Plywood Stencil (precision inlay & repeatable)

I guess CNCROi.com has a few cylinders firing at the moment and one of them is custom CNC laser cut stencils, so let’s take a closer look at stencils and the precision we are bringing to the market in this area.

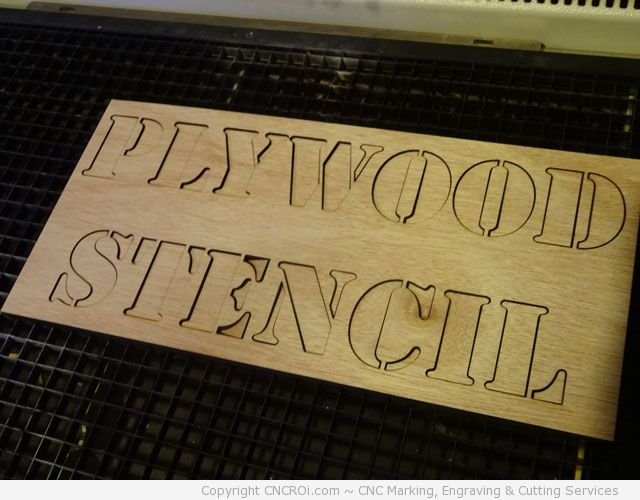

For today’s blog post, I decided to grab two plywood scraps that are different types of wood (one maple, the other birch) and thicknesses (6 mm, the other 4 mm) and interchange them to show the precision of our Austrian CNC laser.

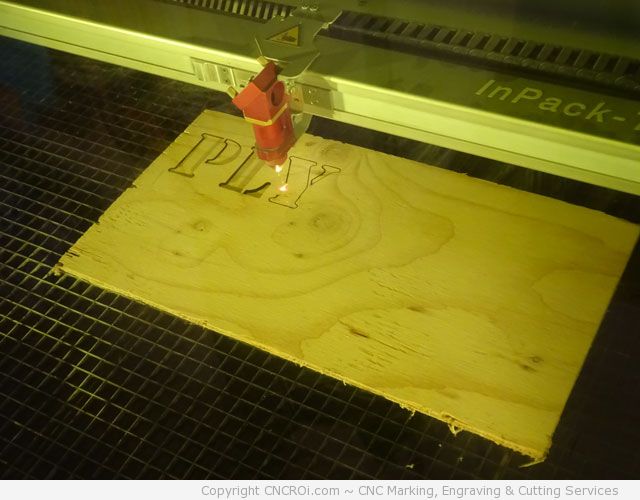

I decided to be rather creative with the words on these two plywood, I needed something small enough to fit in my sample case and couldn’t come-up with anything that said plywood stencil other than use those words.

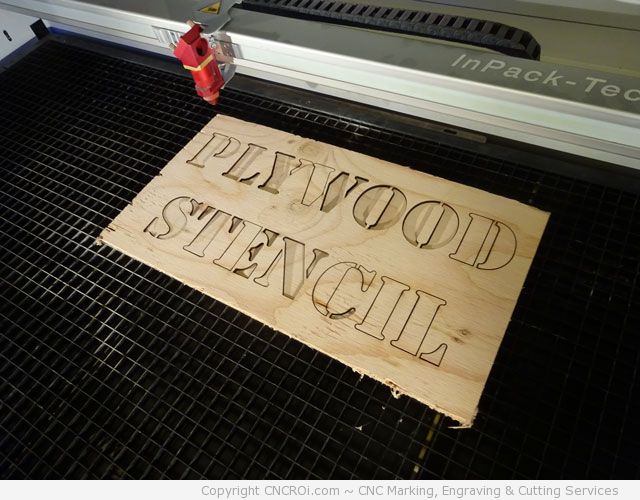

The cutting process produced little smoke, this was 6 mm (1/4 inch) which is a breeze for our industrial wide format CNC laser. Some of the letters fell “through” slightly, as mentioned, this is scrap and as such, warped. Generally, this would be a big problem but we have good machinery and it isn’t.

The stencil is clear, easy to read and very precise. Unlike a CNC router, there is no pushing or pulling or actually, any touching of the material during the cutting process. Small details are kept.

Watch the video of this being cut at CNCROi.com HQ!

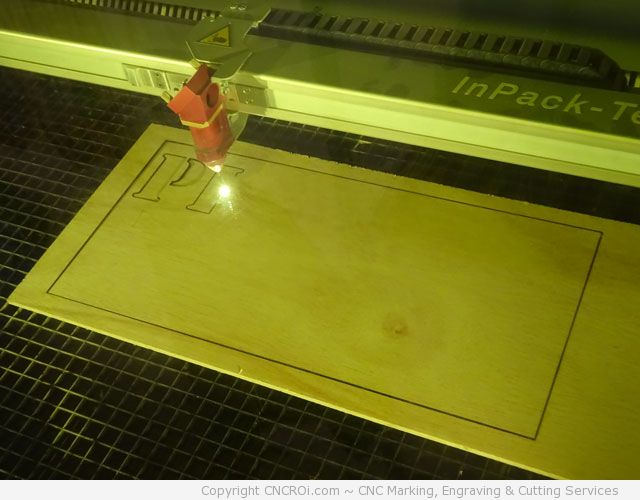

Once our maple plywood was cut out, it was time to throw in a piece of 4 mm birch plywood.

The cutting process is the same as the maple though it does cut a bit faster as the material is thinner and less dense overall.

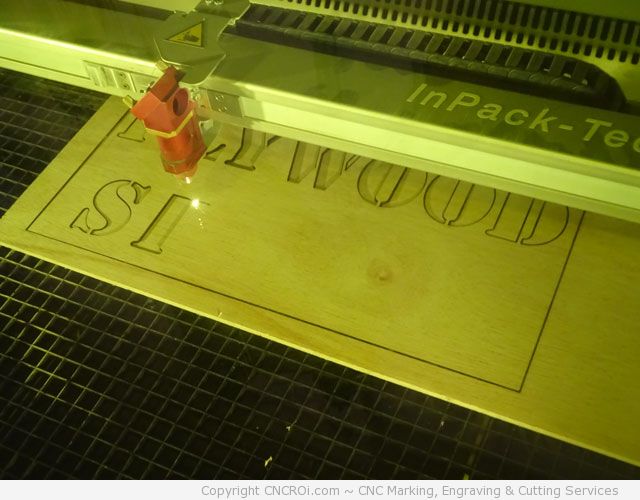

Looking at this from another angle, you can see that even our scrap birch is warped! For our clients, we use the straight and flat stuff, for us, it’s the stuff we can’t use for anything else but educating our customers and suppliers with.

The birch looks nicer than the maple, it isn’t nearly as old. You can see that our CNC laser cut right through a knot in the upper part of the C as well, did that cause any issues? Nope.

Watch the video of the above plywood board being cut!

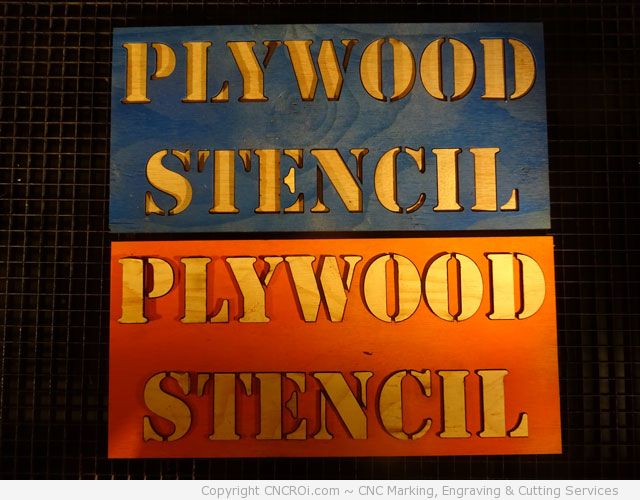

Let’s compare the two boards for a second so you can see how identical they are. How precise is our CNC laser? Well, let’s do a test!

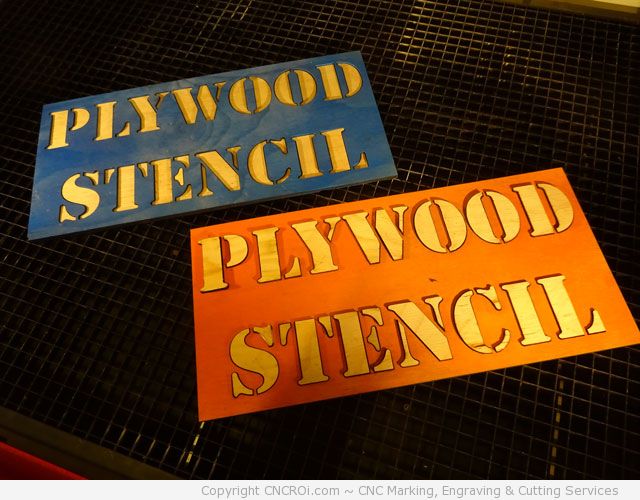

What I did instead of just straight stencil exchange was add a bit of color to make the stencils come out a bit more. This had an added benefit, they look better!

As you can clearly see, from a few angles, is that the stencil of one fits perfectly in the other, the only difference is the material thickness. You can see that one is “inside” while the other letters are poking out. I put a backing on these plywood sheets so this isn’t due to warping.

You might think “hey, that could be a sign” and you’d be totally right! We’ve done lots of signage using this same philosophy, basically, the client ends-up with two signs from one job.

If you are wondering about lifespans for these custom laser cut stencils, it all depends on material, thickness and application.

We’ve made stencils out of regular plywood like these and also acrylic, we can also produce them out of solid stainless steel or aluminum in pretty much any size you need. Just the other day, we made some stencils out of dibond (3M composite) using our CNC router even!

The question isn’t “who can make a stencil for us”, as you’ve found the answer right here, the question is “what’s my budget” as that will dictate material and the size of the stencil you wish to have made.

For instance, if you want a 316 stainless steel stencil that’s 2 x 3 meters and 1/8th thick, it will cost significantly more than one that’s the same size but out of cardboard but if you calculate in lifespan, the stainless steel will easily outlast hundreds of cardboard stencils, making it cheaper over the long run.

Contact us today!