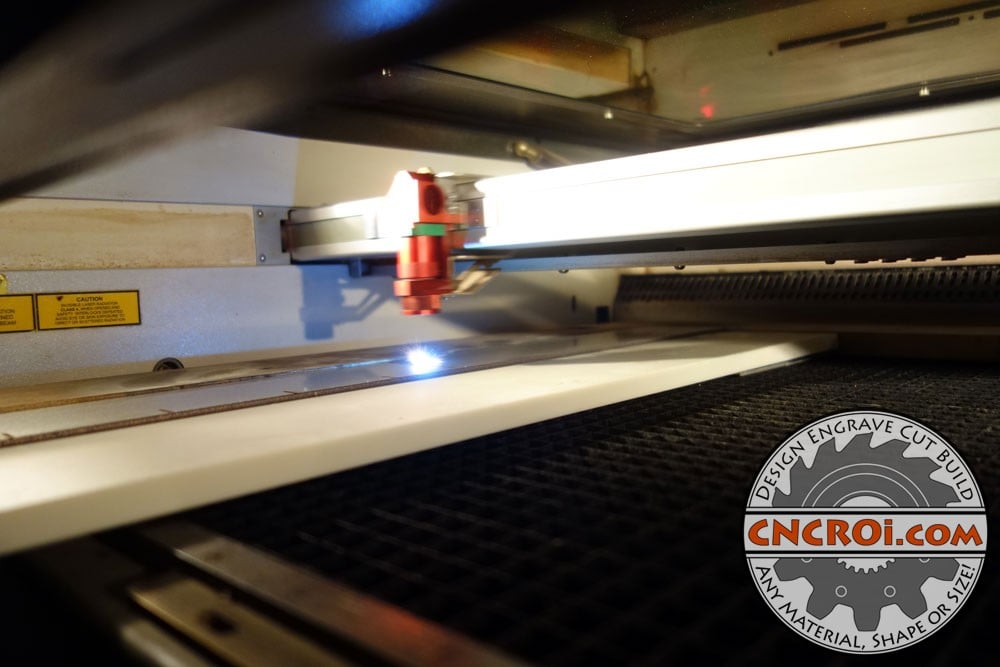

To make the slats, I used my CNC plasma cutter, it did quick work of the 12 ga stainless steel.

I could honestly plasma cut things all day at CNCROi.com, I just really enjoy the process with the heat, the noise and the power that’s unleashed by the plama once it has been arc’ed.

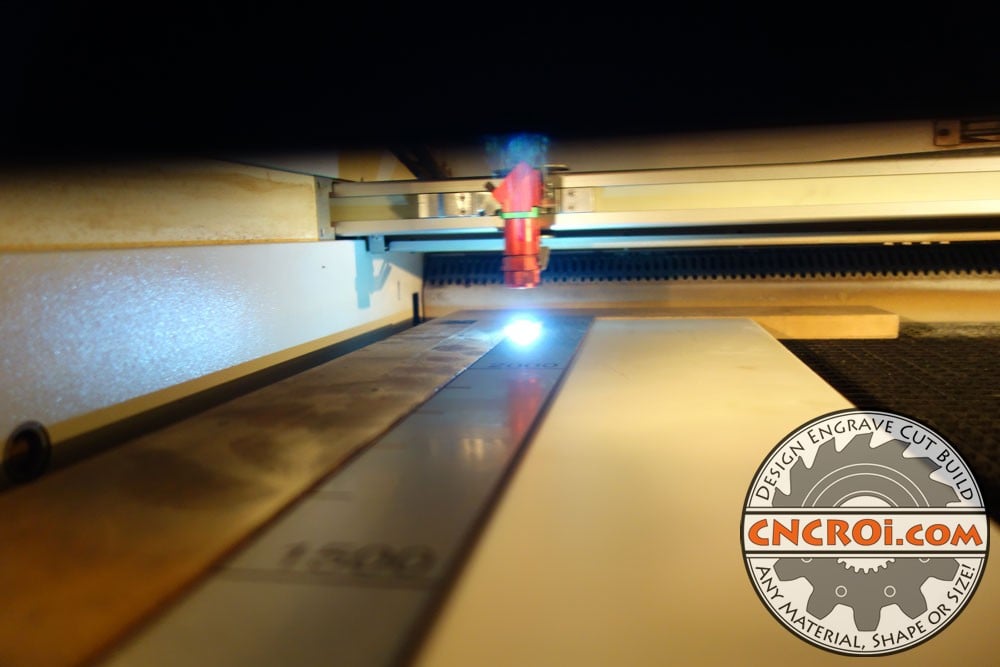

Of course, laser cutting is always a possibility as well at our shop.

There are many ways to cut metal, from waterjet to laser, but plasma in my mind is a step apart in my mind, it’s like comparing welding to self-taping screws, sure, they both do similar things, but the welding is just more impressive.

I keep forgetting to add a barrier between the plasma cutter and the computer running it, some sparks melted into the screen but if the screen lasts me a decade, it’s a sacrifice that I’m willing to make at CNCROi.com.

The sparks come from the instant vaporization of the stainless steel from the plasma, there is a lot more fire and sparks under the sheet of 12 ga than above it.

Sometimes plasmas aren’t the best tool, having diversity means we never have to push one technology for everything, we can use the best for the given application.

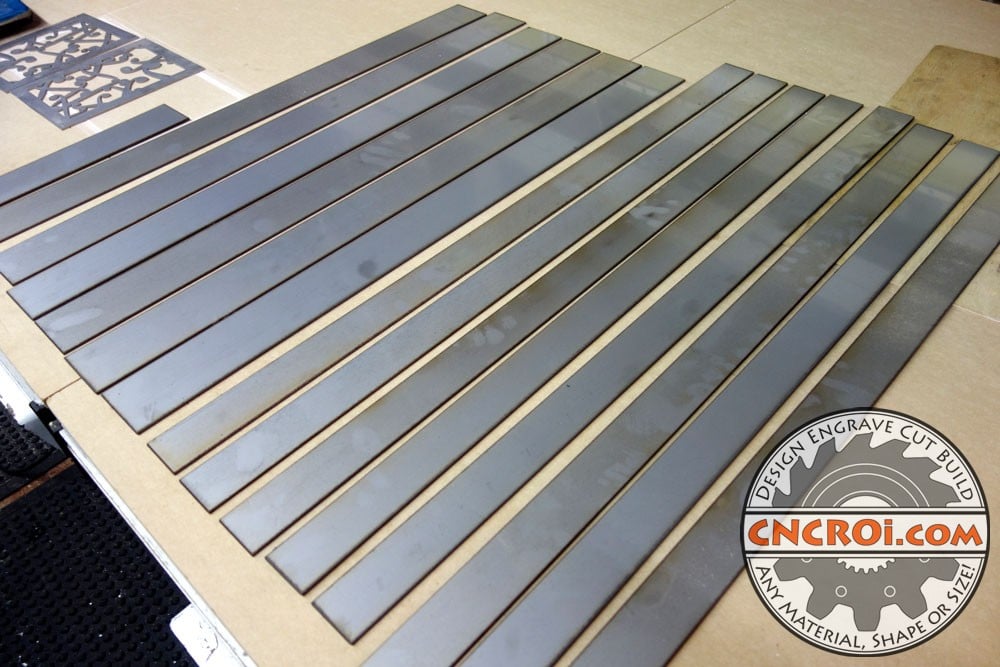

I probably would have made this project using flat bar but time was of the essence and stainless steel flat bar is a special order at this spec, hence cutting up a sheet rather than just vertical pieces using my metal chop saw at CNCROi.com.

Projects such as this really showcase the power of CNC synergy across multiple platforms, in this case, the first step of the custom metal tank level gauges was CNC plasma cutting and then the second will be CNC fiber laser etching the slats I made using said plasma.

When it comes to stainless steel, it really holds onto heat, there were two slats that warped slightly during production so I just re-cut those to make sure their dimensions were within the customer’s specs for these custom metal tank level gauges.

Another idea as to mixing and matching plasmas with laser etching.

As CNCROi.com continues it’s investments into metal fabrication, you’ll begin seeing the tools of the trade a lot more this year than in the previous ones, it has just been a long hull to get things to this point with both CNC and non-CNC capabilities growing in the shop.

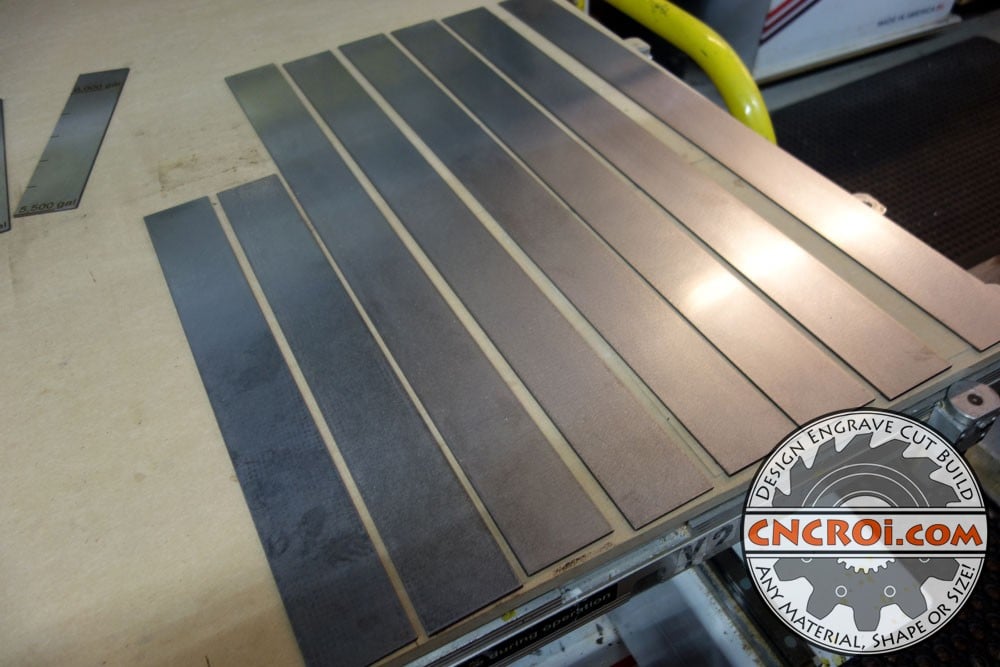

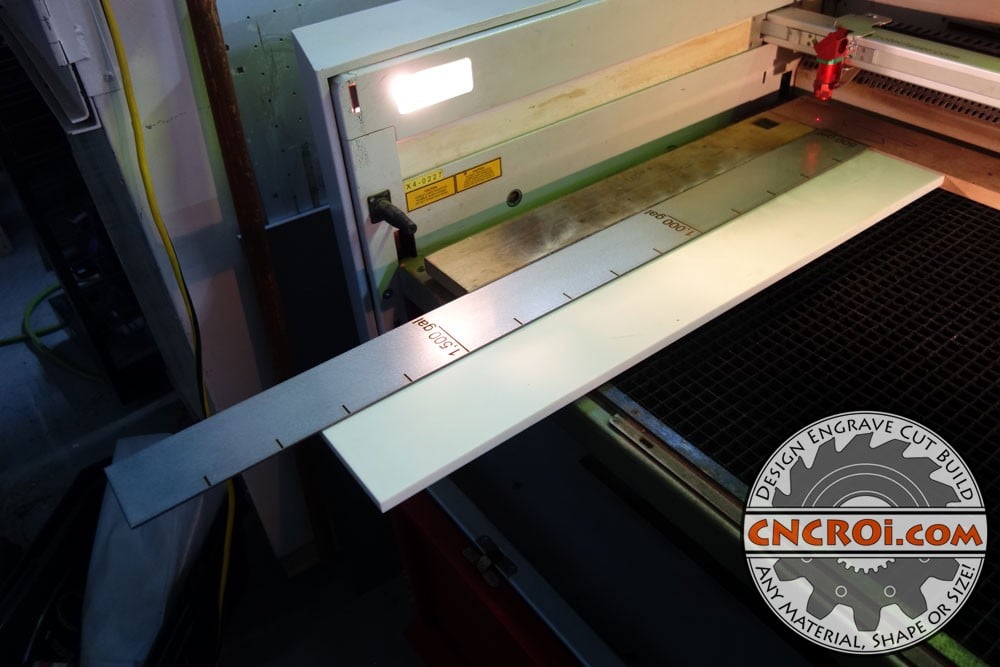

This custom metal tank level gauges project is actually two, one with thinner longer slats and the other with wider shorter stainless steel slats.

You can see the surface is a little rough, that’s easily cleaned-up using my orbital sander at CNCROi.com, the finish from that process just looks great and I prefer it to finish #4 though that finish does have its place as well for particular applications.

I look forward to showing a lot more welding videos at CNCROi.com, it’s a very fun and complimentary process for our customers.

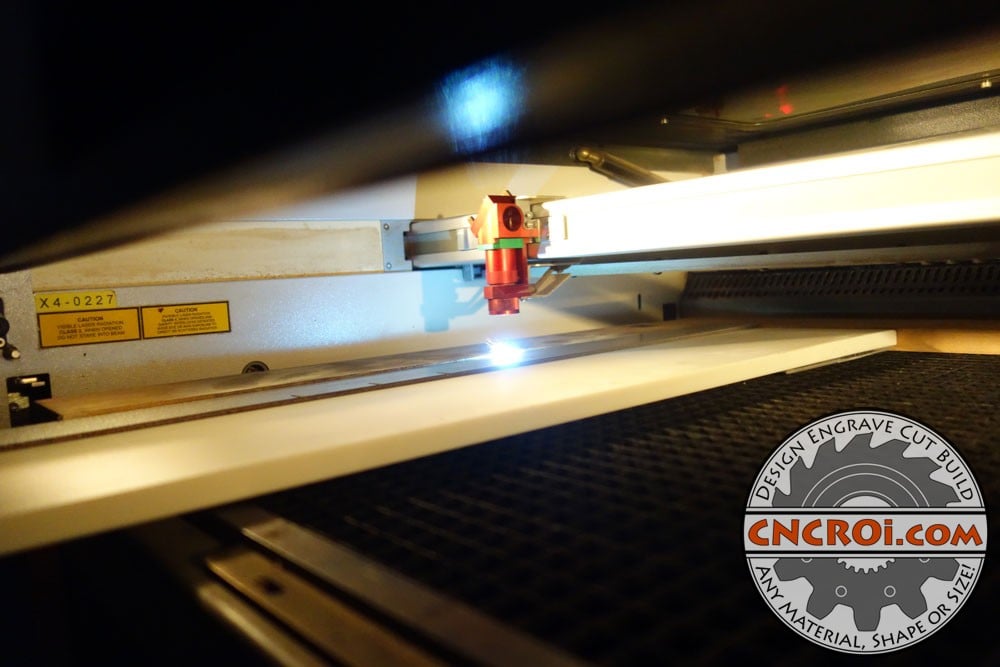

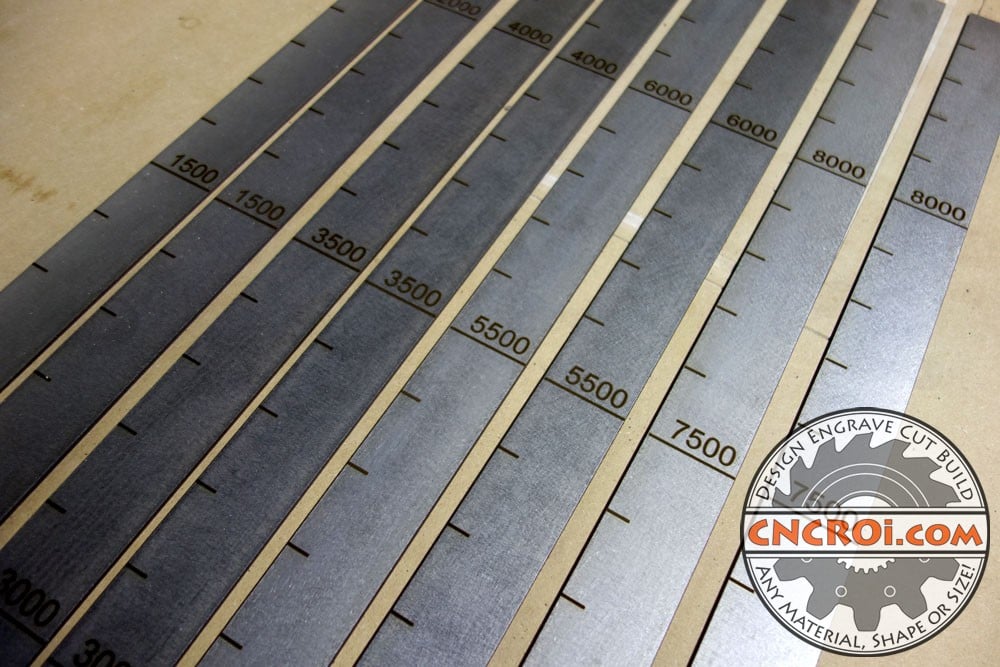

The massive advantage of fiber laser etching, unlike any other process involving branding stainless steel, is that it’s permanent, unlike paint or dyes or any printing method, the markings will not fade, crack or peel over time.

Additionally, fiber laser etching is incredibly resilient, requiring actual grinding of the surface to remove, no chemicals can remove this short of acids that would also dissolve the metal in the process.

CNCROi.com is a very compact shop, the sand blaster you see on the left of the laser could have also produced a nice finish on the stainless steel except it’s a far more matte finish, the orbital still maintains the stainless aesthetic meanwhile.

Plasma cutters can be used for a huge variety of items, this was a simple sign I made using 12 ga hot rolled mild steel.

Keep in mind that although these custom metal tank level gauges came from a sheet, they are even more accurate width wise than flat bar, starting from a sheet also produced a nice plasma cut edge to all the slats, unlike the laser, which would have produced a sharp one.

There is no process that matches the beauty, durability and flexibility of CNC fiber laser etching.

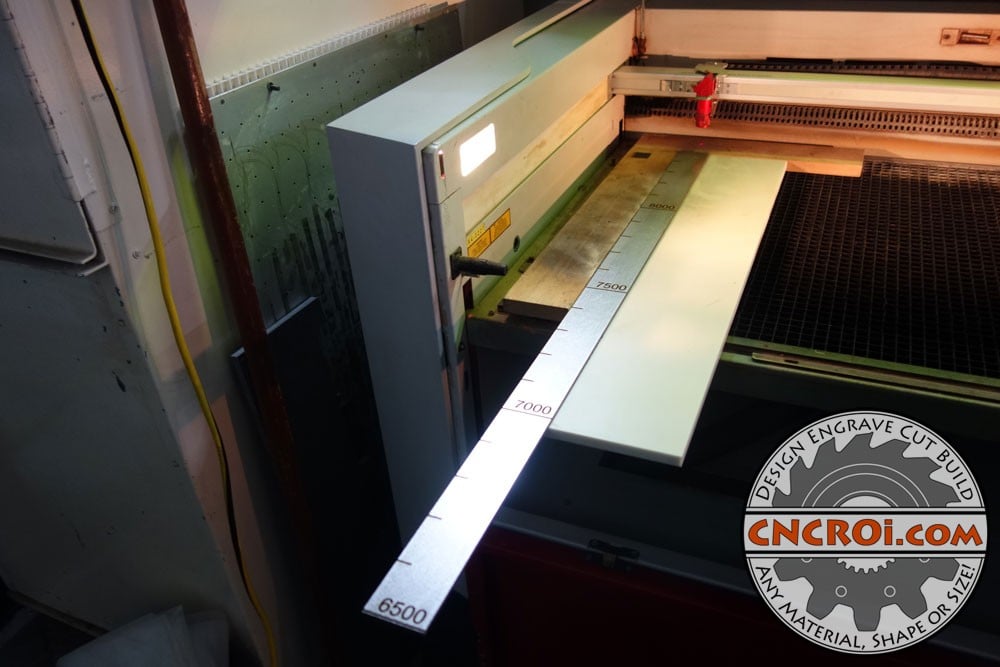

Now it’s time to go ahead and fiber laser etchin the thinner yet taller custom metal tank level gauges at CNCROi.com.

CNCROi.com can mix and match different materials using all our different CNC platforms with absolute repeatability and precision.

Having a laser that can open-up both front and back, allows us to etch items far larger than the general platform size we have, for this custom metal tank level gauges project, I actually just flipped the slats end to end to etch both sides, etching one backwards and the other forwards.

Any mix of images, fonts and anything else can be put etched onto custom metal tank level gauges or any size or spec you can imagine with CNCROi.com.

Need custom metal tank level gauges? Contact CNCROi.com right now!