Power of CNC Laser Pass-through

The primary piece of equipment in our CNCROi.com shop is our Austrian wide-format industrial CNC laser with both a fiber and CO2 laser tube in it… but that’s only the beginning.

I did a video a while back of a Trotec Speedy 400 (non-flexx) so you can get an idea of how powerful our machine is for our customers.

Going through the stats of our machine, let’s take a look at the one I have in the shop right now. The advantage of our current machine over the one in the video, ignoring a few bells and whistles we threw into it, is the ability to use a fiber tube (the one in the video is CO2 only).

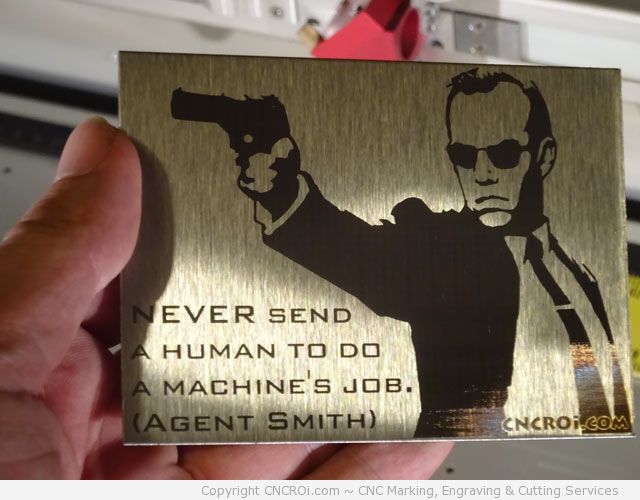

This means for applications from color changing plastic to annealing metal, we can do it efficiently and cost effectively at pretty much any size. If you aren’t familiar with the type of machines we have in our shop, here’s a quick video to help you out.

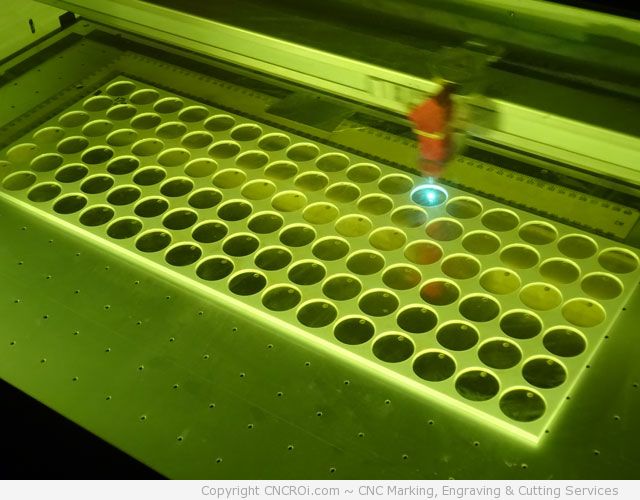

Our work area is 39 x 24 inches (~1 meter x 61 cm) but that doesn’t take into account pass-through, in reality, our machine can accept (and has accepted) far larger pieces. Our TRUE limit is really 42.5 inches (1.08 meter) and infinite length.

The added benefit if our machine isn’t just the size (X and Y) of the piece we can work on with our CNC laser but also the height. Here’s a picture of the machine “fully open” to give you some perspective. Yes, I could easily fit in this machine and engrave my forehead to boot.

The maximum height of a workpiece we can fit in our CNC flexx laser is just shy of 30 cm (~12 inches) with a maximum processing speed of over 3 meters a second @ 4G acceleration. As for the pass-through portion, our max is just shy of 18 cm (~7 inches).

Yes, it would make for an awesome catapult which is why everything is enclosed for safety and to make sure nothing moves around during production. Our machine weights north of 350 kg by the way so it’s not going anywhere anytime soon, which is a great anti-theft mechanism built right in!

How accurate is your Trotec Speedy 400 flexx?

Addressable accuracy: 5μm

Static repeat accuracy: < ±15μm

What bells and whistles did you add to your CNC laser?

We added to our machine a fire detection unit so if a fire happens in the machine, we are notified immediately… a handy thing to have considering our laser beams are hotter than the Sun.

We also added a gas kit which means we can feed various gases (mostly normal air) directly from the overhead gantry head onto the workpiece, which drastically reduces the possibility of HAVING a fire in the first place.

We also added PRO level software, as a CNC machine is useless without the absolute top of the line software controlling it. We added a hazard kit which means the optics and other sensitive parts are protected from smoke and vapor which, over time, will affect the machine’s accuracy and repeatability.

While we were at it, we went with a Ceramic Tube which produces a far more consistent laser beam so our results are identical from the start of a project to the end and a whole set of extra tables to handle different media optimally and a rotary kit as well for round parts so we can engrave or cut AROUND, say, a baseball bat.

I’m sure I’m forgetting a few things but these are the major ones above and beyond the typical “base model”.

How much did our Trotec Speedy 400 flexx cost?

If you are in business, the cost of a machine is really nothing, it doesn’t matter. Why? Because the only number that’s really important is the ROI of the machine.

I could have bought A LOT of equipment very cheaply to fill the whole shop going with a Chinese or Indian brand… but I didn’t.

The reason being, the reputation of CNCROi.com is on the line, when a customer needs a project done ON TIME AND ON BUDGET, they don’t care the cost, they care that it’s done ON TIME AND ON BUDGET.

Being able to offer this and have the backup support of Trotec Laser at my back should any issues arise (nothing yet after a year of industrial production!) is worth any type of premium I put into the machine.

Our clients are what makes CNCROi.com possible, it’s ridiculous to have to buy 2 or three machines as spares – especially in an industrial setting – for fear of something breaking. It’s ridiculous to give our customers a project that isn’t square, isn’t to spec or worse, simply not possible with lots of rejects.

Some of the parts we have confidently put into our machine had a value of almost 10 000$US! This is NOT something you screw around with as ONE reject means I cut a cheque for the project, not the other way around.

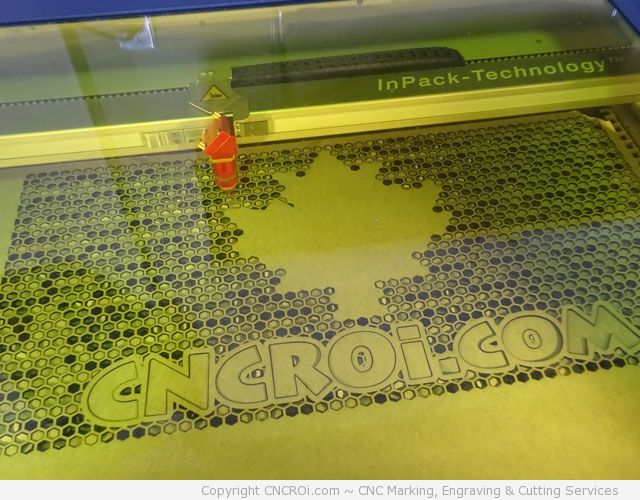

We’ve done work with military, aerospace as well as mill work and our clients want ACCURACY, REPEATABILITY and most of all, as few (none?) rejects as possible. We recently completed a large wood project that had one piece that was literally a meter wide by 3 meters long.

Did it fit in our machine? Yes! Did we have any spares (machine or material wise), absolutely not! Did CNCROi.com complete the project on time and on budget? ABSOLUTELY!

We’ve done some crazy awesome projects over the past year, and we will continue to work as hard as possible to maintain our relationships with customers who trust us with their materials, parts and reputation.

When you need something done RIGHT and PERFECT – please do give us some spares if at all possible for material testing though – contact CNCROi.com today!