Pine Backed Rubber Stamps

Pine backed rubber stamps made at CNCROi.com offer repeatability and functionality for years to come.

https://www.youtube.com/watch?v=4M4MwNuc8vw/

Making lots of manual stamps at CNCROi.com and after making many I use internally, I’ve come to realize that self-inking rubber stamps are great but their pre made configurations don’t match all the possibilities that exist for their use, so having a manual one with an ink pad works just as well.

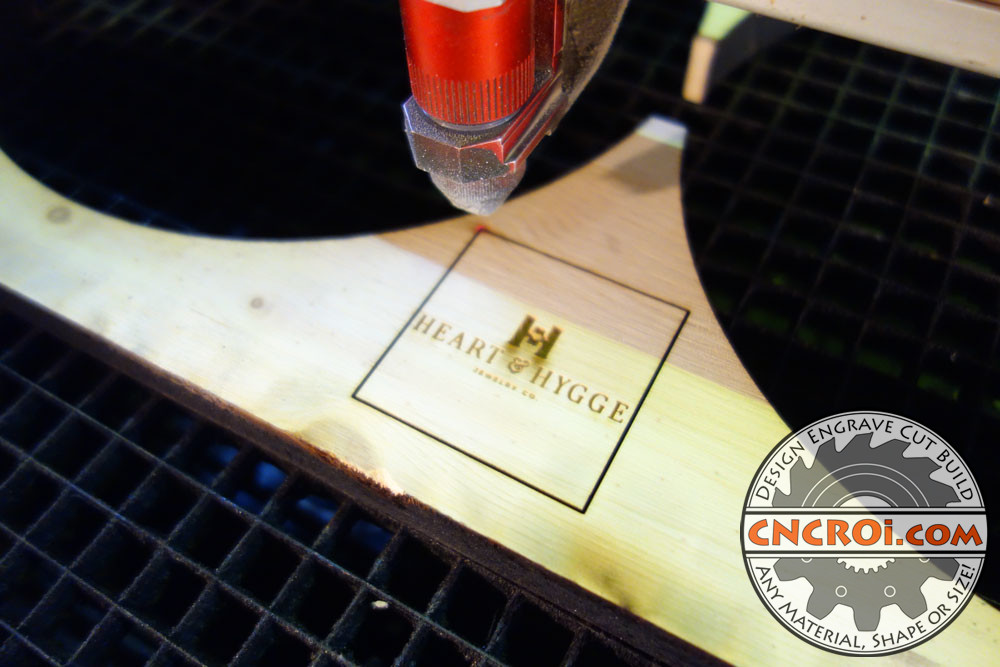

Regardless of whether the stamp is a manual or self-inking one, the process always starts the same, once the customer approves the digital proof, CNCROi.com gets some rubber and starts engraving and cutting it to form the base.

When it comes to the design option, like many other services at CNCROi.com, they are as endless as your budget and timeline allow, the limitations are rarely at our end when it comes to production.

As an official Trodat distributor, we have the full range of self-inking stamps available to us for your use.

https://www.youtube.com/watch?v=hGZH8JfEnes/

How big is the biggest rubber stamp CNCROi.com has ever made? About 39″ x 25″ that was to fit on a drum roller for high speed wallpaper production, this of course, is only 2″ square, so dramatically smaller and faster to produce.

Even highly intricate custom rubber stamps can be made at CNCROi.com with little fuss, you got a design, we make it, it’s that simple!

https://www.youtube.com/watch?v=-kt7cNMnWtM/

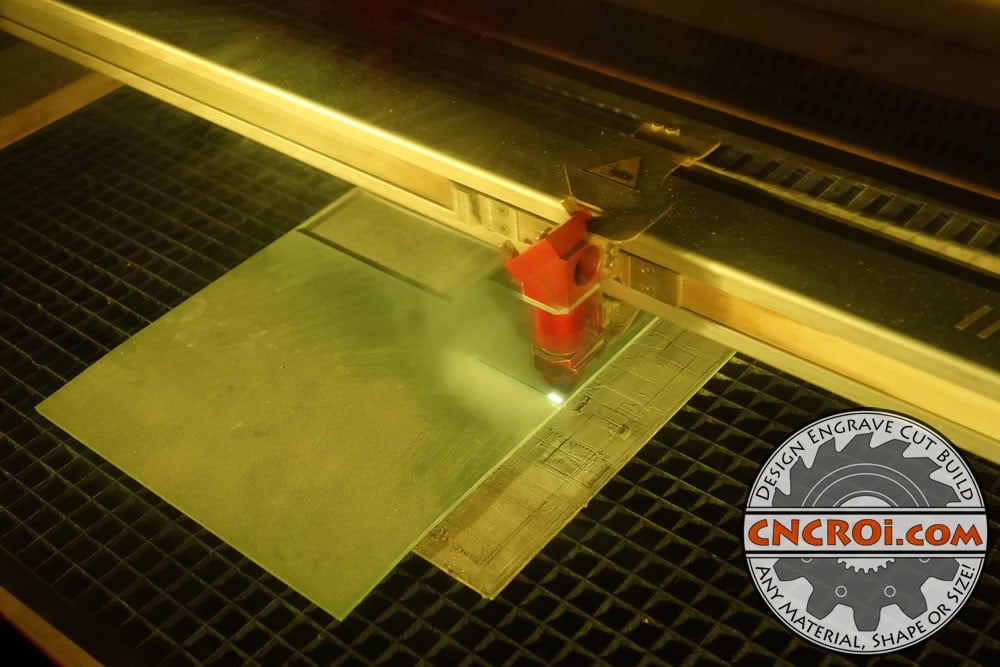

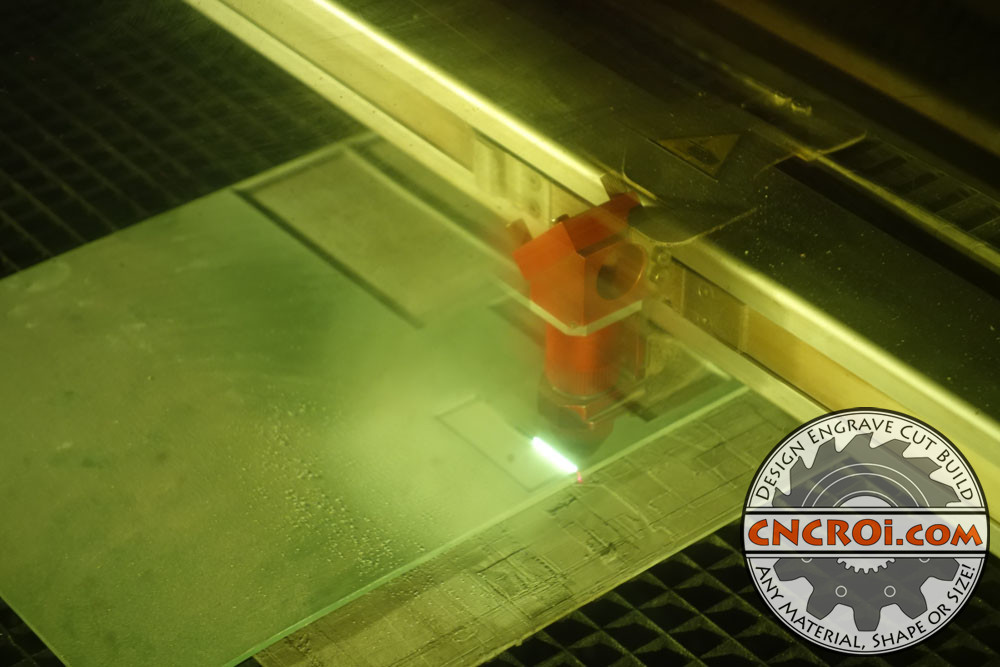

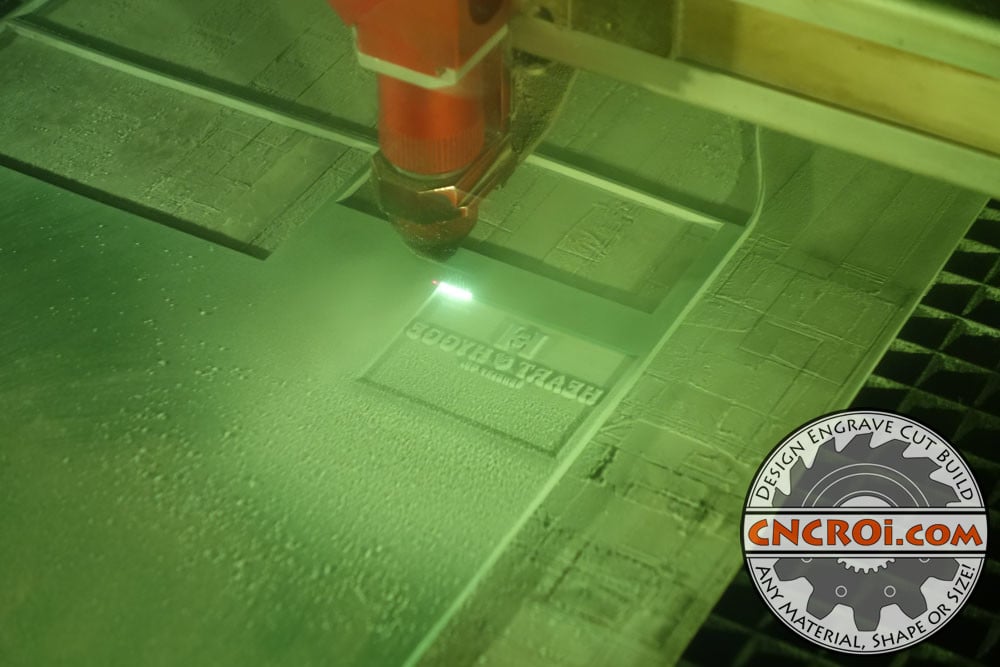

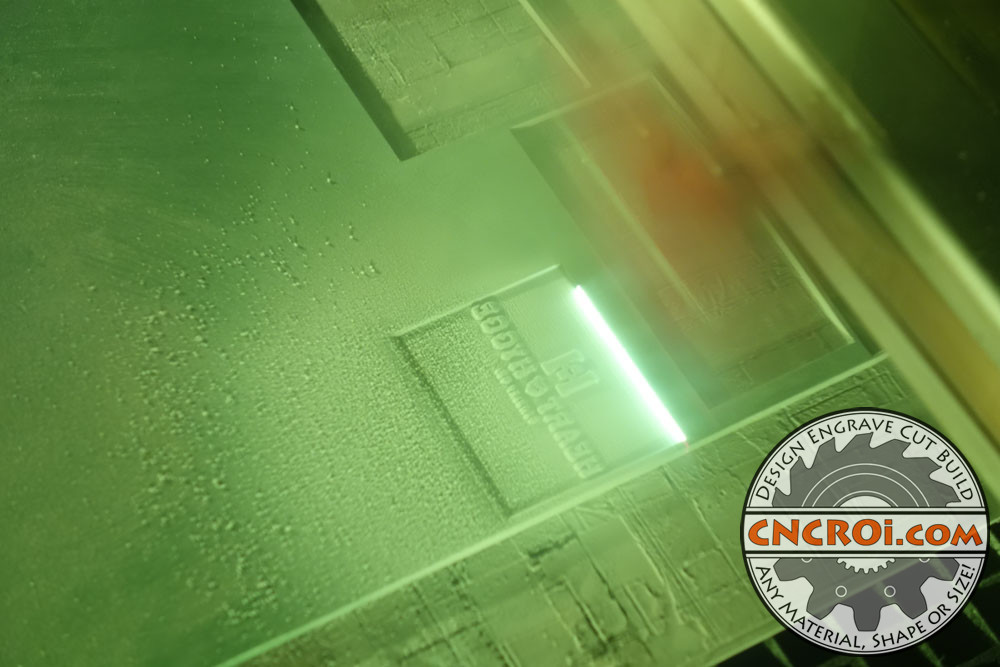

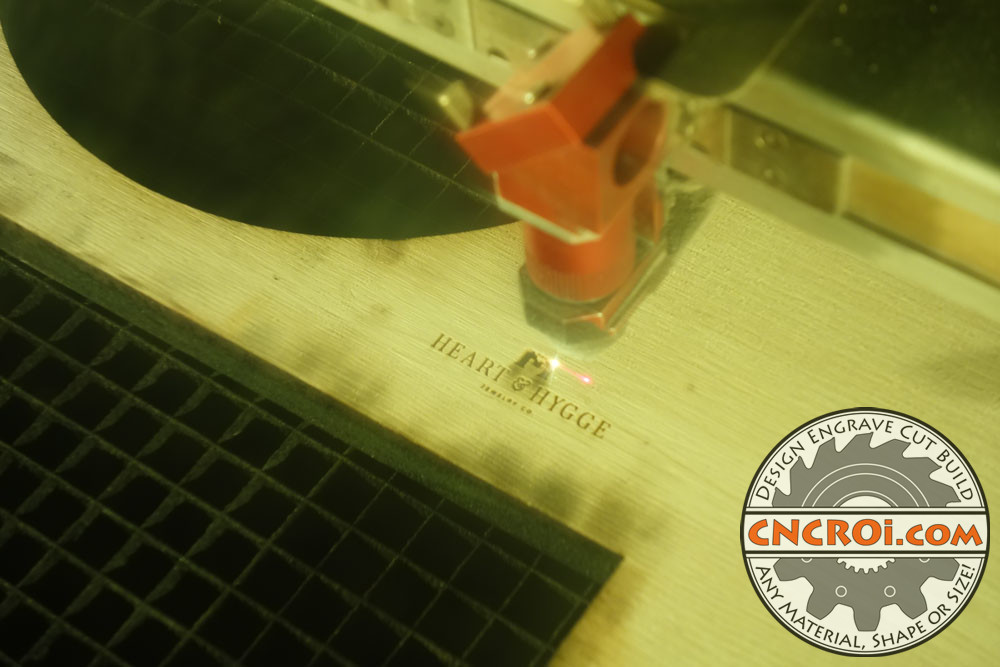

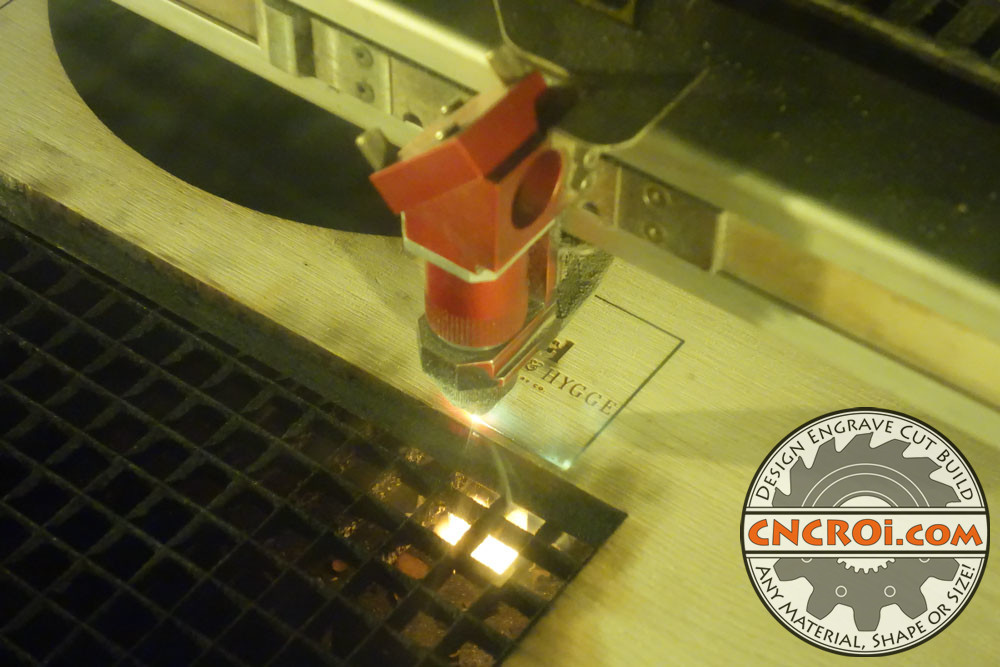

The bright light is the instant vaporization of the rubber that will form the Pine backed rubber stamp, and the dust is whatever didn’t get incinerated in the incredible heat generated by CNCROi.com‘s laser source.

The engraving process is generally the same regardless of the shape or size, the gantry head goes back and forth, stepping up ever so lightly between each pass, until the digital proof made earlier is converted into a real life rubber stamp.

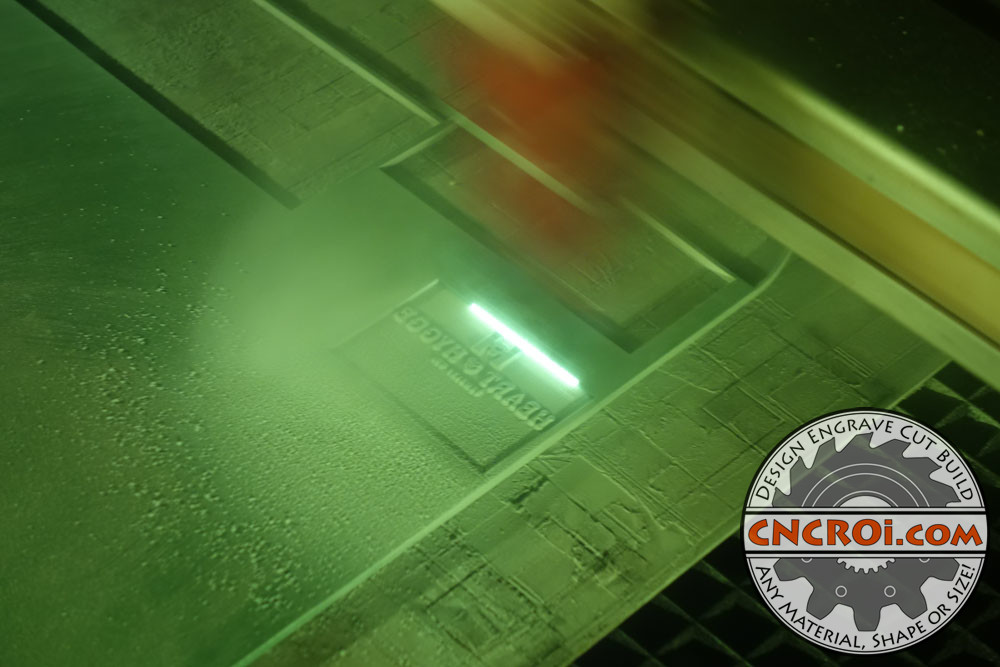

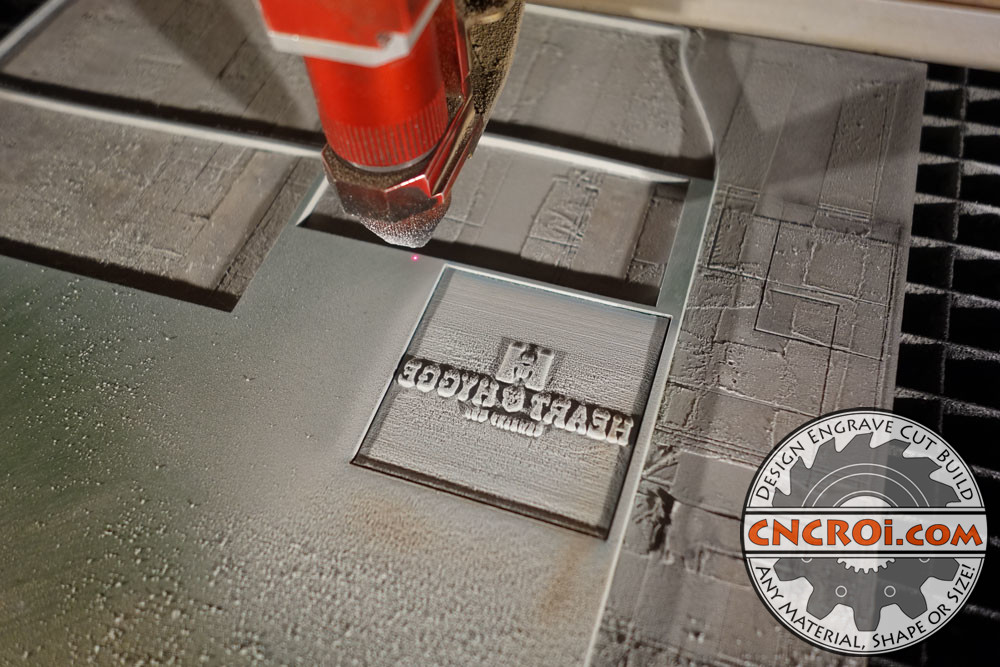

After the laser engraving process is finished for this Pine backed rubber stamps at CNCROi.com, the next step is cutting it out of the rubber, sometimes we cut it full as you see here, sometimes we give the stamp a little border and cut a lot less, it all depends on the use and finishing methods of the design itself.

Trodat’s 5212 Professional self-inking stamps are the biggest on the market, and our top seller – here’s a job we did that used many different colors.

https://www.youtube.com/watch?v=BSnHyjY3lTA/

After the Pine backed rubber stamps have been laser engraved, there are two of them in this production cycle, the next step is to clean them up from all the soot and debris that filled both the inside of the stamp and all around the laser engraving area.

Only after cleaning can we really see the finished custom rubber stamp that will become the base of the Pine backed rubber stamps.

As for the Pine used, it’s 3/4″ and dead-flat, something that’s very important, because you don’t want one area more elevated than another when it come to actually using these Pine backed rubber stamps.

You aren’t limited to only English or even Western characters with your custom rubber stamp, self-inking or otherwise, anything goes, including font selection and sizing.

https://www.youtube.com/watch?v=1WIys_vDIp0/

CNCROi.com can of course use a variety of backings when it comes to rubber stamp production, if you want acrylic, Cedar or whatever, including the staple in the shop, MDF, that works just as great.

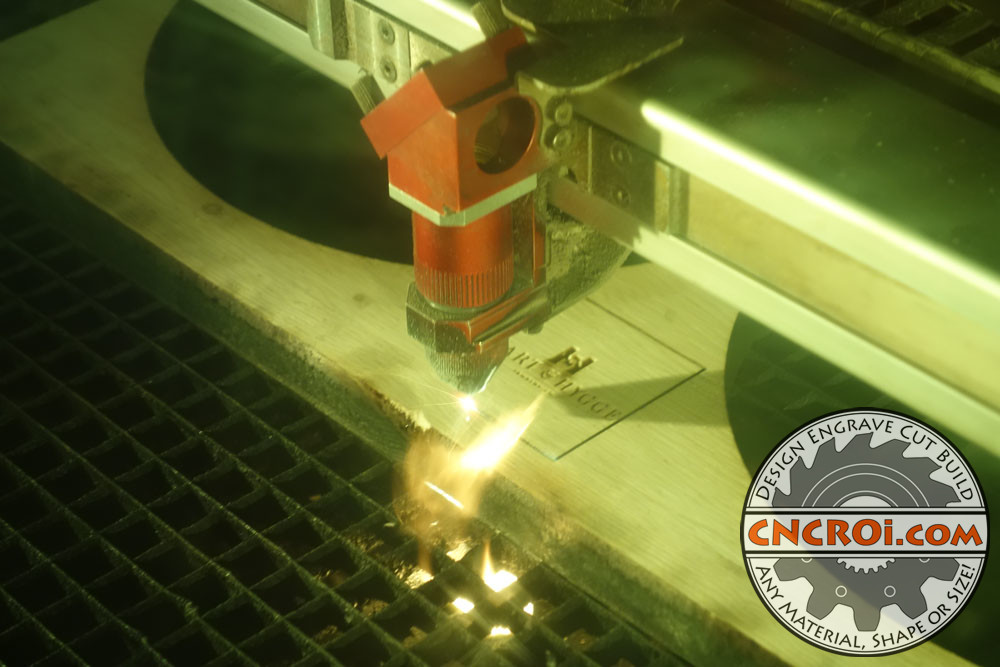

Like the rubber in the Pine backed rubber stamps, the Pine is laser engraved first for ultimate precision followed by cutting it out, the material might be thicker but CNCROi.com‘s laser just goes slower to get through it all.

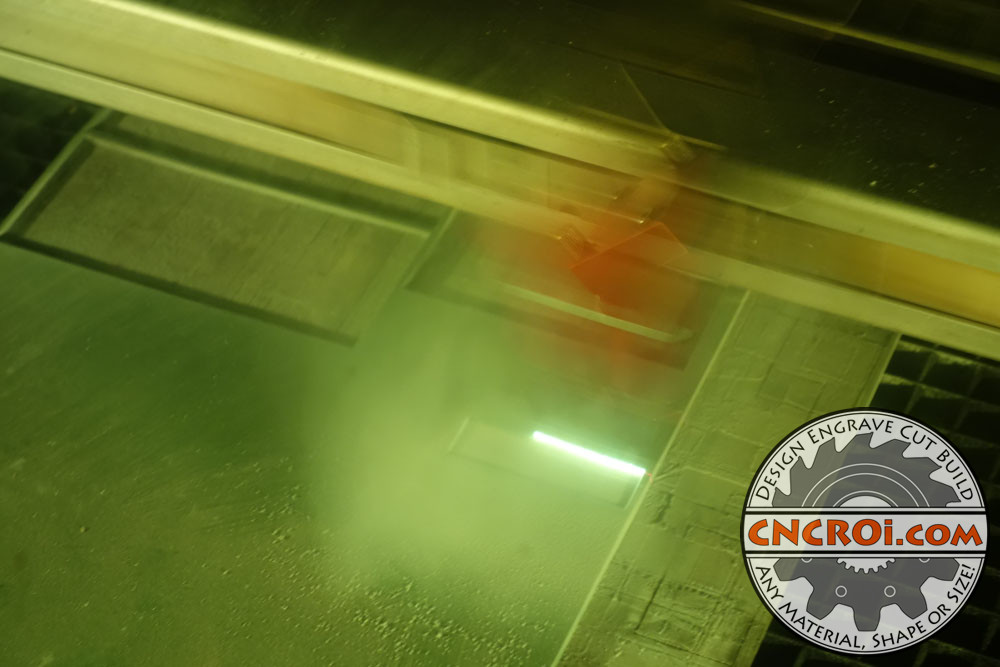

Yes, there is fire, both during the rubber engraving and cutting regardless of the material but the combustion is short lived as we have compressed air shooting down from the laser head nozzle and underneath, a vacuum table sucking-up the smoke as well.

The design variety that CNCROi.com has for rubber stamps is pretty incredible, here are two made at the same time and they couldn’t be any different, this time on Trodat’s Professional 5211 self-inking stamps.

https://www.youtube.com/watch?v=cLNgemwT0co/

After the first of the components that will become the Pine backed rubber stamps is done, it’s time to cut out the other Pine backing so that both stamps have a solid and repeatable surface area.

Whether CNCROi.com makes 1 or a thousand Pine backed rubber stamps (in this case), it makes no difference, each one is made one at a time with the same attention to detail.

The Pine backed rubber stamps are rectangular in this case but any shape works well, circular, oval or even the shape of anything you can imagine, your options are endless with CNCROi.com!

Self-inking stamps have the advantage of not needing a separate ink pad as part of the stamp itself is that ink pad, it’s just faster, but produces the same results regardless of mechanical or manual use.

https://www.youtube.com/watch?v=y3EX23NR1BY/

As the laser is completely invisible throughout this process, even the continuous beam needed to cut things out, all you see are the results and not the cause as the head of the laser only contains mirrors and not the laser source itself.

The finished Pine backed rubber stamps is now done, the Pine needs to be lightly sanded to remove the smoke that settled around the engraving and the rubber was cleaned during the process of cutting out the Pine at CNCROi.com.

The finished stamps are now ready to be stuck together using double sided tape then shipped to the customer, another successful rubber stamp made at CNCROi.com!

Need custom rubber stamps? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=V3ESW3NobDw/