Polycarbonate VS Acrylic: Custom Material Comparison

Although when comparing Polycarbonate VS Acrylic, you might say they are about the same as they are both plastic, when it comes to custom production they are quite different and each has their costs and benefits when it comes to physical items CNCROi.com can make for you.

Polycarbonate VS Acrylic: Custom Material Comparison – PETG

Before we jump too deep in the weeds, one material that customers sometimes bring-up when a project calls for polycarbonate is PETG.

The nice thing about PETG is that like polycarbonate, you can see right through it and like acrylic, when CNCROi.com laser cuts it, the edge is a flame polish rather than a burned black edge BUT this comes at a big cost, notably strength.

In the thinner gauges, PETG gets incredibly brittle after being laser cut and machining it also is hit and miss because it’s too easily moved if we are cutting it full of holes no matter how much hold-down we apply.

This is why unless the spec from the engineer actually outlines specifically PETG, we always recommend to go with polycarbonate instead, its way more stable, easier to work with and far stronger.

Polycarbonate VS Acrylic: Custom Material Comparison – Polycarbonate

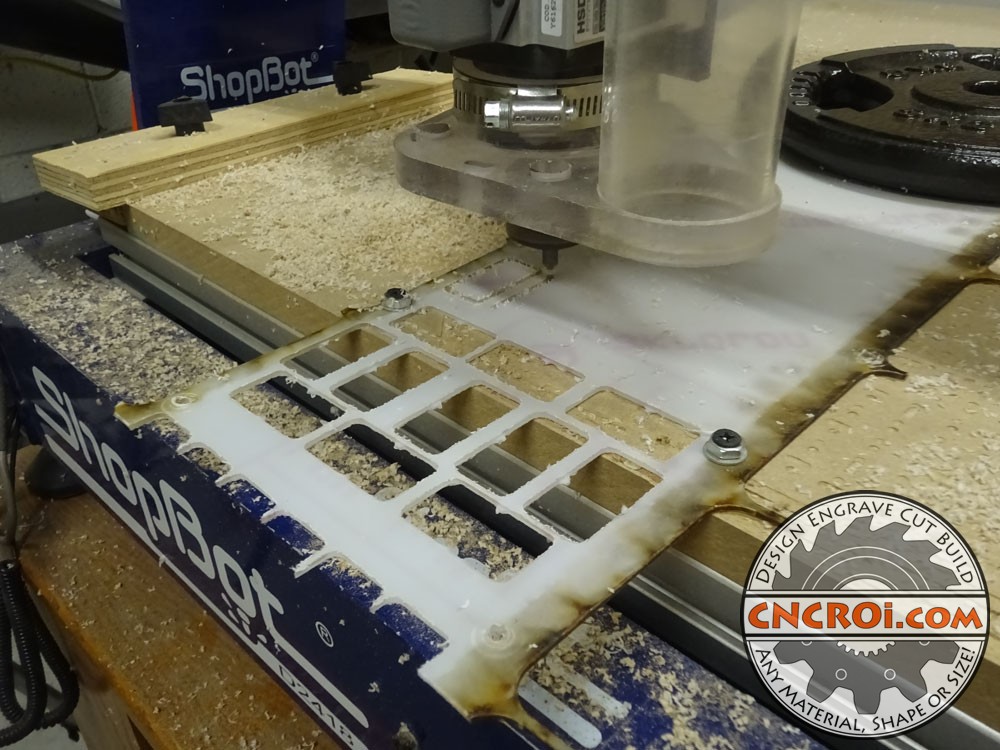

Before we jump into the advantages and disadvantages of acrylic, just looking at the video above you can see the major drawback of polycarbonate when it comes to being laser cut, the edge esthetic is burned black.

Some customers love this but most don’t but luckily, CNCROi.com has other equipment to cut it out without this drawback using our CNC router produces a nice edge almost comparable to acrylic that’s been laser cut.

On the image above, to the left is laser cut polycarbonate while on the right, CNC router cut – it isn’t a flame polish like acrylic but pretty close.

There are three massive advantages to using polycarbonate over acrylic though, strength, optical clarity and color changing.

Polycarbonate VS Acrylic: Custom Material Comparison – Polycarbonate Strength

Polycarbonate is literally bullet proof glass, this is HUGE because it means it’s a lot more scratch resistant as a result, which unlike acrylic, is INCREDIBLY EASY TO SCRATCH.

No matter how powerful or mad I get, there is no way for me to break polycarbonate with my bare hands, additionally, even with mechanical leverage, I can bend polycarbonate but not break it while acrylic by comparison is incredibly brittle and all you need to do is drop it on the floor with enough force and IT WILL SHATTER.\

This strength aspect of polycarbonate is HUGE because it means it’s a wonderful material for use in custom stencils and not only is it strong, but at the thinner thicknesses, it can also be rolled-up!

Polycarbonate is such a great choice for stencils that quite often, our customers compare it to metal stencils we can also make with the huge difference being that if you are using a torch to brand wood, polycarbonate will catch fire while metal will not.

Polycarbonate VS Acrylic: Custom Material Comparison – Polycarbonate Optically Clear

Another huge benefit to polycarbonate is that it’s optically clear.

CNCROi.com has medical industry clients whom we help brand their devices and the reason this very reason is why they choose this material over just about anything else on the market.

Although polycarbonate does cost a lot more money, I never quite understood why people build aquariums using thick acrylic which tends to dry out and get frosty over time compared to polycarbonate which would produce a result so fantastic, the fish would probably keep banging on the edge of the bullet proof glass as they can’t see it.

Polycarbonate VS Acrylic: Custom Material Comparison – Polycarbonate Color Changing

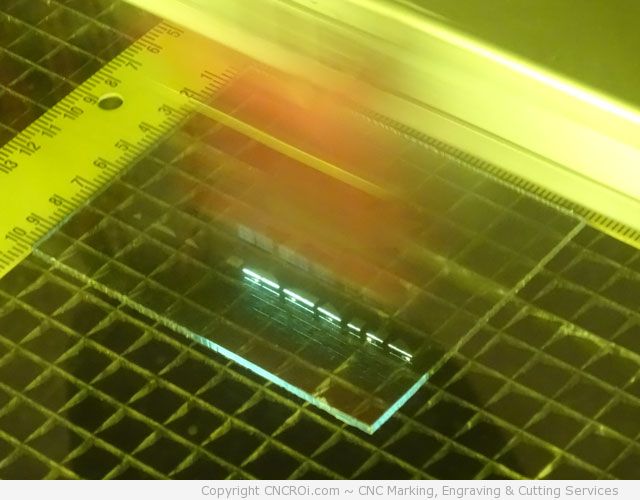

Another huge advantage of polycarbonate is unique to CNCROi.com‘s equipment, we don’t just have a CO2 laser that can cut polycarbonate but also a fiber laser source in our Austrian wide-format industrial laser.

What does this mean? It means we can color change polycarbonate, essentially, anneal it like we do with stainless steel!

Yep, that’s right, CNCROi.com can produce a jet black PERMANENT etching into the polycarbonate without having to resort to ink or dyes which will eventually fade, crack or peel over time.

This permanent contrasting capability by our equipment makes it a wonderful choice for totally unrelated medical products like wedding party favors and corporate award branding when a lighter material is used in its place.

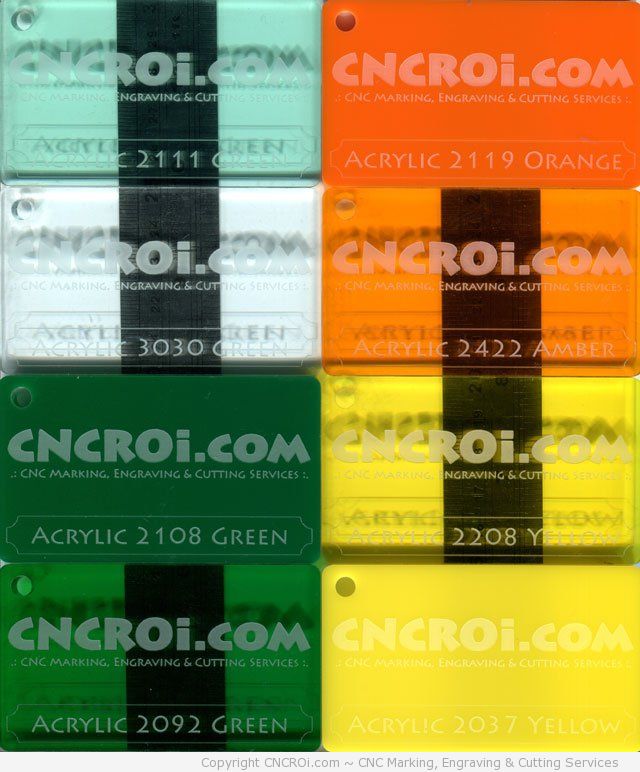

Polycarbonate VS Acrylic: Custom Material Comparison – Acrylic Color Options

Now that we’ve reviewed polycarbonate, let’s compare it directly with acrylic.

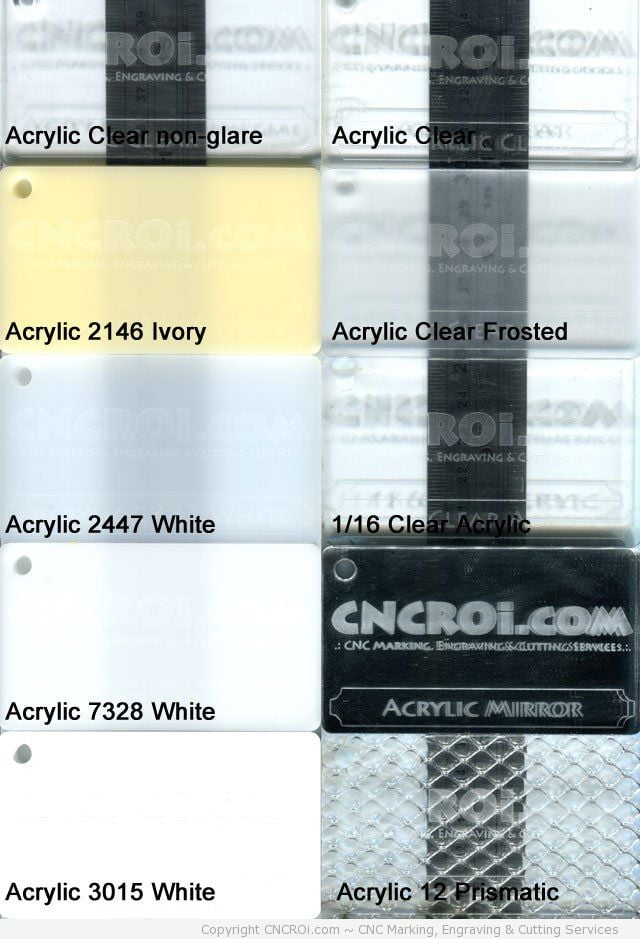

Like polycarbonate, acrylic can be had in a variety of thicknesses but one HUGE advantage of acrylic is that it can be had in a multitude of colors!

and the other flag I made that’s behind me in the shop… I’m due to make a third soon!

There is a huge diversity in color options and transparency when it comes to acrylic that just isn’t possible with polycarbonate.

Here’s some color swathes so you can see for yourself, the ruler indicates opacity.

Polycarbonate VS Acrylic: Custom Material Comparison – Acrylic Paint Filling

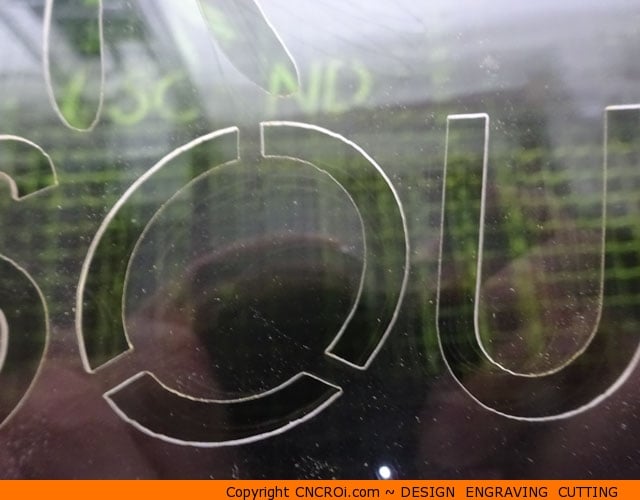

Unlike polycarbonate, when acrylic is laser engraved, it produces an engraving that’s rough enough to be paint filled.

I don’t really promote this fact too much at CNCROi.com because this will eventually fade, crack and peel off and I want the products CNCROi.com produces for clients to be long-lasting but it is an option.

But there is one black acrylic that CNCROi.com can color change to off-white which is permanent using our fiber laser source, same idea as the blackening of the polycarbonate you saw above.

So we don’t have to use paint, but the applications where this is actually good and useful are limited.

Polycarbonate VS Acrylic: Custom Material Comparison – Mirrored Acrylic

Another really nice option when it comes to acrylic is that CNCROi.com has access to mirrored acrylic, it isn’t a perfect mirror, it does have some distortions but it’s pretty neat for use in a variety of applications.

The advantage to mirrored acrylic over traditional glass mirrors is that it won’t shatter and it weighs practically nothing, it can be paint filled and cut into any shape or size.

Polycarbonate VS Acrylic: Custom Material Comparison – Acrylic Strength

Although acrylic has absolutely nothing on polycarbonate when it comes to strength characteristics, at a small scale, I’d argue it’s actually totally fine for use in key chains and other items where yes, it can break but at a quarter inch in thickness and more, it’s actually pretty resilient.

This strength characteristic does quickly drop though the larger the item, for instance, the shop mirror I made from the video above has already been broken along one edge just carrying it around, but the small key chain I made is still intact.

Remember that acrylic isn’t optically clear, but for applications that aren’t medical or fish aquarium related, that’s totally fine and the advantage of color diversity really helps.

Polycarbonate VS Acrylic: Custom Material Comparison – Which is best?

As you can see, and I repeat often to customers, there is no BEST material, it’s the one with the most advantages given your application.

Luckily, we actually have these two wonderful materials (and others) from great suppliers who have come through for us thick and thin, but the best way forward is for you to describe your application if you aren’t sure and I’ll steer you in the right direction.

Have an application requiring polycarbonate, acrylic or any other plastic?

Contact CNCROi.com right now!