Neon Yellow Camels: Custom Acrylic Laser Cutting

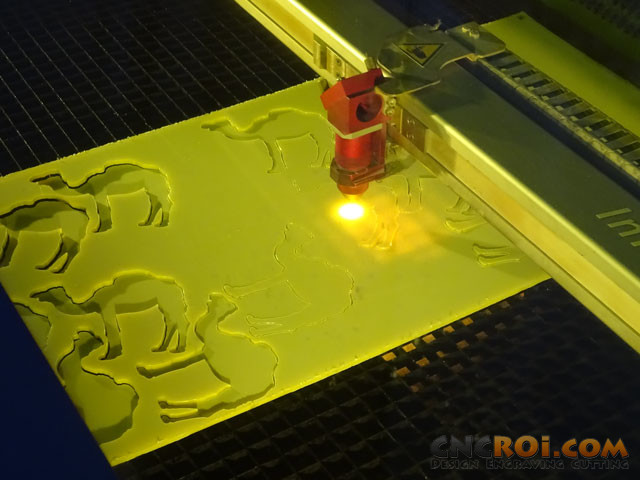

If you need some neon yellow camels for a local craft show, CNCROi.com can do some serious custom acrylic laser cutting for you within 24 hours generally.

Due to our custom production methods that are realtime and on-demand, CNCROi.com can make you hundreds or thousands of unique shapes in one batch (all different) or all the same, it makes really no difference to us.

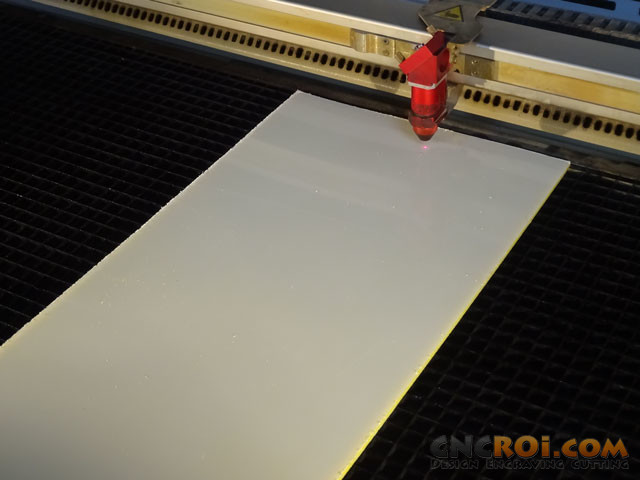

Custom acrylic laser cutting is the same regardless of color, thickness or fabrication method.

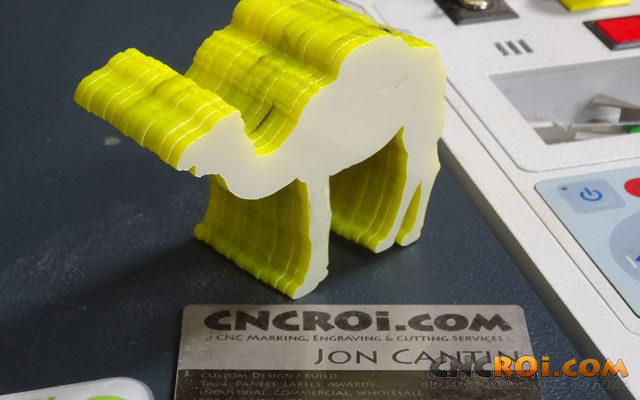

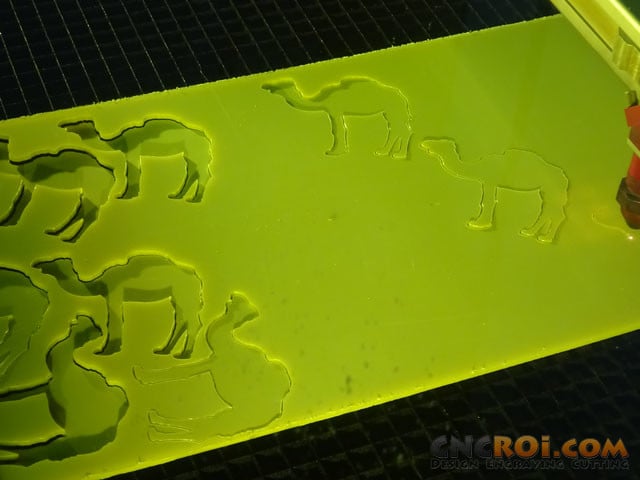

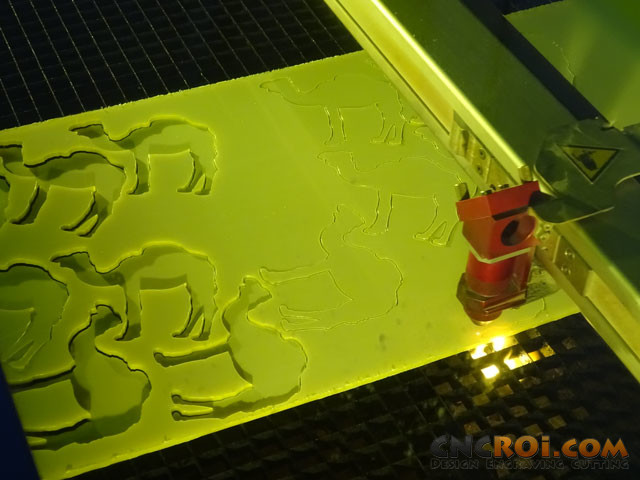

In this case, a customer wanted 50 custom neon yellow camels cut out of 1/8th inch or 3 mm acrylic.

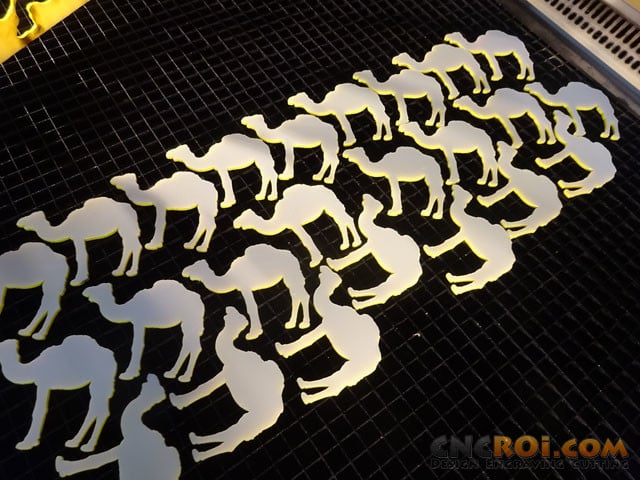

In all these pictures, you’ll see a white layer over the front back of the acrylic, this is just protection left on for production and shipping, it comes right off and the face is the same color as the edges you see.

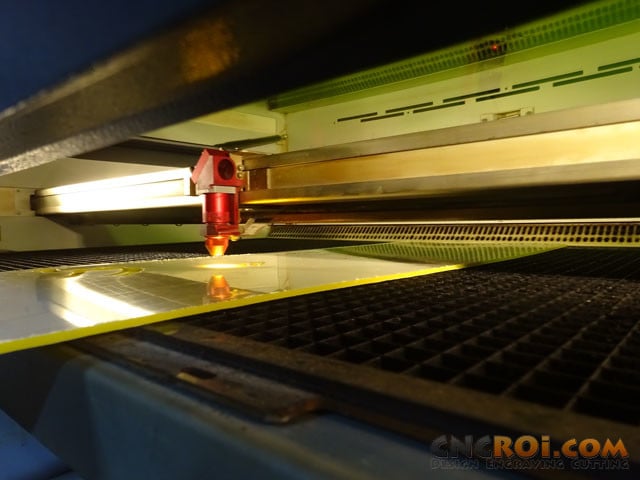

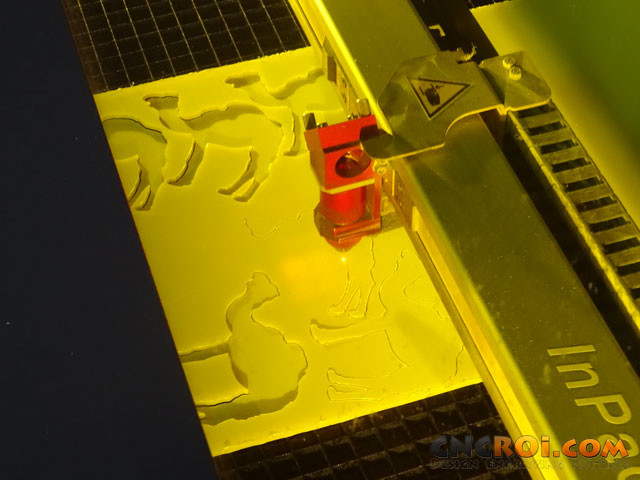

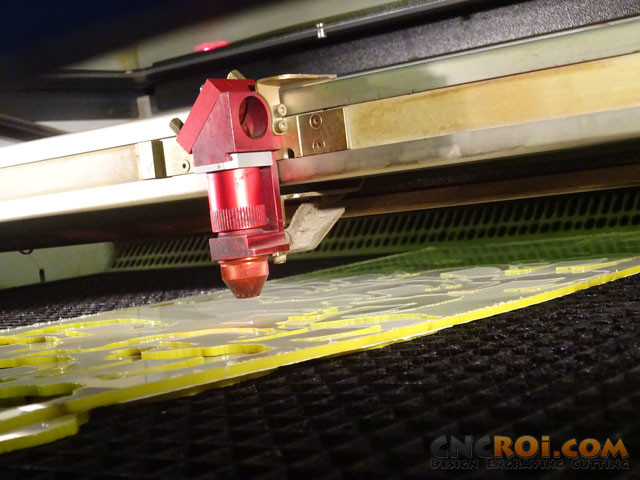

Unlike wood or other materials we cut here in the shop, custom acrylic laser cutting is a hazard in the machine, it’s a petroleum product that does produce fire and acrylic itself is flammable.

This isn’t much of a concern for CNCROi.com though, we have a top of the line machine, extraction and air compression system.

The flames never even have a chance to ever become dangerous in our laser or shop for that matter.

Having a save shop, a lean shop and a highly efficient shop means we can do things here at CNCROi.com that many others can’t because we invested heavily into these custom production capabilities with equipment that has built-in redundancies just incase.

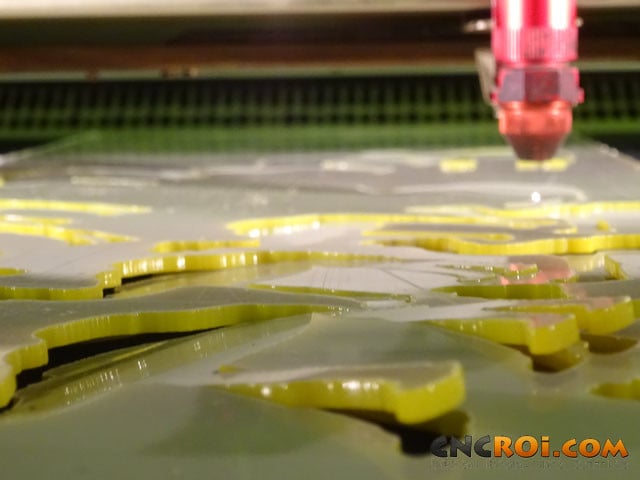

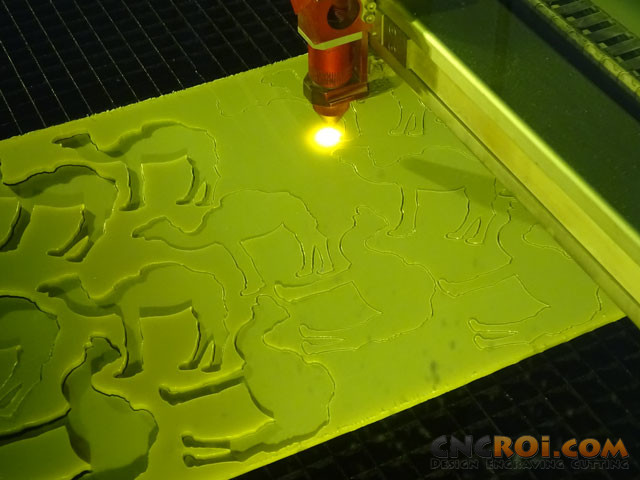

Custom laser cutting acrylic is a pretty smooth process, the edges are all flame polished, which looks great, and the results repeatable and predictable.

Acrylic is also a wonderful material to work with in the shop, it’s available in many colors, many thicknesses and can be cut into just about any shape and even combined together to form 3D shapes for uses like model making and signage.

CNCROi.com does keep a small inventory of our most often used acrylics so that even if we don’t have enough for an emergency order, we can get a good chunk of it done right away while the rest gets delivered to us.

As a result, we can be counted upon to design through fabricate just about anything you want out of plastics, including polycarbonates and Corians (yes, that’s plastic too!).

Generally what I tell customers is that if your application is for outdoor use, acrylics isn’t the best choice, even if it is UV stable, it will fade and crack under the elements like Sun and temperature.

What we suggest instead is going with metal, paint filled Corian or even better, wood.

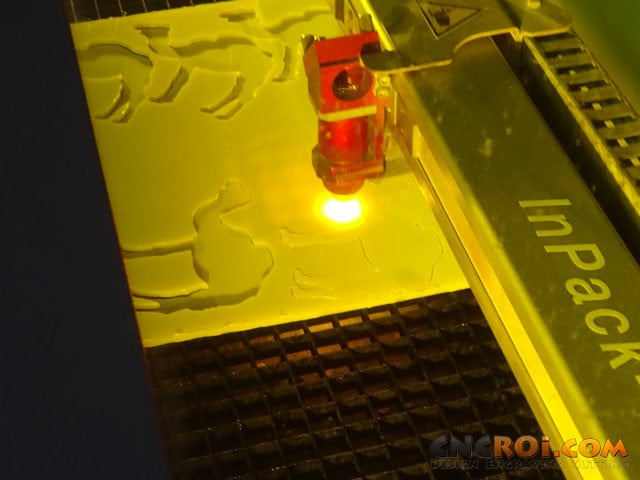

Custom laser cutting acrylic is quite fun to cut in the shop, these animals look great and when you line them all up, even if they were cut out in different order, they all still clearly match, as if they were stamped.

This is the power of highly advanced and industry leading Austrian CNC lasers, they are built for 24/7/365 production and it shows everyday we use them.

Looking at the picture below, you can see the fire shooting down and away from the custom laser cutting acrylic process, this fire is only bigger when cutting thicker plastics.

CNCROi.com is also unique in that our laser is a dual-sourced machine, we have both a CO2 and Fiber laser source, the video above gives you a glimpse as to what’s possible with that when they are both combined for a custom laser cutting project.

CNCROi.com has an extensive Shapes Library as well, you can find it by clicking “buy online” in the top navigational bar of this website, in this case, the customer wanted camels but they could have been any combination of animals.

There are many advantages to laser cutting acrylic vs using our other machine an American CNC router like our Shopbot.

The flame polish happens at the same time as the cutting process, which makes production very efficient.

We can more thoroughly use an entire sheet of material as we don’t have to be concerned about hold down and we can do finer details.

Where the CNC router excels though is in speed when huge volumes are concerned, when you want a beveled edge and/or want pockets.

As I tell all our customers, we have the equipment and the experience to pick the best machine for a given application, that’s why we are so fast and yet, produce amazing results for them!

CNCROi.com has cut out endless varieties of custom shapes, animals to trees, logos to jewelry.

Here’s a video showing you what can be done, specifically relating to custom acrylic jewelry using our custom production methods.

CNCROi.com can also cut household items too, such as custom acrylic hangers, designed and branded to your exact specifications.

We’ve made custom acrylic coasters, cake toppers, widgets, mirrors… yes, mirrors… check this out!

I hope this gives you a glimpse as to what CNCROi.com can do for you and we are only discussing ACRYLIC!

Expand your horizons into other materials and it just shows you the incredible diversity of capabilities we bring to the table for your custom production needs.

These neon yellow camels look great, the customer will remove the protective wrapping on these so they look great at their end upon delivery.

CNCROi.com also invests in premium nesting software, which you can see the results of here, though I still manually tweek things a little more when it comes to repeatable shapes, just to eek out the absolute smallest amount of waste possible.

You can now see the results of laser cutting acrylic animals, they look fantastic!

Here’s a close-up, as you saw way up in this blog post, these can also be used to make custom inlays, we could have also produced the exact same results using metal, wood, composites and even laminates or lamacoids.

Here’s a fraction of the custom neon yellow camels we cut out during this production run, they look great and I’m sure the customer will thoroughly enjoy them as well!

Need custom production of just about anything? Contact CNCROi.com.

Metal, wood, plastics, we’ve got you covered!