… it’s about PASSION!

It’s Sunday and guess where I’m at? The shop! (this is a post-dated blog post but I know where I was going to be anyhow). Why? Because I just love working with CNC equipment and I have clients that need to get stuff done ASAP!

24 hour turnaround available

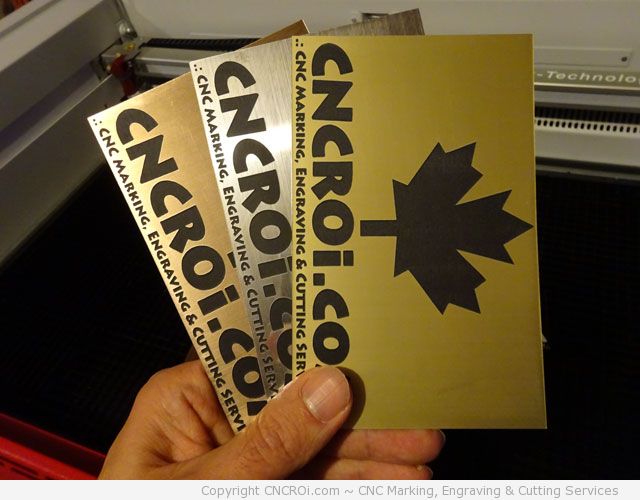

A potential customer asked me the other day if anybody has ever taken me up on my “24 hour turnaround available” that’s featured at the bottom of my business card, which in turn, is engraved on more things that I can remember. The answer is YES!

Sometimes, clients come into projects where for various reasons, they are behind schedule… it happens to all of us! How do you catch-up? Well, working when everybody else is sleeping! I can’t think of a day that I’m not in the shop, the only exception is when I’m on a business trip far away. It’s just such a fun place to be in where anything is possible. I’m like a traditional woodworker who loves the smell of wood in the morning, except for me, it’s whatever we cut last… except for laser cut or engraved rubber, that just reeks! Cut through a bit of cedar and that smell is gone!

Design background… not CNC

My background in the CNC world actually originates in the design and not the equipment operation. I taught myself how to design for CNC machines since 2008, there were no books showing how to do things “my way” so I wrote them… now working on my 5th volume actually!

Even before that, I taught myself how to “translate” engineering documents and blueprints into a 3D animation that companies would use to showcase their machinery. That’s when I realized how much “simpler” things can be when you have no measurements.

I know, it’s weird, but it’s so liberating to not have to be bound by measurements when designing stuff. It really isn’t needed but that’s a conversation for another day! Don’t worry though, if you send me stuff and it’s a few mm off the DXF files you sent to me, I’ll let you know ASAP and hold-up production until I hear back!

Passionate crowd!

The best part of CNCROi.com is by far the plant tours, it’s great seeing machinery doing their thing, each company has their own configuration and their own production methods, it’s like a combination lock that you can jig to open using just about any number combination!

I can’t think of a client who hasn’t shown incredible pride in their business and that really shows when they show me what’s “out back”. No matter how beautiful the front offices are, it’s the back that’s making the money and has the most invested into it in both time and treasure… it’s what pays for everything in the front!

Never during a building tour have I ever been shown the accounting department, if I’m lucky, they’ll show me marketing but without fail the back is the one we spend the most time in. This is great because that’s where I enjoy being!

When I’m not “working”

Luckily for me, I found my passion in life and am even luckier to be surrounded by people who share it! To me, I’m not going to work, I’m having fun… there is always something to do or to explore.

For instance, I can design pretty much anything and transform pixels into product. In this case, I transformed six full sheets of 6 mm (1/4 inch) plywood…

into a vehicle that brought back memories of my childhood!

All without doing any measurements ANYWHERE! Now, that’s a fun challenge and so, I took my “Jon the Builder” hat off and put on my “Jon the Marketer”.

This required a bit of planning so I started by making videos showcasing the build process, start to “hanging like an animal trophy” background image finish.

As part of the sizzle, I then put on my “Jon the 3D Animator” to produce a 3D animation showcasing how my creation all came into being including a video showing how the design evolved over the designing process.

The nice thing about being self-taught is that I’m not bound by ideas imposed on you during the “teaching” process, meaning, anything is possible because I don’t know any better!

The result? Well, it got me press around the world, which was my original goal!

Some people questioned why I spent about a thousand dollars building this thing by the time all was set and done. What a waste of money and time is something many told me… actually, it’s an awesome investment!

A full-page ad in Make Magazine that’s distributed to hundreds of thousands of “makers” around the world costs more than 14KUS, I did it for 1K and best of all, promoted one of my longtime partners, ShopBot Tools, in the process.

It was an awesome day when I let Ted Hall (founder of ShopBot Tools) know his company was about to be showcased in a magazine full of potential clients for his fantastic CNC routers! Those are the kind of surprises every company owner should get on a regular basis and I don’t even work for ShopBot Tools!

I don’t “think outside the box”, I just don’t see it! I’m blinded by passion! Have a project you’d like my company to help you with? Send me a shout!