Paint Filled Metal: 316 Stainless Steel Fiber Laser Etched

CNCROi.com does offer paint filled metal, whether its anodized aluminium or stainless steel, 316SS in this case using our standard sized plates we use for customers far and wide.

There are two ways to create colored signage at CNCROi.com, the first above is paint filled and the other is just to cut straight through.

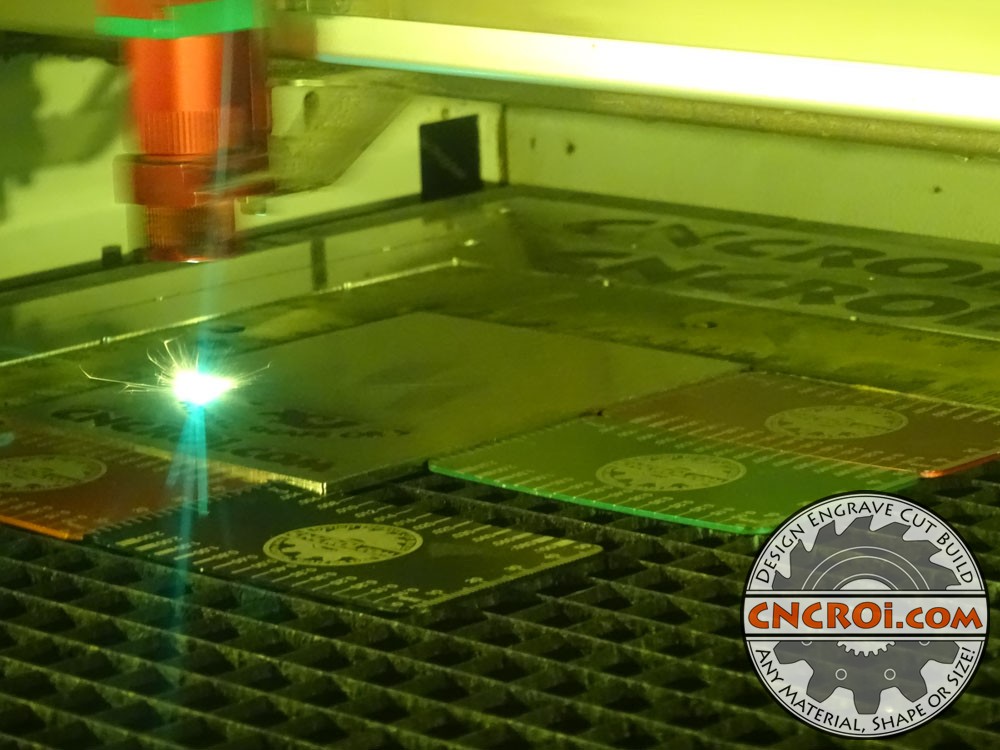

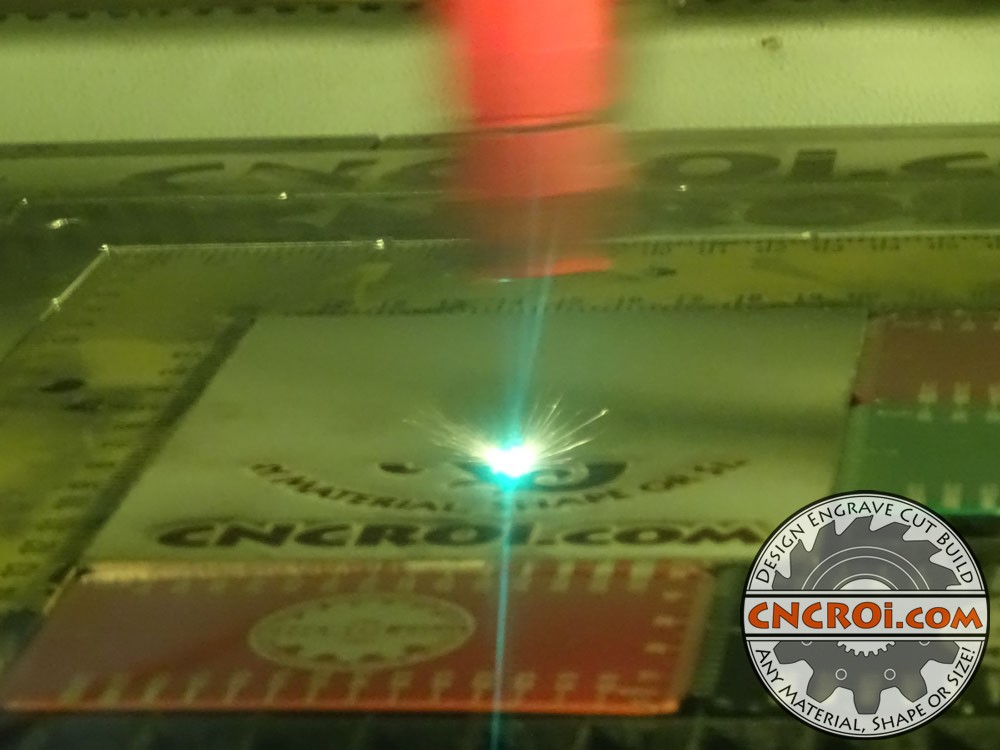

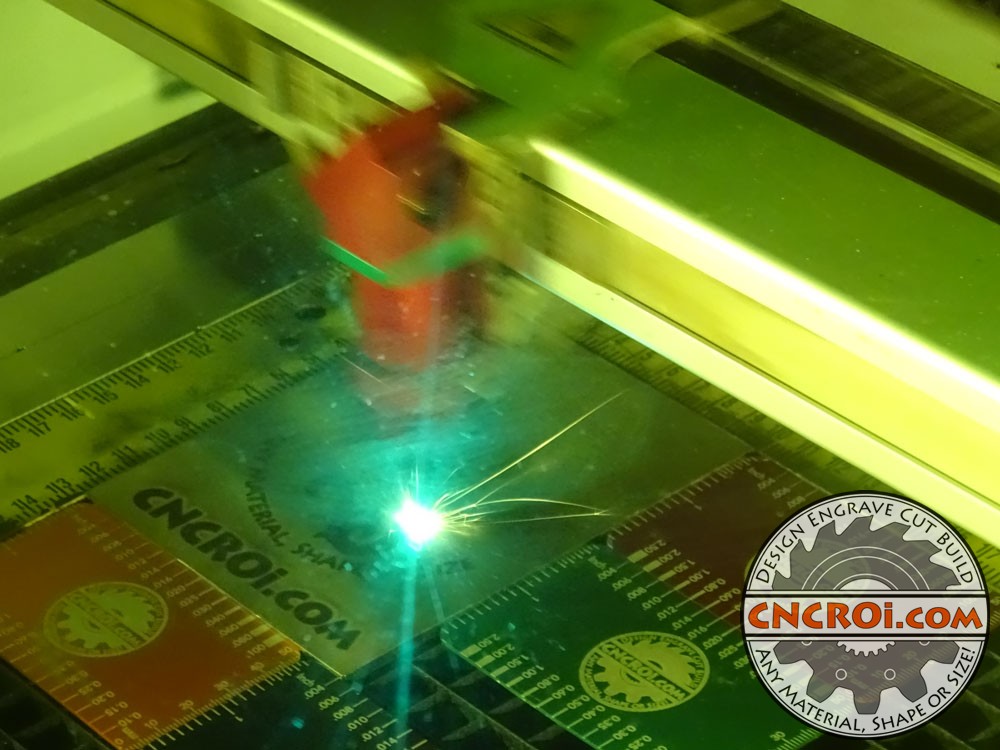

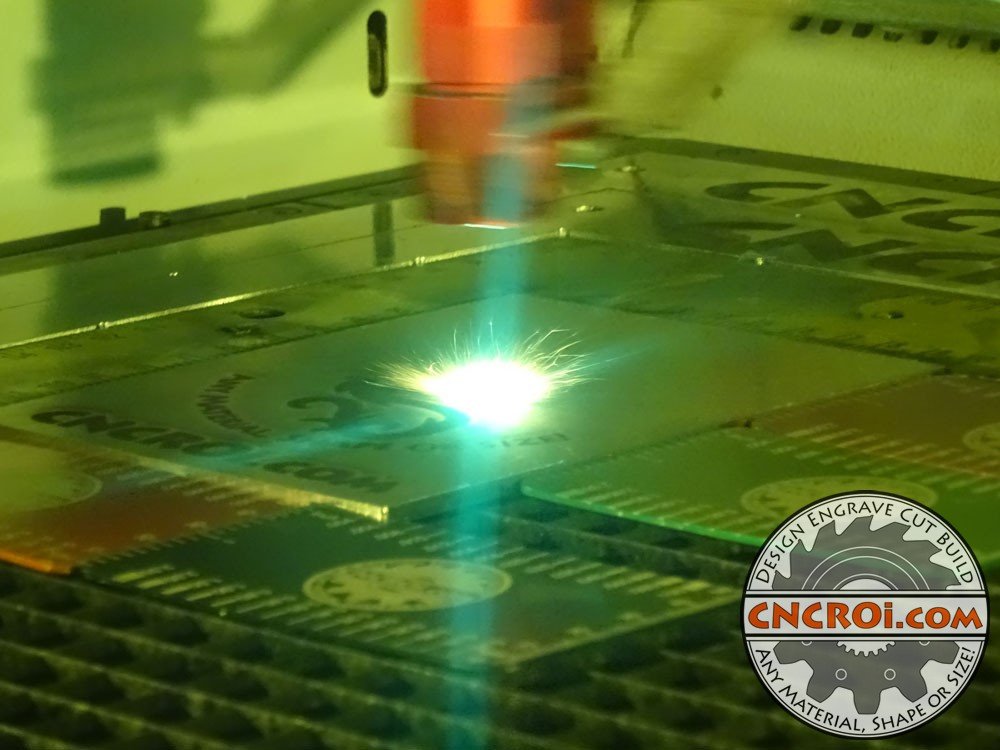

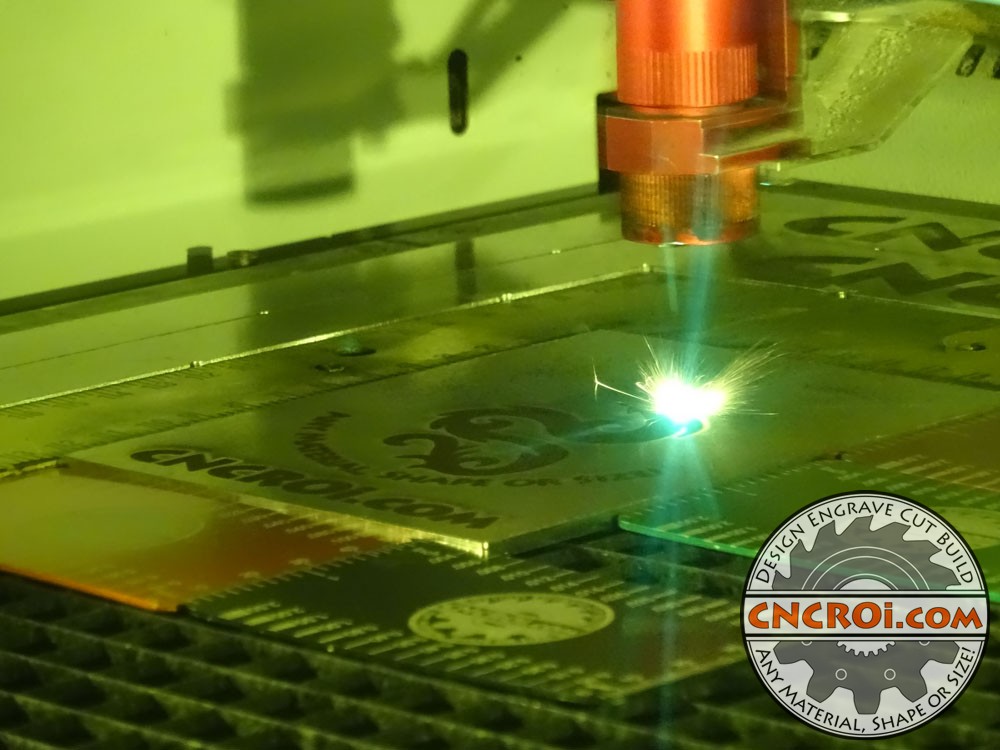

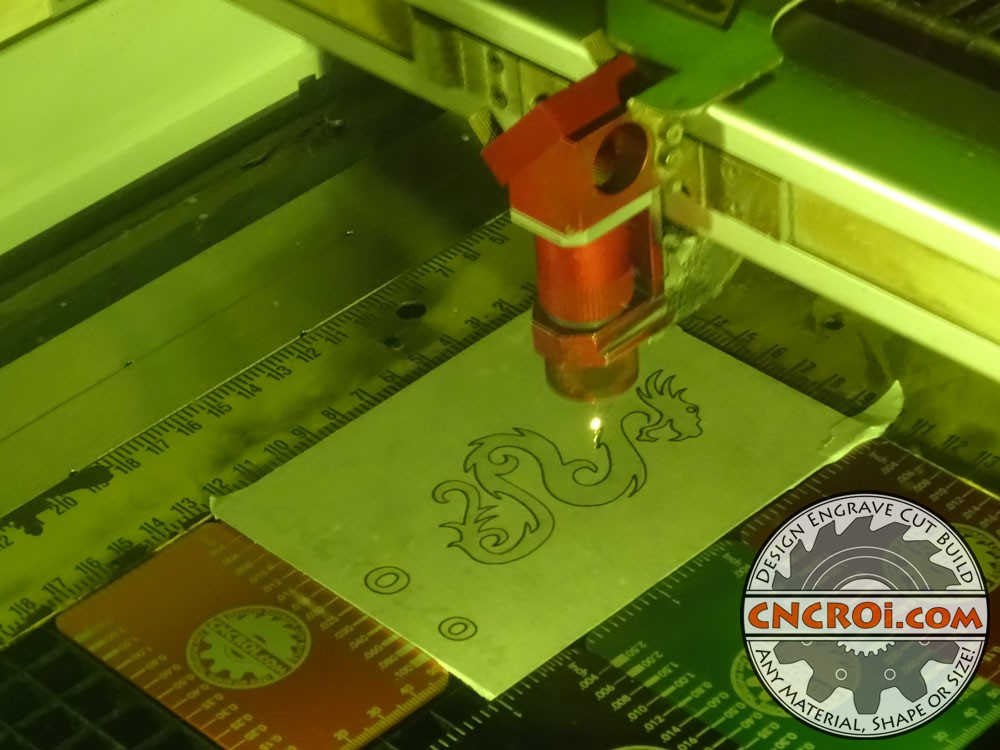

When it comes to paint filled metal, the only way to make it work is to use our Austrian wide-format CNC laser’s fiber diode to etch the surface so that there is enough paint surface for the proper adhesion of the enamel, otherwise it just comes right off.

Etching the soon to be paint filled metal does produces a black mark on the metal that has the equivalent to a 1 grit surface texture.

If you are wondering why we are etching the metal in this case rather than annealing, check this video out.

Annealing wouldn’t scratch the surface, it gives a nice smooth texture so when it comes to paint filled metal, it’s a totally useless process for that application, CNCROi.com needs the very rough surface etching surface for this to work.

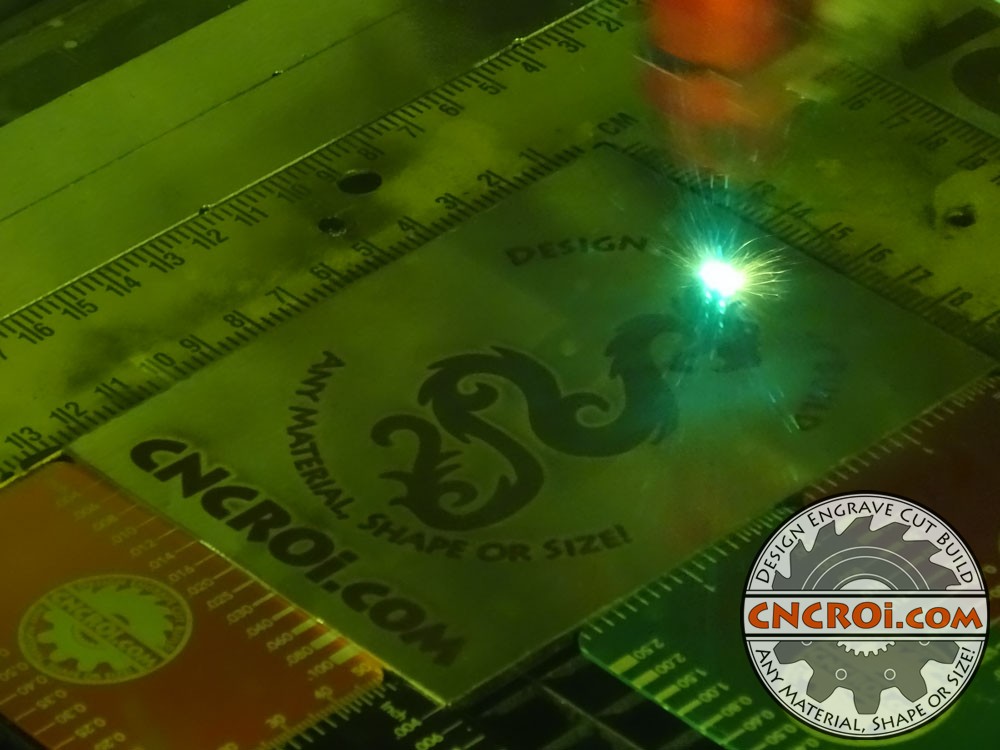

The other small business card sized anodized aluminium plates you see around the 1/8″ or 3 mm 316 stainless steel plate we are using for this paint filled metal are used to help with camera focus during all these photos and film, otherwise, they serve no purpose in this production setting.

There are many degrees of surface etching that CNCROi.com can achieve on stainless steel, for the paint filling, just a quick pass is all that’s required but we can also do the same using deep etching, though the cost is pretty high up there.

CNCROi.com pushes through lots of metal for our customers but generally, it’s divided between either stainless steel or anodized aluminium, ironically, both can be paint filled though the process behind that is rather different.

Let’s say you wanted a memorial plate that was deeply engraved, then we’d resort to casting or using our CNC router to engrave-out the soon to be paint filled metal, but we’d do that out of aluminium as it’s far easier on machinery.

Otherwise, it’s generally either fiber etching or annealing that our customers require more often than not when it comes to their custom branding requirements, paint filled metal is just another option in the bracket.

Before the paint filled metal plate is to be masked then painted, it needs to be washed to remove the metal flakes and lots of little pieces of burned metal that settle on the surface of this 316 stainless steel plate, giving it a brown fuzzy hue otherwise.

If you are wondering how durable CNCROi.com‘s surface etching is, with or without paint, check out this video, for sure, the paint will eventually fade and crack away over an extended period of time but the surface etching we did under the paint will last well into the future.

After the surface etching of the paint filled metal is complete, it’s time for CNCROi.com to mask it, this is important as although removing paint off the non-etched surface of the stainless steel is easy, it’s still a pain and a huge waste of paint to do this if it’s not needed.

Other applications where we use our fiber laser source, in this case annealing, include custom stainless steel and anodized aluminium business cards, one customer’s business card is another’s machine plate and another’s valve tags or yet another’s welding tags.

Of course, if you need something to hold your business cards, CNCROi.com can help you out with that too!

The mask is applied and then our laser goes right back to work, cutting out the elements we want to paint fill, originally I was going to paint fill CNCROi.com but decided not to just to have all the focus entirely on the dragon.

The advantage of paint filling metal is that you get a bright color but unlike UV printing, it’s dramatically more durable and most importantly, the etching is still there after decades of wear and tear so you don’t slowly lose function in the plate with peeling, cracking and fading issues.

If you want something highly durable in metal though, just straight anodized aluminium is a great way to go, it’s available in a lot of different colors but the engraving by CNCROi.com is always an off-white.

Now that the stencil of the paint filled metal dragon is cut out, it’s the long tedious process of peeling it away, this may sound easy but the adhesion of the etched stainless steel is so great, that it’s quite a challenge to remove the mask.

Most of the mask paper is now removed, you can see a few bits and pieces here but as this is a prototype (lots of lessons learned by the way), it’s more than fine to be quickly cleaned and then enameled followed by a few sealing passes.

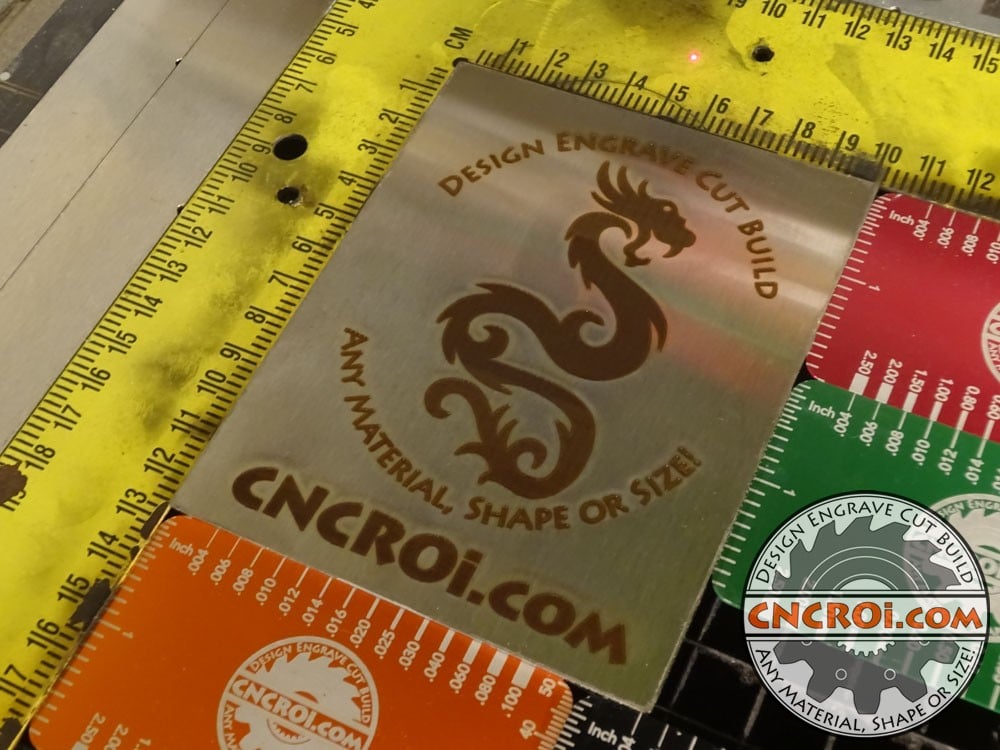

The results once the mask is removed after the red paint is allowed to dry is pretty amazing, regardless of the angle, it’s clearly visible and really looks amazing, even I was surprised by the results of the paint filling process on this 316 stainless steel plate on my first try.

A few layers of sealant and you can see how the etched metal pop out dramatically along with the enameled dragon.

This paint filled metal process does work extremely well for larger details but for extremely fine aspects of the design, etching and annealing is by far the bet way forward.

There are also sizing issues to contend with, the amount of detail we can achieve at CNCROi.com is far higher using our CO2 or fiber laser etching or annealing than paint can ever hope to get.

Paint filled metal also won’t work for welding applications as the sealant and the paint itself would simply burn away from the heat of a welding torch, revealing the etching underneath.

Regardless of your application, lamacoid or metal, paint filled or etched, be sure to contact CNCROi.com to produce it for you.