Positive and Negative Mold Production

Positive and negative mold production are two essential techniques used in various industries for creating duplicates of objects or components with accuracy and precision.

Positive and negative mold production serve as the basis for manufacturing processes, enabling the production of identical replicas at a larger scale. In this guide, we will explore the concepts, advantages, and applications of positive and negative mold production.

Positive molds are exact replicas of the desired object or component, they are created using materials that can directly replicate the object’s surface features.

In contrast, negative molds, also known as female molds, capture the object’s shape but in a reverse manner, they are used when the final product requires more complex features or when production with a positive mold is impractical.

Positive molds, also known as male molds, involves creating molds that have the same shape and features as the desired object or component, these molds are typically made from materials that can directly replicate the object’s surface details.

Positive molds are often used when the desired object has complex shapes or intricate details that are challenging to reproduce using negative molds.

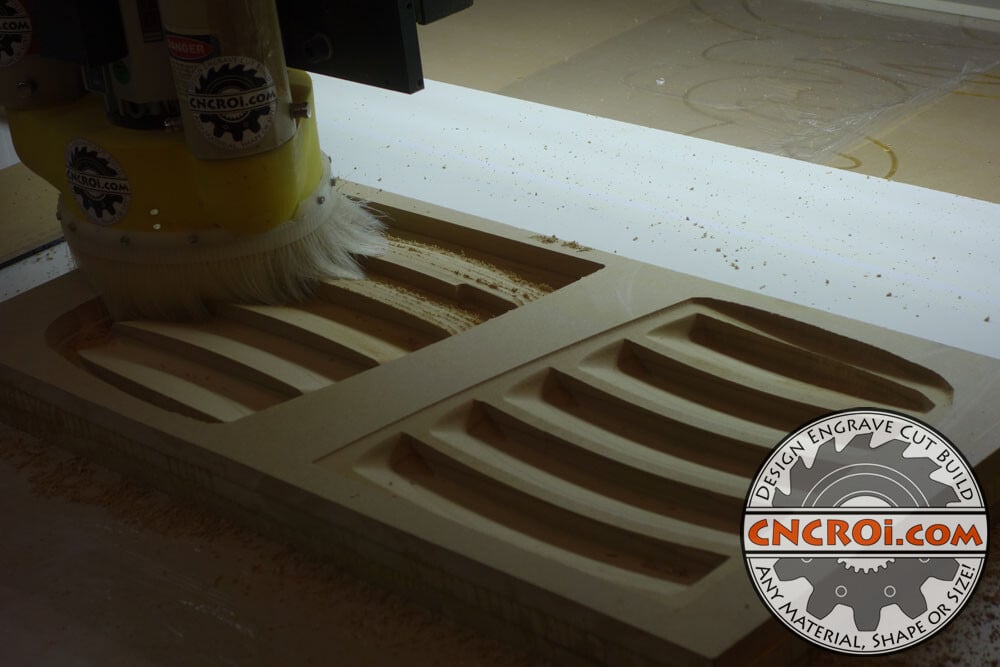

When it comes to positive and negative mold production, the process at CNCROi.com may seem like the same, but the intended use and after-fabrication process can be very different depending on the customer’s requirements.

Various materials can be used to create positive molds, depending on the specific application requirements, common materials include silicone rubber, plaster, urethane resins, composites including wood, and even certain thermoplastics.

Silicone rubber is often used for creating flexible and durable positive molds, the object to be replicated is first placed in a container, and liquid silicone rubber is poured around it.

Plaster is commonly used for making positive molds, especially for simpler shapes and prototypes. The plaster is poured over the object in a container and allowed to harden. After setting, the plaster mold is separated from the object, yielding a positive replica.

Urethane resins are versatile materials used for creating positive molds with excellent dimensional stability and durability. They can be poured into a mold box containing the object, and after curing, the positive mold is removed.

Positive molds find applications in various industries, including product design, prototyping, architecture, and art. Their benefits include:

- Accuracy: Positive molds faithfully replicate the original object’s shape and surface details, ensuring precise replicas.

- Versatility: Positive molds can be used for replicating objects of varying complexities and sizes.

- Rapid Prototyping: Positive molds are valuable tools in the rapid prototyping process, allowing designers to quickly evaluate and refine their designs.

- Small-scale Production: Positive molds are suitable for small-batch production, enabling cost-effective manufacturing of limited quantities.

When it comes to positive and negative mold production, CNCROi.com can make them concurrently as you see in this blog post or as individual unique units.

Negative mold production involves creating molds that have the inverse shape of the desired object or component. Also known as female molds, these molds capture the external features of the object to be replicated. The process of creating negative molds is widely used in large-scale production processes, particularly in injection molding and composite manufacturing.

Negative molds, also known as female molds, are used when the final product requires more complex features, or the production with a positive mold is impractical. They are created by forming the mold material around or over a positive model, capturing its shape and details in reverse.

The selection of materials for creating negative molds depends on the manufacturing process and the number of replicates needed. Common materials include high-quality silicone rubber, epoxy resins, fiberglass, and certain thermosetting plastics.

Similar to creating positive molds, silicone rubber is often used for making flexible and durable negative molds. The positive model is placed in a container, and liquid silicone rubber is poured around it. Once cured, the silicone mold can be removed, leaving a negative impression of the object.

Epoxy resins are widely used for making negative molds with high dimensional stability and temperature resistance. They can be poured around a positive model and cured to create a rigid negative mold.

For larger and more complex molds, fiberglass reinforcement is often used to add strength and durability. The fiberglass is laid over the positive model and saturated with resin to form the negative mold.

When it comes to machinery, CNCROi.com isn’t limited to just using our CNC routers to make both positive and negative mold production a reality, we can also use our laser for smaller items.

Negative molds find extensive applications in industries such as injection molding, composite manufacturing, and architectural casting. Their benefits include:

- Complex Shapes: Negative molds can replicate objects with complex geometries and undercuts, making them ideal for intricate components.

- Large-scale Production: Negative molds are commonly used in mass production processes due to their durability and ability to produce a high volume of replicas.

- Consistency: Negative molds ensure consistent replication of objects, meeting quality and performance standards in manufacturing.

- Cost-effectiveness: Once the negative mold is created, it can be used repeatedly, reducing the per-unit production cost.

While both positive and negative mold production serve essential roles in mold production, they have distinct advantages and disadvantages that make them suitable for specific applications.

Positive Mold Advantages:

- Accurate replication of the original object’s surface features.

- Versatile and suitable for various shapes and sizes.

- Ideal for rapid prototyping and small-scale production.

- Easy to work with for manual mold-making techniques.

Positive Mold Disadvantages:

- Not suitable for complex shapes with undercuts.

- Limited to replicating objects with outward-facing features.

- May require more extensive finishing for the final product.

Negative Mold Advantages:

- Ability to replicate complex shapes and undercuts.

- Ideal for large-scale production processes.

- Ensures consistent replication and quality.

- Suitable for automated manufacturing processes.

Negative Mold Disadvantages:

- More complex to create compared to positive molds.

- Limited to replicating objects with outward-facing features.

- May require release agents for easy demolding.

Whether you require positive or negative mold production, CNCROi.com can make it and ship it right to your door.